Summary of Contents for BeaconMedaes MEGA 2

- Page 1 Installation, Operation, and Maintenance Instructions MEGA ® Medical Electronic Gas Alarm MAN 01-027 Part No. 6-847684-00 Rev. D01 Pg. 1...

-

Page 2: Table Of Contents

Table of Contents Introduction Alarm Modular Components................4 Definitions......................5 Alarm Configuration....................6 Unpacking ......................7 Rough-In Installation Alarm Panel Back Box Mounting................8 Remote Sensor Back Box Mounting ..............9 Pipeline Connection Sensor Module .....................9 Pressure Switch..................10 Wiring Installation General Requirements..................11 Wire Type and Size ..................11 Wire Routing Inside The Alarm Panel ..............11 Determining Number Of Conductors ..............12 Wiring Schematics....................13... - Page 3 Table of Contents Operation Start-Up and Checking ..................34 Set-Up Procedure Digital Display Module................35 Multi-Signal Module ..................38 Monitoring Mode Digital Display Module................40 Multi-Signal Module ..................41 Testing Digital Display Module..................41 Multi-Signal Module ..................42 Power Supply Module ..................43 Troubleshooting Guide ..................45 Replacement Parts Front Panel Components .................50 Back Box Components..................51 Sensor Components..................52...

-

Page 4: Introduction

Introduction Alarm Modular Components Annunciator Module Multi-Signal Module Features: Features: • User interface • Monitors up to five pushbuttons for alarm normally closed dry- panel TEST function, contact switch audible alarm MUTE signals. • Separate indicators and set-up increase for each of five and decrease signals for normal •... -

Page 5: Definitions

Introduction Definitions Remote Sensors Area Alarm Panel Pressure/vacuum sensors that are mounted Alarm panel that monitors medical gas and outside of alarm panel box. Sensor rough-ins vacuum systems serving a specific area. may be mounted separately or ganged together Auxiliary Fault Relay (optional) near pressure/vacuum pipelines. -

Page 6: Alarm Configuration

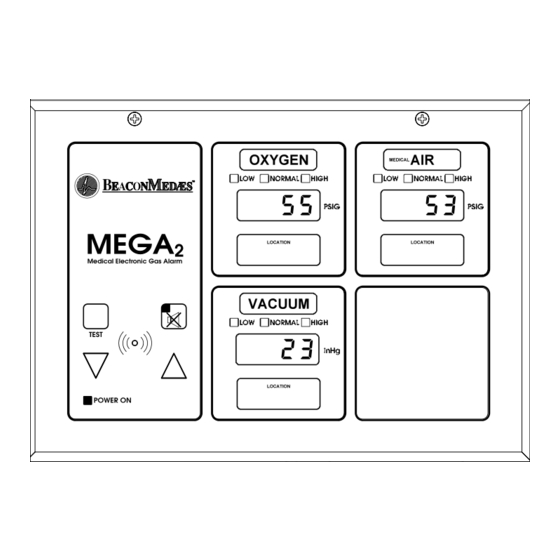

Introduction The required alarm panel configuration may be specified within the part number scheme as Alarm Configuration described below: An alarm panel may consist of any Part Number Scheme: combination of digital display modules, multi- signal modules, or blank modules. Position within alarm 1 2 3 4 5 6 7 8 panel (Figures 1 and 2) -

Page 7: Unpacking

Introduction Alarm Configuration Unpacking 1. Remove alarm panel back box from shipping carton. Do not remove alarm front panel (wrapped in anti-static Example: P/N 6-M2R-OAVB shipping bag). 2. If alarm panel is configured with remote sensors, remove sensor rough-in and mounting box from small individual boxes shipped within main alarm panel shipping carton. -

Page 8: Rough-In Installation

Rough-In Installation 1. Prepare a rough wall opening large Alarm Panel Back Box Mounting enough to accommodate alarm panel back box. Alarm panel back box must The alarm panel back box will be one of have rigid vertical members for two sizes. -

