Summary of Contents for Sel SEL-351S

- Page 1 SEL-351S Relay Relay, Meter, Control, Fault Locator Instruction Manual 20080103 *PM351S-01-NB*...

- Page 2 © 1999–2008 by Schweitzer Engineering Laboratories, Inc. All rights reserved. All brand or product names appearing in this document are the trademark or registered trademark of their respective holders. No SEL trademarks may be used without written permission. SEL products appearing in this document may be covered by US and Foreign patents.

-

Page 3: Table Of Contents

Front-Panel and Rear-Panel Connection Diagrams..................2.3 User-Configurable Label Option for the Front Panel ..................2.9 Making Rear-Panel Connections ........................2.14 SEL-351S AC/DC Connection Diagrams for Various Applications ............. 2.25 Circuit Board Connections ..........................2.40 Section 3: Overcurrent, Voltage, Synchronism Check, Frequency, and Power Elements Instantaneous/Definite-Time Overcurrent Elements .................. - Page 4 Section 9: Setting the Relay Introduction..............................9.1 Settings Changes via the Front Panel.......................9.3 Settings Changes via the Serial Port ........................9.4 Time-Overcurrent Curves ..........................9.5 Relay Word Bits (Used in SEL Control Equations)................9.27 OGIC Settings Explanations.............................9.48 Settings Sheets ...............................9.57 Section 10: Serial Port Communications and Commands Introduction..............................10.1...

- Page 5 Factory Assistance............................13.14 Appendix A: Firmware and Manual Versions Firmware................................. A.1 Instruction Manual............................A.6 Appendix B: SEL-300 Series Relays Firmware Upgrade Instructions Overview .................................B.1 Relay Firmware Upgrade Instructions......................B.1 Ethernet Port Firmware Upgrade Instructions....................B.18 Appendix C: SEL Distributed Port Switch Protocol Settings ................................C.2...

- Page 6 Operation ................................. I.3 Protocol for the Pulsar 9600 Baud Modem ................I.6 IRRORED Settings................................I.7 Appendix J: SEL-351S Fast SER Protocol Introduction..............................J.1 Make Sequential Events Recorder (SER) Settings With Care................. J.2 Recommended Message Usage ........................J.3 Functions and Function Codes......................... J.4...

-

Page 7: List Of Tables

SEL-351S Firmware Versions ....................1.3 Table 2.1 Options and Explanations for the User-Configurable Front-Panel Labels......2.13 Table 2.2 Communication Cables to Connect the SEL-351S to Other Devices ........2.24 Table 2.3 Output Contact Jumpers and Corresponding Output Contacts ..........2.45 Table 2.4 “Extra Alarm”... - Page 8 Serial Port Automatic Messages...................10.9 Table 10.5 Serial Port Command Summary ..................10.12 Table 10.6 SEL-351S Word and Its Correspondence to TAR Command..........10.35 Table 10.7 SEL-351S Control Subcommand ..................10.41 Table 10.8 Factory Default Passwords for Access Levels 1, B, and 2 ..........10.42 Table 10.9...

- Page 9 SEL-351S Global Settings for Synchrophasors ..............L.8 Table L.6 SEL-351S Serial Port Settings for Synchrophasors ...............L.8 Table L.7 Time Synchronization Relay Word Bits................L.11 Table L.8 SEL Fast Message Voltage and Current Selections Based on PHDATAV and PHDATAI...L.14 Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 10 This page intentionally left blank...

-

Page 11: List Of Figures

Horizontal Rack-Mount Example, (Connectorized, With Additional I/O Board)....2.8 Figure 2.7 SEL-351S (Horizontal) With User-Configurable Default Labels.......... 2.9 Figure 2.8 SEL-351S (Horizontal) Blank Slide-In Label Set and Label Removal Tool ....... 2.10 Figure 2.9 SEL-351S (Vertical) With User-Configurable Default Labels ..........2.11 Figure 2.10 SEL-351S (Vertical) Blank Slide-In Label Set and Label Removal Tool ...... - Page 12 SEL-351S Example Wiring Diagram Using the Auxiliary {TRIP}/{CLOSE} Pushbuttons for 0351Sxxx5/6/A/B Models ..............2.39 Figure 2.32 Jumper, Connector, and Major Component Locations on the SEL-351S Main Board ..2.41 Figure 2.33 Jumper, Connector, and Major Component Locations on the SEL-351SxY Extra I/O Board (Plug-In Connector Version) ................2.42 Figure 2.34...

- Page 13 POTT Logic.......................... 5.18 Figure 5.7 Permissive Input Logic Routing to Trip Logic..............5.19 Figure 5.8 SEL-351S Connections to Communications Equipment for a Two-Terminal Line POTT Scheme..........................5.20 Figure 5.9 SEL-351S Connections to Communications Equipment for a Three-Terminal Line POTT Scheme..........................5.20 Figure 5.10...

- Page 14 Figure 6.6 Reclose Supervision Limit Timer Operation (Refer to Bottom of Figure 6.5).......6.8 Figure 6.7 SEL-351S Relays Installed at Both Ends of a Transmission Line in a High-Speed Reclose Scheme ..........................6.11 Figure 6.8 Reclosing Relay States and General Operation ..............6.15 Figure 6.9...

- Page 15 Figure 8.1 Plotted Breaker Maintenance Points for a 25 kV Circuit Breaker ......... 8.3 Figure 8.2 SEL-351S Breaker Maintenance Curve for a 25 kV Circuit Breaker ........8.5 Figure 8.3 Operation of SEL Control Equation Breaker Monitor Initiation Setting ....... 8.6 OGIC Figure 8.4...

- Page 16 Correcting the Communications Parameters ................. B.6 Figure B.8 Preparing HyperTerminal for ID Command Display ............B.8 ................B.9 Figure B.9 List of Commands Available in SEL BOOT Figure B.10 Matching Computer to Relay Parameters................B.10 Figure B.11 Example Receive File Dialog Box..................B.10 Figure B.12...

-

Page 17: Preface

Overview This manual provides information and instructions for installing, setting, configuring, and operating the SEL-351S Relay. The manual is for use by power engineers and others experienced in protective relaying applications. Included are detailed technical descriptions of the relay and application examples. - Page 18 OGIC equation, global, SER, text label, and serial port settings The Settings Sheets can be photocopied and filled out to set the SEL-351S. Note that these sheets correspond to the serial port SET commands listed in Table 9.1. Section 10: Serial Port Communications and Commands.

- Page 19 Preface xvii ➤ Appendix K: acSELerator QuickSet SEL-5030 Software ➤ Appendix L: SEL Synchrophasors SEL-351S Relay Command Summary briefly describes the serial port commands that are described in detail in Section 10: Serial Port Communications and Commands. Instruction Manual SEL-351S Relay...

- Page 20 Examples This instruction manual uses several example illustrations and instructions to explain how to effectively operate the SEL-351S. These examples are for demonstration purposes only; the firmware identification information or settings values included in these examples may not necessarily match those in the current version of your SEL-351S.

- Page 21 Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury. DANGER Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury. Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 22 This page intentionally left blank...

- Page 23 Section 1 Introduction and Specifications This section includes the following overviews of the SEL-351S Relay: SEL-351S Models on page 1.2 Applications on page 1.5 Hardware Connection Features on page 1.6 Communications Connections on page 1.9 Specifications on page 1.10 Instruction Manual...

-

Page 24: Section 1: Introduction And Specifications

(see Table 1.2). These numbers should not be used to order an SEL-351S. To order an SEL-351S, refer to the actual ordering information sheets. Models 0351Sx1 and 0351SxY can be ordered with a horizontal rack mount or horizontal/vertical panel mount. -

Page 25: Table 1.2 Sel-351S Firmware Versions

Includes firmware version 6 features plus power and voltage sag/swell/interruption elements. SEL-351S relays with firmware version 5, 6, or 7 come with 300 Vac voltage inputs only (connect any voltage up to 300 Vac, line-to-neutral). Auxiliary {TRIP} and The SEL-351S part number indicates whether the relay has auxiliary {TRIP} and {CLOSE} pushbuttons. - Page 26 Introduction and Specifications SEL-351S Models severe CT saturation, the adaptive current is the output of the bipolar peak detector. When the harmonic distortion index is below the fixed threshold, the adaptive current is the output of the cosine filter. The cosine filter provides excellent performance in removing dc offset and harmonics.

-

Page 27: Applications

Recloser Line Recloser SEL-351R Installations The SEL-351R Recloser Control is a similar product to the SEL-351S. The SEL-351R is powered by 120 Vac and is ideally suited for applications outside the substation. q See Figure 2.19 Figure 2.20, w See Figure 2.21... -

Page 28: Hardware Connection Features

{TRIP}/{BREAKER OPEN} operator control pushbuttons are replaced by POWER — {AUX 3} and {AUX 4}. SUPPLY BATTERY MONITOR CHASSIS GROUND Figure 1.2 Inputs, Outputs, and Communications Ports (Extra I/O Boards in Figure 1.3 Figure 1.4) SEL-351S Relay Instruction Manual Date Code 20080103... - Page 29 If the output contacts are high- OUT201 current interrupting output contacts, they are polarity dependent. See Table 1.1 for information on SEL-351S models with the high-current OUT202 interrupting output contact option. Output Contacts on page 2.16 more information on the polarity...

- Page 30 If the output contacts are high- OUT201 current interrupting output contacts, they are polarity dependent. See Table 1.1 for information on SEL-351S models with the high-current OUT202 interrupting output contact option. Output Contacts on page 2.16 more information on the polarity...

