TOHATSU BFT 60A Owner's Manual

Hide thumbs

Also See for BFT 60A:

- Original instructions manual (618 pages) ,

- Owner's manual (141 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for TOHATSU BFT 60A

- Page 2 OWNER’S MANUAL BFT 60A BFW 60A Original instructions...

- Page 3 © 2016 Honda Motor Co , Ltd PGM-FI is a trademark of Honda Motor Co , Ltd registered in Japan and other countries...

- Page 4 Here’s Outboard Motor, consult an This manual covers operation and what they mean: authorized TOHATSU Outboard maintenance of the TOHATSU Motor dealer. BFT60A/BFW60A Outboard Motor. All information in this publication is Indicates serious injury or death...

- Page 5 This Owner’s Manual is using the FRAME SERIAL NUMBER following type names when it describes the operations special to a type. Tiller handle type: H type Remote control type: R type The remote control type is classified into the following three categories according to the control box position.

- Page 6 Control and Feature Identification Codes Model BFT60A BFW60A Type LRTD LRTU LHTD LRTU Shaft Length Tiller Handle Remote Control Power Trim/Tilt Trim Meter – Tachometer Rudder Meter – Tilt Limit Mechanism –...

-

Page 7: Table Of Contents

CONTENTS 1. SAFETY ................... 7 Power Tilt Switch (outboard motor pan) ....... 35 SAFETY INFORMATION............7 Manual Relief Valve.............. 36 2. SAFETY LABEL LOCATIONS............ 10 Tilt Lock Lever ..............36 Oil Pressure Indicator/Buzzer..........37 CE mark location................. 12 Overheat Indicator/Buzzer............. 38 3. - Page 8 CONTENTS 6. PRE-OPERATION CHECKS ............55 Common TRL (Trolling Control) Switch..........88 Engine Cover Removal/Installation ..........55 Trimming the Outboard Motor ..........89 Engine Oil ................... 56 Trim Meter................91 Fuel....................58 Tilting the Outboard Motor ........... 92 GASOLINE CONTAINING ALCOHOL......59 Moorage.................

- Page 9 CONTENTS 12. MAINTENANCE ............... 111 Tool Kit, Spare and Emergency Parts ........112 MAINTENANCE SCHEDULE..........113 Engine Oil ................. 115 Spark Plugs................116 Battery ..................118 Lubrication ................121 Fuel Filter/Water Separator............123 Fuel Tank and Tank Filter............126 EMISSION CONTROL SYSTEM ........... 127 Fuse ...................

-

Page 10: Safety

If any fuel is spilled make sure that the area is dry before starting the engine. • TOHATSU outboard motor is designed to give safe and dependable service if operated • Gasoline is harmful or fatal if according to instructions. - Page 11 SAFETY • Know how to stop the engine • Always wear a life-jacket when on quickly in case of emergency. board. Understand the use of all controls. • Do not operate the outboard motor • Do not exceed the boat without the engine cover.

- Page 12 SAFETY Fire and Burn Hazards The engine and exhaust system Carbon Monoxide Poisoning Gasoline is extremely flammable, and become very hot during operation and Hazard gasoline vapor can explode. Use remain hot for a while after stopping. Exhaust contains poisonous carbon extreme care when handling gasoline.

-

Page 13: Safety Label Locations

They warn you of potential hazards that can cause serious injury. Read the labels and safety notes and precautions described in this manual carefully. If a label comes off or becomes hard to read, contact your TOHATSU outboard motor dealer for a replacement. READ OWNER’S MANUAL EMERGENCY ENGINE STARTING READ OWNER’S... - Page 14 SAFETY LABEL LOCATIONS PORTABLE FUEL TANK FUEL CAUTION FUEL CAUTION...

-

Page 15: Ce Mark Location

SAFETY LABEL LOCATIONS CE mark location [U type only] CE MARK (1) Model name (2) Engine family name (10) (3) Year code (4) Rated power (5) Dry mass (weight) (with propeller, without battery cable) (6) Country of manufacture (7) Frame number (8) Manufacturer and address (9) Name and address of authorized representative... -

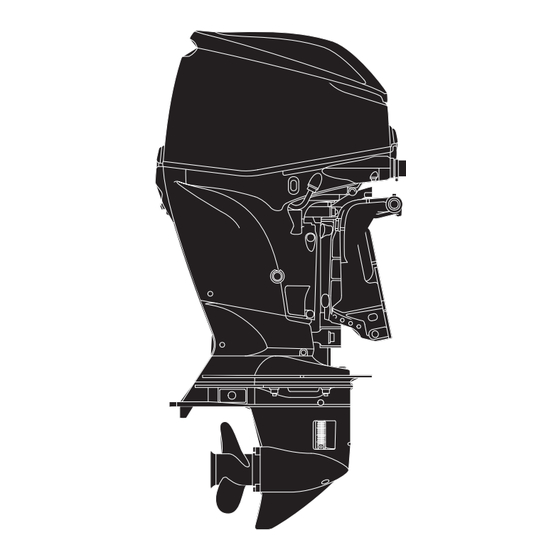

Page 16: Component Identification

3. COMPONENT IDENTIFICATION [H (Tiller Handle) type] ENGINE COVER ENGINE COVER FIXING LEVER FUEL HOSE (front) ENGINE COVER FIXING LEVER (rear) POWER TILT SWITCH TILLER IDLE PORT HANDLE TILT LOCK LEVER FLUSH PORT COOLING CONNECTOR WATER STERN FRAME SERIAL CHECK BRACKET NUMBER ENGINE OIL... - Page 17 COMPONENT IDENTIFICATION ACG FUSE MAIN FUSE BOX INTERFACE COUPLER OIL LEVEL DIPSTICK ENGINE SERIAL ENGINE OIL FILLER CAP NUMBER SPARK PLUG CAPS FUEL FILTER/WATER SEPARATOR (inside strainer cup)

- Page 18 COMPONENT IDENTIFICATION TILLER HANDLE SHIFT LEVER THROTTLE FRICTION INDICATORS TRL (Trolling Control) ADJUSTER (Oil pressure, Overheat, ACG, PGM-FI) SWITCH THROTTLE GRIP EMERGENCY STOP EMERGENCY SWITCH CLIP STOP SWITCH FUEL HOSE EMERGENCY STOP SWITCH LANYARD STEERING FRICTION POWER TRIM/TILT SWITCH ENGINE SWITCH ADJUSTER ENGINE SWITCH KEY SPARE EMERGENCY STOP SWITCH CLIP...

