Table of Contents

Advertisement

Quick Links

INTRODUCTION

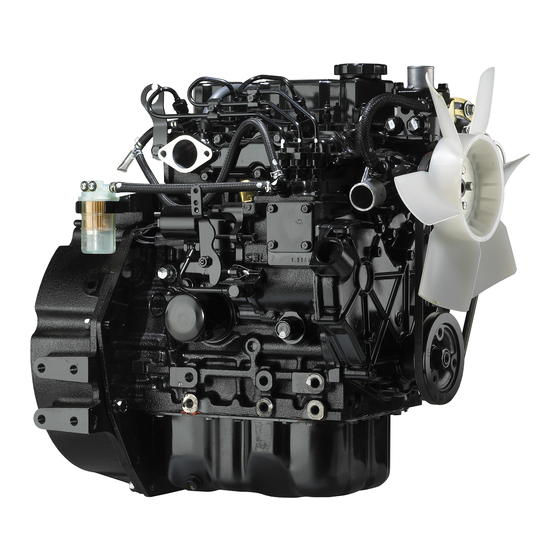

This service manual has instructions and procedures for the Mitsubishi SL-series diesel engines.

The information, specifications and illustrations in this manual are on the basis of the information that was current at

the time this issue was written.

Correct servicing, test and repair procedures will give the engine a long service life. Before starting a test, repair or

rebuild job, the serviceman must read the respective sections of this manual to know all the component he will work

on.

Continuing improvement of product design may have caused changes to your engine which are not included in this

manual.

Whenever a question arises regarding your engine, or this manual, consult your Mitsubishi dealer for the latest

available information.

Service Manual

Mitsubishi SL-Series diesel engines

Version 08/2004

Copyright © 2004 MHI Equipment Europe B.V.

ENGLISH

1 / 195

Service Manual Mitsubishi SL-Series diesel engines

Version 08/2004

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Mitsubishi S3L

- Page 1 Continuing improvement of product design may have caused changes to your engine which are not included in this manual. Whenever a question arises regarding your engine, or this manual, consult your Mitsubishi dealer for the latest available information. Service Manual...

-

Page 2: How To Use This Manual

Tighten bolts, nuts, etc. in a wet condition (apply oil to threads) when specified as [WET]. Tighten them in a dry condition unless so specified. Use the general tightening torques unless otherwise specified. 2 / 195 2 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 3: Table Of Contents

14.3 Cylinder head bolt removal ....................44 14.4 Cylinder head assembly removal................... 45 14.5 Valve and valve spring removal ..................... 45 14.6 Valve stem seal removal......................45 Timing Gears and Flywheel......................46 Service Manual Mitsubishi SL-Series diesel engines ENGLISH 3 / 195 Version 08/2004... - Page 4 20.7 Piston and connecting rod installation ................... 87 20.8 Connecting rod cap installation....................88 20.9 Oil screen installation......................89 20.10Oil pan installation........................89 Timing Gears and Flywheel......................91 21.1 Front plate installation......................92 4 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

- Page 5 28.2 Wiring diagrams ........................113 STARTER............................115 29.1 Disassembly......................... 115 29.2 Inspection..........................116 29.3 Assembly ..........................119 29.4 Inspection and Testing after Assembly ................120 ALTERNATOR ..........................122 Service Manual Mitsubishi SL-Series diesel engines ENGLISH 5 / 195 Version 08/2004...

- Page 6 41.2 Assembly ..........................160 41.3 Torque spring set installation ....................161 FUEL PUMP..........................162 42.1 Inspection..........................162 FUEL FILTER..........................163 AIR INLET SYSTEM AND EXHAUST SYSTEM GENERAL ............................. 166 6 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

- Page 7 56.1 Major bolts and nuts......................191 56.2 Torques for bolts and nuts with standard threads..............192 56.3 Torques for plugs with taperlock threads ................192 SEALANTS............................ 193 SPECIAL TOOLS .......................... 194 Service Manual Mitsubishi SL-Series diesel engines ENGLISH 7 / 195 Version 08/2004...

