Table of Contents

Advertisement

Quick Links

INSTALLATION / OWNER'S MANUAL

ECOSCHWANK

X-Series

FOR YOUR SAFETY:

Do not store or use gasoline or other flam-

mable vapours and liquids in the vicinity

of this or any other appliance.

If you smell Gas:

>Extinguish any open flames

>Don't touch electrical switches

LUMINOUS GAS FIRED

INFRA RED HEATERS

FOR YOUR SAFETY

If you smell gas:

1) Open windows

2) Don't touch electrical switches

3) Extinguish any open flame

Immediately call your gas supplier

IL

X-Series

FIELD CONVERTIBILITY:

"The conversion shall be carried out in accordance with the

requirements of the authorities having jurisdiction and in

accordance with the requirements of the B149.1-00 ( latest

edition) INSTALLATION CODE" in Canada, and the ANSI

Z223.1 (latest edition) in the U.S.A.

GP-MECX-CX-1A

eco-X / IL-X Manual

RD: SEPT 2005

RL: 1A

BA

Advertisement

Table of Contents

Summary of Contents for Schwank X-Series

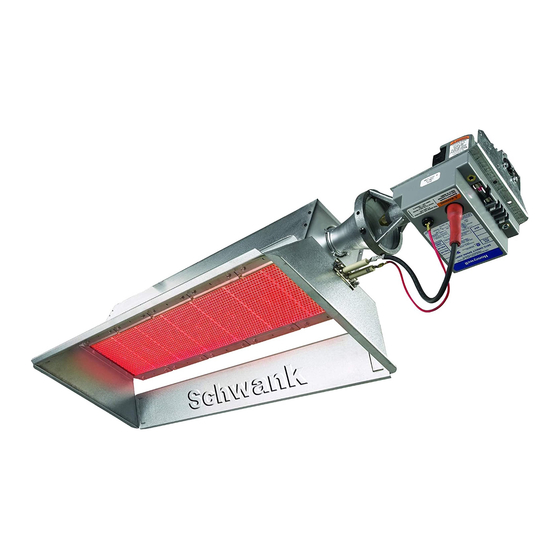

- Page 1 INSTALLATION / OWNER’S MANUAL ECOSCHWANK X-Series X-Series LUMINOUS GAS FIRED INFRA RED HEATERS FOR YOUR SAFETY: FIELD CONVERTIBILITY: Do not store or use gasoline or other flam- “The conversion shall be carried out in accordance with the mable vapours and liquids in the vicinity requirements of the authorities having jurisdiction and in of this or any other appliance.

- Page 2 Waynesboro,Georgia Mississauga, Ontario, 1-866-INFRASV (463-7278) phone: (905) 712-4766 Fax: 1-866-724-9265 fax: (905) 712-8336 1-866-361-0417 Info@infrasave.com www.infrasave.com PO Box 988, 2 Schwank Way Waynesboro,Georgia, USA 30830 Phone: (706) 554-6191 Technical Support: 1-877-446-3727 Fax: (706) 554 9390 e-mail: info@schwankheaters.com www.schwankheaters.com GP-MECX-CX-1A eco-X / IL-X Manual...

-

Page 3: Table Of Contents

ecoSchwank X Series / IL X Series LUMINOUS INFRA-RED GAS HEATERS TABLE OF CONTENTS TOPIC PAGE NUMBER TOPIC PAGE NUMBER GENERAL………………………………………….1 7A. TROUBLESHOOTING GUIDE ......6 INSTALLATION REQUIREMENTS……………...1 DIAGRAMS AND SPECIFICATIONS ....7 2.1 INSTALLATION IN AIRCRAFT HANGARS.1 8.1 DIMENSION DIAGRAM ......7 2.2 INSTALLATION IN COMMERCIAL 8.2 SUSPENSION HARDWARE DIAGRAM .. -

Page 4: General

In case of discrepancies, Schwank and IL model heaters. All installations the latest installation manual will take priority. must conform to the following installation re- The ecoSchwank or IL heater may be installed quirements. -

Page 5: Installation In Commercial Garages

2.2 INSTALLATION IN COMMERCIAL GARAGES ecoSchwank and IL Luminous Heaters are suitable for use in commercial garages when installed in accordance with ANSI/NFPA No. 88B 1985 (latest edition), which states clearances to combustible construction or material in storage, from heater and vent, must conform to standard NFPA No. 54 (ANSI Z223.1 latest edition), in the U.S.A. -

Page 6: Ventilation Requirements

A. All piping must be installed according to local codes. B. It is recommended to install an approved flexible connector between the heater and gas piping available as option from Schwank. C. A drip-pocket at the inlet connection must be provided. -

Page 7: Electrical Requirements & Thermostat Control

D. Connect heater to the main gas line. It is recommended to use a 1/2" flexible connector to absorb gas line expansion and any building vibration (available as option from Schwank Ltd.). E. Mount thermostat at desired location, away from direct infra-red rays of heater and not on cold wall without sufficient insulation backing. -

Page 8: Lighting Instructions

C. Faulty sealing of the ceramic tile to the C. Combustion is taking place inside the burner burner body, caused by breakdown of gas- body. keting material = contact your Schwank dis- tributor. 5. SHUT DOWN INSTRUCTIONS A. Turn off electrical circuit for temporary shutdown. -

