DKS 6002 Owner's Manual

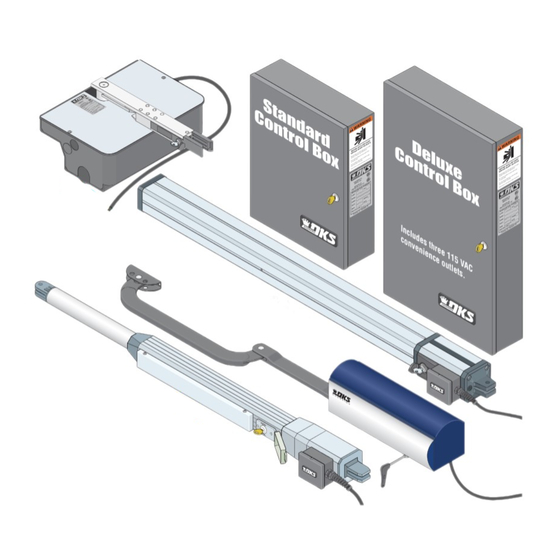

115 vac control boxes for gate operators

Hide thumbs

Also See for 6002:

- Owner's manual (41 pages) ,

- Installation manual (28 pages) ,

- Installation instructions manual (22 pages)

Table of Contents

Advertisement

Quick Links

Wiring / Owner's

Manual

Use this manual for circuit board 4302-010 Revision A or higher.

6 4

0 0

Date Installed:

Installer/Company Name:

Phone Number:

Leave Manual with Owner

UL 325 Compliant

115 VAC Control Boxes for

115 VAC Control Boxes for

115 VAC Control Boxes for

6002, 6003, 6004 and 6400 gate operators

S t

C o

6 0

6 0

0 3

Copyright 2012 DoorKing, Inc. All rights reserved.

a n

d a

I N

n t

R N

W A

r d

r o

l B

C A

E A

N

C A

R D

T E

Y O

G A

U R

in

G

a is

N J

o x

V I N

a re

s .

S I

o n

M O

g a

te

c ti

O U

tr u

e n

a re

R I

w h

b s

d o

g a

te

S E

ly

o n

a n

y in

te

le

g a

o p

p la

p e

te

o f

to

e ra

re n

th ro

O p

e e

il d

d fr

c h

w a

lk

a n

w

o r

ll o

te .

t a

g a

p a

th

n o

g .

tr u

te

te

in s

D o

e ra

g a

v in

o p

m o

ty

o r

d in

a fe

ta n

is

d s

te

t s

g a

a n

n o

il e

a l

n u

D o

w h

m a

p a

th

r' s

n e

o w

a d

R e

T O

M S

O R

-3 2

5

N F

U L

C O

S I/

4 7

A N

T O

D

. 2

A T

N O

IF IE

E R

R T

2 .2

O P

C E

C 2

T E

S A

G A

H P

N /C

A R

C A

U L

H IC

V E

A S

S

C L

L

E

D E

A S

P H

M O

L

H z

R IA

S E

6 0

S

L T

V O

C A

d ,

D

P S

O A

o o

le w

A M

E L

In g

A T

X G

c .,

M A

, In

in g

o rK

D o

0 2

D

O

O

R

K

I

N

G

6 0

Circuit Board

Serial Number

and Revision Letter:

4302-065-E-5-12

G

E

D e

U S

T H

h t

s ig

C o

a

l u

u g

h

s .

o n

n t

c ti

x e

r o

l B

2

38

53

O R

I n c

l u d

c o n

e s

t h r

v e n

e e

i e n

1 1

c e

5 V

o u

t l e

t s .

0 4

Copyright 2009 DoorKing, Inc. All rights reserved.

G

I N

R N

W A

E

U S

C A

T H

E A

N

C A

R D

T E

Y O

h t

s ig

G A

U R

in

G

a is

N J

V I N

a re

s .

