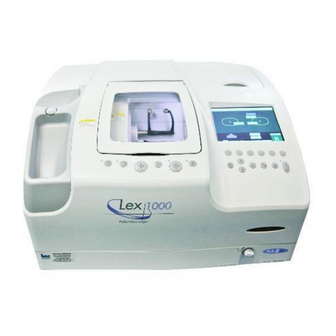

Summary of Contents for Nidek Medical LEX-1000

- Page 1 Installation-Adjustment Manual Rev. 11-18- 08...

- Page 3 LEX 1000 Unpacking, Installation, Calibrations and Adjustments Unpacking Opening Carton. Inspecting Unit & Accessories. Bench Preparation. (See Diagram) Installation Unit Placement and Packing Material Removal. Tank & Pump Hook Up. Power Up, Software Verification, Upgrade procedure. Inspection of Water Flow. III.

- Page 4 Tank & Pump Hook Up • Connect the Tank & Pump to the Main Body (see Diagram below) • Screw Drain Hose into bottom Feed Hoses of edger receiver grey quick • Connect front hose to Pump 1 disconnect • Connect rear hose to Pump 2 button •...

- Page 5 4. Press and hold the Stop button while turning on the power switch. The LEX-1000 starts the initialization and the USB stick check. 5. After checking the USB memory stick, the LEX-1000 LCD screen displays the software versions that are found on the USB memory stick. Following the instructions on the screen, you can scroll to select the desired version and press [Enter].

- Page 6 LEX-1000 Adjustment Manual 11/18/2008 Santinelli International Franco Aluigi 1.Before starting adjustment. 1.1 Confirming wheel configuration Before starting adjustment, please check the wheel configuration. ① ② ③ ④ ⑤ ① ② ③ ④ ⑤ PLB-G 13 + 12 + 17.5 + 17.5 + 17 = 77 PL-8 13 + 17 + 17.5 + 12 + 17 = 76.5...

- Page 7 1.2 Checking chuck pressure Adjustment Parameter: ( STOP ) , Press and hold then press to go to Parameter screen. Select Parameter setting, then press . Scroll page to Parameter setting (9/12 page) Chuck pressure (CR39/HPL) : Chuck pressure (PC/ACR/TRX/PUR) : Chuck pressure (GLS)...

- Page 8 2.1 Calibration Calibration Procedure (STOP), Press and hold then press to go to Parameter screen. Select Calibration, then press . The Calibration screen appears. Remove cup holder, then install the calibration JIG. Bring the cursor to the calibration that you would like to do, then press to start SFB calibration Calibration for SFB unit.

- Page 9 2.2 Finish Size and Bevel Position Adjustment Here, in this adjustment we cut internal 45 circle and check finish size and bevel position. For adjusting the finish size of CR39 plastic lens, -2D to -4D is recommended to be used. Finish Size adjustment Adjustment Parameter : (...

- Page 10 : 0.00mm GLS, Flt : 0.00mm GLS, HCrv Call up internal 45 circle and grind lens in Bevel and Flat mode. Measure the diameter of the lens (always at 180º line). The tolerance for bevel is 45.00±0.05mm. The tolerance for flat is 45.00±0.10mm. Please adjust the size if it is out of tolerance.

- Page 11 2.3 AXIS Adjustment Here, in this adjustment we cut internal 45 square and check axis. For adjusting Axis of CR39 plastic lens, -3D to –5D lens is recommended to be used. Adjustment parameter : ( STOP ) , Press and hold then press to go to Parameter screen.

- Page 12 Horizontal line – 2.4 Feeler AXIS Adjustment Adjustment Parameter: ( STOP ) , Press and hold then press to go to Parameter screen. Select Parameter setting, then press . Scroll the page to AXIS Adjustment (Page 6/12) : 0.00 Front feeler :...

- Page 13 If tilted in CW direction, please increase the value. If tilted in CCW direction, please decrease the value. See the picture below (this is viewed from the rear). – Cutting internal 45 square to check feeler axis Please call up internal 45 square. Bring the Size up to +3.00.

