Tektronix WFM8200 Service Manual

Waveform monitors

Hide thumbs

Also See for WFM8200:

- User manual (193 pages) ,

- Technical reference (138 pages) ,

- Installation and safety manual (90 pages)

Summary of Contents for Tektronix WFM8200

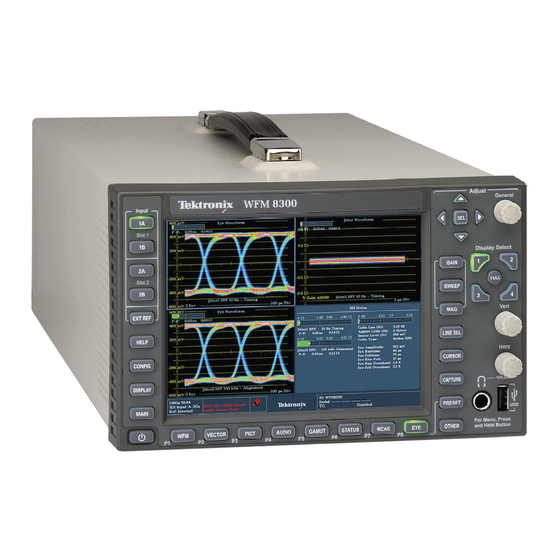

- Page 1 WFM8200 and WFM8300 Waveform Monitors Service Manual *P077039300* 077-0393-00...

- Page 3 WFM8200 and WFM8300 Waveform Monitors Service Manual Warning The servicing instructions are for use by qualified personnel only. To avoid personal injury, do not perform any servicing unless you are qualified to do so. Refer to all safety summaries prior to performing service.

- Page 4 Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are protected by national copyright laws and international treaty provisions. Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously published material.

- Page 5 Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

-

Page 7: Table Of Contents

Audio Options AD and DPE ................Option EYE/PHY.................... Fan Control ....................Power Supply and Distribution................Adjustment Procedures Adjustments ....................... Required Equipment..................Procedures ....................Maintenance General Maintenance..................... Preventing ESD ....................Inspection and Cleaning..................Troubleshooting....................WFM8200 and WFM8300 Waveform Monitors Service Manual... - Page 8 Preparation....................4-23 Module Removal................... 4-25 Repackaging Instructions ..................4-32 Packaging ....................4-32 Shipping to the Service Center ................4-32 Replaceable Parts Replaceable Parts ....................Parts Ordering Information ................. Using the Replaceable Parts Lists................WFM8200 and WFM8300 Waveform Monitors Service Manual...

- Page 9 Figure 4-7: Front panel board removal............... 4-30 Figure 5-1: Circuit boards and connectors..............Figure 5-2: Chassis components ................Figure 5-3: Main board replaceable components ............. Figure 5-4: Analog audio breakout cable assembly ............5-10 WFM8200 and WFM8300 Waveform Monitors Service Manual...

- Page 10 Table 5-1: Circuit boards and connectors (See Figure 5-1.) ..........Table 5-2: Chassis components (See Figure 5-2.) ............Table 5-3: Replaceable parts list (See Figure 5-3.) ............Table 5-4: Replaceable parts list (See Figure 5-4.) ............5-10 Table 5-5: Accessories ..................5-11 WFM8200 and WFM8300 Waveform Monitors Service Manual...

-

Page 11: General Safety Summary

Do not operate in an explosive atmosphere. Keep product surfaces clean and dry. Provide proper ventilation. Refer to the manual’s installation instructions for details on installing the product so it has proper ventilation. WFM8200 and WFM8300 Waveform Monitors Service Manual... - Page 12 DANGER indicates an injury hazard immediately accessible as you read the marking. WARNING indicates an injury hazard not immediately accessible as you read the marking. CAUTION indicates a hazard to property including the product. The following symbol(s) may appear on the product: WFM8200 and WFM8300 Waveform Monitors Service Manual...