S I

o n

M O

g a

te

c ti

O U

tr u

a

e n

a re

R I

w h

b s

d o

g a

te

S E

ly

o n

a n

y in

te

le

g a

o p

p la

p e

u g

h

te

o f

to

e ra

re n

th ro

O p

e e

il d

d fr

c h

w a

lk

s .

a n

w

o r

o n

ll o

te .

t a

g a

p a

th

c ti

n o

g .

tr u

te

te

in s

D o

e ra

g a

v in

o p

m o

ty

o r

d in

a fe

ta n

is

d s

te

t s

g a

a n

n o

il e

a l

n u

D o

w h

m a

p a

th

r' s

n e

o w

o x

a d

R e

2

38

53

T O

M S

O R

-3 2

5

N F

U L

C O

S I/

4 7

O R

A N

T O

D

. 2

A T

N O

IF IE

E R

R T

2 .2

O P

C E

C 2

T E

S A

G A

H P

N /C

A R

C A

U L

H IC

V E

A S

S

C L

L

E

D E

A S

P H

M O

L

H z

R IA

S E

6 0

S

L T

V O

C A

d ,

D

P S

O A

o o

le w

A M

E L

In g

A T

X G

c .,

M A

, In

in g

o rK

D o

A C

TM

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for DKS 6002

- Page 1 Wiring / Owner’s 115 VAC Control Boxes for 115 VAC Control Boxes for 115 VAC Control Boxes for Manual 6002, 6003, 6004 and 6400 gate operators Use this manual for circuit board 4302-010 Revision A or higher. 4302-065-E-5-12 s ig a is...

-

Page 3: Specifications

115 VAC CONTROL BOXES SPECIFICATIONS Class of Operation Models 6002, 6003, 6004 and 6400 - UL325 Class I Type of Gate Residential Vehicular Automated Gates Only Voltage / Phase 115 VAC 60 Hz Single Phase Input Power – 24 VDC Output Power to Gate Operators Back-Up Power 24 VDC battery power during power outages. -

Page 4: Table Of Contents

2.1 3402 Circuit Board Description and Adjustments 2.2 DIP-Switches 17-18 2.3 Limit Sensors Adjustment - Select your specific operator 19-21 6002 Limit Sensors ONLY 6003 Limit Sensors ONLY 6004 Limit Sensors ONLY 6400 Limit Sensors ONLY 2.4 Inherent Reverse Sensor Adjustment 2.5 Shutdown Conditions... -

Page 5: Astm F2200 Standard For Gate Construction

ASTM F2200 Standard for Gate Construction Vehicular gates should be constructed and installed in accordance with ASTM F2200; Standard Specification for Automated Vehicular Gate Construction. For a copy of this standard, contact ASTM directly at 610-832-9585; service@astm.org; or www.astm.org. Important Safety Instructions WARNING - To reduce the risk of injury or death: 1. -

Page 6: Important Notices

• For gate operators utilizing contact sensors: 1. One or more contact sensors shall be located where the risk of entrapment or obstruction exist, such as at the leading edge, trailing edge, and post mounted both inside and outside of a vehicular horizontal slide gate. 2. -

Page 7: Ul 325 Entrapment Protection

UL 325 Entrapment Protection Class I Class II A vehicular gate operator (or system) intended for use in a A vehicular gate operator (or system) intended for use in a home of one-to four single family dwelling, or a garage or commercial location or building such as a multi-family parking area associated therewith. -

Page 8: Glossary

Glossary GATE - A moving barrier such as a swinging, sliding, raising, lowering, or the like, barrier, that is a stand-alone passage barrier or is that portion of a wall or fence system that controls entrance and/or egress by persons or vehicles and completes the perimeter of a defined area. -

Page 9: Swing Gate Requirements

Swing Gate Requirements The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access opening. The pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate such that persons will not come in contact with the vehicular gate during the entire path of travel of the vehicular gate. -

Page 10: Swing Gate Protection

Swing Gate Protection Non-contact Sensor Minimizes the potential Reverse Loop of the gate closing on Minimizes the potential of the gate vehicular or other traffic closing when a vehicle is present. that loops cannot sense. Number and placement of loops is dependent on the application. -