- Page 19 COMPONENT IDENTIFICATION [R (Remote Control) type] ENGINE COVER ENGINE COVER FIXING LEVER (front) ENGINE COVER FIXING LEVER FUEL HOSE (rear) POWER TILT SWITCH TILT LOCK IDLE PORT LEVER COOLING FLUSH PORT WATER STERN CONNECTOR CHECK BRACKET HOLE FRAME SERIAL MANUAL RELIEF NUMBER VALVE ANODE...

- Page 20 COMPONENT IDENTIFICATION ACG FUSE MAIN FUSE BOX INTERFACE COUPLER OIL LEVEL DIPSTICK ENGINE SERIAL ENGINE OIL FILLER CAP NUMBER SPARK PLUG CAPS FUEL FILTER/WATER SEPARATOR (inside strainer cup)

- Page 21 COMPONENT IDENTIFICATION REMOTE CONTROL BOX (R type) (equipped type or optional equipment) SIDE-MOUNT TYPE REMOTE CONTROL LEVER NEUTRAL RELEASE LEVER POWER TRIM/TILT SWITCH TRL (Trolling) CONTROL SWITCH INDICATORS (Oil pressure, Overheat, BUZZER ACG, PGM-FI) (inside) FAST IDLE LEVER ENGINE SWITCH ENGINE SWITCH KEY EMERGENCY STOP SWITCH EMERGENCY STOP...

- Page 22 COMPONENT IDENTIFICATION [Common] FUEL GAUGE PORTABLE FUEL TANK (equipped type or optional equipment) FUEL FILLER CAP FUEL TANK TUBE FUEL FILLER CAP ASSEMBLY VENT KNOB FUEL LINE JOINT (outboard motor side) PRIMING BULB...

- Page 23 COMPONENT IDENTIFICATION TACHOMETER TRIM METER RUDDER METER (equipped type or optional equipment) (equipped type or optional equipment) (optional equipment: R type) TRL (Trolling Control) SWITCH PANEL (optional equipment: R type) TRL (Trolling Control) SWITCH...

-

Page 24: Controls And Features (H Type)

4. CONTROLS AND FEATURES (H type) Engine Switch (Ignition Switch) NEUTRAL START SHIFT LEVER ENGINE SWITCH (IGNITION SWITCH) START NEUTRAL This tiller handle is equipped with an automotive type engine switch. Do not leave the engine switch (ignition switch) ON (key in ON Key positions: position) when the engine is not START:... -

Page 25: Shift Lever

The shift lever will not move unless forward or reverse gear, or to cut off shift lever installed. Consult your the throttle grip is in the fully closed authorized TOHATSU outboard the engine power from the propeller. position. motor dealer. -

Page 26: Throttle Grip

CONTROLS AND FEATURES (H type) Throttle Grip Throttle Friction Adjuster FAST START THROTTLE FRICTION SLOW ADJUSTER RELEASE THROTTLE THROTTLE GRIP THROTTLE GRIP INDICATOR The throttle friction adjuster adjusts Turn the grip clockwise or The curve on the grip indicates the resistance to throttle grip rotation. -

Page 27: Emergency Stop Switch

CONTROLS AND FEATURES (H type) Emergency Stop Switch Emergency Stop Switch Lanyard/Clip EMERGENCY STOP SWITCH EMERGENCY STOP EMERGENCY STOP SWITCH SWITCH CLIP STOP STOP EMERGENCY STOP EMERGENCY EMERGENCY STOP SWITCH CLIP STOP SWITCH SWITCH LANYARD LANYARD The emergency stop switch lanyard is Press the emergency stop switch to If the emergency stop switch provided to stop the engine... -

Page 28: Steering Friction Adjuster

CONTROLS AND FEATURES (H type) Steering Friction Adjuster TRL (Trolling) Control Switch STEERING FRICTION ADJUSTER DOWN SPARE EMERGENCY STOP SWITCH CLIP To decrease To increase friction friction TROLLING (FREE) (LOCK) CONTROL SWITCH The steering friction adjuster adjusts The engine speed can be adjusted The engine does not start unless the steering resistance. -

Page 29: Side-Mount Type

CONTROLS AND FEATURES (R type) SIDE-MOUNT TYPE Remote Control Lever NEUTRAL 32° 32° REMOTE CONTROL LEVER FORWARD REVERSE NEUTRAL RELEASE LEVER SHIFT SHIFT FORWARD MINIMUM MINIMUM THROTTLE OPENING NEUTRAL THROTTLE OPENING REVERSE MAXIMUM MAXIMUM REMOTE CONTROL LEVER Shifting gear into forward, reverse, or FORWARD: REVERSE: neutral and the engine speed... -

Page 30: Neutral Release Lever

CONTROLS AND FEATURES (R type) Neutral Release Lever Engine Switch (Ignition Switch) Do not leave the engine switch REMOTE CONTROL LEVER START (ignition switch) ON (key in ON position) when the engine is not ENGINE running as the battery will SWITCH discharge. -

Page 31: Fast Idle Lever

CONTROLS AND FEATURES (R type) Fast Idle Lever Emergency Stop Switch REMOTE CONTROL LEVER The fast idle lever is only needed for NEUTRAL MAXIMUM starting carbureted outboard models. FAST IDLE The BFT60A and BFW60A models use programmed fuel injection so, this lever will not be needed for LOWEST STOP... -

Page 32: Emergency Stop Switch Lanyard/Clip

CONTROLS AND FEATURES (R type) Emergency Stop Switch Lanyard/ EMERGENCY Clip STOP SWITCH If the emergency stop switch EMERGENCY STOP lanyard is not set, the boat might SWITCH LANYARD run out of control when the operator, for example, falls overboard and is not able to STOP operate the outboard motor. -

Page 33: Spare Emergency Stop Switch Clip (Optional Equipment)

CONTROLS AND FEATURES (R type) Spare Emergency Stop Switch Clip TRL (Trolling) Control Switch (optional equipment) Store the spare emergency stop switch clip in the tool bag. TROLLING CONTROL SWITCH TROLLING CONTROL SWITCH Remote Control Box TRL (Trolling) Control Switch (Side-mount type) Panel (optional equipment: R type) -

Page 34: Power Trim/Tilt Switch

CONTROLS AND FEATURES (Common) Power Trim/Tilt Switch (H type) Excessive trim/tilt angle during Power Trim operation can cause the propeller Press the power trim/tilt switch on the to raise out of the water and cause tiller handle or on the remote control propeller ventilation and engine lever to adjust the outboard motor over-revving. -

Page 35: Nmea Interface Coupler

CONTROLS AND FEATURES (Common) NMEA Interface Coupler Operating Hour Notification Power Tilt The NMEA2000 interface coupler System Press the power trim/tilt switch to can provide information regarding adjust the outboard motor tilt angle of engine speed, fuel consumption, and This outboard motor engine counts 16°... - Page 36 CONTROLS AND FEATURES (Common) Periodic maintenance is required <Operating hour notification timing> when either the operating hours or the time since last maintenance reaches the prescribed limit. Therefore, peri- odic maintenance may be required Every 100 hours based on the number of months since the last maintenance before the alert based on engine operating hours dis- 80 hours...