-

Page 13: Service Safety Summary

Use Care When Servicing With Power On. Dangerous voltages or currents may exist in this product. Disconnect power, remove battery (if applicable), and disconnect test leads before removing protective panels, soldering, or replacing components. To avoid electric shock, do not touch exposed connections. WFM8200 and WFM8300 Waveform Monitors Service Manual... - Page 14 Service Safety Summary viii WFM8200 and WFM8300 Waveform Monitors Service Manual...

-

Page 15: Preface

Preface This manual supports servicing to the module level of the WFM8200 and WFM8300 Waveform Monitors, which process video signals for display on an internal XGA LCD. The instrument finds use as a monitor for broadcasting, production, and post-production environments. - Page 16 Procedure for checking performance and Product Documentation CD Monitor Specifications and Performance list of specifications www.tektronix.com/manuals Verification WFM and WVR Series Management Programmers command reference for Product Documentation CD Information DataBase (MIB) controlling the waveform monitor www.tektronix.com/manuals WFM8200 and WFM8300 Waveform Monitors Service Manual...

-

Page 17: Introduction

Introduction... -

Page 19: Service Strategy

The Performance Verification procedures for this product are found in the WFM8200 and WFM8300 Waveform Monitors Specifications and Performance Verification Technical Reference located on the Product Documentation CD that ships with the product and is published on the Tektronix Web site. (See page ix, Related Manuals.) Options and Accessories... -

Page 20: Hardware Installation

Product Upgrade Hardware and software upgrades are available for all products, either as a field upgrade kit or as a free software download from the Tektronix Web site. The WFM8200 and WFM8300 Waveform Monitors User Manual includes instructions for updating product software. -

Page 21: Theory Of Operation

Theory of Operation... - Page 23 Theory of Operation The WFM8200 and WFM8300 are modular waveform monitors. They can be configured, with options, to accept Analog Composite inputs. Audio options can add inputs for digital only or analog audio capability. All models use an internal DVI-I monitor for the display, and have an output to drive an external monitor with the same display.

-

Page 24: Figure 2-1: Main Block Diagram

Theory of Operation Power Distribution is not shown in the block diagram but is covered at the end of this section. Figure 2-1: Main block diagram 2–2 WFM8200 and WFM8300 Waveform Monitors Service Manual... -

Page 25: Main Board

XGA DAC to drive the external monitor. Note that the parallel data from the serial digital inputs connect directly to this FPGA to provide the picture functionality, bypassing the waveform processing engine. WFM8200 and WFM8300 Waveform Monitors Service Manual 2–3... -

Page 26: Front Panel

AES/EBU Digital Audio support (8 channels at a time). This option is available for all models. Option DPE adds Option AD capabilities plus support for decoding and monitoring Dolby E and Dolby D Audio. This option is available for all models. 2–4 WFM8200 and WFM8300 Waveform Monitors Service Manual... -

Page 27: Option Eye/Phy

Dolby audio channels may be output if Option DPE is installed. Option EYE/PHY Option EYE and Option PHY provide the following features: Eye pattern display Equalized Eye pattern display Jitter readout Jitter Meter Cable Loss readout Test Signal Output Approx Cable readout WFM8200 and WFM8300 Waveform Monitors Service Manual 2–5... - Page 28 These measurements are read by the CPU on the Main board, which calculates Cable Loss, Approximate Cable Length, and Source Level for display in the SDI Status screen. 2–6 WFM8200 and WFM8300 Waveform Monitors Service Manual...

-

Page 29: Figure 2-2: Option Eye/Phy Block Diagram

Theory of Operation Figure 2-2: Option EYE/PHY block diagram WFM8200 and WFM8300 Waveform Monitors Service Manual 2–7... -

Page 30: Fan Control

Fuses on the Primary supply 5 V output protect the main board. The secondary supplies and their tolerances are specified in the troubleshooting section. The location of the supply test points is shown in the Maintenance section. 2–8 WFM8200 and WFM8300 Waveform Monitors Service Manual... -

Page 31: Adjustment Procedures

Adjustment Procedures... -

Page 33: Adjustments

Verification procedure. For more details refer to Specifications and Performance Verification. Procedures NOTE. If you do not see the calibration case you are looking for, make sure to go to the next page using the up or down arrow key. WFM8200 and WFM8300 Waveform Monitors Service Manual 3–1... - Page 34 2. Press the CONFIG button, and then select Utilities > Calibration. Press SEL to enter the calibration menu. 3. Use the up and down arrow buttons to navigate to the appropriate Eye Gain Adjust selection, and press SEL to start the calibration. 3–2 WFM8200 and WFM8300 Waveform Monitors Service Manual...