-

Page 31: Communications Connections

Computer Port 1 Port 1 Port 1 SEL-351 Relay (#1) SEL-351 Relay (#2) SEL-351 Relay (#32) Local Connections Connect to the SEL communications processor once and communicate with Front Panel any connected SEL relay SEL-2032 Port 2 Port 2 Rear Panel... -

Page 32: Specifications

Introduction and Specifications Specifications Specifications Important: Do not use the following specification information to Rated: 48/125 Vdc or 125 Vac order an SEL-351S. Refer to the actual ordering information sheets. Range: 38–200 Vdc or 85–140 Vac Section 1 Introduction and Specifications Burden: <25 W... - Page 33 Part 2: Tests – Test Bd: Dry Heat Routine Dielectric and Impulse Tests Current inputs, optoisolated inputs, and output contacts: 2500 Vac for 10 s Power supply: 3100 Vdc for 10 s Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 34 IEC 60255-21-3:1993 Electrical relays, Note: See pickup and reset time curves in Figure 3.5 Part 21: Vibration, shock, bump, and Figure 3.6. seismic tests on measuring relays and protection equipment, Section Three: Seismic tests, Class 2 SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 35 Phase Angle Accuracy: Slip Frequency (wye- Pickup Range: 0.005–0.500 Hz, 0.001 Hz steps connected voltages) Slip Frequency ±0.003 Hz (delta Pickup Accuracy: connected voltages) ±0.5° Phase Angle Range: 0–80°, 1° steps Phase Angle Accuracy: ±4° Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 36 1–7800 VA power factor for reactive power {1 A nominal}: element {5 A nominal} (Specification is with respect to MET PM command and SEL Fast Message Synchrophasor Protocol.) ±0.005 A • (L-L voltage secondary) and ±5% of setting at unity power Voltages (33.5–150 V;...

-

Page 37: Section 2: Installation

Relay Mounting Rack Mount We offer the SEL-351S Relay in a rack-mount version that bolts easily into a standard 19-inch rack. See Figure 2.1. From the front of the relay, insert four rack screws (two on each side) through the holes on the relay mounting flanges. - Page 38 Installation Relay Mounting Figure 2.1 SEL-351S Dimensions for Rack-Mount and Panel-Mount Models SEL-351S Relay Instruction Manual Date Code 20080103...

-

Page 39: Front-Panel And Rear-Panel Connection Diagrams

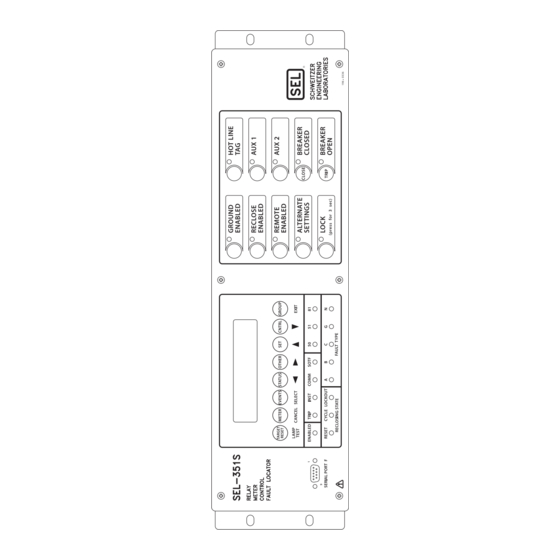

All units can be ordered with either conventional terminal blocks or plug-in connectors. For model options, view the SEL-351S Model Option Tables on our website or contact your local SEL sales representative. Figure 2.2–Figure 2.5 show the various front-panel configurations available for the SEL-351S. - Page 40 Installation Front-Panel and Rear-Panel Connection Diagrams Figure 2.2 SEL-351S Front- and Rear-Panel Drawings (Model 0351SxYH3xxxx6x); Horizontal Rack Mount Example, (Connectorized, With Additional I/O Board) SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 41 Installation Front-Panel and Rear-Panel Connection Diagrams Figure 2.3 SEL-351S Front- and Rear-Panel Drawings (Model 0351Sx133xxxx2x); Horizontal Panel Mount Example, (Conventional Terminal Blocks, With Additional I/O Board) Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 42 Installation Front-Panel and Rear-Panel Connection Diagrams Vertical Model Top i3190a Figure 2.4 SEL-351S Front- and Rear-Panel Drawings (Model 0351Sx143xxxxXx); Vertical Panel Mount Example, (Conventional Terminal Blocks, No Additional I/O Board) SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 43 Installation Front-Panel and Rear-Panel Connection Diagrams Vertical Model Top i3183a Figure 2.5 SEL-351S with Auxiliary {TRIP}/{CLOSE} Pushbuttons (Model 0351Sx145xxxx6x); Vertical Panel-Mount Example, (Conventional Terminal Blocks, With Additional I/O Board) Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 44 Installation Front-Panel and Rear-Panel Connection Diagrams Figure 2.6 SEL-351S with Auxiliary {TRIP}/{CLOSE} Pushbuttons (Model 0351SxYH5xxxx2x); Horizontal Rack-Mount Example, (Connectorized, With Additional I/O Board) SEL-351S Relay Instruction Manual Date Code 20080103...

-

Page 45: User-Configurable Label Option For The Front Panel

User-Configurable Label Option for the Front Panel User-Configurable Label Option for the Front Panel SEL-351S relays with front-panel user-configurable labels have three (or four, depending on the model) pockets for slide-in labels: one for the target LED label, one for the breaker LEDs (for models with auxiliary {TRIP}/{CLOSE} pushbuttons), and two for the operator-control labels. - Page 46 INSERT UNDER LABEL LABEL WITH PUSH IN ALL THE WAY WITH OTHER FINGER HAND 196-0525 HERE Label Removal Tool LABEL REMOVAL TOOL Figure 2.8 SEL-351S (Horizontal) Blank Slide-In Label Set and Label Removal Tool SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 47 Operator Label Control Control Label Labels Opening Opening Opening Breaker Label I1406.AI i1521A Default View Without Default View With Auxiliary {TRIP}/{CLOSE} Pushbuttons Auxiliary {TRIP}/{CLOSE} Pushbuttons Figure 2.9 SEL-351S (Vertical) With User-Configurable Default Labels Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 48 FINGER 196-0525 HAND HERE Label Removal Tool LABEL REMOVAL TOOL Figure 2.10 SEL-351S (Vertical) Blank Slide-In Label Set and Label Removal Tool WARNING The SEL-351S comes with default Table 2.1 lists the various options, with explanations, available for custom labels and settings. Any change in the labeling of the SEL-351S Front Panel.

-

Page 49: Table 2.1 Options And Explanations For The User-Configurable Front-Panel Labels

Front-Panel Breaker Rear-Panel Breaker Labeling With Connectorized Rear-Panel Default Labeling Conventional Terminal Blocks Breaker Status Labeling Figure 2.11 Breaker LED Front-Panel Default Labels and Rear-Panel Labels Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 50: Making Rear-Panel Connections

Wiring Harness The wiring harness includes all connectors necessary for relay installation. All connectors requiring special termination come prewired from the factory. The SEL-WA0351 Wiring Harness includes the following connectors (not prewired): ➤ (2) 8-position female plug-in connectors for output contacts OUT101–ALARM. - Page 51 These prewired connectors (and the serial port connector) are unique and may only be installed in one orientation. Model 0351SxY OUT101–OUT104 OUT105–ALARM Circuit Board-Mounted Connectors (male) IN101–IN103 IN104–IN106 Figure 2.12 SEL-351S Plug-In Connector Coding (Top View; Model 0351SxY) Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 52 To determine the type of output contacts on the extra I/O board of your Model 0351S relay, refer to the part number on the serial number sticker on the relay rear panel. SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 53 I/O board with standard output contacts). Optoisolated Inputs The optoisolated inputs in any of the SEL-351S models (e.g., IN102, IN207) are not polarity dependent. With nominal control voltage applied, each optoisolated input draws approximately 4 mA of current. Refer to Specifications on page 1.10...

- Page 54 Note the signal labels (VA, VB, VC, N, VS, NS) on terminals Z09–Z14. Figure 1.2 shows the internal connection for terminals VA, VB, VC, and N. Note also that VS-NS is a separate single-phase voltage input. SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 55 R108 (or higher) indicates “300 V Wye/Delta.” The part number sticker on previously manufactured SEL-351S relays indicates “300 V Wye.” If older SEL-351S relays (with firmware revisions R102 through R107) are upgraded to R108 (or higher) firmware, they too can be wye connected or delta connected, provided that the voltage rating is not exceeded.

- Page 56 Synchronism Check Elements on page 3.36. SEL-351S relays with firmware revisions R107 and earlier do not have a VSCONN setting. In these relays, voltage input VS-NS operates in its traditional role of voltage input for synchronism check (as if setting VSCONN = VS).

- Page 57 VC-N (ABC rotation used in this example). For this scenario of the collapse of secondary voltage V = 0) in the broken-delta secondary, note that voltage V is 180 degrees out-of-phase with voltage V (from voltage input VA-N). Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 58 To verify the correct polarity on voltage input VS-NS, perform the following test on the primary side of one of the PTs connected in broken-delta secondary (refer to Figure 2.15) and observe the resultant voltage phase angle differences: SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 59 System Voltages) Serial Ports Serial PORT 1 on all the SEL-351S models is an EIA-485 port (4-wire). The serial PORT 1 plug-in connector accepts wire size AWG 24 to 12. Strip the wires 0.31 inches (8 mm) and install with a small slotted-tip screwdriver.