- Page 37 CONTROLS AND FEATURES (Common) NMEA2000-compatible display: When "Periodic Maintenance" is indicated: • Follow instructions for the display. 1. Have the periodic maintenance • If the display allows selection of performed without delay after notification to be preset, select returning to port. "Notify"...

-

Page 38: Trim Meter

CONTROLS AND FEATURES (Common) Trim Meter Power Tilt Switch (equipped type or optional (outboard motor pan) The tilt limit mechanism (optional equipment) equipment for R type) is not operated by the power tilt switch (motor pan). The tilt limit mechanism is operated with the power trim/tilt switch on the control lever side. -

Page 39: Manual Relief Valve

CONTROLS AND FEATURES (Common) Tilt Lock Lever Manual Relief Valve MANUAL RELIEF VALVE POWER MANUAL FREE (To fix) (To release) LOCK TILT LOCK LEVER If the power trim/tilt switch will not Check that nobody is under the Use the tilt lock lever to raise the tilt the outboard motor, the outboard outboard motor before opening the outboard motor and lock it in the... -

Page 40: Oil Pressure Indicator/Buzzer

CONTROLS AND FEATURES (Common) Oil Pressure Indicator/Buzzer (H type) (GREEN) The oil pressure indicator turns off and the buzzer sounds when the oil level is low and/or the engine lubrication system is faulty. The engine speed slows down OIL PRESSURE gradually this time. -

Page 41: Overheat Indicator/Buzzer

CONTROLS AND FEATURES (Common) Overheat Indicator/Buzzer (H type) (RED) The overheat indicator turns on and the buzzer sounds when the engine cooling circuit is faulty. The engine speed slows down this time. OVERHEAT INDICATOR (internal buzzer) (Side-mount type) OVERHEAT INDICATOR (RED) BUZZER... -

Page 42: Acg Indicator/Buzzer

CONTROLS AND FEATURES (Common) ACG Indicator/Buzzer (H type) (RED) The ACG indicator turns on and the buzzer sounds when the charging system is faulty. ACG INDICATOR (internal buzzer) (Side-mount type) ACG INDICATOR (RED) BUZZER... -

Page 43: Pgm-Fi Indicator/Buzzer

CONTROLS AND FEATURES (Common) PGM-FI Indicator/Buzzer (H type) (RED) The PGM-FI indicator turns on and the buzzer sounds when the engine control system is faulty. PGM-FI INDICATOR (internal buzzer) (Side-mount type) PGM-FI INDICATOR (RED) BUZZER... -

Page 44: Trim Tab

CONTROLS AND FEATURES (Common) Trim Tab BFW60A model: BFT60A model: GEAR CASE GROMMET TRIM TAB TIGHTENING BOLT PROPELLER TIGHTENING BOLT TRIM TAB If the steering wheel/handle is pulled BFW60A model: to the side while running at full Remove the gear case grommet. Loosen the tightening bolt and turn speed, adjust the trim tab so that the boat runs straight ahead. -

Page 45: Anode

CONTROLS AND FEATURES (Common) Anode ANODE (stern bracket) ANODE (each side) The anode metal is a sacrificed metal which protects the outboard motor from corrosion. Do not paint the anode. It deteriorates the function of the anode metal, which can lead to rust and corrosion damage to the outboard motor. -

Page 46: Cooling Water Check Hole

CONTROLS AND FEATURES (Common) Cooling Water Check Hole Cooling Water Intake Port COOLING WATER CHECK HOLE COOLING WATER INTAKE PORT The engine cooling water is drawn The cooling water is checked here to see whether it is circulating inside the into the engine through this port. -

Page 47: Engine Cover Fixing Lever

CONTROLS AND FEATURES (Common) Fuel Filler Cap (equipped type) Engine Cover Fixing Lever (rear) (with vent knob) (Front/Rear) LATCH (front) FUEL FILLER CAP VENT KNOB ENGINE COVER LATCH FIXING LEVER OPEN (rear) ENGINE COVER FIXING LEVER (front) UNLOCK CLOSE UNLOCK LOCK LOCK FUEL FILLER CAP... -

Page 48: Fuel Gauge

CONTROLS AND FEATURES (Common) Fuel Gauge Fuel Line Connector And Joint The fuel line connector and joint are (equipped type or optional used to connect the fuel line between equipment) the fuel tank and the outboard motor. FUEL GAUGE HOSE PLUG Tachometer (equipped type or optional equipment) -

Page 49: Rudder Meter

CONTROLS AND FEATURES (Common) Rudder Meter (optional equipment: R type) The rudder meter shows the boat’s travelling direction in accordance with the rudder angle. -

Page 50: Installation

Damage and much fuel consumption. injury may result. We recommend that the outboard motor be installed by an authorized TOHATSU outboard motor dealer. Consult the authorized TOHATSU dealer in your area for the Y-OP (User Model Type: T (Outboard Motor... -

Page 51: Location

INSTALLATION Location Installation Height IDLE PORT BOAT TRANSOM HEIGHT 150 mm (5.9 in) IDLE PORT or more 0 – 50 mm (0 – 2 in) WATER LEVEL FULLY TRIM/TILT CENTER LINE OUTBOARD MOTOR DOWN TRANSOM HEIGHT ANTICAVITATION PLATE • The water level must be at least Install the outboard motor at the The anticavitation plate of the 100 mm (4 in) above the... -

Page 52: Outboard Motor Installation

The standard torque is given just as a guideline. Torque of the nut can be different according to the material of the boat. Consult with an authorized Ф22 WASHER (8) TOHATSU outboard motor dealer. NUT (8) Ф33 WASHER (4) Install the outboard motor securely. Loosely mounted... -

Page 53: Outboard Motor Angle Inspection (Cruising)