Page 9: Troubleshooting Guide

7A. TROUBLE SHOOTING GUIDE SERVICE HINTS AND MAINTENANCE CAUSE AND CORRECTIONS TURN THERMOSTAT TO CALL FOR HEAT CHECK FOR LINE VOLTAGE POWER SUPPLY 24 VOLTS AT CONTROL TRANSFORMER REPLACE TRANSFORMER CHECK 24V WIRING FROM TRANSFORMER TO 24 VOLT AT CONTROL IGNITION CONTROL REPLACE CONTROL 24 VOLTS OUT CONTROL... -

Page 10: Diagrams And Specifications

8. DIAGRAMS AND SPECIFICATIONS: 8.1 DIMENSION DIAGRAM FOR THE LUMINOUS HEATERS TABLE 1: DIMENSIONS : RATING BTU/ WEIGHT (SUSPENSION MODEL N0. LBS. POINTS) ecoSchwank 6 / IL 25 12 5/8” 24” 14” 21,500 ecoSchwank 10 / IL 37 19 3/4" 30 1/4”... -

Page 11: Mounting Diagram

8.3 MOUNTING DIAGRAM FOR LUMINOUS HEATERS Minimum clearance to combustibles Minimum clearance to combustibles HORIZONTAL CLEARANCES TO COMBUSTIBLES CHART : HEATER SIDE BOTTOM MODEL NO < A> < B> < C > < D > ecoSchwank 6 N/L - IL 25 N/L 24”... -

Page 12: Suggested Mounting Distance For Comfort

Maximum distance between heater rows 25’ 30’ 40’ 50’ 70’ * These mounting distances are suggested and are subject to site conditions. If in doubt, please contact your Schwank distributor. GP-MECX-CX-1A Page 9 eco-X / IL-X Manual RD: SEPT 2005 RL: 1A... -

Page 13: Electrical Wiring Diagram

8.7 ELECTRICAL WIRING DIAGRAM FOR THE LUMINOUS HEATERS DIAGRAM 11: LUMINOUS WITH INTERLOCKED EXHAUST Page 10 GP-MECX-CX-1A eco-X / IL-X Manual RD: SEPT 2005 RL: 1A... -

Page 14: Electrical Wiring Diagram-Usa

8.8 ELECTRICAL WIRING DIAGRAM FOR THE LUMINOUS HEATERS USA WITHOUT EXHAUST FAN INTERLOCK DIAGRAM 11: 9. HIGH ALTITUDE INSTALLATIONS Canada: All Luminous heaters are approved for USA: If a heater is to be installed at altitudes altitudes zero to 2000 ft above sea level. If in- above 2000 ft, the input must be reduced by 4% stalled at 2000 ft to 4500 ft above sea level the per 1000 ft. -

Page 15: Sequence Of Operation For Honeywell S87C Dsi Control

10. SEQUENCE OF OPERATION FOR HONEYWELL S87C DSI CONTROL 1. On A call for heat the S87C DSI Control will check for a false flame condition / short to ground. The module will lock out if a false flame condition is present. (Reset is usually done from the Thermostat manually). -

Page 16: Spark Ignition Circuit

11. SPARK IGNITION CIRCUIT The step-up transformer in the ignition control provides spark ignition at 30,000 volts (open circuit). To check the spark ignition circuit, proceed as follows. 1 Shut off gas supply to the gas control 2 Disconnect the ignition cable at the ignition control stud terminal to isolate the circuit from the spark igniter or igniter/sensor 3 Prepare a short jumper lead, using heavily insulated wire such as ignition cable CAUTION... -

Page 17: Start Up Commisioning

COMMISSIONING REPORT AS PER I&O MANUAL AND LOCAL CODES CONTRACTOR NAME: ................DATE........ ADDRESS:............................................................CITY:..................PHONE:................... CELL: ..................JOB SITE......................CITY........ HEATER MODEL NUMBER:................. HEATER SERIAL NUMBER: ................THIS EQUIPMENT HAS BEEN FACTORY FIRED AND TESTED BEFORE DELIVERY, NEVERTHELESS IT IS NOT A PLUG IN APPLIANCE..IT DOES REQUIRE COMMISSIONING AND FIELD ADJUSTMENTS TO ENSURE THAT SITE CONDITIONS ARE COMPATIBLE WITH THIS HEATER, AND TO ALLEVIATE NUISANCE CALL BACKS FOR THE CONTRACTOR, THE FOLLOWING START-UP NEEDS TO BE COMPLETED BY THE LICENSED GAS INSTALLER. - Page 18 TO BE COMPLETED BY THE LICENSED INSTALLER: HIGH INTENSITY COMMISSIONING REPORT TYPE OF GAS: DOES BUILDING HAVE A NEGATIVE CONDITION: WILL HEATER BE EXPOSED TO WELDING FUMES: IS HEATER EXPOSED TO CHEMICAL OR CORROSIVE ATMOSPHERE: IS AN OPEN FLAME COMPATIBLE WITH THE INSTALLED LOCATION: MINIMUM CLEARANCES CONFORM AS PER I&O MANUAL: Feet IF THIS IS A HIGH ALTITUDE AREA WHAT IS THE ALTITUDE ABOVE SEA LEVEL...

-

Page 19: Limited Warranty

Warranty is only applicable to Schwank components, other parts are limited to their own Manufacturers warranty. (1 year)

Need help?

Do you have a question about the X-Series and is the answer not in the manual?

Questions and answers