-

Page 60: Table 2.2 Communication Cables To Connect The Sel-351S To Other Devices

PORT 1 or PORT 2, but not both. A demodulated IRIG-B time code can be input into serial PORT 2 by connecting serial PORT 2 of the SEL-351S to an SEL-2032, SEL-2030, or SEL-2020 Communications Processor using Cable C273A. -

Page 61: Sel-351S Ac/Dc Connection Diagrams For Various Applications

). But in this residual connection example, the neutral ground and residual ground overcurrent elements operate the same because I Figure 2.17 SEL-351S Provides Overcurrent Protection and Reclosing for a Utility Distribution Feeder (Includes Fast Bus Trip Scheme) (Wye-Connected PTs) - Page 62 Although automatic reclosing is probably not needed in this example, output contact OUT102 can close the circuit breaker via initiation from various means (serial port communications, optoisolated input assertion, etc.), with desired supervision (e.g., synchronism check). Figure 2.18 SEL-351S Provides Overcurrent Protection for a Distribution Bus (Includes Fast Bus Trip Scheme) (Wye-Connected PTs) SEL-351S Relay...

- Page 63 = 3I ). But in this residual connection example, the neutral ground and residual ground overcurrent elements operate the same because I Figure 2.19 SEL-351S Provides Directional Overcurrent Protection and Reclosing for a Transmission Line (Wye-Connected PTs) Instruction Manual SEL-351S Relay...

- Page 64 Separate from Channel IN, the residual ground overcurrent elements operate from the internally derived residual current I = 3I Figure 2.20 SEL-351S Provides Directional Overcurrent Protection and Reclosing for a Transmission Line (Current-Polarization Source Connected to Channel IN) (Wye-Connected PTs) SEL-351S Relay...

- Page 65 (serial port communications, optoisolated input assertion, etc.), with desired supervision (e.g., hot bus check). For sensitive earth fault (SEF) applications, the SEL-351S should be ordered with Channel IN rated at 0.2 A or 0.05 A nominal. See current input specifications in the subsection Specifications: General on page 1.10.

- Page 66 Although automatic reclosing is probably not needed in this example, output contact OUT102 can close the circuit breaker via initiation from various means (serial port communications, optoisolated input assertion, etc.), with desired supervision (e.g., hot bus check). Figure 2.22 SEL-351S Provides Overcurrent Protection for a Transformer Bank With a Tertiary Winding (Wye-Connected PTs) SEL-351S Relay...

- Page 67 (serial port communications, optoisolated input assertion, etc.), with desired supervision. For sensitive earth fault (SEF) applications, the SEL-351S should be ordered with Channel IN rated at 0.2 A or 0.05 A nominal. See current input specifications in subsection Specifications: General on page 1.10.

- Page 68 I = 3I ). But in this residual connection example, the neutral ground and residual ground overcurrent elements operate the same because I Figure 2.24 SEL-351S Provides Dedicated Breaker Failure Protection SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 69 ORDER=U (see Table 4.3–Table 4.5). Nondirectional sensitive earth fault (SEF) protection is also available. Figure 2.25 SEL-351S Provides Overcurrent Protection for a High-Impedance or Low-Impedance Grounded System (Wye-Connected PTs) Instruction Manual SEL-351S Relay...

- Page 70 Directional control for a Petersen Coil grounded system is selected with setting ORDER containing P (see Table 4.3– Table 4.5). Nondirectional sensitive earth fault (SEF) protection is also available. Figure 2.26 SEL-351S Provides Overcurrent Protection for a Petersen Coil Grounded System (Wye-Connected PTs) SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 71 Directional control for an ungrounded system is selected with setting ORDER=U (see Table 4.3–Table 4.5). Nondirectional sensitive earth fault (SEF) protection is also available. Figure 2.27 SEL-351S Provides Overcurrent Protection for an Ungrounded System (Wye-Connected PTs) Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 72 The polarity of voltage input VS-NS connection should be verified prior to placing the relay into service. See Polarity Check for VSCONN = 3V0 on page 2.20 for a suggested procedure. Figure 2.28 SEL-351S Provides Overcurrent Protection for an Ungrounded System (Open-Delta Connected PTs, Broken-Delta 3V0 Connection) SEL-351S Relay Instruction Manual...

- Page 73 ). But, in this residual connection example, the neutral ground and residual ground overcurrent elements operate the same because I Figure 2.29 SEL-351S Provides Overcurrent Protection and Reclosing for a Utility Distribution Feeder (Open-Delta Connected PTs and Line-to-Ground Synch-Check Connection)

-

Page 74: Figure 2.30 Sel-351S Provides Underfrequency Load Shedding, Overcurrent Protection, And

). But, in this residual connection example, the neutral ground and residual ground overcurrent elements operate the same because I Figure 2.30 SEL-351S Provides Underfrequency Load Shedding, Overcurrent Protection, and Reclosing for a Utility Distribution Feeder (Single Voltage Connection) SEL-351S Relay... -

Page 75: Figure 2.31 Sel-351S Example Wiring Diagram Using The Auxiliary {Trip}/{Close} Pushbuttons For 0351Sxxx5/6/A/B Models

Manual Close Pushbutton Open Closed Pushbutton Local Remote Close/ Auto-Reclose Remote Trips/ Protection Trips To Close Circuit — — Figure 2.31 SEL-351S Example Wiring Diagram Using the Auxiliary {TRIP}/{CLOSE} Pushbuttons for 0351Sxxx5/6/A/B Models Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 76: Circuit Board Connections

ESD damage. which drawout tray needs to be removed. The main board on the SEL-351S is the top board in the chassis. If the relay has an extra I/O board it is located underneath the main board. The magnetics/auxiliary pushbutton board and power supply are mounted to the bottom of the chassis. -

Page 77: Figure 2.32 Jumper, Connector, And Major Component Locations On The Sel-351S Main Board

Step Step 16. Reenergize the relay. (On plug-in connector versions, replace the power connector at rear-panel terminals Z25 and Z26.) Figure 2.32 Jumper, Connector, and Major Component Locations on the SEL-351S Main Board Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 78: Figure 2.33 Jumper, Connector, And Major Component Locations On The Sel-351Sxy Extra

2.42 Installation Circuit Board Connections Figure 2.33 Jumper, Connector, and Major Component Locations on the SEL-351SxY Extra I/O Board (Plug-In Connector Version) SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 79: Figure 2.34 Jumper, Connector, And Major Component Locations On The Sel-351Sx1 Extra

Installation 2.43 Circuit Board Connections Figure 2.34 Jumper, Connector, and Major Component Locations on the SEL-351Sx1 Extra I/O Board (Screw Terminal Block Version) Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 80: Figure 2.35 Jumper Locations For The 0351Sxxx5/6/A/B Model Magnetics/Auxiliary Pushbutton Board

“b” type output contacts and the other output contacts are all “a” type output contacts. This is how these jumpers are configured in a standard relay shipment. Refer to corresponding Figure 7.27–Figure 7.28 for examples of output contact operation for different output contact types. SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 81: Table 2.3 Output Contact Jumpers And Corresponding Output Contacts

0351Sx1 JMP17–JMP28 Figure 2.34 “Extra Alarm” The SEL-351S has dedicated alarm output contacts (labeled ALARM—see Figure 2.2–Figure 2.6). Often more than one alarm output contact is needed Output Contact for such applications as local or remote annunciation, backup schemes, etc. -

Page 82: Table 2.6 Password And Breaker Jumper Positions For Standard Relay Shipments

Table 2.8 EIA-232 Serial Port Voltage Jumper Positions for Standard Relay Shipments EIA-232 Serial Port 2 EIA-232 Serial Port 3 Reference Figures (rear panel) (rear panel) JMP2 = OFF JMP1 = OFF Figure 2.32 SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 83: Table 2.9 Jumper Positions For Breaker Open/Close Indication

To meet product safety compliance for end-use applications in North America, use an external fused rated 3 A or less in-line with the +5 Vdc source on Pin 1. SEL fiber-optic transceivers include a fuse that meets this requirement. Auxiliary {TRIP}/ The jumpers listed in Table 2.9... - Page 84 Boards. Set the relay date and time via serial batteries according to the manufacturer’s instructions. communications port or front panel (see Section 10: Serial Port Communications and Commands Section 11: Front-Panel Interface, respectively).w SEL-351S Relay Instruction Manual Date Code 20080103...

-

Page 85: Section 3: Overcurrent, Voltage, Synchronism Check, Frequency, And Power Elements

(5 A nominal phase current inputs, IA, IB, IC) ±0.01 A secondary and ±3% of setting (1 A nominal phase current inputs, IA, IB, IC) Timer: ±0.25 cycles and ±0.1% of setting Transient Overreach: ±5% of setting Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 86: Figure 3.1 Levels 1-4 Phase Instantaneous Overcurrent Elements

Figure 3.1 Levels 1–4 Phase Instantaneous Overcurrent Elements Relay Enabled Word Levels Settings Bits Level 5 50P5P 5OP5 Setting E5OP ≥ 5) Level 6 50P6P 5OP6 Setting E5OP ≥ 6) (Max. Phase) Figure 3.2 Levels 5–6 Phase Instantaneous Overcurrent Elements SEL-351S Relay Instruction Manual Date Code 20080103... - Page 87 Note that single-phase overcurrent elements are not available in Levels 5 and 6 (see Figure 3.2). Ideally, set 50P1P > 50P2P > 50P3P > 50P4P so that instantaneous overcurrent elements 67P1–67P4 will display in an organized fashion in event reports (see Figure 3.3 Table 12.3). Instruction Manual SEL-351S Relay Date Code 20080103...

-

Page 88: Figure 3.3 Levels 1-4 Phase Instantaneous/Definite-Time Overcurrent Elements

(asserted to logical 1 continuously if E32 = N) OGIC OGIC Setting Torque Control 67P4TC q From Figure 3.1; w from Figure 4.24. Figure 3.3 Levels 1–4 Phase Instantaneous/Definite-Time Overcurrent Elements (With Directional Control Option) SEL-351S Relay Instruction Manual Date Code 20080103... - Page 89 E32 = then the directional control input from Figure 4.24 (Level 1) is asserted to logical 1 continuously. Then only the corresponding SEL control OGIC equation torque control setting 67P1TC has to be considered in the control of the phase instantaneous/definite-time overcurrent elements 67P1/67P1T.