INSTALLATION Outboard Motor Angle Inspection (Cruising) INCORRECT INCORRECT CORRECT CAUSES BOAT TO ‘‘SQUAT’’ CAUSES BOAT TO ‘‘PLOW’’ GIVES MAXIMUM PERFORMANCE Install the outboard motor at the best Trim angle too small: Incorrect The trim angle differs according to trim angle for stable cruising and causes boat to ‘‘plow.’’... -

Page 54: Battery Connections

INSTALLATION Battery Connections • POISON: Electrolyte is poison. Use a battery which has CCA (COLD ANTIDOTE: Batteries produce explosive gases: ─ External: Flush thoroughly CRANKING AMPERES) 420A at If ignited, an explosion can cause – 18°C (0°F) and a reserve capacity with water. - Page 55 INSTALLATION • Battery cable extension: (+) TERMINAL Extending the original battery (-) TERMINAL • Be sure to connect the (+) side cable will cause the battery battery cable first. When voltage to drop due to the disconnecting the cables, increased length of the cable and disconnect the (-) side first then number of connections.

-

Page 56: Remote Control Installation

CABLE remote control cable, or installing those of the different types could cause unpredictable accident. Consult an authorized TOHATSU outboard motor dealer for proper installation. The control box is available in three types. Install the remote control box in the... -

Page 57: Remote Control Cable Length

Recommended cable length is 300 – Consult with your authorized 450 mm (11.8 – 17.7 in) longer than TOHATSU outboard motor dealer for the measured distance. proper propeller selection. Set the cable along the predetermined route and be sure that it is long enough to the route. -

Page 58: Pre-Operation Checks

6. PRE-OPERATION CHECKS BFT60A/BFW60A is 4-stroke, water Engine Cover Removal/Installation cooled outboard motor which uses unleaded gasoline for fuel. It also (front) (rear) requires the engine oil. Check the LATCH following before operating the outboard motor. ENGINE COVER FIXING LEVER Perform the following pre-operation checks with the UNLOCK... -

Page 59: Engine Oil

PRE-OPERATION CHECKS Engine Oil SAE 10W-30 is recommended for <Inspection and Refilling> general use. • Engine oil is a major factor affecting engine performance UPPER and service life. Nondetergent LEVEL and low quality oils are not MARK recommended, because they have inadequate lubricating LOWER properties. - Page 60 PRE-OPERATION CHECKS When the engine oil is contaminated When you check the oil level with the dipstick, you might notice the engine oil or discolored, replace with the fresh appears milky or the oil level has increased. If you notice either condition, engine oil (see page 115 for change the engine oil.

-

Page 61: Fuel

PRE-OPERATION CHECKS Fuel Check the fuel gauge and refill the (Portable Fuel Tank equipped type tank to the upper level mark if or optional equipment) necessary. Do not fill the fuel tank above the UPPER level mark. FUEL GAUGE Open the vent knob before removing the fuel filler cap. -

Page 62: Gasoline Containing Alcohol

• Refuel in a well-ventilated area its octane rating is at least as high as recommended is not covered under with the engine stopped. that recommended by TOHATSU. the warranty. • Do not smoke or allow flames or There are two types of “gasohol”: one •... -

Page 63: Propeller And Cotter Pin Inspection

Consult an authorized TOHATSU life as well. outboard motor dealer for propeller Consult with your authorized selection. TOHATSU outboard motor dealer for Keep the spare washer, castle nut and proper propeller selection. cotter pin with you on your boat. -

Page 64: Tiller Handle Height/Angle Adjustment (H Type)

PRE-OPERATION CHECKS Tiller Handle Height/Angle Install the height adjustment block Adjustment (H type) so that the selected angle of the tiller handle is in this position. The tiller handle height and angle can 293 mm be adjusted to three positions by (11.5 in) changing the installation direction of HANDLE ANGLE: 7°... -

Page 65: Steering Handle Friction (H Type)

Clean it or consult with an authorized Do not apply grease or oil on the TOHATSU outboard motor dealer for friction plate. Grease or oil will cleaning (see page 123). reduce the friction of the adjuster. -

Page 66: Battery

PRE-OPERATION CHECKS Battery • Keep flames and sparks away, POSITIVE (+) and do not smoke in the area. TERMINAL ANTIDOTE: If electrolyte gets Battery handling differs according into your eyes, flush thoroughly to the type of the battery and the with warm water for at least 15 instructions described below might minutes and call a physician... -

Page 67: Other Checks

PRE-OPERATION CHECKS Other Checks The possibility of corrosion damage Check the following items: is increased if the anode is painted (1) The fuel hose for kinking, over or allowed to deteriorate. collapsing or a loose connection. Parts/materials which should be (2) The tiller handle for loose installed on board: installation, wobble or smooth... -

Page 68: Starting The Engine

7. STARTING THE ENGINE Fuel Line Connection FUEL HOSE BARB (outboard • Set the fuel tank securely so that it motor side) does not move or fall down while Gasoline is extremely flammable, cruising. and gasoline vapor can explode, • Position the fuel tank so the tank causing serious injury or death. -

Page 69: Fuel Priming

STARTING THE ENGINE Fuel Priming FUEL FILLER CAP FUEL LINE CONNECTOR VENT KNOB (TO FUEL TANK) ARROW OUTLET END OPEN (outboard motor side) PRIMER BULB INLET END (fuel tank side) (tank side) Hold the priming bulb so that the 2. Connect the fuel tube assembly to 3. -

Page 70: Starting The Engine (H Type)

STARTING THE ENGINE Starting the Engine (H type) 1. Insert the emergency stop switch clip at one end of the emergency Do not touch the priming bulb with EMERGENCY STOP stop switch lanyard into the SWITCH the engine running or when tilting emergency stop switch. - Page 71 STARTING THE ENGINE START NEUTRAL SPARE EMERGENCY STOP ‘‘ ’’ MARK SWITCH CLIP SHIFT LEVER Store the spare emergency stop switch clip in the tool bag. THROTTLE GRIP Use the spare emergency stop switch clip to make the disabled engine start when the emergency stop switch lanyard is not available as, for example, when the operator falls...

- Page 72 STARTING THE ENGINE ENGINE SWITCH KEY COOLING WATER CHECK HOLE • The starter motor consumes a large amount of current. Do not START therefore run it continuously for more than 5 seconds at a time. If the engine does not start within 5 seconds, wait at least 10 seconds before running the starter motor again.

- Page 73 TOHATSU outboard motor dealer. and overheat indicator may Do not operate the engine until the activate and the engine speed will problem has been corrected.