Page 9: Remote Sensor Back Box Mounting

Rough-In Installation Alarm Panel Back Box Mounting Four holes in back of box are provided for surface mounting Rear conduit knockouts (either side) are recommend- ed for sensor wiring Figure 8: Remote Sensor Back Box Loosen screws to adjust back box depth Pipeline Connection (same each side) Sensor Module... -

Page 10: Pressure Switch

Rough-In Installation Pressure Switch Pipeline Connection DISS (Diameter Index Safety System) REMOTE SENSOR Connection connection kits are recommended for use should be made when attaching pressure switches to on top of pipe pressure/vacuum pipeline. To utilize these kits, a 1/4-18 NPT female thread must be provided in piping system. -

Page 11: Wiring Installation General Requirements

Wiring Installation General Requirements Wire Routing • Power all alarms from life safety Two 7/8” holes are provided for entrance branch of emergency power system as of AC mains power. One hole on lower required by applicable standards. left side and one hole on top left of alarm panel back box. -

Page 12: Determining Number Of Conductors

Wiring Installation • Two panels may be connected Determining Number Of Conductors together so digital display module MEGA2 alarm panels can be ordered in pressure reading(s) of first panel will numerous configurations. The following be duplicated at second panel. Two rules along with references to this conductors for EACH digital display manual’s schematics clarify wiring... -

Page 13: Wiring Schematics

Wiring Installation Wiring Schematics Alarm Wiring Examples The wiring schematics listed below are Wiring examples of master/area alarms for the following systems are provided: provided. Call BeaconMedæs at 1-888- 4MEDGAS (1-888-463-3427), for technical 1. Two master alarm panels with digital support . - Page 14 Wiring Schematic 1: Power Supply Module Ground (green) Power Supply Fuse Holder Ground Orange Screw Line (black) Black Neutral (white) Orange 3-wire power supply harness Black 20-wire ribbon cable to adjacent module 20-wire ribbon cable to adjacent module Annunciator Module Part No.

- Page 15 Wiring Schematic 2: Sensor Module to Digital Display Module LOCAL SENSOR NOTE: Sensor pigtails for local sensors 2-pin polarized connector are factory connected to digital dis- play module. Sensor pigtail Pin 5 - red (+) Pin 6 - black (-) ribbon to adjacent module...

- Page 16 Wiring Schematic 3: Multi-Signal Module Dry normally-closed NOTE: contacts at source Field wiring cable shields must be grounded at equipment or line only one end, inside alarm panel back box. Refer pressure switches to page 31 for details. SIGNAL 1 SIGNAL 2 SIGNAL 3 SIGNAL 4...

- Page 17 Wiring Schematic 4: Remote Pressure / Vacuum Transmission NOTE: Field wiring cable shields must be grounded at only one end, inside alarm panel back box. Refer to page 31 for details. Signal from sensor module Pin 5 (+) Pin 6 (-) Slave input Master output from master...

- Page 18 Wiring Schematic 5: Multi-Signal Module Relays (Optional) NOTE: Field wiring cable shields must be grounded at Dry normally-closed only one end, inside alarm panel back box. Refer contacts at source to page 31 for details. equipment or line pressure switches SIGNAL 1 SIGNAL 2 SIGNAL 3...

- Page 19 Wiring Schematic 6: General Fault / Auxiliary Relays Auxiliary Relay General Fault Relay NOTE: General Fault Relay activates when ANY N/O (pin 6) N/C (pin 5) alarm on panel is in progress. Pressing Common (pin 7) Common (pin 4) MUTE on Annunciator Module DOES N/C (pin 8) N/O (pin 3)

- Page 20 Wiring Schematic 8: Remote Pressure / Vacuum Switches P/N 6-129020-01 (Dual switch for medical gases with 50 PSI nominal pressure) seven - approx. 18” free leads NOTE: through 3/4” conduit connection Switch contacts shown with 50 PSI pressure applied. adjustment high dials Low switch is...