-

Page 90: Figure 3.4 Combined Single-Phase Instantaneous Overcurrent Elements

Figure 3.6 show pickup and reset time curves applicable to all nondirectional instantaneous overcurrent elements in the SEL-351S Relay (60 Hz or 50 Hz relays). These times do not include output contact operating time and, thus, are accurate for determining element operation time for use in internal SEL control equations. -

Page 91: Figure 3.5 Sel-351S Nondirectional Instantaneous Overcurrent Element Pickup Time Curve

≤4: add 0.25 cycle multiples of pickup setting >4: add 0.50 cycle Maximum Minimum Applied Current (Multiples of Pickup Setting) Figure 3.5 SEL-351S Nondirectional Instantaneous Overcurrent Element Pickup Time Curve M aximum M inimum Applied Current (M ultiples of Pickup Setting) Figure 3.6 SEL-351S Nondirectional Instantaneous Overcurrent Element... - Page 92 (Channel IN current) for phase currents and substituting like settings and Relay Word bits. Table 4.3 and accompanying note for a list of the directional features available with each neutral Channel (IN) rating. SEL-351S Relay Instruction Manual Date Code 20080103...

-

Page 93: Figure 3.7 Levels 1-4 Phase-To-Phase Instantaneous Overcurrent Elements

E5OP ≥ 3) 50CA3 50PP4 50AB4 ⏐I — I ⏐ Level 4 50BC4 (Setting ⏐I — I E5OP ≥ 4) ⏐ 50CA4 ⏐I — I ⏐ Figure 3.7 Levels 1–4 Phase-to-Phase Instantaneous Overcurrent Elements Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 94: Figure 3.8 Levels 1-4 Neutral Ground Instantaneous/Definite-Time Overcurrent Elements (With Directional Control Option)

(Level 4) (asserted to logical 1 continuously if E32 = N) OGIC OGIC Setting Torque Control 67N4TC From Figure 4.18. Figure 3.8 Levels 1–4 Neutral Ground Instantaneous/Definite-Time Overcurrent Elements (With Directional Control Option) SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 95: Figure 3.9 Levels 5-6 Neutral Ground Instantaneous Overcurrent Elements

Two additional levels of residual ground instantaneous Instantaneous/ overcurrent elements (Levels 5 and 6) are also available. The different levels Definite-Time are enabled with the E50G enable setting, as shown in Figure 3.10 Figure 3.11. Overcurrent Elements Instruction Manual SEL-351S Relay Date Code 20080103... - Page 96 ±0.01 A secondary and ±3% of setting (1 A nominal phase current inputs, IA, IB, IC) Timer: ±0.25 cycles and ±0.1% of setting Transient Overreach: ±5% of setting Pickup and Reset Time Curves Figure 3.5 Figure 3.6. SEL-351S Relay Instruction Manual Date Code 20080103...

-

Page 97: Figure 3.10 Levels 1-4 Residual Ground Instantaneous/Definite-Time Overcurrent Elements

(Level 4) (asserted to logical 1 continuously if E32 = N) OGIC OGIC Setting Torque Control 67G4TC From Figure 4.17. Figure 3.10 Levels 1–4 Residual Ground Instantaneous/Definite-Time Overcurrent Elements (With Directional Control Option) Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 98: Figure 3.11 Levels 5-6 Residual Ground Instantaneous Overcurrent Elements

0.05–20.00 A secondary (1 A nominal phase current inputs, IA, IB, IC) Setting range for definite-time settings 67Q1D–67Q4D: 0.00–16000.00 cycles, in 0.25-cycle steps Setting range for definite-time setting 67Q2SD (used in DCB logic): 0.00–60.00 cycles, in 0.25-cycle steps SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 99: Figure 3.12 Levels 1-4 Negative-Sequence Instantaneous/Definite-Time Overcurrent Elements (With Directional Control Option)

E5OQ ≥ 4) (Level 4) (asserted to logical 1 continuously if E32 = N) OGIC OGIC Setting Torque Control 67Q4TC From Figure 4.23. Figure 3.12 Levels 1–4 Negative-Sequence Instantaneous/Definite-Time Overcurrent Elements (With Directional Control Option) Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 100: Figure 3.13 Levels 5-6 Negative-Sequence Instantaneous Overcurrent Elements

±0.01 A secondary and ±3% of setting (1 A nominal phase current inputs, IA, IB, IC) Timer: ±0.25 cycles and ±0.1% of setting Transient Overreach: ±5% of setting Pickup and Reset Time Curves Figure 3.5 Figure 3.6. SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 101: Time-Overcurrent Elements

Similarly, setting 51P2RS is not available when setting 51P2C is set to a recloser curve. control equation torque control setting (e.g., 51P1TC) cannot be set directly to OGIC logical 0. Section 9: Setting the Relay for additional time-overcurrent element setting information. Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 102: Figure 3.14 Phase Time-Overcurrent Element 51P1T (With Directional Control Option)

±0.01 A secondary and ±3% of setting (1 A nominal phase current inputs, IA, IB, IC) Curve Timing: ±1.50 cycles and ±4% of cure time for currents between (and including) 2 and 30 multiples of pickup SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 103: Table 3.3 Phase Time-Overcurrent Element (Maximum Phase) Logic Outputs

If the Torque Control Switch is then opened, I effectively appears as a magnitude of zero (0) to the pickup comparator: = 0 A (effective) < pickup setting 51P1P Instruction Manual SEL-351S Relay Date Code 20080103... - Page 104 Refer to Figure 3.14. control equation torque control settings (e.g., 51P1TC) cannot be set OGIC directly to logical 0. The following are setting examples of SEL control OGIC equation torque control setting 51P1TC for phase time-overcurrent element 51P1T. SEL-351S Relay...

- Page 105 I goes below 51P1P, the element starts to time to reset, emulating electromechanical reset timing. Relay Word bit 51P1R (resetting indication) = logical 1 when the element is fully reset. Instruction Manual SEL-351S Relay Date Code 20080103...

-

Page 106: Figure 3.16 Neutral Ground Time-Overcurrent Element 51N1T (With Directional Control Option)

Torque Control Setting TCN1 State Switch Position 51N1RS = Reset Timing Logical 1 Closed Electromechanical Logical 0 Open 1 Cycle From Figure 4.18. Figure 3.16 Neutral Ground Time-Overcurrent Element 51N1T (With Directional Control Option) SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 107: Table 3.4 Neutral Ground Time-Overcurrent Elements Settings

(51N1C) is set to a recloser curve. In this situation, 51N1RS is effectively set to “N” internally. Similarly, setting 51N2RS is not available when setting 51N2C is set to a recloser curve. control equation torque control setting (e.g., 51N1TC) cannot be set directly to OGIC logical 0. Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 108: Figure 3.18 Residual Ground Time-Overcurrent Element 51G1T (With Directional Control Option)

Torque Control Setting TCG1 State Switch Position 51G1RS = Reset Timing Logical 1 Closed Electromechanical Logical 0 Open 1 Cycle From Figure 4.17. Figure 3.18 Residual Ground Time-Overcurrent Element 51G1T (With Directional Control Option) SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 109: Table 3.5 Residual Ground Time-Overcurrent Elements Settings

Similarly, setting 51G2RS is not available when setting 51G2C is set to a recloser curve. control equation torque control setting (e.g., 51G1TC) cannot be set directly to OGIC logical 0. Section 9: Setting the Relay for additional time-overcurrent element setting information. Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 110: Table 3.6 Negative-Sequence Time-Overcurrent Elements Settings

(5 A nominal phase current inputs, IA, IB, IC) 0.05–3.20 A secondary (1 A nominal phase current inputs, IA, IB, IC) 51QC curve type U1–U5 (US curves), C1–C5 (IEC curves), recloser curves (Table 9.5)—see Figure 9.1–Figure 9.20 SEL-351S Relay Instruction Manual Date Code 20080103... - Page 111 ±0.01 A secondary and ±3% of setting nominal phase current inputs, IA, IB, IC (1 A Curve Timing: ±1.50 cycles and ±4% of curve time for currents between (and including) 2 and 30 multiples of pickup. Instruction Manual SEL-351S Relay Date Code 20080103...

-

Page 112: Voltage Elements

Voltage VS cannot be used for 3V0 measurement and as a synchronism check input at the same time. Voltage Table 3.8–Table 3.10 list available voltage elements and the corresponding voltage inputs and settings ranges for SEL-351S Relays (also refer to Element Settings Figure 1.2). SEL-351S Relay... -

Page 113: Table 3.8 Voltage Elements Settings And Settings Ranges (Wye-Connected Pts)

(Wye-Connected PTs) because they can assert or deassert due to noise when no signal is applied. Voltage Element Operating SEL recommends a minimum setting Pickup Setting/Range See Figure of 2.00 V. (Relay Word Bits) Voltage... -

Page 114: Table 3.10 Voltage Elements Settings And Settings Ranges (Delta-Connected Pts)

0.00–300.00 V secondary 59BC 59CA 3P59 = 59AB * 59BC * 59CA 59AB2 59PP2P 0.00–300.00 V secondary 59BC2 59CA2 59QP Figure 3.24 0.00–120.00 V secondary 59Q2 59QP2 0.00–120.00 V secondary 59V1 59V1P 0.00–170.00 V secondary SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 115: Figure 3.21 Single-Phase And Three-Phase Voltage Elements (Wye-Connected Pts)

To POTT Logic Bits 27P1P 27A1 27B1 27C1 3P27 27P2P 27A2 27B2 27C2 59A1 59B1 59C1 59P1P 3P59 59A2 59B2 59C2 59P2P Figure 5.6. Figure 3.21 Single-Phase and Three-Phase Voltage Elements (Wye-Connected PTs) Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 116: Figure 3.22 Phase-To-Phase And Sequence Voltage Elements (Wye-Connected Pts)

Settings/ Word Voltages Bits 27PP 27AB 27BC 27CA 59AB 59BC 59CA 59PP To POTT Logic 59N1 59N1P 59N2 59N2P 59QP 59V1 59V1P Figure 5.6. Figure 3.22 Phase-to-Phase and Sequence Voltage Elements (Wye-Connected PTs) SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 117: Figure 3.23 Phase-To-Phase Voltage Elements (Delta-Connected Pts)

59CA2 59PP2P Figure 5.6. Figure 3.23 Phase-to-Phase Voltage Elements (Delta-Connected PTs) Relay Settings/ To POTT Logic Word Voltages Bits 59QP 59Q2 59Q2P 59V1 59V1P Figure 5.6. Figure 3.24 Sequence Voltage Elements (Delta-Connected PTs) Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 118: Figure 3.25 Channel Vs Voltage Elements (Wye- Or Delta-Connected Pts)

(bottom of the figure). Pickup setting 59P1P is compared to the magnitudes of the individual phase voltages V , and V . The logic outputs in Figure 3.21 are the following Relay Word bits: SEL-351S Relay Instruction Manual Date Code 20080103... - Page 119 (if the settings are applicable). If the weak-infeed portion of the POTT logic is not enabled, these voltage elements can be used in any desired application. Instruction Manual SEL-351S Relay Date Code 20080103...