-

Page 74: Starting The Engine (R Type)

STARTING THE ENGINE Starting the Engine (R type) 1. Insert the emergency stop switch SPARE EMERGENCY (Side-mount type) clip at one end of the emergency STOP SWITCH CLIP stop switch lanyard into the (optional equipment) EMERGENCY STOP SWITCH emergency stop switch. Attach the other end of the emergency stop switch lanyard securely to the operator. - Page 75 STARTING THE ENGINE REMOTE CONTROL LEVER • The starter motor consumes a START large amount of current. Do not NEUTRAL therefore run it continuously for more than 5 seconds at a time. If the engine does not start within 5 NEUTRAL seconds, wait at least 10 seconds before running the starter motor...

- Page 76 If water still does not flow out, have your outboard motor checked by an authorized TOHATSU outboard motor dealer. Do not operate the engine until the COOLING WATER INTAKE PORT (each side) problem has been corrected.

-

Page 77: Emergency Starting

STARTING THE ENGINE 7. Warm up the engine as follows: Emergency Starting Above 5°C (41°F) – run the engine (front) (rear) for at least 3 minutes. LATCH Below 5°C (41°F) – run the engine for at least 5 minutes at approx. 2,000 min (rpm). - Page 78 STARTING THE ENGINE (H type) (Side-mount type) 6 × 25 mm BOLTS ACG COVER NEUTRAL NEUTRAL NEUTRAL SHIFT LEVER REMOTE CONTROL LEVER NEUTRAL 4. Set the shift lever or remote control lever is in the NEUTRAL position. 3. Remove the two 6 × 25 mm bolts, then remove the ACG cover.

- Page 79 STARTING THE ENGINE (H type) (Side-mount type) KNOT START START ‘‘ ’’ MARK THROTTLE GRIP ACG ROTOR FAST IDLE LEVER EMERGENCY STARTER ROPE 5. H type: 6. Set the ACG rotor so the cutouts are on the right and left sides of the Align the “...

- Page 80 STARTING THE ENGINE (H type) (Side-mount type) EMERGENCY EMERGENCY STOP SWITCH STOP SWITCH SPARE EMERGENCY STOP SWITCH CLIP STOP STOP EMERGENCY STOP SWITCH CLIP EMERGENCY STOP Store the spare emergency stop SWITCH CLIP switch clip in the tool bag. EMERGENCY STOP EMERGENCY STOP SWITCH LANYARD SWITCH LANYARD...

- Page 81 STARTING THE ENGINE (H type) (Side-mount type) ENGINE Direction to pull SWITCH EMERGENCY STARTER ROPE ENGINE 9. Pull the emergency starter rope SWITCH KEY lightly until resistance is felt, then pull briskly in the direction of the arrow as shown above. 8.

- Page 82 12. After returning to the closest boat landing, contact your closest authorized TOHATSU outboard motor dealer and perform the following. • Have the electrical system checked. • Have your dealer reassemble the parts removed in the emergency starting procedure.

-

Page 83: Operation

8. OPERATION Break-in Procedure Next 60 minutes: Break-in period: 10 hours Run the outboard motor up to maximum of 4,000 to 5,000 min Break-in operation allows the mating (rpm) or 50% to 80% throttle surfaces of the moving parts to wear opening. -

Page 84: Gear Shifting

OPERATION Gear Shifting SLOW (H type) FORWARD REVERSE NEUTRAL N (NEUTRAL) SLOW FORWARD THROTTLE GRIP SHIFT LEVER REVERSE The shift lever has 3 positions: FORWARD, NEUTRAL, and 1. Align the pointer on the throttle 2. Move the shift lever to engage the REVERSE. -

Page 85: Steering

OPERATION Steering STEERING FRICTION ADJUSTER Do not apply grease or oil on the (H type) FRICTION PLATE friction plate. Grease or oil will RIGHT TURN LEFT TURN reduce the friction of the adjuster. (R type) Steer the boat in the same manner as an automobile. -

Page 86: Cruising

OPERATION Cruising (H type) FORWARD POWER TRIM/ TILT SWITCH SHIFT (down) LEVER LOWERMOST POSITION FORWARD 2. With the shift lever in the 1. Press the DN (down) portion of the FORWARD position. power trim/tilt switch and trim the outboard motor to the lowermost position. - Page 87 OPERATION THROTTLE FRICTION ADJUSTER • When cruising at full throttle, note FAST that the engine speed must be in the range between 5,000 min (rpm) and 6,000 min (rpm). • If you feel that the engine speed jumped up when the hull jumped or at ventilation, cruise the boat by returning the throttle to the slow THROTTLE GRIP...

-

Page 88: Gear Shifting

OPERATION Gear Shifting (R type) (Side-mount type) FORWARD NEUTRAL NEUTRAL REMOTE NEUTRAL FORWARD REVERSE CONTROL LEVER 32° 32° MAXIMUM MAXIMUM OPENING OPENING REVERSE Pull up NEUTRAL RELEASE LEVER While pulling the neutral release lever, move the remote control lever Avoid sharp and abrupt operation approximately 32°... -

Page 89: Cruising

OPERATION Cruising (R type) NEUTRAL (Side-mount type) REVERSE FORWARD POWER TRIM/TILT SWITCH REMOTE CONTROL LEVER (down) LOWERMOST POSITION FORWARD 1. Press the DN (down) of the power 2. Move the remote control lever from trim/tilt switch and trim the NEUTRAL toward FORWARD position. - Page 90 OPERATION OUTBOARD MOTOR TRIMMED OUTBOARD MOTOR TRIMMED TOO LOW TOO HIGH OUTBOARD MOTOR TRIMMED CORRECTLY When cruising: (A) Into a high wind, trim the outboard motor down slightly to lower the bow and improve boat stability. (B) With a tail wind, trim the outboard motor up slightly to raise the bow and improve boat stability.

-

Page 91: Trl (Trolling Control) Switch

OPERATION TRL (Trolling Control) Switch TRL (Trolling Control) Switch A long buzz sounds once. (H type) Panel When the mode is changed to trolling (optional equipment: R type) mode, the engine speed is 850 min (rpm). DOWN You can adjust the engine speed by 50 min (rpm) every time you press the switch once. -

Page 92: Trimming The Outboard Motor

OPERATION Trimming the Outboard Motor (H type) (Side-mount type) POWER TRIM/TILT SWITCH Press UP to raise bow. Press DN to lower bow. Press UP to raise bow. Press DN to lower bow. 60° 12° 16° TRIM POWER TRIM/TILT SWITCH REMOTE CONTROL LEVER TILT –... - Page 93 OPERATION The power trim/tilt system operates when the switch is pressed, and it • Improper trim angle results in stops when the switch is released. To unstable steering condition. trim up slightly, press on UP • Do not trim excessively while momentarily but securely.