- Page 8 TABLE OF CONTENTS 8 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 9: General Information

GENERAL INFORMATION ENGLISH 9 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 10: Model Identification And Serial Number Location

L - Series code [Bore: 78 mm (3.07 in.)] (2) - Stroke code • (No code: 78.5 mm (3.09 in.) • 2: 92 mm (3.62 in.) 61 - Export code A - Specification code 10 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 11: Serial Number Location

General NUMBER LOCATION Serial Number Location The serial number is punched on the cylinder block, near the fuel injection pump mount. Serial number Figure 2 Serial number location ENGLISH 11 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 12: Component Location

Oil drain plug REAR FRONT RIGHT SIDE VIEW Thermoswitch Exhaust manifold Thermostat Hanger Flywheel housing Alternator Starter Flywheel V-belt Oil pan FRONT REAR LEFT SIDE VIEW 12 / 195 12 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 13: Engine S3L-T/S3L2-T

Oil filter Oil drain plug REAR FRONT RIGHT SIDE VIEW Thermoswitch Turbocharger Exhaust manifold Thermostat Hanger Flywheel housing Alternator Starter V-belt Flywheel Oil pan FRONT REAR LEFT SIDE VIEW Service Manual Mitsubishi SL-Series diesel engines ENGLISH 13 / 195 Version 08/2004... -

Page 14: S4L/S4L2

Oil drain plug Dipstick RIGHT SIDE VIEW REAR FRONT Thermoswitch Exhaust manifold Thermostat Hanger Flywheel housing Alternator Starter Flywheel V-belt Oil pan FRONT REAR LEFT SIDE VIEW 14 / 195 14 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 15: Engine S4L-T/S4L2-T

Oil drain plug Dipstick RIGHT SIDE VIEW REAR FRONT Thermoswitch Turbocharger Exhaust manifold Thermostat Hanger Flywheel housing Alternator Starter Flywheel V-belt Oil pan FRONT LEFT SIDE VIEW REAR Service Manual Mitsubishi SL-Series diesel engines ENGLISH 15 / 195 Version 08/2004... -

Page 16: Specifications

12V, 65 Ah or more 12V, 80 Ah or more (capacity depends on application) Table 1 Specifications 1. All specifications are subject to change without any prior notice. 16 / 195 16 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 17: Overhaul Instructions

OVERHAUL INSTRUCTIONS ENGLISH 17 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 18: Determining When To Overhaul The Engine

(4): in actually determining when to overhaul the engine, it is reasonable to take this trouble into account in conjunction with the other ones. 18 / 195 18 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 19: Compression Pressure Measurement

It drops as the engine [3 138] [2 452] components wear down. Maximum permissible difference between average compression (42.7) pressure of all cylinders in one [294] engine, kgf/cm2 (psi) [kPa] ENGLISH 19 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 20: Troubleshooting

Hunting (when the engine speed is quickly decreased) • Some white exhaust smoke (when the engine is cold, or shortly after the engine has been started) 20 / 195 20 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 21: Engine Troubleshooting

Is fuel injection nozzle discharge pattern normal? Is injection pressure Make adjustment to the correct? nozzles. Check valves, piston rings Is compression pressure correct? and cylinder head gasket. Fuel injection pump is faulty. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 21 / 195 Version 08/2004... - Page 22 Is injection pressure (injection nozzle valve opening pressure) correct (not Make adjustment to the too low)? pressure. Check valves, piston rings, Is compression pressure correct? and cylinder head gasket. Fuel injection pump is faulty. 22 / 195 22 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

- Page 23 Are lubrication system components (oil filter, oil pump and oil screen) Check the components and normal and oil level correct? oil level. Make adjustment to the Is governor adjustment correct? governor. Engine is in continuous full- load operation. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 23 / 195 Version 08/2004...

- Page 24 Make adjustment to the (not too high)? nozzles. Check valves, piston rings Is compression pressure correct? and cylinder head gasket. Fuel injection pump is faulty. 24 / 195 24 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

- Page 25 Make adjustment to the constant? nozzles. Is compression pressure correct (no difference in compression pressure Check valves, piston rings between cylinders)? and cylinder head gasket. Fuel injection pump is faulty. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 25 / 195 Version 08/2004...

- Page 26 Make adjustment to the Is injection pressure correct? nozzles. Check valves, piston rings Is compression pressure correct? and cylinder head gaskets. Fuel injection pump is faulty. 26 / 195 26 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 27: Starting System Troubleshooting

Pinion shifted excessively Pinion is forced into mesh with ring gear again when starter is Overrunning clutch shell peeled coasting Pinion chamfered insufficiently or wrong Pinion is chipped Service Manual Mitsubishi SL-Series diesel engines ENGLISH 27 / 195 Version 08/2004... - Page 28 Incorrect wiring S and B circuits shorted Make reference to “Key not returning completely” [Other possibility is sticking pinion metal in case of overrun trouble.] 28 / 195 28 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 29: Basic Precautions For Disassembly And Assembly

BASIC PRECAUTIONS FOR DISASSEMBLY AND ASSEMBLY This section outlines basic precautions recommended by Mitsubishi that should always be observed. Disassembly Always use tools that are in good condition and be sure you understand how to use them before performing any job. - Page 30 BASIC PRECAUTIONS FOR DISASSEMBLY AND ASSEMBLY OVERHAUL INSTRUCTIONS 30 / 195 30 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 31: Disassembly