-

Page 120: Synchronism Check Elements

25VHI high voltage threshold 0.0–300.0 V secondary for “healthy voltage” window 25SF maximum slip frequency 0.005–0.500 Hz 25ANG1 synchronism check element 0°–80° 25A1 maximum angle 25ANG2 synchronism check element 0°–80° 25A2 maximum angle SEL-351S Relay Instruction Manual Date Code 20080103... - Page 121 SYNCP setting for this example is 270 degrees, the amount that V lags V See SEL Application Guide 2002-02, Compensate for Constant Phase Angle Difference in Synchronism Check with the SEL-351 Relay Family for more information on setting SYNCP with an angle setting. Instruction Manual...

-

Page 122: Figure 3.26 Synchronism Check Voltage Window And Slip Frequency Elements

Calculator q Frequency Calculator Slip Slip Frequency Absolute Value Frequency Element Setting Maximum Slip Frequency 25SF q See bottom of Figure 3.27; Figure 3.27. Figure 3.26 Synchronism Check Voltage Window and Slip Frequency Elements SEL-351S Relay Instruction Manual Date Code 20080103... - Page 123 Maximum Angle 1 25A1 25ANG1 Synchronism Check Element 2 Maximum Angle 2 25A2 25ANG2 Angle Difference Increasing Last Check of Setting OGIC 79CLS (w) From Figure 3.26; Figure 6.6. Figure 3.27 Synchronism Check Elements Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 124 Inputs for delta-connected voltages), designated by setting SYNCP (e.g., if SYNCP = VB, then V Synchronism check voltage, from SEL-351S rear-panel voltage input VS For example, if V is designated as phase input voltage V (setting SYNCP =...

- Page 125 ACB, then setting SYNCP = 240 degrees (V constantly lags V by 240°). See the SEL Application Guide 2002-02, Compensate for Constant Phase Angle Difference in Synchronism Check with the SEL-351 Relay Family for more information on setting SYNCP with an angle setting.

- Page 126 V , and V (or V for delta) are healthy (59VP, 59VS, and 59VA asserted to logical 1) and the SEL control equation setting OGIC BSYNCH (Block Synchronism Check) is deasserted (= logical 0). The Slip Frequency Calculator output is: Slip Frequency = f –...

- Page 127 ) is faster than the system (V ). If the enable into the slip frequency calculator in Figure 3.26 is disabled (e.g., SEL setting BSYNCH asserts OGIC because the breaker closes; BSYNCH = 52A + …), then both SSLOW = logical 0 and SFAST = logical 0, regardless of slip frequency.

- Page 128 This six degree angle than six degrees. Figure 3.28 is for compensation is applied to voltage V , resulting in derived voltage V *, as general illustrative purposes only. shown in Figure 3.28. SEL-351S Relay Instruction Manual Date Code 20080103...

-

Page 129: Figure 3.28 Angle Difference Between V

. Ideally, circuit breaker closing is initiated when V * is in phase with V (Angle Difference = 0 degrees). Then when the circuit breaker main contacts finally close, V is in phase with V . But in this case, Instruction Manual SEL-351S Relay Date Code 20080103... - Page 130 V (Angle Difference = 0 degrees). There might not be enough time to wait for this to happen. Thus, the “Angle Difference = 0 degrees” restriction is eased for this scenario. SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 131 6.6). Refer to the top of Figure 6.5. If timer 79CLSD is set to zero (79CLSD = 0.00), SEL control equation setting 79CLS OGIC (Reclose Supervision) is checked only once to see if it is asserted to logical 1. If it is not asserted to logical 1, the relay goes to the Lockout State.

- Page 132 (25 degrees) than for an automatic reclose (15 degrees). A single output contact (e.g., OUT102 = CLOSE) can provide the close function for both automatic reclosing and manual closing (see Figure 6.1 logic output). SEL-351S Relay Instruction Manual Date Code 20080103...

-

Page 133: Frequency Elements

Figure 3.29 Undervoltage Block for Frequency Elements (Group Setting VNOM ≠ OFF) to Frequency Element Logic (q) Setting 27B81P Relay Word Voltages Wye/Delta 27B81 VA/VAB Figure 3.31. Figure 3.30 Undervoltage Block for Frequency Elements (Group Setting VNOM = OFF) Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 134: Figure 3.31 Levels 1-6 Frequency Elements

Frequency Element 6 81D6P 81D6D (Setting E81 = 6) 81D6T 81D6P ≥ NFREQ 81D6P < NFREQ Underfrequency 3.30; w 81D1–81D6 are for testing purposes only. Figure 3.29 Figure Figure 3.31 Levels 1–6 Frequency Elements SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 135: Table 3.12 Frequency Elements Settings And Settings Ranges

(frequency element 1 pickup) 81D1P = 61.25 Hz. With these settings: 81D1P≥NFREQ the overfrequency part of frequency element 1 logic is enabled. 81D1 and 81D1T operate as overfrequency elements. 81D1 is used in testing only. Instruction Manual SEL-351S Relay Date Code 20080103... - Page 136 Note that all six frequency elements are controlled by the same undervoltage element (Relay Word bit 27B81). For example, when group setting VNOM ≠ OFF, and Global setting PTCONN = WYE, Relay Word bit 27B81 asserts to SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 137 If frequency elements are not being used, Relay Word bit 27B81 can still be used in other logic, with voltage setting 27B81P set as desired. Enable the frequency elements (setting E81≥1) and make setting 27B81P. Apply Relay Word bit 27B81 in the desired logic scheme, using SEL control OGIC equations.

-

Page 138: Voltage Sag, Swell, And Interruption Elements (Available In Firmware Version 7)

Voltage Sag, Swell, and Interruption Elements (Available in Firmware Version 7) The SEL-351S-7 has three types of elements to detect voltage disturbances. These elements detect voltage sags, swells, and interruptions (abbreviated as “VSSI” or “SSI”). These elements are enabled by group setting ESSI = Y and controlled by the VINT, VSWELL, and VSAG settings. -

Page 139: Figure 3.33 Voltage Swell Elements

The settings ranges for the SSI thresholds are shown in Table 3.13. and Interruption The factory default settings match the Interruption, Sag, and Swell definitions in IEEE Standard 1159-1995 “Classifications of RMS Variations.” Elements Settings Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 140: Table 3.13 Sag/Swell/Interruption Elements Settings (Must First Set Essi = Y)

This allows the SAG, SWELL, and INT elements voltage comparisons to be made with the reference Vbase locked at a “healthy” system voltage level. Once the disturbance is over and all of the SAGp, SWp, and INTp Relay Word bits deassert, and the FAULT SEL control equation OGIC setting deasserts, the thermal element for Vbase is unblocked. -

Page 141: Figure 3.35 Vbase Tracking Example (Three-Phase Disturbance, Wye Connected)

Vbase thermal element to remain blocked. Vbase thermal element blocking by the FAULT Relay Word bit is programmable via SEL setting FAULT. SEL control equation setting OGIC... - Page 142 SSI Reset Command After commissioning tests or other maintenance activities that have applied test voltages to the SEL-351S, the Vbase element may have locked onto a test voltage. Use the SSI R (reset) command once normal system voltages are restored on the voltage terminals. Powering up the relay automatically performs this reset.

-

Page 143: Power Elements (Available In Firmware Version 7)

The power element type settings are made in reference to the load convention: +WATTS: positive or forward real power –WATTS: negative or reverse real power +VARS: positive or forward reactive power (lagging) –VARS: negative or reverse reactive power (leading) Instruction Manual SEL-351S Relay Date Code 20080103... - Page 144 The four power element time delay settings (PWR1D–PWR4D) can be set to have no intentional delay for testing purposes. For protection applications involving the power element Relay Word bits, SEL recommends a minimum time delay setting of 5.00 cycles for general applications. The classical power calculation is a product of voltage and current, to determine the real and reactive power quantities.

- Page 145 Open-delta connected voltages (PTCONN = DELTA), with properly configured broken-delta 3V0 connection (VSCONN = 3V0): any conditions, ➤ Open-delta connected voltages, without broken-delta 3V0 connection (VSCONN = VS): balanced conditions only. Timer: ±0.25 cycles and ±0.1% of setting Instruction Manual SEL-351S Relay Date Code 20080103...