Page 11: Section 1 - Wiring

SECTION 1 - WIRING Before attempting to connect any wiring to the control box, be sure that the circuit breaker in the electrical panel is in the OFF position. Permanent wiring must be installed to the control box as required by local electrical codes. It is recommended that a licensed electrical contractor perform this work. -

Page 12: Wiring Operators To 4302 Circuit Board

1.2 Wiring Operators to 4302 Circuit Board Primary or Secondary Operator Cable Terminal Operator Terminal Note: The 8-pin Brown Wire terminals can be unplugged from circuit board for easy wire connections. Blue Wire Orange Wire Red Wire Yellow Wire Green Wire Green/Yellow Wire Not Used Secondary Operator ONLY... -

Page 13: Secondary Entrapment Protection Wiring

1.3 Secondary Entrapment Protection Wiring In addition to the inherent entrapment sensing system, this operator has provisions for the connection of a non-contact (type B1) secondary entrapment protection device. This is required by UL 325 standards. Entrapment protection devices are required to reduce the risk of injury. Install sensors where the risk of entrapment or obstruction exists while gate is moving. -

Page 14: Main Terminal Description

1.4 Main Terminal Description For specific wiring information, see next page. 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 DC power is not present on the board until first initial cycle of gate. Maglock: SW 2, •... -

Page 15: Main Terminal Wiring

1.5 Main Terminal Wiring Controls must be far enough from the gate so that the user is prevented from coming in contact with the gate while operating the controls. Outdoor or easily accessible controls should have a security feature to prevent unauthorized use. When installing electrical equipment make certain all wiring complies with local code requirements. -

Page 16: Loop Detector Wiring

1.6 Loop Detector Wiring To help protect the operator from accidentally closing on vehicles in the gate’s path, DoorKing highly recommends that loops and loop detectors are used. A loop detection system will sense a vehicle like a metal detector and send a signal to the gate operator preventing the gate from automatically opening or closing on a vehicle when it is in the gate’s path. -

Page 17: High Voltage Wiring And Battery Connection

1.7 High Voltage Wiring and Battery Connection CONTROL BOX MUST BE PROPERLY GROUNDED!! CAUTION Do not connect the battery to the circuit board until power Reset Button is needed to test the operator. Battery Plug AC Power Switch 4302 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Alarm Chassis... -

Page 18: Section 2 - Adjustments

SECTION 2 - ADJUSTMENTS The switch settings and adjustments in this section should be made after your installation and wiring to the operator(s) is complete. Whenever any programming or switch setting on the control board are changed, press the reset switch for new settings to take effect. -

Page 19: Dip-Switches

Drive Motor Orientation Same opening directions as illustrated above for the primary operator type. Opening • Switch 2 will be the SAME setting as switch 1 for the 6002 or 6003 ONLY. Direction of SECONDARY • Switch 2 will be the OPPOSITE setting as switch 1 for the 6004 and 6400 ONLY. -

Page 20: Dip-Switches

2.2 DIP-Switches Continued SW 1 (Top 8 Switches) continued Switch Function Setting Description Auto-close timer is OFF. Manual input required to close gate. Auto-Close Timer Auto-close timer is ON. Adjustable from 1-23 seconds. OFF (normal) Terminal #8 is a standard Reverse input. Reverse On setting is NOT used. -

Page 21: Limit Sensors Adjustment - Select Your Specific Operator

The limit sensors on the operator MUST be adjusted to control the travel of the gate and to precisely set the full open and full closed position of the gate. Use ONLY the limit sensor instructions for your specific operator type (6002, 6003, 6004 or 6400). - Page 22 2.3 Limit Sensors Adjustment Continued 6004 Limit Switches ONLY Power to the circuit board must be ON when adjusting the limit sensors. v e r With operator cover removed, un-lock operator with Limit Switch Adjustment Note: release tool to release arm. Two thru-bolts 13 mm can be loosened to allow the electronic pallet to be moved around a little.

