Summary of Contents for Avdel 74405

- Page 1 I n s t r u c t i o n M a n u a l O r i g i n a l I n s t r u c t i o n 7 4 4 0 5 H y d ro - P n e u m a t i c P o w e r To o l...

-

Page 3: Table Of Contents

AND REMEDIES. ANY IMPLIED WARRANTY AS TO QUALITY, FITNESS FOR PURPOSE, OR MERCHANTABILITY ARE HEREBY SPECIFICALLY DISCLAIMED AND EXCLUDED BY AVDEL. Avdel UK Limited policy is one of continuous product development and improvement and we reserve the right to change the specification of any product without prior notice. -

Page 4: Safety Instructions

Any modification undertaken by the customer to the tool/machine, nose assemblies, accessories or any equipment supplied by Avdel UK Limited or their representatives, shall be the customer’s entire responsibility. Avdel UK Limited will be pleased to advise upon any proposed modification. -

Page 5: Tool Specification For Intensifier

S p e c i f i c a t i o n s To o l S p e c i f i c a t i o n f o r 7 4 4 0 5 Air Pressure Minimum - Maximum 5-7 bar 60 - 100 lbf/in... -

Page 6: Intent Of Use

I n t e n t o f U s e ® The hydro-pneumatic 74405 tool is designed to place Avdel Threaded Inserts at high speed making it ideal for batch or flow-line assembly in a wide variety of applications throughout all industries. -

Page 7: Putting Into Service

P u t t i n g i n t o S e r v i c e A i r S u p p l y All tools are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators and filtering systems on the main air supply. -

Page 8: Stroke Adjustment

P u t t i n g i n t o S e r v i c e S t ro k e A d j u s t m e n t This adjustment is necessary to insure optimum insert deformation. It is suggested, therefore, that a test plate with the same thickness and hole size as the workpiece is used. -

Page 9: Fitting Instructions

(Item numbers in bold refer to illustration below, 51* refers to illustration on page 16). LOCK NUT SPINDLE FRICTION RING ADAPTOR NUT NOSE CASING * Items in grey are included in the base tool. * Item included in the 74405 Service Kit. For complete list see page 11. -

Page 10: Servicing Instructions

S e r v i c i n g I n s t r u c t i o n s • Remove the nose equipment using the reverse procedure to the ‘Fitting Instructions’ (see page 9). • Any worn or damaged part should be replaced. •... -

Page 11: Servicing The Tool

We e k l y • Check for oil leaks and air leaks on air supply hose and fittings. For all servicing we recommend the use of the Service Kit, part number 74405-99990, detailed below. SERVICE KIT : 74405-99990 PART Nº... -

Page 12: Moly Lithium Grease Ep 3753 Safety Data

S e r v i c i n g t h e To o l M o l y L i t h i u m G r e a s e E P 3 7 5 3 S a f e t y D a t a Grease can be ordered as a single item, the part number is shown in the Service Kit page 11. -

Page 13: Maintenance

When reassembling, clean threads of air motor and piston and assemble using Loctite ® 243. • *refers to items included in the 74405 Service Kit. For a complete list see page 11. Item numbers in bold refer to the Base Tool General Assembly drawings and Parts Lists pages 16-17. -

Page 14: Air Motor Assembly

• Assemble in reverse order to dismantling. *refers to items included in the 74405 Service Kit. For a complete list see page 11. Item numbers in bold refer to the Base Tool General Assembly drawing and Parts List pages 16-17. -

Page 15: Intensifier

Priming is ALWAYS necessary after the tool has been dismantled and prior to operating. * Refers to items included in the 74405 Service Kit. For complete list see page 11. Items in bold refer to the Intensifier General Assembly drawing and Parts List on pages 18-19. - Page 16 H e a d A s s e m b l y 7 4 4 0 5 - 1 2 0 0 0 General Assembly...

-

Page 17: Head Assembly Parts List

H e a d A s s e m b l y 7 4 4 0 5 - 1 2 0 0 0 P a r t s L i s t... -

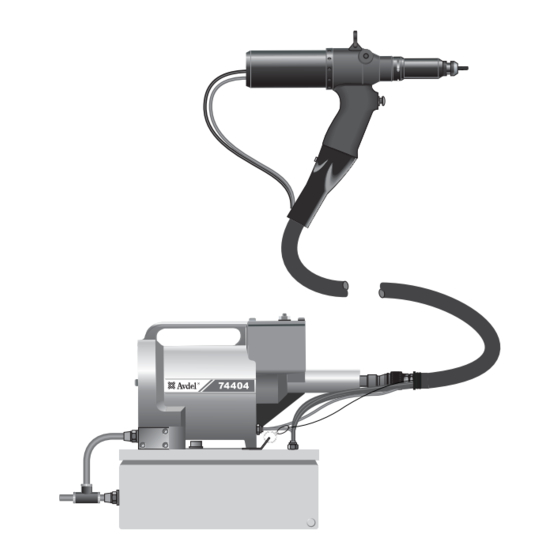

Page 18: Intensifier General Assembly

I n t e n s i f i e r 7 4 4 0 4 - 0 2 0 0 0 G e n e r a l A s s e m b l y... -

Page 19: Intensifier Parts List

I n t e n s i f i e r 7 4 4 0 4 - 0 2 0 0 0 P a r t s L i s t... -

Page 20: Hand Tool General Assembly And Parts List

H a n d To o l 7 4 4 0 5 - 0 1 0 0 0 G e n e r a l A s s e m b l y a n d P a r t s L i s t 74405-01000 PARTS LIST ITEM PART Nº... -

Page 21: Priming

P r i m i n g Priming is ALWAYS necessary after the tool has been dismantled and prior to operating. It may also be necessary to restore the full stroke after considerable use, when the stroke may have been reduced and fasteners are not now being fully placed by one operation of the trigger. -

Page 22: Priming Procedure

P r i m i n g P r i m i n g P ro c e d u r e I M P O R T A N T All operations should be carried out on a clean bench, with clean hands in a clean area. Ensure that the new oil is perfectly clean and free from air bubbles. -

Page 23: Fault Diagnosis

Screw adaptor nut loose Tighten No air supply Connect Item numbers in bold refer to the Base Tool General Assembly drawing and Parts List pages 16-17. Other symptoms or failures should be reported to your local Avdel authorised distributor or repair centre. -

Page 24: Symptom, Possible Cause And Remedy

F a u l t D i a g n o s i s S y m p t o m , P o s s i b l e C a u s e a n d R e m e d y S Y M P T O M P O S S I B L E C A U S E R E M E D Y... - Page 25 N o t e s...

- Page 26 N o t e s...

- Page 27 D e c l a r a t i o n o f C o n f o r m i t y We, Avdel UK Limited, Watchmead Industrial Estate, Welwyn Garden City, Herts, AL7 1LY declare under our sole responsibility that the product: Model 74405 Serial No.

- Page 28 This document is for informational purposes only. Infastech makes no warranties, expressed or implied, in this document. Data shown is subject to change without prior notice as a result of continuous product development and improvement policy. Your local Avdel representative is at your disposal should you need to confirm latest information.