- Page 21 Wiring Schematic 9: Johnson Controls METASYS® Johnson Controls METASYS® or compatible building automation system (Metasys Integrator) Serial + Serial NOTE: Maintain correct network wiring polarity. Serial - (pin 2) Serial (pin 1) Annunciator Module of each alarm panel connected to the network shown above Part No.

- Page 22 Typical Master/Area Alarm Wiring Examples MASTER ALARM PANEL #1 pin 6 (-) pin 5 (+) Oxygen Sensor Module MAIN LINE Connected to main oxygen pipeline Digital Display Module pin 2 (com) pin 1 (+) O2 Secondary Supply Multi-Signal Module Normally-closed contacts at high-pressure oxygen manifold pin 2 (com) pin 1 (+)

- Page 23 Typical Master/Area Alarm Wiring Examples MASTER ALARM PANEL #1 pin 6 (-) pin 5 (+) Oxygen Sensor Module MAIN LINE Connected to main oxygen pipeline Digital Display Module pin 1 (+) pin 6 (com) O2 Secondary Supply O2 Reserve In Use Secondary Supply - O2 Reserve from liquid O2 manifold...

- Page 24 Typical Master/Area Alarm Wiring Examples MASTER ALARM PANEL #1 pin 6 (-) pin 5 (+) Oxygen Sensor Module MAIN LINE Connected to main oxygen pipeline Digital Display Module pin 1 O2 Main Tank Liquid Low O2 Reserve In Use Main Tank Liquid Low - O2 Reserve from main bulk tank Liquid Low...

- Page 25 Typical Master/Area Alarm Wiring Examples MASTER ALARM PANEL #1 n/c - not used Med. Air Line Pressure Low HIGH Med. Air Line n/o - not used Pressure High Med. Air Line Pressure Switch - Med. Air connected to main med. air pipeline Dew Point High Med.

- Page 26 Typical Master/Area Alarm Wiring Examples NOTE: Field wiring cable shields must be grounded at only one end, inside alarm panel back box. Refer to page 31 for details. pin 6 (-) pin 5 (+) Oxygen Sensor Module I. C. U. Connected to main oxygen pipeline Oxygen Digital Display Module...

-

Page 27: Finish Installation

Finish Installation Line Voltage Electrical Connection Front Panel Installation 1. Remove four nuts from plastic power 1. Remove front panel assembly from supply shield. anti-static shipping bag. 2. Remove plastic shield from power 2. Remove two front panel hinge supply. The plastic shield contains an mounting screws and lanyard mounting in-line fuse holder that is wired to a screw from alarm panel back box... -

Page 28: Sensor Installation Remote Sensors

Finish Installation Front Panel Installation Sensor Installation Remote Sensors: 4. The alarm panel’s power supply is 1. Remove sensor module from shipping factory installed with a three-wire carton. Each sensor module is harness attached to its right side. shipped with a wiring pigtail that has a Connect loose end of three wire two-pin polarized connector. -

Page 29: Local Sensors

Finish Installation Sensor Installation 5. Tuck excess wiring into open space behind sensor. Location label 6. Mark location monitored by sensor in space provided on sensor label. Refer to Figure 17. Local Sensors: 1. Remove sensor module from shipping Figure 17: Sensor Module Location Label carton. -

Page 30: Source Equipment Wiring

Finish Installation Remote Sensor Wiring Source Equipment Wiring 3. Connect positive sensor wire to 1. Identify each pair of field installed terminal 5 and negative sensor wire to source equipment signal wires inside terminal 6 for each remote sensor and alarm panel back box assembly. -

Page 31: Field Wiring Cable Shield Grounding

Finish Installation Source Equipment Wiring Holes provided for entrance of remote wiring Sample label Route wires behind (provided) metal brace Slide label(s) into slits in front panel overlay Figure 23: Multi-Signal Front Panel Labeling Field Wiring Cable Shield Grounding Figure 21: Source Equipment Wire Routing All field wiring cable shields must be grounded inside alarm panel back box. -