-

Page 146: Figure 3.36 Single-Phase Power Elements Logic (+Vars Example Shown)

Single-Phase VA sec Relay PWRnP Word Bits PWRnD PWRAn 40 V Sufficient Signal = 1, 2, 3, or 4 Repeat for Phases B and C Figure 3.36 Single-Phase Power Elements Logic (+VARS Example Shown) SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 147: Figure 3.37 Three-Phase Power Elements Logic

Figure 3.38 Power Elements Operation in the Real/Reactive Power Plane Figure 3.36, an example is shown with setting PWRnT = +VARS. This corresponds to the settings PWR1P (pickup) and PWR1T (type) in Figure 3.38. Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 148: Figure 3.39 Sel-351S(B) Provides Var Control For 9600 Kvar Capacitor Bank

Figure 3.39, if the SEL-351S(C) trips circuit breaker 52-C for a fault in the capacitor bank, then a block close signal is sent from the SEL-351S(C) to the SEL-351S(B). This prevents the SEL-351S(B) from issuing an automatic close to circuit breaker 52-C. - Page 149 These block close signals seal in when the SEL-351S(C) trips circuit breaker 52-C for a fault in the capacitor bank. Automatic closing of circuit breaker 52-C with the SEL-351S(B) can then take place only after the block close signals are reset. The exact implementation of this block close logic requires an application note beyond the scope of this discussion.

-

Page 150: Figure 3.40 Per Unit Setting Limits For Switching 9600 Kvar Capacitor Bank On- And Off-Line

9600 kVAR ≈ 1.0 per unit VARs ≈ 80.0 VA secondary (single-phase) Convert the per unit VAR levels 0.3 and –1.2 to single-phase VA (voltamperes) secondary: 0.3 • 80.0 VA secondary (single-phase) = 24.0 VA secondary (single- phase) SEL-351S Relay Instruction Manual Date Code 20080103... - Page 151 Figure 3.38). These elements are used in close logic in the SEL-351S(B) to automatically put the 9600 kVAR capacitor bank on-line. Resulting single-phase power elements PWRA2, PWRB2, and PWRC2 assert when the leading VAR level exceeds the –1.2 per unit VAR level (leading) for each respective phase (see Figure 3.40...

- Page 152 This page intentionally left blank...

-

Page 153: Section 4: Loss-Of-Potential, Load Encroachment, And Directional Element Logic

Table 4.1 LOP Logic Inputs (Sheet 1 of 2) Input Description Three-pole open condition (indicates circuit breaker open condition; see Figure 5.3). Positive-sequence voltage (V secondary). Positive-sequence current (A secondary). Zero-sequence current (A secondary). Instruction Manual SEL-351S Relay Date Code 20080103... - Page 154 (ORDER settings V, S, P, and U) are not disabled by a loss-of-potential condition on relay inputs VA, VB, and VC, because these directional elements use the 3V zero-sequence voltage that comes directly from voltage input VS, rather than the zero-sequence voltage calculated from SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 155 LOP asserts to logical 1 for a loss-of-potential condition) but does not disable any voltage-based directional elements (as occurs with ELOP = Y or Y1) or enable overcurrent elements set direction forward (as occurs with ELOP = Y). Instruction Manual SEL-351S Relay Date Code 20080103...

-

Page 156: Load-Encroachment Logic

PLAR Pos.-Seq. Threshold Positive-Sequence Threshold = (Phase Channels Nominal Rating) • (0.1) (90˚) ZLIN (Load In Region) ZLOUT (Load Out Region) (180˚) (0˚) Example Settings (270˚) (—90˚) Figure 4.21. Figure 4.2 Load-Encroachment Logic SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 157: Table 4.2 Load-Encroachment Settings Ranges

Convert Maximum Loads to Equivalent Secondary Impedances Start with maximum forward load: 800 MVA • (1/3) 267 MVA per phase 230 kV • (1/√3) = 132.8 kV line-to-neutral 267 MVA • (1/132.8 kV) • (1000kV/MV) = 2010 A primary Instruction Manual SEL-351S Relay Date Code 20080103... - Page 158 ° ° ° Setting PLAR = 180 (0.95) = 180 = 162 – – – ° ° ° ° Setting NLAR = 180 + cos – (0.80) = 180 + 37 = 217 SEL-351S Relay Instruction Manual Date Code 20080103...

-

Page 159: Figure 4.3 Migration Of Apparent Positive-Sequence Impedance For A Fault Condition

0 + logical 0 logical 0 Refer to Figure 3.14. To prevent phase time-overcurrent element 51P1T from OGIC ® operating for high load conditions, make the following SEL control equation torque control setting: 51P1TC = !ZLOAD*!LOP + 50P6(=NOT[ZLOAD]*NOT[LOP] + 50P6) As shown in Figure 4.2, load-encroachment logic is a positive-sequence... - Page 160 SEL-351S. Note that Application Guide AG93-10 discusses applying the load-encroachment feature to phase distance elements in the SEL-321. The SEL-351S does not have phase distance elements, but the principles and settings example are still applicable to the SEL-351S.

-

Page 161: Directional Control For Neutral Ground And Residual Ground Overcurrent Elements

Channel IN current-polarized directional element ➤ Zero-sequence voltage-polarized directional element (low- impedance grounded system) ➤ Wattmetric and incremental conductance directional elements (Petersen Coil grounded system) ➤ Zero-sequence voltage-polarized directional element (ungrounded/high-impedance grounded system) Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 162: Figure 4.4 General Logic Flow Of Directional Control For Neutral Ground And Residual Ground Overcurrent Elements (Excluding Ungrounded/High-Impedance Grounded Systems)

Figure 3.18 Figure 3.19; Figure 3.10; Figure 3.16 Figure 3.17; Figure 3.8; Figure 4.5. Figure 4.4 General Logic Flow of Directional Control for Neutral Ground and Residual Ground Overcurrent Elements (Excluding Ungrounded/High-Impedance Grounded Systems) SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 163: Table 4.3 Available Ground Directional Elements

See Figure 3.8, Figure 3.9, and Figure 3.18 No ground directional elements enabled All models (not accompanying settings ranges dependent on explanation. 32QGE neutral channel [IN]) 32QGE 32VE 32VE 32VE 32QGE Instruction Manual SEL-351S Relay Date Code 20080103... - Page 164 (or only) (Petersen Coil) listed choice for 32QGE 32NE the ORDER (Petersen Coil) setting 32QGE 32VE 32NE (Petersen Coil) 32VE 32NE (Petersen Coil) 32VE 32QGE 32NE (Petersen Coil) 32NE (Ungrounded/ High- Impedance) SEL-351S Relay Instruction Manual Date Code 20080103...

-

Page 165: Table 4.5 Ground Directional Element Availability By Voltage Connection Settings

The order in which these directional elements are listed in setting ORDER determines the priority in which they operate to provide Best Choice Ground Directional logic control. See the discussion on setting ORDER in the Directional Control Settings on page 4.39. Instruction Manual SEL-351S Relay Date Code 20080103... - Page 166 If the logic in Figure 4.8 (and Figure 4.12, and Figure 4.14) operates on neutral current I , then settings 50NFP and 50NRP are not adjusted, and just operate as: 50NFP base) 50NRP base) SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 167 , or a measured 3V from the VS channel, typically connected to a broken-delta PT secondary. The global setting VSCONN selects the zero- sequence voltage source to be used by the affected directional elements. Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 168 F32C/R32C do not propogate to directional outputs F32N/R32N, respectively, as do the wattmetric directional element outputs F32W/R32W. Incremental conductance elements are used more for alarming purposes than for controlling overcurrent elements for tripping. Incremental conductance SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 169 However, this disable condition is overridden for these overcurrent elements set direction forward if setting ELOP = Y. Refer to Figure 4.1 and accompanying text for more information on loss-of- potential. Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 170 In some applications, level direction settings DIR1–DIR4 are not flexible enough in assigning the desired direction for certain overcurrent elements. Subsection Directional Control Provided by Torque Control Settings on page 4.58 describes how to avoid this limitation for special cases. SEL-351S Relay Instruction Manual Date Code 20080103...

-

Page 171: Figure 4.6 Internal Enables (32Qe And 32Qge) Logic For Negative-Sequence Voltage-Polarized Directional Elements

Figure 4.1; from Figure 4.7; Figure 4.9 Figure 4.20; Figure 4.20 Figure 4.21; Figure 4.9, Table 4.3, and Table 4.4. Figure 4.6 Internal Enables (32QE and 32QGE) Logic for Negative-Sequence Voltage-Polarized Directional Elements Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 172: Figure 4.7 Internal Enables (32Ve And 32Ie) Logic For Zero-Sequence Voltage-Polarized And Channel In Current-Polarized Directional Elements

Figure 4.10; Figure 4.6, Table 4.3, and Table 4.4; Figure 4.11, Figure 4.15, and Figure 4.16. Figure 4.7 Internal Enables (32VE and 32IE) Logic for Zero-Sequence Voltage-Polarized and Channel IN Current-Polarized Directional Elements SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 173: Figure 4.8 Internal Enable (32Ne) Logic For Zero-Sequence Voltage-Polarized Directional Elements (Low-Impedance Grounded, Petersen Coil Grounded, And Ungrounded/High-Impedance Grounded Systems)

4.4. Figure 4.8 Internal Enable (32NE) Logic for Zero-Sequence Voltage-Polarized Directional Elements (Low-Impedance Grounded, Petersen Coil Grounded, and Ungrounded/High-Impedance Grounded Systems) Refer to the setting ideas for SEL setting E32IV, near the back of this OGIC section, especially if setting ORDER = U (ungrounded or high-impedance grounded system). -

Page 174: Figure 4.9 Negative-Sequence Voltage-Polarized Directional Element For Neutral Ground And Residual Ground Overcurrent Elements