- Page 14 2.5 Polish Adjustment Polish Differential, Polish AXIS, Bevel Position (Pol) Adjustment Parameter : ( STOP ) , Press and hold then press to go to Parameter screen. Select Parameter setting, then press .Scroll the page to Polish Differential (Page 5/12) :0.00mm CR39, Bvl :0.00mm...

- Page 15 Polish Size Adjustment Adjustment Paremeter : ( STOP ) , Press and hold then press to go to Parameter screen. Select Parameter setting, then press .Scroll the page to Polish Size (Page 4/12) :0.00mm CR39, Bvl :0.00mm CR39, Flt :0.00mm HPL, Bvl :0.00mm HPL, Flt...

- Page 16 2.6 Groove Adjustment Groove Depth Adjustment Parameter : ( STOP ) , Press and hold then press to go to Parameter screen. Select Parameter setting, then press .Scroll the page to Parameter setting (Page 9/12) : 0.00mm Groove Depth Call up internal 45 circle. Use a CR39, -3D to -5D lens then grind lens in Nylor Guide (Depth 0.0) mode.

- Page 17 Groove AXIS Adjustment Parameter : ( STOP ) , Press and hold then press to go to Parameter screen. Select Parameter setting, then press . Scroll the page to Axis Adjustment (Page 6/12) : 0.00 CR39/HPL, Grv : 0.00 PC/ACR/TRX/PUR, Grv Call up internal 45 square.

- Page 18 2.7 Safety Bevel Adjustment Before starting Safety Bevel Adjustment please set the parameters as shown below. :0.3mm Front SFB size (Bevel) :0.3mm Rear SFB size (Bevel) :0.3mm Rear SFB size (Flat) :0.3mm Rear SFB size (Flat) Also set the SFB mode (Bevel) to F & L :F &...

- Page 19 Call up internal 45 circle. Use a CR39, -3D to -5D lens then grind it in Nylor Flat with SFB mode. Check amount of safety bevel on both the front and the rear side. The tolerance is +/- 0.2mm. If the amount needs to be increased, please increase the value. If it needs to be decreased, please decrease the value.

- Page 20 Safety Bevel AXIS (Flat) Adjustment Parameter : (STOP), then press Press and hold to go to Parameter screen. Select Parameter setting, then press Scroll the page to SFB (Page 8/12) :0.00 Axis Adjustment (Flt, Re) :0.00 Axis Adjustment (Fltl, Fr) Call up internal 45 square.

- Page 21 2.8 High Curve Grinding For high curve grinding adjustment you do not have to use high base curve lenses. You can use plano (2.2mm) 6-base lenses or –2D ~ –3D, spherical 4-base lenses. However, after you finish all adjustments, please cut some high base curve lenses to check lens fitting into a frame and how the bevel comes out.

- Page 22 Wheel position (HCrvRe) Adjustment Parameter : ( STOP ) , Press and hold then press to go to Parameter screen. Select Parameter setting, then press . Scroll the page to Parameter setting (Page 11/12) :0.00mm Wheel position (HcrvRe) Call up internal 45 round. Press START. After LMU measures, in Bevel Simulation Screen, change “TILT”...

- Page 23 Call up internal 45 circle, then grind lens in metal Hi-curve mode. Check the size and adjust it. Bevel height (HCrv) Adjustment Parameter: ( STOP ) , Press and hold then press to go to Parameter screen. Select Parameter setting, then press .

- Page 24 AXIS adjustment (HCrvFr and HcrvRe) Adjustment Parameter : ( STOP ) , Press and hold then press to go to Parameter screen. Select Parameter setting, then press . Scroll the page to Parameter setting (Page 11/12) :0.00 AXIS adjustment (HCrvFr) :0.00 AXIS adjustment (HcrvRe) Call up internal 45 square.

- Page 25 Notes...

- Page 26 Notes...

- Page 27 Notes...

- Page 28 325 Oser Avenue | Hauppauge, NY | 11788 www.Santinelli.com 800-644-3343 631-435-9200 November 2008...

Need help?

Do you have a question about the LEX-1000 and is the answer not in the manual?

Questions and answers