Page 32: Building Automation System Wiring

Finish Installation Building Automation System Wiring There are several methods of connecting When alarm condition is corrected, relay MEGA2 alarm panels to a building contacts will close. Relay contact ratings automation system depending upon what are 2 A @ 30 VDC/0.5 A @ 125 VAC. type of information is required and what Refer to Figure Schematic 7 (Pg. -

Page 33: Johnson Controls Metasys® System

Finish Installation Building Automation System Wiring Slave Panel Wiring Johnson Controls METASYS® System: Digital display modules of two alarm The MEGA2 alarm panel is compatible panels may be wired together in such a with Johnson Controls METASYS® way that pressure readings of first panel building automation system (Using can be duplicated at second panel. -

Page 34: Operation

Operation Start-Up and Checking 1. Turn on electrical power to alarm panel. 2. Make following observations: • POWER ON light illuminates on Status LED front of alarm panel. Indicators • Digital display and multi-signal modules warm-up for ten seconds. During warm-up, no audible or LED Display visual alarms activated. -

Page 35: Set-Up Procedure Digital Display Module

Operation Digital Display Module Set-Up Procedure Digital Display Module SETUP button Digital display modules are shipped from the factory with the following settings: Gas/Vacuum Alarm Set Point Service High Low alarm High alarm Pressure (50 psig) 40 psig 60 psig indicator indicator Pressure (100 psig) 80 psig... - Page 36 Operation N N D D F F (network data format) Defines data word length transmitted to Set-Up Procedure building automation system. User choices are 8 8 (bits) or 1 1 6 6 (bits). Factory Digital Display Module setting is 8 8 . 6.

- Page 37 Operation then current network data format. Select desired data format by Set-Up Procedure pressing buttons. 5. Press and release TEST button. P P D D F F Digital Display Module (Advanced) will be displayed for one second and then current pressure data format. R R E E P P T T (audible alarm repeat) Select desired data format by...

-

Page 38: Multi-Signal Module

Operation Multi-Signal Alarm Module Circuit Board Set-Up Procedure Multi-Signal Module SETUP button Changing signal options: 1. Loosen two screws on front of alarm panel. Hinge open front cover. 2. Locate SETUP button on circuit board of multi-signal module to be adjusted. Red LED Green LED 3. - Page 39 Operation 1. Press and HOLD set-up button. Set-Up Procedure Audible alarm will chirp when set-up button is first pushed and again two Multi-Signal Module (Advanced) seconds later. Release button after second audible alarm chirp. Multi- Two additional levels of “advanced” set-up signal alarm module front panel LED features are available.

-

Page 40: Monitoring Mode

Set-Up Procedure Monitoring Mode Monitoring mode is the normal operating Multi-Signal Module (Advanced) mode of the MEGA 2 system. Setting Audible Alarm Repeat Time and Digital Display Module: Display Intensity: Digital display modules monitor pipeline Used to set time interval for reactivation pressure or vacuum. -

Page 41: Multi-Signal Module

Operation Monitoring Mode Multi-Signal Module: Multi-Signal modules monitor up to five dry-contact switches. • If the signal is normal (switch contacts closed), green indicator for signal is illuminated. • If an alarm occurs (switch contacts open), audible alarm activates and red Front panel indicator for signal flashes. -

Page 42: Multi-Signal Module

Testing Multi-Signal Module: Press and hold front panel TEST button for five seconds to initiate following sequence:. • Audible alarm sounds briefly. • All red and green indictors flash for five Bit 4 (green) seconds. • Software revision is displayed as Bit 5 (green) follows: SIGNAL 1... -

Page 43: Power Supply Module

Testing Power Supply Assembly: 10. Using a digital volt meter, measure The power supply assembly converts AC AC voltage between white (neutral) mains power to +5 and +24 volts DC. AC and black (line) wires on back of mains power can be any value between power supply connector (Figure 27). - Page 44 Testing Three-wire harness Orange (+5) from power supply Black (gnd) Red (+24) Annunciator Module Figure 26: Power Supply Output Testing Fuse Holder Line (black) Neutral (white) Power Supply Assembly Figure 27: Power Supply AC Input Testing Part No. 6-847684-00 Rev. D01...