-

Page 94: Trim Meter

OPERATION Trim Meter BOW TOO LOW DUE TO BOW TOO HIGH DUE TO (equipped type or optional 1. LOAD IN THE FRONT 1. LOAD IN THE REAR 2. OUTBOARD MOTOR TRIMMED 2. OUTBOARD MOTOR TRIMMED equipment) TOO LOW TOO HIGH The trim meter indicates the trim angle of the outboard motor. -

Page 95: Tilting The Outboard Motor

OPERATION Tilting the Outboard Motor (H type) If your outboard motor is equipped Tilt the outboard motor to prevent the with the tilt limit mechanism propeller and gear case from hitting (optional equipment for R type), you the bottom when the boat is beached can set the tilt limit angle. -

Page 96: Moorage

OPERATION Moorage TILT LOCK LEVER FREE LOCK TILT LOCK LEVER 1. Raise the outboard motor as full as Tilt up the outboard motor using the Stop the engine and disconnect the it goes using the power trim/tilt tilt lock lever when mooring the boat. fuel line from the outboard motor switch. -

Page 97: Manual Relief Valve

OPERATION Manual Relief Valve After tilting up/down manually, close Power Tilt Switch (outboard motor pan) the manual relief valve to lock the MANUAL RELIEF VALVE outboard motor in the position. POWER TILT SWITCH POWER MANUAL Check that nobody is under the (To fix) (To release) outboard motor before opening the... -

Page 98: Trim Tab Adjustment

OPERATION Trim Tab Adjustment (BFT60A model) (BFW60A model) LEFT GEAR CASE The trim tab is provided to adjust for GROMMET “torque steer” which is a reaction of the propeller rotation or propeller LEFT torque. If during a high speed turn an unequal amount of effort is required LEFT to turn the boat right or left, adjust the... - Page 99 OPERATION (BFT60A model) (BFW60A model) RIGHT GEAR CASE GROMMET RIGHT RIGHT TIGHTENING BOLT TIGHTENING TRIM TAB BOLT TRIM TAB If less effort is required to make right Make small adjustments at a time and turns: retest. Incorrect trim tab adjustment Loosen the trim tab tightening bolt can cause adverse steering.

-

Page 100: Engine Protection System

OPERATION If the engine oil pressure drops and/ Engine Protection System (Side-mount type) or the engine overheats, either or both <Engine Oil Pressure, Overheat, OIL PRESSURE warning systems could be activated. PGM-FI and ACG Warning INDICATOR INDICATOR When activated the engine speed will Systems>... - Page 101 OPERATION System INDICATOR LIGHTS BUZZER Oil pressure Overheat PGM-FI CORRESPONDING Symptom (Green) (Red) (Red) (Red) SYSTEM With the engine key At starting ON (2 sec) ON (2 sec) ON (2 sec) turned on: ON (2 times) During operation Low oil pressure ON (continuously) Overheat ON (continuously)

- Page 102 2. If water is flowing out of the and contact your closest authorized cooling water check hole, continue TOHATSU outboard motor dealer. idling for 30 seconds. If the overheat warning system stops after 30 seconds the system is...

- Page 103 OPERATION When the PGM-FI activated: 1. Consult with an authorized TOHATSU outboard motor dealer. When the ACG warning system is activated. 1. Check the battery (see page 118). If the battery is OK, consult with an authorized TOHATSU outboard motor dealer.

-

Page 104: Over-Rev Limiter

There are also 4 small sacrificial Correct or service as necessary, by anodes in the water passages of the contacting your authorized engine block. TOHATSU outboard motor dealer. -

Page 105: Shallow Water Operation

OPERATION Shallow Water Operation Multiple Outboard Motors On boats equipped with more than one outboard motor, all motors Excessive trim/tilt angle during normally operate at the same time. operation can cause the propeller to raise out of the water and cause If one or more motor(s) is stopped propeller ventilation and engine while the other(s) is running, put the... -

Page 106: Stopping The Engine

9. STOPPING THE ENGINE Emergency Engine Stop To stop the engine in an emergency, pull the emergency stop switch clip (H type) out of the emergency stop switch by EMERGENCY STOP SWITCH pulling the emergency stop switch lanyard. We suggest that you stop the engine this way occasionally to verify that the emergency stop switch is operating properly. -

Page 107: Normal Engine Stop

STOPPING THE ENGINE Normal Engine Stop 1. Turn the throttle grip to SLOW (H type) position and move the shift lever to In the event that the engine does not NEUTRAL. stop when the engine switch key is SLOW turned to OFF, pull the emergency stop switch clip out of the emergency After sailing with the throttle fully stop switch by pulling the emergency... -

Page 108: (R Type)

STOPPING THE ENGINE (R type) (Side-mount type) NEUTRAL ENGINE SWITCH KEY NEUTRAL EMERGENCY STOP SWITCH REMOTE CONTROL LEVER 1. Move the remote control lever to 2. Turn the engine switch key to the 3. When the boat is not in use, remove the NEUTRAL position. -

Page 109: Transporting

10. TRANSPORTING Fuel Line Disconnection FUEL LINE CONNECTOR FUEL FILLER CAP VENT KNOB Before transporting the outboard motor, disconnect and remove the fuel line in the following procedure. Gasoline is extremely flammable, and gasoline vapor can explode, CLOSE causing serious injury or death. •... -

Page 110: Transporting

TRANSPORTING Transporting HOIST HOOKS Do not carry the outboard motor by the engine cover. The engine cover can be unlatched and outboard motor can drop, resulting ENGINE HANGERS in an accidental injury and damage. 3. Secure the outboard motor on an When transporting the outboard outboard motor stand with the motor on a vehicle, perform the... - Page 111 TRANSPORTING PROTECTOR Before transporting the outboard motor horizontally, be sure to drain the gasoline and oil from the outboard motor as instructed on pages 115 and 135. (Starboard side turned down as shown.) OUTBOARD MOTOR STAND 4. Remove the hoist hook and When you place the outboard motor reinstall the engine cover.