If Z2R Setting < 0, Reverse Threshold = 1.25 • Z2R + 0.25 • Note: 1∠Z1L = One Ohm at the Positive-Sequence Line Angle From Table 4.4; Figure 4.15 Figure 4.16. Figure 4.9 Negative-Sequence Voltage-Polarized Directional Element for Neutral Ground and Residual Ground Overcurrent Elements SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 175: Figure 4.10 Zero-Sequence Voltage-Polarized Directional Element

(when global settings VSCONN = VS and PTCONN = WYE) or a measured value (when global setting VSCONN = 3V0). See Zero-Sequence Voltage Sources on page 4.15. Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 176: Figure 4.11 Channel In Current-Polarized Directional Element

Nominal Rating) • (Phase Channels Nominal Rating) • (0.05) Reverse Threshold: Reverse Threshold = —(Channel I Nominal Rating) • (Phase Channels Nominal Rating) • (0.05) From Table 4.4; Figure 4.15 Figure 4.16. Figure 4.11 Channel IN Current-Polarized Directional Element SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 177: Figure 4.12 Zero-Sequence Voltage-Polarized Directional Element (Low-Impedance Grounded Systems)

(when Global Settings VSCONN = VS and PTCONN = WYE) or a measured value (when Global Setting VSCONN = 3V0). See Zero-Sequence Voltage Sources on page 4.15 earlier in this section. Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 178: Figure 4.13 Wattmetric And Incremental Conductance Directional Elements (Petersen Coil Grounded Systems)

(when Global Settings VSCONN = VS and PTCONN = WYE) or a measured value (when Global Setting VSCONN = 3V0). See Zero-Sequence Voltage Sources on page 4.15 Directional Control Settings on page 4.39. SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 179: Figure 4.14 Zero-Sequence Voltage-Polarized Directional Element (Ungrounded/High-Impedance Grounded Systems)

(when Global Settings VSCONN = VS and PTCONN = WYE) or a measured value (when Global Setting VSCONN = 3V0). See Zero-Sequence Voltage Sources on page 4.15. Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 180: Figure 4.15 Routing Of Directional Elements To Residual Ground Overcurrent Elements

Figure 4.9; from Figure 4.10; from Figure 4.11; from Figure 4.12, Figure 4.13, and Figure 4.14; Figure 4.18; o from Figure 9.21. Figure 4.16 Routing of Direction Elements to Neutral Ground Overcurrent Elements SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 181: Figure 4.17 Direction Forward/Reverse Logic For Residual Ground Overcurrent Elements

DIR4 = F Forward Level 4 DIR4 = N DIR4 = R Reverse Reverse 32GR From Figure 4.15; Figure 3.18 Figure 3.19; Figure 3.10. Figure 4.17 Direction Forward/Reverse Logic for Residual Ground Overcurrent Elements Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 182: Figure 4.18 Direction Forward/Reverse Logic For Neutral Ground Overcurrent Elements

DIR4 = F Forward Level 4 DIR4 = N DIR4 = R Reverse Reverse 32NR From Figure 4.16; Figure 3.16 Figure 3.17; Figure 3.8. Figure 4.18 Direction Forward/Reverse Logic for Neutral Ground Overcurrent Elements SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 183: Directional Control For Negative-Sequence And Phase Overcurrent Elements

Internal Enables Refer to Figure 4.6 Figure 4.19. The internal enable 32QE corresponds to the negative-sequence voltage- polarized directional element. Instruction Manual SEL-351S Relay Date Code 20080103... - Page 184 But this disable condition is overridden for the overcurrent elements set direction forward if setting ELOP = Y. Refer to Figure 4.1 and accompanying text for more information on loss-of- potential. SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 185 In some applications, level direction settings DIR1–DIR4 are not flexible enough in assigning the desired direction for certain overcurrent elements. Directional Control Provided by Torque Control Settings on page 4.58 describes how to avoid this limitation for special cases. Instruction Manual SEL-351S Relay Date Code 20080103...

-

Page 186: Figure 4.20 Negative-Sequence Voltage-Polarized Directional Element For Negative-Sequence And Phase Overcurrent Elements

If Z2R Setting ≥ 0, Reverse Threshold = 0.75 • Z2R + 0.25 • If Z2R Setting < 0, Reverse Threshold = 1.25 • Z2R + 0.25 • Figure 4.22. Figure 4.20 Negative-Sequence Voltage-Polarized Directional Element for Negative-Sequence and Phase Overcurrent Elements SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 187: Figure 4.21 Positive-Sequence Voltage-Polarized Directional Element For Phase Overcurrent Elements

Setting [fixed at (phase channels nominal rating) • (0.1) when enable setting ELOAD = Y] From Figure 4.2; from Figure 4.6; from Figure 4.1; Figure 4.22. Figure 4.21 Positive-Sequence Voltage-Polarized Directional Element for Phase Overcurrent Elements Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 188: Figure 4.22 Routing Of Directional Elements To Negative-Sequence And Phase Overcurrent Elements

R32Q (Reverse) 32PF F32P (Forward) 32PR R32P (Reverse) From Figure 4.1; from Figure 4.20; from Figure 4.21; Figure 4.23; Figure 4.24. Figure 4.22 Routing of Directional Elements to Negative-Sequence and Phase Overcurrent Elements SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 189: Figure 4.23 Direction Forward/Reverse Logic For Negative-Sequence Overcurrent Elements

DIR4 = F Forward Level 4 DIR4 = N Relay Word DIR4 = R Reverse Reverse 32QR From Figure 4.22; Figure 3.20; Figure 3.12. Figure 4.23 Direction Forward/Reverse Logic for Negative-Sequence Overcurrent Elements Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 190: Figure 4.24 Direction Forward/Reverse Logic For Phase Overcurrent Elements

DIR4 = F Forward Level 4 DIR4 = N Relay Word DIR4 = R Reverse Reverse 32PR From Figure 4.22; Figure 3.14 Figure 3.15; Figure 3.3. Figure 4.24 Direction Forward/Reverse Logic for Phase Overcurrent Elements SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 191: Directional Control Settings

E32 = AUTO. They have to be set by the user, whether setting E32 = AUTO or Y. These settings are: DIR1, DIR2, DIR3, DIR4, ORDER, 50P32P, 50NFP, 50NRP, a0N, 59RES, 32WFP, 32WRP, 32WD, and E32IV (E32IV is a SEL OGIC setting) All these settings are explained in detail in the remainder of this subsection. -

Page 192: Table 4.6 Directional Control Settings Not Made For Particular Conditions

(Figure 3.8) 67G3T (Figure 3.10) 67Q3T (Figure 3.12) DIR4 67P4 (Figure 3.3) 67N4 (Figure 3.8) 67G4 (Figure 3.10) 67Q4 (Figure 3.12) 67P4T (Figure 3.3) 67N4T (Figure 3.8) 67G4T (Figure 3.10) 67Q4T (Figure 3.12) SEL-351S Relay Instruction Manual Date Code 20080103... - Page 193 DIRn (n = 1–4) settings to be directionally controlled (see Figure 4.17 Figure 4.18). Another example, if setting: ORDER = Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 194 ORDER = QP or ORDER = QVP (see Table 4.4). Then, the residual ground elements (Figure 4.17) are controlled by the directional control logic and provide directional protection for higher ground fault currents. SEL-351S Relay Instruction Manual Date Code 20080103...

-

Page 195: Table 4.8 Z Constant For Z2R Setting

Z0R. The same general approach outlined for deriving settings Z0F and Z0R can also be applied to deriving settings Z2F and Z2R in the negative-sequence impedance network, though the preceding method of automatically making settings Z2F and Z2R usually suffices. Instruction Manual SEL-351S Relay Date Code 20080103... - Page 196 For setting a2 = 0.1, the negative-sequence current (I ) magnitude has to be greater than 1/10 of the positive-sequence current (I ) magnitude in order for the negative-sequence voltage-polarized directional elements to be enabled | > 0.1 • |I SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 197 1/5 of the zero-sequence current (I ) magnitude in order for the negative-sequence voltage-polarized directional elements to be enabled 0.2 • |I |). Again, this presumes at least one of the internal enables 32VE or 32IE is asserted. Instruction Manual SEL-351S Relay Date Code 20080103...

- Page 198 The a0 factor increases the security of the zero-sequence voltage-polarized and channel IN current-polarized directional elements. This factor keeps the elements from operating for zero-sequence current (system unbalance), which circulates due to line asymmetries, CT saturation during three-phase faults, etc. SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 199 If enable setting E32 = Y, settings Z0F and Z0R (zero-sequence impedance values) are calculated by the user and entered by the user, but setting Z0R must be greater in value than setting Z0F by 0.1 Ω secondary. Instruction Manual SEL-351S Relay Date Code 20080103...

-

Page 200: Table 4.9 Z Constant For Z0R Setting

Deriving Z0F and Z0R Settings when needed (effectively, Z0F•CTRN/CTR and Z0R•CTRN/ Figure 4.25 shows the voltage and current polarity for an SEL-351S in a zero- CTR). See Internal Enables on page 4.14. sequence impedance network (the same approach can be instructive for negative-sequence impedance analysis, too). -

Page 201: Figure 4.25 Zero-Sequence Impedance Network And Relay Polarity

0.2 A nominal neutral channel (IN), then settings 50NFP and 50NRP are not made or displayed. Instruction Manual SEL-351S Relay Date Code 20080103... - Page 202 The a0N factor increases the security of the zero-sequence voltage-polarized directional elements: low-impedance grounded or ungrounded/high- impedance grounded. It keeps the elements from operating for zero-sequence current (system unbalance), which circulates due to line asymmetries, etc. SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 203 VS-NS input signal. The 32WFP and 32WRP settings must be entered on the same secondary base as the voltage terminals VA, VB, and VC. See Settings Considerations for Petersen Coil Grounded Systems on page 4.54 for an example. Instruction Manual SEL-351S Relay Date Code 20080103...

