Summary of Contents for Kranzle W 11/135

- Page 1 High Pr High Pr essur essur e Cleaners e Cleaners High Pr High Pr essur High Pr essur essur e Cleaners e Cleaners e Cleaners W 11/135 W 13/230 W 15/200 W 19/160...

-

Page 2: Dear Customer

Description Dear Customer We would like to congratulate you on your new high pressure cleaner and to thank you for the purchase. To ease your introduction to the use of the cleaner, we have provided the follow- ing pages of explanations, tips and hints, which we ask you to read before using for the first time. -

Page 3: Preparation For Use

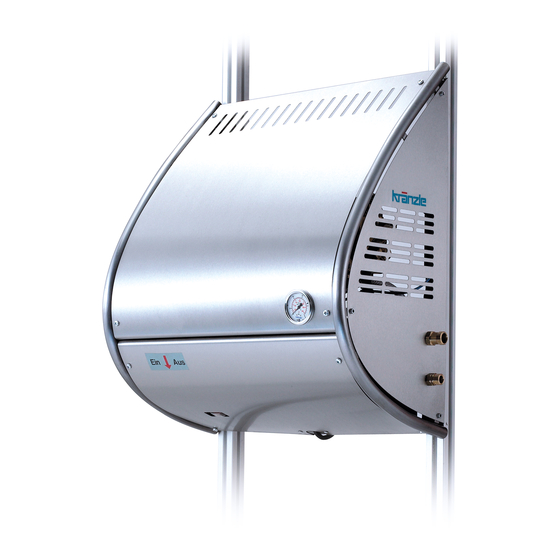

Preparation for use Stationary cold water high pressure cleaner: The stationary wall-mounted systems are supplied with a stainless steel housing. Equipped with an AQ pump, 10m steel fabric heavy duty hose, pressure fully ad- justable, automatic total-stop feature and adjustable after-running. 1-5 bar ad- vance pressure required (not self-intake). -

Page 4: Water And Cleaning System

The liquid is then pumped to the nozzle. The spray pressure increases and quickly reaches the selected operating pressure.(Not with W 11/135). When the trigger is released, the trigger gun closes and any further spraying of liquid from the lance is stopped and the manometer must show 0 bar. - Page 5 Description With delayed motor cut-out Frequent, work-necessitated switching on and off of motors on machines of this size puts a heavy load on the power network and causes increased wear on internal electrical parts. That’s why the motor on the new KRÄNZLE switches itself off 30 seconds after the trigger is released, and switches itself back on again when the trigger is pressed.

-

Page 6: Electrical Connection

Description Electrical connection The machine is supplied with an electrical power cord with plug. The mains plug must be fitted to a standard grounded socket with a 30mA residual current operated device. The socket must be protected with a 16A delay action fuse on the mains side. -

Page 7: High Pressure Hose And Spray Device

Description Brief operating instructions: 1. Connect the high pressure hose with spray gun and machine. 2. Connect to suitable water supply. 3. Flush the air from the pump (open and close the spray gun several times). 4. Make the electrical connection - (400 Volt three-phase current). 5. - Page 8 Safety notes As to the recoil - see no- tice on page 2! Apply the safety catch on the spray gun after each use, in order to prevent unintentional spraying! Always aim the underbody lance. Note when using an angled underbody lance, like for example lance No.

- Page 9 Operation Adjusting the pressure at the gun Simply turn the adjustment ring. (not with W 11/135). The machine is set to operate at maximum pressure.

- Page 10 This is prohibited ! Never allow children to use the high pressure cleaner ! Never direct the water jet at the machine itself ! Never direct the water jet at a power socket !

- Page 11 This is prohibited ! Never direct the water jet at people or animals ! Do not damage the power cord or repair it incorrectly ! Never pull the high pressure hose if it has formed kinks or “nooses”! Never pull the hose over sharp edges !

- Page 12 Valve housing...

- Page 13 Spare parts list...

- Page 14 Motor...

- Page 15 Spare parts list...

- Page 16 Drive unit AQ...

- Page 17 Spare parts list...

- Page 18 Power-Colt...

- Page 19 Spare parts list...

- Page 20 ULH 250...

- Page 21 Spare parts list Spare parts list Combi-valve ULH 250 Description Qty. Ord.-No Ventilkörper 14.145 Kolbenführung (ULH) 14.130 Steuerkolben (ULH) M 8 x 1 14.133 Eingangsstück R 3/8" IG 13.136 Ausgangsstück R 1/4" IG 14.136 Ausgangsstück R 3/8" IG 14.115 Ausgangsstück R 3/8" AG 14.137 Ausgangsstück ST30 M 22 x 1,5 14.117...

- Page 22 Control unit...

- Page 23 Spare parts list Spare parts list Control unit Description Qty. Ord.-No Kabelverschraubung PG 9 41.430 Kabelverschraubung PG 16 41.431 Schütz 400 V 41.432 Schütz 230 V 41.432 1 Motorschütz 10-16 A 400 V 13.433 Motorschütz 16-24 A 230 V 41.433 1 Lampe rot kpl.

- Page 24 Hose screw connection...

- Page 25 Spare parts list Spare parts list Hose screw connection Description Qty. Ord.-No Abstandsrohr 1/4" AG x 1/4" AG 41.039 Winkel 1/4" IG x 1/4" IG 41.445 Doppelnippel 1/4" AG x M 18 x 1,5 AG 41.446 By-Pass-Schlauch 41.447 Doppelnippel 3/8" AG x M 18 x 1,5 AG 13.288 Verschraubung 3/8"...

- Page 26 Standard Vario-Jet Nozzle Spare parts list Lance with Standard vario-jet nozzle Description Qty. Ord.-No Nippel ST30 M22x1,5 AG / M 12 x 1 13.363 Rohr 400 mm, bds. M 12 x 1 15.002 Regeldüse mit Regulierring 13.201 2 Flachstrahldüse Please specify nozzle size: D25045 with W 11 / 135 D25045 with W 13 / 230 D2505 with W 15 / 200...

- Page 27 Wiring diagram...

- Page 28 Wall mounting...

-

Page 29: General Rules

General rules Inspections The machine must be inspected according to the “Guidelines for Liquid Spray Devices” at least once every 12 months by a qualified person, to ensure that continued safe operation is guarateed. The results of the inspection are to be recorded in writing. This may be done in any form. -

Page 30: Inspection Report

Inspection report for KRÄNZLE - High Pressure Cleaners Regular inspection every 12 months if used professionally! Appliance No: Type: The following must be checked: 1. Safety features 2. General condition a) Manometer a) High pressure hose b) Cable, plug, switch b) Safety valve (pressure control) (VDE) c) Spray gun... - Page 31 Hochdruckreiniger High-pressure-cleaners Nettoyeurs à Haute Pression I. Kränzle GmbH Elpke 97 . 33605 Bielefeld EC declaration of conformity defined by machinery directive 89/392/EEC Annex II A the EC low-voltage directive 73/23 EEC and the EC-EWV directive 89/336 EEC Herewith we W 11 / 135, W 19 / 160, declare that W 15 / 200, W 13 / 230...

- Page 32 Reprint only allowed with the authorization of As of date of 13. 09. 1999...

Need help?

Do you have a question about the W 11/135 and is the answer not in the manual?

Questions and answers