-

Page 112: Trailering

TRANSPORTING Trailering (H type) Do not trailer or transport the boat with the outboard motor in the STEERING FRICTION ADJUSTER tilted position. The boat or outboard motor could be severely damaged if the outboard motor drops. The outboard motor should be trailered in the normal running To decrease To increase... -

Page 113: Cleaning And Flushing

11. CLEANING AND FLUSHING After each use in salt water or dirty Shut off the engine before performing 4. Disconnect the flush port water, thoroughly clean and flush the the cleaning and flushing. connector. outboard motor with fresh water. 5. Screw the flush port connector onto 1. -

Page 114: Maintenance

Shut off the engine before engine will overheat. performing any maintenance. If the • Use only TOHATSU Genuine engine must be run, make sure the parts or their equivalents for area is well ventilated. maintenance or repair. The use of... -

Page 115: Tool Kit, Spare And Emergency Parts

MAINTENANCE Tool Kit, Spare and Emergency Parts EMERGENCY The following tools and emergency FLAT STARTER ROPE starter rope, spare emergency stop SCREWDRIVER TOOL BAG switch clip are supplied with the outboard motor for maintenance, adjustment, and emergency repairs. SPARK PLUG <Spare Emergency Stop Switch WRENCH GRIP... -

Page 116: Maintenance Schedule

(2) These items should be serviced by your servicing dealer, unless you have the proper tools and are mechanically proficient. Refer to the TOHATSU Service Manual for service procedures. (3) For professional commercial use, log hours of operation to determine proper maintenance intervals. - Page 117 (2) These items should be serviced by your servicing dealer, unless you have the proper tools and are mechanically proficient. Refer to the TOHATSU Service Manual for service procedures. (3) For professional commercial use, log hours of operation to determine proper maintenance intervals.

-

Page 118: Engine Oil

MAINTENANCE Engine Oil <Engine Oil Replacement> DRAIN BOLT Insufficient or contaminated engine OIL FILLER CAP SEALING WASHER oil adversely affects the service life of the sliding and moving parts. GUIDE Oil change interval: 20 operating hours after the date of purchase or first month for initial replacement, then every 100 operating hours or 6 months. -

Page 119: Spark Plugs

MAINTENANCE 6. Reinstall the oil filler cap securely. Spark Plugs Do not overtighten. To ensure proper engine operation, 7. Install and lock the engine cover the spark plug must be properly securely. gapped and free of deposits. Please dispose of used motor oil in a UPPER The spark plug becomes very hot LEVEL... - Page 120 MAINTENANCE 1. Remove the engine cover. (2) Replace a spark plug if the central electrode is worn. 2. Remove the spark plug caps. The spark plug can wear out in 3. Use the spark plug wrench, 10 mm different ways. box wrench and screwdriver If the sealing washer shows supplied in the tool kit to loose the...

-

Page 121: Battery

MAINTENANCE Battery If installing new spark plugs, tighten 1/2 turn after the spark plugs seat to Battery handling differs according compress the washers. to the type of the battery and the If reinstalling used spark plugs, instructions described below might tighten 1/8–1/4 turn after the spark not be applicable to the battery of plugs seat to compress the washers. - Page 122 MAINTENANCE • Keep flames and sparks away, <Battery Cleaning> UPPER LEVEL and do not smoke in the area. 1. Disconnect the battery cable at the ANTIDOTE: If electrolyte gets battery negative (–) terminal, then into your eyes, flush thoroughly at the battery positive (+) terminal. with warm water for at least 15 2.

- Page 123 MAINTENANCE POSITIVE (+) NEGATIVE (–) TERMINAL When disconnecting the battery TERMINAL cable, be sure to disconnect at the battery negative (–) terminal first. To connect, connect at the positive (+) terminal first, then at the negative (–) terminal. Never dis/connect the battery cable in the reverse order, or it causes a short circuit when a tool contacts the terminals.

-

Page 124: Lubrication

MAINTENANCE Lubrication TILLER HANDLE (H type) THROTTLE ARM/ Wipe the outside of the engine with a LINK/PIVOT/PLATE THROTTLE ROD/LINK cloth dipped in clean oil. Apply marine anticorrosion grease to the following parts: Lubrication interval: 20 hours or a month after the date of purchase for initial lubrication, then every 100 hours or 6 months. - Page 125 MAINTENANCE SHIFT LINK BRACKET/ SHIFT PIVOT/SHIFT ARM/ TILT LOCK LEVER LINK PIN/PIVOT PLATE/ (each side) SLIDE PIVOT/ CLICK SPRING ROLLER UPPER CYLINDER PIN/BUSHING UPPER SWIVEL CASE LOWER CYLINDER BUSHING/COLLAR...

-

Page 126: Fuel Filter/Water Separator

MAINTENANCE Fuel Filter/Water Separator <Inspection> The fuel filter (inside the strainer cup) Gasoline is extremely flammable, FUEL TUBE ASSEMBLY is located under the engine cover near CONNECTOR and gasoline vapor can explode, the engine cover latch on the boat causing serious injury or death. Do side. - Page 127 MAINTENANCE <Replacement> FUEL FILTER ASSEMBLY SUSPENSION STRAP FUEL FILTER BRACKET FUEL TUBES CLAMPS FUEL FILTER SUSPENSION STRAP (inside strainer cup) FUEL TUBES FUEL FILTER TUBE CLIPS (inside strainer cup) (commercially available) 1. Remove the suspension strap from 3. Looking through the translucent 2.

- Page 128 MAINTENANCE Align the center of the two fuel tubes and FILTER BODY the arrow of the suspension strap rib O-RINGS (Replace) Touch the suspension FUEL FILTER strap to the lower face of PROJECTIONS the filter body FLOAT (red ring) STRAINER CUP HEXAGON PART 3.

-

Page 129: Fuel Tank And Tank Filter

MAINTENANCE 9. Connect the fuel tube assembly Fuel Tank and Tank Filter <Fuel Tank Cleaning> connector to the fuel tank and (equipped type) outboard motor securely. Gasoline is extremely flammable, Turn the vent knob to OPEN side, squeeze and release the priming and gasoline vapor can explode, bulb to feed the fuel, (see page 66) causing serious injury or death. -

Page 130: Emission Control System

TOHATSU Dealer: 2. Clean the filter in nonflammable 1. Hard starting or stalling after solvent. Inspect the fuel tank filter starting and the connector gasket. -

Page 131: Fuse

MAINTENANCE Fuse SPARE ACG SPARE FUSES FUSE (40 A) (10 A, 15 A, 30 A) ACG FUSE (40 A) FUSES (10 A, 15 A, 30 A) BLOWN FUSE If the fuse blows, running the engine will not charge the battery. Before replacing the fuse, check the current ACG FUSE CASE LID ratings of the electrical accessories... - Page 132 MAINTENANCE 3. Remove the fuse case lid and pull the old fuse out of the clip with the If the fuse is blown, check the Disconnect the battery cable at the fuse puller supplied in the tool bag. cause, then replace the fuse with a battery terminal before checking or 4.