- Page 35 2. Connect an XGA to 5x BNC adapter cable to the PixMon output. 3. Connect the Y/Green video signal to the oscilloscope input. (Use an oscilloscope with a 75 Ω input, or a 75 Ω feed through termination.) WFM8200 and WFM8300 Waveform Monitors Service Manual 3–3...

- Page 36 9. Use the General knob to adjust the signal zero level to 0 V on the oscilloscope. 10. Follow the instructions at the bottom of the calibration screen to Save and Exit Calibration mode. 3–4 WFM8200 and WFM8300 Waveform Monitors Service Manual...

- Page 37 6. Follow the on-screen instructions to adjust the response. 7. Follow the instructions at the bottom of the screen to Save and Exit calibration mode. 8. Repeat the Composite Analog Frequency Response test in the Performance Verification procedure. WFM8200 and WFM8300 Waveform Monitors Service Manual 3–5...

- Page 38 7. Check for an indication of 18 dBu in the newly adjusted audio bar. 8. If multiple inputs require adjustment, repeat this procedure for each input. 9. After all adjustments are made, you should perform a complete performance verification procedure. 3–6 WFM8200 and WFM8300 Waveform Monitors Service Manual...

-

Page 39: Maintenance

Maintenance... -

Page 41: General Maintenance

4. Nothing capable of generating or holding a static charge should be allowed on the work station surface. 5. Handle circuit boards by the edges when possible. WFM8200 and WFM8300 Waveform Monitors Service Manual 4–1... -

Page 42: Inspection And Cleaning

Use a glass cleaner to clean the LCD. For the rest of the instrument, use a 75% isopropyl alcohol solution as a cleaner and rinse with deionized water. Before using any other type of cleaner, consult your Tektronix Service Center or representative. -

Page 43: Table 4-1: External Inspection Checklist

Loose, broken, or corroded Remove and replace solder connections. damaged circuit board. Burned circuit boards. Burned, broken, or cracked circuit-run plating. Resistors Burned, cracked, broken, Remove and replace blistered condition. damaged circuit board. WFM8200 and WFM8300 Waveform Monitors Service Manual 4–3... - Page 44 5. Spray wash dirty parts with the isopropyl alcohol and wait 60 seconds for the majority of the alcohol to evaporate. 6. Dry all parts with low-pressure, deionized air. Lubrication. There is no periodic lubrication required for the instrument. 4–4 WFM8200 and WFM8300 Waveform Monitors Service Manual...

-

Page 45: Troubleshooting

Unknown Problem section in the Symptoms and Causes table. The WFM8200 and WFM8300 Waveform Monitors are highly configurable and behavior is sometimes complex. Before troubleshooting in-depth, verify that: The installed options are as expected. -

Page 46: Table 4-3: Required Test Equipment

48 kHz, 24 bit word length signals Rohde & Schwarz UPV, Tektronix AM700 option installed) and AM70. Analog Audio Signal Generator (If any Rohde & Schwarz UPV, Tektronix AM700 audio option installed) and AM70. 4–6 WFM8200 and WFM8300 Waveform Monitors Service Manual... -

Page 47: Table 4-4: Symptoms And Causes

Perform primary power supply checks Perform secondary power supply checks Composite DAC Comm: Run Advanced Diagnostics and look for other information Composite SPI Comm: Replace the Composite board Front Panel Version Information WFM8200 and WFM8300 Waveform Monitors Service Manual 4–7... - Page 48 Search for an intermittent problem in the audio board, cables, or main board. Fail AUDIO_DSP_HEARTBEAT No text or traces on LCD Perform LCD troubleshooting test Traces on LCD but not on Ext Replace Main board Display output 4–8 WFM8200 and WFM8300 Waveform Monitors Service Manual...

