Advertisement

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 999019 / 22/12/2009

page 1 of 29

Technology for Vacuum Systems

Instructions for use

RP 12C

RP 15C VARIO

RP 22C VARIO

RP 35C VARIO

Roots pumping units

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for vacuubrand RP 15C VARIO

- Page 1 1 of 29 Technology for Vacuum Systems Instructions for use RP 12C RP 15C VARIO RP 22C VARIO RP 35C VARIO Roots pumping units Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check...

- Page 2 2 of 29 Dear customer, Your VACUUBRAND diaphragm pumps should support you for a long time without trouble and with maximal power. Thanks to our long practical experience we have much information how you could ensure powerful application and personal safety. Please read these instructions for use before the initial operation of your pump.

-

Page 3: Table Of Contents

page 3 of 29 Contents Safety information! ....................4 Technical data ......................9 Use and operation ....................12 Troubleshooting ...................... 14 Oil change ........................16 Replacing diaphragms and valves ................ 17 Notes on return to the factory ................26 Health and safety clearance form ................27 Documents are only to be used and distributed completely and unchanged. -

Page 4: Safety Information

page 4 of 29 Safety information! Remove all packing material, remove the product from its packing-box, remove protec- tive covers from inlet and outlet ports and keep them. Inspect the equipment. If the equipment is damaged, notify the supplier and the carrier in writing within three days;... - Page 5 page 5 of 29 Comply with all relevant safety requirements (regulations and guidelines) and adopt suitable safety measures. The mains on/off switch is located sidewise at the terminal box. The pumps cannot be hooked up separately. ☞ If the equipment is brought from cold environment into a room for operation, allow the equipment to warm up (pay attention to water condensation on cold surfaces).

- Page 6 page 6 of 29 The pumps are not suitable for pumping substances which may form deposits inside the pump. ☞ If there is a danger of the formation of deposits in the pump chamber (check inlet and outlet of the pump) inspect the pump chamber regularly and clean if necessary. The pumps are not suitable to pump unstable substances and substances which react explosively under impact (mechanical stress) and/or when being exposed to elevated temperatures without air.

- Page 7 page 7 of 29 ☞ If the diaphragm pump is shut down, the Roots pump is not shut down automati- cally. However, the variable speed drive of the Roots pumps of the pumping units RP 15C/22C/35C VARIO reduces the speed of the Roots pump following a limiting current regulation, if necessary to standstill of the Roots pump.

- Page 8 page 8 of 29 The A-weighed emission sound pressure level of the pump does not exceed 70 dB(A). Measurement according to EN ISO 2151:2004 and EN ISO 3744:1995 with standard silencer or exhaust tube at outlet. Ensure that maintenance is done only by suitable trained and supervised techni- cians.

-

Page 9: Technical Data

page 9 of 29 Technical data i t l i t l a l l ° v i t y t i l i o l i o l l a * The pump achieves its ultimate pumping speed and ultimate total pressure only at operating termperature (after approx. - Page 10 page 10 of 29 t t i o l l , s l We reserve the right for modifications without prior notice! Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully the validity of this document with respect to his product.

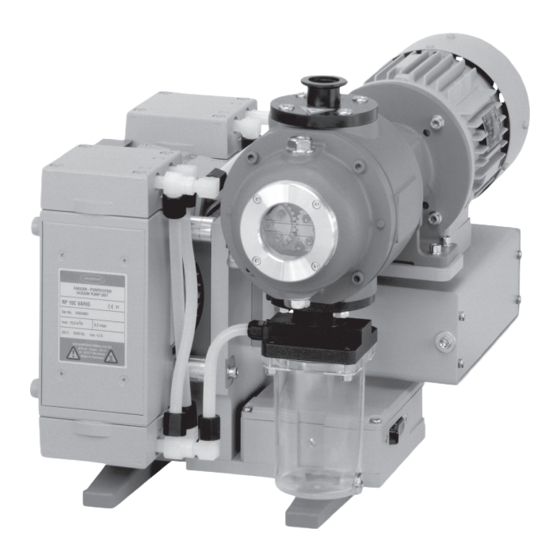

- Page 11 RP 12C with MBS 030 RP 15C VARIO with MBS 030 and frequency converter rating plate pumping unit condensate drain plug mains switch RP 22C/35C VARIO inlet: small flange NW 25 (fig.

-

Page 12: Use And Operation

page 12 of 29 Use and operation Installation in a vacuum system ☞ Avoid throttling losses by using connecting pipes with large diameter and keep them as short as possible. ☞ Reduce the transmission of vibration and prevent loading due to rigid pipelines. Insert elastic hoses or flexible elements as couplings between the pump and rigid pipes. - Page 13 page 13 of 29 ☞ The frequency is reduced at high inlet pressures (especially at atmospheric pres- sure) in order to avoid thermal overload of the roots pump. ☞ Under normal conditions, the maximum pump speed is reached only at inlet pres- sures <...