-

Page 133: Propeller

MAINTENANCE <Installation> Propeller PROPELLER (equipped type or optional equipment) 1. Apply marine grade grease to the COTTER PIN propeller shaft. SPACER (BFT60A model only) 2. Install the thrust washer with the grooved side toward the gear case. CASTLE 3. Install the propeller. 4. - Page 134 • Use a TOHATSU Genuine aligns with the cotter pin hole. Do stainless steel cotter pin or not tighten past the first alignment...

-

Page 135: Submerged Outboard Motor

ROTOR 115). recovered from the water in order to minimize corrosion. If there is a TOHATSU outboard motor dealer nearby, take the outboard motor immediately to the dealer. If you are far from a dealer, proceed as follows: EMERGENCY STARTER ROPE 1. - Page 136 7. Attempt to start the engine. 8. As soon as possible, take the • If the engine fails to start, remove outboard motor to a TOHATSU the spark plugs, clean and dry the outboard motor dealer for electrodes, then reinstall the spark inspection and service.

-

Page 137: Storage

(see page motor, have your outboard motor gasoline in a certified fuel 123) serviced by an authorized TOHATSU container. 2. Drain the gasoline from the vapor outboard motor dealer before storage. • If long storage (more than 30 days) separator. -

Page 138: Vapor Separator Draining

STORAGE Vapor Separator Draining VAPOR TUBE CLAMPER SEPARATOR Operate the priming valve after confirming the drain screw is Gasoline is extremely flammable, tightened. When the drain screw is and gasoline vapor can explode, loose, gasoline will flow out. causing serious injury or death. Do not smoke or allow flames or 5-d. -

Page 139: Engine Oil

STORAGE 6. When the gasoline starts to flow Engine Oil out of the drain tube, tilt down the Before storing the outboard motor for 1. Change the engine oil (see pages outboard motor and hold it in the a prolonged period, we recommend 115 –... -

Page 140: Battery Storage

STORAGE Battery Storage • Keep flames and sparks away, (+) TERMINAL and do not smoke in the area. (–) TERMINAL ANTIDOTE: If electrolyte gets Battery handling differs according into your eyes, flush thoroughly to the type of the battery and the with warm water for at least 15 instructions described below might minutes and call a physician... -

Page 141: Outboard Motor Position

STORAGE Outboard Motor Position PROTECTOR UPPER LEVEL (Starboard side turned down as shown.) OUTBOARD MOTOR STAND Horizontal transport or storage: 3. Fill the battery with distilled water Transport and store the outboard Rest the outboard motor on a cushion to the upper level line. Never motor either vertically or overfill the battery. -

Page 142: Disposal

14. DISPOSAL To protect the environment, do not dispose of this product, battery, engine oil, etc. carelessly by leaving them in the waste. Observe the local laws and regulations or consult your dealer for disposal. -

Page 143: Troubleshooting

• Engine speed cannot be increased by opening the throttle. • Faulty water pump. Consult with an authorized • Engine will stop in 20 seconds after engine speed is limited. TOHATSU outboard motor dealer. • Thermostat clogged. • Faulty thermostat. • Cooling water passage clogged. -

Page 144: Specifications

8 , 12 , 16 , 20 , 24 control system remote control Starter system Electric starter Ignition system Full transistor battery Lubrication Trochoid pump pressure lubrication system * Without battery cable, with propeller This TOHATSU outboard is power rated in accordance with ISO8665 (propeller shaft output). - Page 145 8 , 12 , 16 , 20 , 24 control system Starter system Electric starter Ignition system Full transistor battery Lubrication Trochoid pump pressure lubrication system * Without battery cable, with propeller This TOHATSU outboard is power rated in accordance with ISO8665 (propeller shaft output).

- Page 146 SPECIFICATIONS Noise and Vibration MODEL BFT60A BFW60A CONTROL SYSTEM T (Tiller handle) R (Remote control) T (Tiller handle) R (Remote control) Sound Pressure level at operator’s ears 84 dB (A) 79 dB (A) 84 dB (A) 79 dB (A) (2006/42/EC, ICOMIA 39-94) Uncertainty 3 dB (A) 1 dB (A)

-

Page 147: Ec Declaration Of Conformity'' Content Outline

17. ‘‘EC DECLARATION OF CONFORMITY’’ CONTENT OUTLINE... - Page 148 ‘‘EC DECLARATION OF CONFORMITY’’ CONTENT OUTLINE...

- Page 149 ‘‘EC DECLARATION OF CONFORMITY’’ CONTENT OUTLINE...

- Page 150 ‘‘EC DECLARATION OF CONFORMITY’’ CONTENT OUTLINE...

- Page 151 ‘‘EC DECLARATION OF CONFORMITY’’ CONTENT OUTLINE...

-

Page 152: Index

18. INDEX PGM-FI Warning System ..97 Serial Number ......2 ACG Indicator/Buzzer Disposal ........139 Switch Function........39 H type........21 Operation ........97 R type........27 ‘‘EC DECLARATION OF Anode CONFORMITY’’ Content Function........42 Outline ........ 144 Operation .........101 Frame Serial Number ...... 2 Emergency Stop Fast Idle Switch ......... - Page 153 INDEX Power Trim/Tilt Switch Function ........31 Gasoline Containing Alcohol ..59 Neutral Release Lever....27 Pre-operation Checks ....55 Gear NMEA Interface Coupler....32 Battery........63 Shifting Engine Oil ......... 56 H type ........81 Fuel ........... 58 Oil Pressure Indicator/Buzzer R type ........85 Fuel Filter/Water Separator..

- Page 154 INDEX Starting the Engine Tool Kit, Spare and Emergency Starting ....74 Emergency Parts ....64, 112 Remote Control H Type ........67 Trailering........109 R Type ........71 Transom Height......47 Identification ......18 Steering ......... 82 Transporting ........ 106 Installation Location....53 Steering Friction Adjuster.....

- Page 155 OWNER’S MANUAL BFT 60A BFW 60A...

Need help?

Do you have a question about the BFT 60A and is the answer not in the manual?

Questions and answers