- Page 49 The Audio board can place too much of a load on the supplies if they are marginal. If the performance changes with the audio board removed, then you should perform the primary and secondary power supply checks and look for an excess load on one of the supplies. WFM8200 and WFM8300 Waveform Monitors Service Manual 4–9...

-

Page 50: Detailed Troubleshooting Procedures

3.3 V square wave on the tachometer feedback line. Replace the affected fan if resistors are intact but there is no signal on the tachometer line. 4–10 WFM8200 and WFM8300 Waveform Monitors Service Manual... - Page 51 If the input voltage is in the correct range, then disconnect the cable at J22 from the main board and recheck the output voltage. If the voltage is still not correct then replace the power supply. WFM8200 and WFM8300 Waveform Monitors Service Manual 4–11...

-

Page 52: Table 4-5: Main Board Secondary Supplies

Check the Audio supplies on the Audio board (if an Audio board is installed). (See Table 4-6 on page 4-13.). The test points are available with the board installed. (See Figure 4-2 on page 4-21.). 4–12 WFM8200 and WFM8300 Waveform Monitors Service Manual... -

Page 53: Table 4-6: Audio Main Board Secondary Supplies

2. If the buttons are not lit, check the 10 pin cable from the keypad to the main board J21. If the cable is connected and good then replace the front panel assembly. WFM8200 and WFM8300 Waveform Monitors Service Manual 4–13... - Page 54 Checks the serial EEPROM to see which of the analog inputs have been calibrated Tests the Audio DSP/FPGA interface The main CPU detects if the DSP heartbeat fails. This condition will be shown in the diagnostic log 4–14 WFM8200 and WFM8300 Waveform Monitors Service Manual...

- Page 55 Probe pin D19 of J641 on the audio board during the boot sequence. If the signal does not exhibit a low-to-high transition replace the audio board. e. If all signals in a through d are correct replace the audio board. WFM8200 and WFM8300 Waveform Monitors Service Manual 4–15...

- Page 56 Probe pin B21 on audio board connector J641 during the boot sequence. If the signal does not toggle, replace the audio board; otherwise, replace the main board. If all of these steps pass, replace the audio board. 4–16 WFM8200 and WFM8300 Waveform Monitors Service Manual...

- Page 57 Diagnostic Log Each power on is indicated by a boot time stamp, followed by a list of power on tests. If any failures are indicted then refer to the action as noted above. WFM8200 and WFM8300 Waveform Monitors Service Manual 4–17...

- Page 58 Check that the ribbon cable from the Eye board to the main board is securely plugged into J5 on the eye board and J16 on the main board. 4–18 WFM8200 and WFM8300 Waveform Monitors Service Manual...

- Page 59 Operation is unlikely to fail if the basic Eye pattern display works correctly. It is normal for these measurements to stop or become intermittent if there is excessive waveform noise, aberrations, jitter, or cable loss. WFM8200 and WFM8300 Waveform Monitors Service Manual 4–19...

-

Page 60: Figure 4-1: Main Board Power Supply Test Points And Leds

General Maintenance Figure 4-1: Main board power supply test points and LEDs 4–20 WFM8200 and WFM8300 Waveform Monitors Service Manual... -

Page 61: Figure 4-2: Audio Main Board Power Supply Test Point Locations

General Maintenance Figure 4-2: Audio Main board power supply test point locations WFM8200 and WFM8300 Waveform Monitors Service Manual 4–21... -

Page 62: Figure 4-3: Analog Audio Board Power Supply Test Point Locations

General Maintenance Figure 4-3: Analog audio board power supply test point locations 4–22 WFM8200 and WFM8300 Waveform Monitors Service Manual... -

Page 63: Removal And Replacement Procedures

Equipment Required. Most modules in the instrument can be removed with a screwdriver handle mounted with a size T-10, Torx screwdriver tip. All equipment WFM8200 and WFM8300 Waveform Monitors Service Manual 4–23... -