-

Page 23: 6400 Limit Sensors Only

2.3 Limit Sensors Adjustment Continued 6400 Limit Sensors ONLY Power to the circuit board must be ON when adjusting the limit sensors. With operator cover plate removed, un-lock release handle and pull handle to release gate. Embedded magnet on underside activates limit sensors when it passes over them. - Page 24 2.4 Inherent Reverse Sensor Adjustment This vehicular gate operator is equipped with an inherent (Built-In) adjustable reversing sensor (Type A) that is used as the primary entrapment sensing system according to the UL 325 standards. The gate will reverse direction upon encountering an obstruction in either the opening or closing gate cycle. For the reverse system to function correctly, the gate must be properly installed and work freely in both directions.

-

Page 25: Shutdown Conditions

2.5 Shutdown Conditions Under various entrapment conditions the operator will assume either a SOFT or HARD (alarm) shutdown. To determine what type of reset action is required, you will need to understand how the different entrapment conditions affect the gate operator. Soft Shutdown This occurs in various situations where the inherent or secondary entrapment protection devices have been activated. -

Page 26: Hard Shutdown (Alarm Activated)

2.5 Shutdown Conditions Continued Hard Shutdown (Alarm Activated) A hard shutdown condition occurs when: (1.) The inherent entrapment protection system (Type A) gets activated TWO consecutive times before the gate completes the open or close cycle. (2.) The reversing edge (Type B2) gets activated and reverses but before the gate completes the reverse cycle the inherent entrapment protection system (Type A) gets activated. -

Page 27: Section 3 - Maintenance And Troubleshooting

SECTION 3 - MAINTENANCE AND TROUBLESHOOTING Inspection and service of this gate operator by a qualified technician should be performed anytime a malfunction is observed or suspected. High cycle usage may require more frequent service checks. 3.1 Maintenance When servicing the gate operator, always check any secondary (external) reversing devices (loops, photo sensors, etc.) for proper operation. -

Page 28: Troubleshooting

3.2 Diagnostics Check Continued 4. Check that there are no shorted or open control wires from the keying devices to the gate operator. If a keying device fails to open the gate, momentarily jumper across terminals 1 and 2 on the control board. If the gate operator starts, this indicates that a problem exist with the keying device and not with the gate operator. -

Page 29: Accessory Items

3.3 Troubleshooting Continued Symptom Possible Solution • Disconnect the gate from the operator and check that the gate operates freely without any binding. Gate starts to close, • Check the loop detector LED’s and input LED’s. Any that flash ON will cause the gate to reverse. then reverses to •... -

Page 30: 115 Vac Standard Or Deluxe Control Box Schematics

115 VAC Standard or Deluxe Control Box 12 V – 3 Amp/Hr Battery Black Secondary Operator Battery Connector ONLY Plug Black – Primary Operator Connector ONLY 12 V 3 Amp/Hr Battery 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Black P/N 4302-112 P/N 4302-111... -

Page 31: Important Information For Owner

IMPORTANT INFORMATION FOR OWNER Shut-Off ALL Power to Operator OR Shut-Off Alarm Turn OFF AC power switch AND carefully disconnect battery plug from circuit board to shut-off ALL power to operator. 4302 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Push button to SHUT-OFF alarm. -

Page 32: Manually Operating The Gate (No Power)

IMPORTANT INFORMATION FOR OWNER Manually Operating the Gate (NO Power) 6002 Manual Release ONLY ALL power to the operator must be OFF BEFORE manually operating gate (See previous page). 0 ° v e r Insert allen wrench Use key to unlock and remove the cover. Remove allen wrench from inside of cover. - Page 33 4302-065-E-5-12...

-

Page 34: 4302-065

Wiring / Owner’s 115 VAC Control Boxes for 115 VAC Control Boxes for 115 VAC Control Boxes for Manual 6002, 6003, 6004 and 6400 gate operators Use this manual for circuit board 4302-010 Revision A or higher. 4302-065-E-5-12 www.doorking.com DoorKing, Inc.

Need help?

Do you have a question about the 6002 and is the answer not in the manual?

Questions and answers