-

Page 14: Troubleshooting

page 14 of 29 Troubleshooting s l i . y l u l i n i l n i l o l l y f i l i a c t i c t i c t i l l a o l l y f i l i a... - Page 15 page 15 of 29 v i t ? l i l l i l l a l l i ? l i t i s t i s l n i o l l l l i l l i l i o A service manual with exploded view drawings, spare part lists and directions for repair of the diaphragm pump only is available on request.

-

Page 16: Oil Change

page 16 of 29 Oil change Before starting maintenance, isolate the pump from the vacuum system and the elec- trical supply so that the pump cannot be operated accidentally. Has the pump been exposed to dangerous or corrosive gases? Take appropriate safety measures (e. g. safety-clothing and protective goggles) to avoid inhalation and skin contact. -

Page 17: Replacing Diaphragms And Valves

page 17 of 29 Replacing diaphragms and valves All bearings are encapsulated and are filled with long-life lubricant. Under normal opera- ting conditions, the pump is maintenance free. The valves and diaphragms as well as the motor capacitors are wear parts. If the rated ultimate vacuum is no longer achieved or in case of increased noise level, the pump interior, the diaphragms and the valves must be cleaned and the diaphragms and valves must be checked for cracks or other damage. - Page 18 18 of 29 RP 12C and RP 15C VARIO (with MD 4C) Set of seals (diaphragms and valves) for MD 4C ..............69 68 15 ☞ Please read the whole chapter ”Replacing diaphragms and valves” before starting maintenance. Partially the pictures show pumps in other versions. This doesn´t influence replacing diaphragms and valves of the pump.

- Page 19 page 19 of 29 View of the disassembled pump head parts diaphragm clamping disc with square head screw diaphragm support disc valve washer housing connecting rod diaphragm head cover housing cover with housing cover insert ☞ Check diaphragm for damage and replace if necessary. ➨...

- Page 20 Optimum torque for the diaphragm support disc: 6 Nm. ☞ The optimum torque is achieved if the pointer in the handle of the VACUUBRAND face wrench shows to the longer mark- ing line. Assembling pump heads ➨ By turning eccentric bushing (front of connecting rod), bring connecting rod into a position in which diaphragm is in con- tact with housing and centred with respect to bore.

- Page 21 page 21 of 29 Individual performance check of a pump head : By measuring the pressure at the inlet port of the individual head: Use a suitable vacuum gauge (e. g. DVR 2, cat. no.: 68 29 02), make sure that it is correctly calibrated, and measure the pres- sure at the inlet port.

- Page 22 page 22 of 29 RP 22C/35C VARIO (with MD 12C) Set of seals (diaphragms and valves) for MD 12C ..............69 68 21 ☞ Please read the whole chapter ”Replacing diaphragms and valves” before starting maintenance. Partially the pictures show pumps in other versions. This doesn´t influence replacing diaphragms and valves of the pump.

- Page 23 page 23 of 29 valve View of the disassembled pump head parts cover plate distributor cover countersunk head screw housing connecting rod washer diaphragm support disc diaphragm diaphragm clamping disc head cover valve housing cover with housing cover insert Replacing the diaphragm: ➨...

- Page 24 Optimum torque for the diaphragm support disc: 6 Nm. ☞ The optimum torque is achieved if the pointer in the handle of the VACUUBRAND face wrench shows to the longer mark- ing line. Assembling pump heads: ➨ By turning eccentric bushing (front of connecting rod), bring connecting rod into a position in which diaphragm is in con- tact with housing and centred with respect to bore.

- Page 25 page 25 of 29 Montage of the connecting hose: ➨ Use open ended wrench (w/f 15) to reconnect hose to elbow fitting. ➨ Tighten union nuts first by hand and then tighten one full turn using open ended wrench (w/f 17). ☞...

-

Page 26: Notes On Return To The Factory

page 26 of 29 Notes on return to the factory Repair - return - DKD calibration Safety and health of our staff, laws and regulations regarding the handling of danger- ous goods, occupational health and safety regulations and regulations regarding safe disposal of waste require that for all pumps and other products the “Health and safety clearance form“... -

Page 27: Health And Safety Clearance Form

Tel.: +49 9342 808-0 - Fax: +49 9342 808-450 -Technology for Vacuum Systems- E-Mail: info@vacuubrand.de © 2001 VACUUBRAND GMBH + CO KG Printed in Germany Web: www.vacuubrand.com Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check... - Page 28 Déclaration de conformité Pumpstand / Pumping unit / Groupe de pompage RP 12C (230V; 691035, 691036, 691037) RP 15C VARIO (230V; 691040, 691041, 691042) RP 22C VARIO (230; 691050, 691051, 691052) RP 35C VARIO (230V; 691060, 691061, 691062) Hiermit erklären wir, dass das oben bezeichnete Gerät in Konzeption und Bauart sowie in der von uns in Verkehr gebrachten Ausführung den grundlegenden Anforderungen der zutreffenden, aufgeführten EU-...

- Page 29 Tel.: +49 9342 808-0 - Fax: +49 9342 808-450 E-Mail: info@vacuubrand.de © 2009 VACUUBRAND GMBH + CO KG Printed in Germany Web: www.vacuubrand.com Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check...

Need help?

Do you have a question about the RP 15C VARIO and is the answer not in the manual?

Questions and answers