-

Page 204: Figure 4.27 Zero-Sequence Impedance Network For Ground Fault On Feeder 1

Zero-Sequence Reference Bus Petersen Coil Feeder 2 Feeder n Transformer Bank 0(2) Relay 2 Relay 1 0(1) Feeder 1 =0 (Tuned System) Figure 4.27 Zero-Sequence Impedance Network for Ground Fault on Feeder 1 SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 205: Figure 4.28 Wattmetric Element Operation For Ground Fault On Feeder 1

32WFP and 32WRP in the wattmetric plane (setting 32WFP is put on the “negative” side of the wattmetric plane: i.e., “–32WFP”; see Figure 4.13). Instruction Manual SEL-351S Relay Date Code 20080103... - Page 206 3V quantity, as shown in Table 4.10. Thus, when the zero-sequence voltage pickup for the wattmetric element is known in terms of the system primary voltage level, the required calculation for setting SEL-351S Relay Instruction Manual Date Code 20080103...

- Page 207 (secondary), then the setting value must be scaled by PTRS/PTR prior to entry. This pre-scaling makes the 32WFP and 32WRP settings match the scaling the relay does when it converts the VS value into the VA, VB, VC voltage base. Instruction Manual SEL-351S Relay Date Code 20080103...

-

Page 208: Table 4.10 Affect Of Global Settings Vsconn And Ptconn On Petersen Coil Directional Elements

IN current-polarized directional elements for directional control of neutral ground and residual ground overcurrent elements. For most applications, set E32IV directly to logical 1: 1 (numeral 1) E32IV = SEL-351S Relay Instruction Manual Date Code 20080103... - Page 209 E32IV should be OGIC deasserted to logical 0. In this example, connect a circuit breaker auxiliary contact from the isolating circuit breaker to the SEL-351S: E32IV = IN106 (52a connected to optoisolated input IN106) Almost any desired control can be set in SEL...

-

Page 210: Directional Control Provided By Torque Control Settings

51G1TC = 32GF (direction forward; see Figure 3.18) This is just one example of using SEL control equation torque control OGIC settings to make overcurrent elements directional (forward or reverse) or nondirectional. This example shows only Level 1 overcurrent elements (controlled by level direction setting DIR1). - Page 211 Section 5 Trip and Target Logic Trip Logic OGIC ® The trip logic in Figure 5.1 provides flexible tripping with SEL control equation settings: TRCOMM—Communications-Assisted Trip Conditions. Setting TRCOMM is supervised by communications-assisted trip logic. See Communications-Assisted Trip Logic—General Overview on page 5.11...

-

Page 212: Section 5: Trip And Target Logic Trip Logic

OR-1 gate. The output of OR-1 gate asserts Relay Word bit TRIP to logical 1, regardless of other trip logic conditions. It also is routed into the Minimum Trip Duration Timer (setting TDURD). SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 213: Figure 5.2 Minimum Trip Duration Timer Operation (See Bottom Of Figure 5.1)

Use these to force the TRIP Relay Word bit to logical 0 if test conditions are such that setting ULTR does not assert to logical 1 to automatically deassert the TRIP Relay Word bit instead. Instruction Manual SEL-351S Relay Date Code 20080103... - Page 214 OGIC Setting TR) gate and follows into the “seal-in and unlatch” logic for Relay Word bit TRIP. The factory settings for the trip logic SEL control equation settings are: OGIC TR = 51P1T + 51G1T + 67P1 + PB10 + OC (trip conditions)

- Page 215 TRIP Relay Word bit deasserts to logical 0. Program an Output In the factory settings, the resultant of the trip logic in Figure 5.1 is routed to output contact OUT101 with the following SEL control equation setting: OGIC Contact for Tripping TRIP OUT101 = If more than one TRIP output contact is needed, program other output contacts with the TRIP Relay Word bit.

- Page 216 Trip and Target Logic Trip Logic TRIP Used in Other Besides operating a trip output contact (e.g., OUT101 = TRIP), the TRIP Relay Word bit is used in a number of other factory-default SEL control OGIC Settings equations settings: TRIP + … unlatch close—see ULCL = Figure 6.3...

- Page 217 (51G2) to the event report trigger conditions setting (ER = … + /51G2). A rising edge operator (/) is added on front of the element (see Appendix G: Setting SEL OGIC Control Equations for more explanation on rising edge operators).

-

Page 218: Switch-Onto-Fault (Sotf) Trip Logic

Refer to the switch-onto-fault trip logic in Figure 5.1 (middle of figure). The SOTF trip logic permits tripping if both the following occur: ➤ An element asserts in SEL control equation trip setting OGIC TRSOTF ➤ Relay Word bit SOTFE is asserted to logical 1 Relay Word bit SOTFE (the output of the SOTF logic) provides the effective time window for an element in trip setting TRSOTF (e.g., TRSOTF = 50P2) to... - Page 219 3PO = logical 0 (circuit breaker closed) Determining Three-Pole Open Condition Without Circuit Breaker Auxiliary Contact If a circuit breaker auxiliary contact is not connected to the SEL-351S Relay, control equation setting 52A is set: OGIC 0 (numeral 0)

- Page 220 Circuit breaker closure is detected by monitoring the dc close bus. This is accomplished by wiring an optoisolated input on the SEL-351S (e.g., IN105) to the dc close bus. When a manual close or automatic reclosure occurs, optoisolated input IN105 is energized.

-

Page 221: Communications-Assisted Trip Logic-General Overview

Trip and Target Logic 5.11 Communications-Assisted Trip Logic—General Overview Communications-Assisted Trip Logic— General Overview The SEL-351S includes communications-assisted tripping schemes that provide unit-protection for transmission lines with the help of communications. No external coordination devices are required. Level 1 (1) Level 3 (1) - Page 222 POTT, PUTT, DCUB, and DCB communications-assisted tripping schemes are explained in subsections that follow. Trip Setting TRCOMM The POTT, PUTT, DCUB, and DCB tripping schemes use SEL control OGIC equation trip setting TRCOMM for those tripping elements that are supervised...

- Page 223 Function IN102 = PT PT1 = IN102 (received permissive trip) In the above SEL-351S setting example, Relay Word bit IN102 is set in the PT1 SEL control equation. Optoisolated input IN102 is wired to a OGIC communications equipment receiver output contact. Relay Word bit IN102 can also be used in other SEL control equation in the SEL-351S.

- Page 224 The SEL-321 handles trip unlatching with setting TULO. The SEL-351S handles trip unlatching with SEL control equation setting ULTR. OGIC The SEL-321 has single-pole trip logic. The SEL-351S does not have single- pole trip logic. ITS ® Using M The M...

-

Page 225: Permissive Overreaching Transfer Trip (Pott) Logic

Provides a secure means of tripping for weak- and/or zero- infeed line terminals Use Existing SEL-321 Use the existing SEL-321 POTT application guide (AG95-29) to help set up the SEL-351S in a POTT scheme (see preceding subsection Communications- POTT Application Assisted Trip Logic—General Overview on page 5.11... -

Page 226: Figure 5.5 Permissive Input Logic Routing To Pott Logic

Setting ECOMM = DCUB2 Figure 5.6. Figure 5.5 Permissive Input Logic Routing to POTT Logic Also note that SEL control equation setting PT1 in Figure 5.7 is routed to OGIC control Relay Word bit PTRX if enable setting ECOMM = POTT. Relay Word... - Page 227 In a three-terminal line scheme, output contact OUT107 is set the same as OUT105 (see Figure 5.9): OUT107 = EKEY—Echo Key Permissive Trip Permissive trip signal keyed by Echo logic (used in testing). Instruction Manual SEL-351S Relay Date Code 20080103...

-

Page 228: Figure 5.6 Pott Logic

5.18 Trip and Target Logic Permissive Overreaching Transfer Trip (POTT) Logic Figure 4.1; Figure 5.5; Table 3.8; Table 3.10; Figure 5.1. Figure 5.6 POTT Logic SEL-351S Relay Instruction Manual Date Code 20080103... -

Page 229: Figure 5.7 Permissive Input Logic Routing To Trip Logic

Depending on the installation, perhaps one output contact (e.g., OUT105 = KEY) could be connected in parallel to both transmitter inputs (TX) 5.9. Then output contact OUT107 on the communication equipment in Figure can be used for another function. Instruction Manual SEL-351S Relay Date Code 20080103... -

Page 230: Figure 5.8 Sel-351S Connections To Communications Equipment For A Two-Terminal Line Pott Scheme

OUT105 (Partial) IN104 OUT105 = KEY PT1 = IN104 To / From Remote Terminal (—) Figure 5.8 SEL-351S Connections to Communications Equipment for a Two-Terminal Line POTT Scheme SEL-351 OUT105 OUT107 (partial) IN104 IN106 OUT105 = KEY PT1 = IN104 * IN106... -

Page 231: Directional Comparison Unblocking (Dcub) Logic

PT1, PT2—Received Permissive Trip Signal(s) In two-terminal line DCUB applications (setting ECOMM = DCUB1), a permissive trip signal is received from one remote terminal. One optoisolated input on the SEL-351S (e.g., input IN104) is driven by a communications equipment receiver output (see Figure 5.12). - Page 232 LOG1, LOG2—Loss-of-Guard Signal(s) In two-terminal line DCUB applications (setting ECOMM = DCUB1), a loss- of-guard signal is received from one remote terminal. One optoisolated input on the SEL-351S (e.g., input IN105) is driven by a communications equipment receiver output (see Figure 5.12).

- Page 233 Relay Word bit UBB, depending on enable setting ECOMM = DCUB1 or DCUB2. Relay Word bit UBB is the unblock block input into the trip logic in Figure 5.1. When UBB asserts to logical 1, tripping is blocked. Instruction Manual SEL-351S Relay Date Code 20080103...

-

Page 234: Figure 5.10 Dcub Logic