-

Page 45: Troubleshooting Guide

Troubleshooting Guide Symptom Possible Cause Corrective Action 1) No visual indicators a. AC power is not turned on. a. Check AC power source. illuminated on entire alarm b. Blown internal fuse. b. Replace fuse. panel c. AC power wiring is not c. - Page 46 Troubleshooting Guide Symptom Possible Cause Corrective Action 4) Visual indicators are dimly a. Programmable display a. Reset display intensity values for illuminated or vary in intensity levels have been each module. Refer to Set-Up brightness between one or set too low or at different instructions pages 35 - 40.

- Page 47 Troubleshooting Guide Symptom Possible Cause Corrective Action 7) Audible alarm reactivates a a. A new alarm condition has a. If alarm condition previously silenced short period of time after occurred. self-corrects and then reactivates b. Programmable alarm repeat again, alarm panel treats as a new MUTE button has been function has reactivated...

- Page 48 Troubleshooting Guide Symptom Possible Cause Corrective Action 13)Pressure or vacuum digital a. Incorrect digital display “unit a. Use digital display module test mode display does not match of measure”. as described on page 41 to check pressure or vacuum levels b.

- Page 49 Troubleshooting Guide Symptom Possible Cause Corrective Action Pressure or vacuum signal a. Correct sensor wiring. 16)High alarm with - - F F 3 3 - - to digital display module out b. If alarm panel contains another display on digital display of measurement range (too working digital display module, module.

-

Page 50: Replacement Parts

Replacement Parts Front Panel Components ITEM PART NUMBER DESCRIPTION 6-868163-00 20-wire Ribbon Cable (4-module alarm box) 6-868164-00 20-wire Ribbon Cable (8-module alarm box) 6-865315-00 Field Wiring Connector - Annunciator Module 6-231982-00 Circuit Board - Annunciator Module (includes item 2) 6-231982-RL Circuit Board - Annunciator Module with Auxiliary Relay (includes item 2) 6-811611-00... -

Page 51: Back Box Components

Replacement Parts Back Box Components ITEM PART NUMBER DESCRIPTION 6-814669-00 Screw - #6-20 x 1/4”, Pan Head, Self-Tapping 6-425458-00 Shield 6-814669-00 Screw - #6-20 x 1/4”, Pan Head, Self-Tapping 6-231938-00 Wire Harness - Power Supply Ground 6-231941-00 Wire Harness - Ground 6-814008-00 Screw - Grounding 6-231937-00... -

Page 52: Sensor Components

Replacement Parts Sensor Components ITEM PART NUMBER DESCRIPTION ITEM PART NUMBER DESCRIPTION 6-814669-00 Screw - #6-20 x 1/4”, 6-231935-00 Sensor Pigtail Pan Head, Self-Tap Analog Sensor 6-425428-00 End Cap 6-231760-00 Oxygen Sensor Mounting Assy. 6-231761-00 Nitrous Oxide (incl. items 1,2,6,7& 9) 6-231762-00 Medical Air 6-129340-10... -

Page 53: Field Installation Kits

ITEM PART NUMBER DESCRIPTION Field Installation Kits Digital Sensor 6-232460-00 Oxygen Field installation kits include everything required to 6-232461-00 Nitrous Oxide replace a blank module with a digital display mod- 6-232462-00 Medical Air 6-232463-00 Vacuum ule or a multi-signal module. Digital display module 6-232464-00 Nitrogen kits include sensors. - Page 54 Notes Part No. 6-847684-00 Rev. D01...

- Page 55 Notes Part No. 6-847684-00 Rev. D01...

- Page 56 Warranty BeaconMedæs warrants the MEGA 2 Medical All claims against this warranty require prompt notification, within the warranty period, of any Electronic Gas Alarm to be free of defects in seeming defect. Failure to promptly notify materials or workmanship when installed and BeaconMedæs of the seeming defect will invali-...

Need help?

Do you have a question about the MEGA 2 and is the answer not in the manual?

Questions and answers