Page 64: Table 4-8: Tools Required For Module Removal

Special BNC socket wrench with Controlled Torque. Used to remove Audio board BNCs Soldering iron (15 W) Used for replacing Main board Standard tool fuses Long nose pliers Used to compress connector lock Standard tool tabs 4–24 WFM8200 and WFM8300 Waveform Monitors Service Manual... -

Page 65: Module Removal

1. Remove the two T-10 screws securing each board support, and then lift them from the chassis. 2. When reinstalling the board supports, make sure that the module circuit boards line up with the slots in the board supports. WFM8200 and WFM8300 Waveform Monitors Service Manual 4–25... -

Page 66: Figure 4-4: Module Securing Screws

1. Remove the three T-15 screws securing the module to the rear panel. 2. Lift the module out of the instrument, rocking it gently until the connector separates from J16 on the Main board. It may help to loosen the adjacent rear panel screws. 4–26 WFM8200 and WFM8300 Waveform Monitors Service Manual... - Page 67 2. Disconnect the green/yellow ground wire from the chassis, using a inch nutdriver. (See Figure 5-1 on page 5-5.) 3. Disconnect the 10-pin cable from J14 on the Main board. 4. Disconnect the two wire cable from J22 on the Main board. WFM8200 and WFM8300 Waveform Monitors Service Manual 4–27...

- Page 68 USB connectors, until they clear the LCD bracket. 3. Disconnect the cables connecting the Front panel/LCD assembly to the Main board at J27, J31, and J21. (See Figure 4-5 on page 4-29.) 4–28 WFM8200 and WFM8300 Waveform Monitors Service Manual...

-

Page 69: Figure 4-5: Front Panel And Fan Cable Connections

6. Tilt the bottom of the display bracket up and slide the display brackets out from underneath the bezel clips, leading the front panel cable through the cutout in the bracket. WFM8200 and WFM8300 Waveform Monitors Service Manual 4–29... -

Page 70: Figure 4-6: Front Panel Disassembly

4. Lift the front panel board away from the bezel. Figure 4-7: Front panel board removal 4–30 WFM8200 and WFM8300 Waveform Monitors Service Manual... - Page 71 5. Grasp the main board from the front of the instrument, tilt it up slightly, and then pull it toward you, clearing the rear panel BNCs and connectors and removing the main board from the chassis. WFM8200 and WFM8300 Waveform Monitors Service Manual 4–31...

-

Page 72: Repackaging Instructions

Type and serial number of the instrument. Reason for returning. A complete description of the service required. Mark the address of the Tektronix Service Center and the return address on the shipping carton in two prominent locations. 4–32 WFM8200 and WFM8300 Waveform Monitors Service Manual... -

Page 73: Replaceable Parts

Replaceable Parts... -

Page 75: Parts Ordering Information

For more information about the module exchange program, call 1-800-833-9200. Outside North America, contact a Tektronix sales office or distributor; see the Tektronix Web site for a list of offices: www.tektronix.com. Module Repair and Return. You may ship your module to us for repair, after which we will return it to you. -

Page 76: Using The Replaceable Parts Lists

Items in this section are referenced by figure and index numbers to the illustrations that follow. number Orderable modules show the figure number without an index number. Tektronix part Use this part number when ordering replacement parts from Tektronix. number 3 and 4 Serial number Column three indicates the serial number at which the part was first effective. -

Page 77: Table 5-1: Circuit Boards And Connectors (See Figure 5-1.)

SCREW,MACHINE; 6-32 X 0.250,PNH,STL,CDPL,T-15 TORX DR 131-7721-00 CONN,JACK; PCB/PNL,RJ45,CAT5E,W/LEDS YELLOW & GREEN/ORANGE,FEMALE,RTANG,8 POS,0.100 CTR,0.517 H X 0.13 TAIL,10/100/1000 BASE TX AND RX MAGNETICS MODULE, 30 GOLD, SAFETY CONTROLLED 131-8089-00 CONN, DVI-I, FEMALE, RTANG, PANEL MOUNT WFM8200 and WFM8300 Waveform Monitors Service Manual 5–3... - Page 78 TAIL, 30 GOLD, 4-40 THD INSERTS, BOARD RETENTION, HIGH DENSITY CONN 174-5653-00 CABLE ASSEMBLY; POWER SUPPLY, HIGH CURRENT 131-6521-00 CONTACT,ELEC; EMI,CLIP-ON,0.38 L X 0.500 W (2 CONTACTS) X 0.45 H,ELECTROLESS NICKEL PLATE Quantity will vary depending on instrument model and installed options. 5–4 WFM8200 and WFM8300 Waveform Monitors Service Manual...

-

Page 79: Figure 5-1: Circuit Boards And Connectors

Replaceable Parts Figure 5-1: Circuit boards and connectors WFM8200 and WFM8300 Waveform Monitors Service Manual 5–5... -

Page 80: Table 5-2: Chassis Components (See Figure 5-2.)

IN, 3 LEAD WITH CONN, UL, CSA, VDE, SAFETY CONTROLLED 407-5372-00 BRACKET; FAN MOUNTING, SAFETY CONTROLLED 211-1050-00 SCREW,MACHINE; 6-32 X 0.312 L,PNH,STL CAD PLT,T15 850-0124-00 FINAL ASSEMBLY; LCD DISPLAY MODULE; TESTED 214-5152-00 SPRING,CLIP; EMI 5–6 WFM8200 and WFM8300 Waveform Monitors Service Manual... -

Page 81: Figure 5-2: Chassis Components

Replaceable Parts Figure 5-2: Chassis components WFM8200 and WFM8300 Waveform Monitors Service Manual 5–7... -

Page 82: Table 5-3: Replaceable Parts List (See Figure 5-3.)

FUSE; 2.0A,125V,FAST BLOW,0.1 X 0.1 X 0.24,UL REG,CSA CERT,SAFETY CONTROLLED 260-5015-00 SWITCH,DIP; SPST,SLIDE,DIP,4 POSITION,GOLD OVER NICKEL,0.4VA @ 20VDC,0.05 HALF PITCH;TD04H0SK1,SMD 146-0109-00 BATTERY,DRY; 3.0V,LITHIUM MANGANESE DIOXIDE,210MAH,20 X 3.22MM COIN CELL WITH SOLDER TABS,CR2032-1HF1 131-7107-00 CONN, HDR; SMD,MALE,RTANG,1 X 10,0.049 CTR 5–8 WFM8200 and WFM8300 Waveform Monitors Service Manual... -

Page 83: Figure 5-3: Main Board Replaceable Components

Replaceable Parts Figure 5-3: Main board replaceable components WFM8200 and WFM8300 Waveform Monitors Service Manual 5–9... -

Page 84: Figure 5-4: Analog Audio Breakout Cable Assembly

ANALOG AUDIO BREAKOUT CABLE Note: Optional Accessory 012-1688-00 CABLE ASSEMBLY; ANALOG/AUDIO BREAKOUT 200-4804-00 COVER; SHIELD,ELEC CONN,37 POS DSUB,ZINC 131-0422-00 CONN,DSUB; SLDR CUP/PNL,;MALE,STR,37 POS,0.112 CTR,0.186 H X 0.126 TAIL,0.125 DIA THRU MTG Figure 5-4: Analog audio breakout cable assembly 5–10 WFM8200 and WFM8300 Waveform Monitors Service Manual... -

Page 85: Table 5-5: Accessories

CHINA 161-0304-00 Optional Accessories WFM7F02 CABINET; PORTABLE CABINET WITH HANDLE,FEET,TILT BAIL AND FRONT PANEL COVER 200-4716-00 COVER,FRONT; PROTECTIVE,PC/ABS FR110,TV GRAY WFM7F05 RACK ADAPTER; DUAL SIDE BY SIDE 012-1688-00 CABLE ASSEMBLY; ANALOG/AUDIO BREAKOUT WFM8200 and WFM8300 Waveform Monitors Service Manual 5–11...

Need help?

Do you have a question about the WFM8200 and is the answer not in the manual?

Questions and answers