DISASSEMBLY ENGLISH 31 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 32: Preparation For Disassembly

S3L/S3L2: 1.8 (0.5) liter (U.S. gal) S4L/S4L2: 2.5 (0.7) Figure 6 Draining coolant 1. Please refer to the applicable engine model specification sheet for actual data 32 / 195 32 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 33: Electrical System

• When measuring the starter speed at the end of the pinion, be ready for accidental shifting of the pinion. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 33 / 195 Version 08/2004... - Page 34 Due to the amount of current being passed through the solenoid series winding, this test must be made within 10 seconds. Figure 10 Connections for testing hold-in coil 34 / 195 34 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 35: Alternator

Ground return circuit defective Wiring incorrect Figure 13 Alternator on engine Series resistor or winding open-circuited Alternator drive belt loose Voltage regulator setting too low Alternator output low Brushes worn Service Manual Mitsubishi SL-Series diesel engines ENGLISH 35 / 195 Version 08/2004... - Page 36 13.5 volts. Figure 15 Connections for testing output characteristics (alternator with built-in regulator) 36 / 195 36 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

- Page 37 Disconnect the connector from the alternator. Loosen the brace and support bolts. Move the alternator toward the engine and remove the drive belt. Remove the alternator. Figure 16 Removing alternator Service Manual Mitsubishi SL-Series diesel engines ENGLISH 37 / 195 Version 08/2004...

-

Page 38: Cooling System

Remove the water pump assembly. Figure 18 Removing thermostat assembly 10.3 Water pump assembly removal Remove the water pump assembly. Figure 19 Removing water pump assembly 38 / 195 38 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 39: Fuel System

Remove the spring from the tie rod with a pliers to disconnect the tie rod from the fuel injection pump. Remove the governor assembly. Figure 22 Removing governor assembly Service Manual Mitsubishi SL-Series diesel engines ENGLISH 39 / 195 Version 08/2004... -

Page 40: Governor Weight Removal

Removing tie rod Remove the fuel injection pump. NOTE Keep a record of the thickness of shims for installation. Figure 25 Removing fuel injection pump 40 / 195 40 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 41: Lubrication System

Removing pressure relief valve 12.3 Oil pressure switch removal Remove the oil pressure switch with Oil Pressure Switch Socket Wrench (MD998054) (special tool). Figure 28 Removing oil pressure switch Service Manual Mitsubishi SL-Series diesel engines ENGLISH 41 / 195 Version 08/2004... -

Page 42: Air Inlet System And Exhaust System

Figure 29 Removing exhaust manifold 13.2 Air inlet cover removal Remove the air inlet cover from the cylinder head. Figure 30 Removing air inlet cover 42 / 195 42 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 43: Cylinder Head And Valve Mechanism

Cylinder head Valve spring Rocker shaft assembly Cylinder head gasket 10. Valve Valve push rod Valve lock 11. Valve stem seal Cylinder head bolt Valve retainer 12. Valve cap ENGLISH 43 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 44: Rocker Shaft Assembly Removal

If any parts on the cylinder head are faulty, check the cylinder head bolts for tightness with a torque wrench before loosening them. Figure 33 Cylinder head bolt loosening sequence 44 / 195 44 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 45: Cylinder Head Assembly Removal

Remove the valve stem seals with a pliers. NOTE Do not reuse the valve stem seals, but replace them by new ones. Figure 36 Removing valve stem seals ENGLISH 45 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 46: Timing Gears And Flywheel

Speedometer driven gear assembly.) 15. Fuel injection pump camshaft P.T.O. gear 10. Camshaft gear 16. Oil pump 11. Thrust plate 17. Front plate 12. Camshaft 46 / 195 46 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 47: Service Manual Mitsubishi Sl-Series Diesel Engines English

Removing flywheel 15.2 Rear plate removal The rear plate is doweled in position. Pull the plate as straight as possible when removing it. Front Figure 39 Removing rear plate Service Manual Mitsubishi SL-Series diesel engines ENGLISH 47 / 195 Version 08/2004... -

Page 48: Oil Seal Case Removal

Remove the lock plate and speedometer driven gear in that order. NOTE Unless the speedometer driven gear is removed, the camshaft cannot be removed. Figure 42 Removing speedometer driven gear 48 / 195 48 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 49: Crankshaft Pulley Removal

Camshaft gear and 0.08 to 0.19 P.T.O. gear (0.003 1 to 0.007 5) Fuel injection pump 0.07 to 0.20 camshaft gear and oil (0.002 8 to 0.007 9) pump gear Service Manual Mitsubishi SL-Series diesel engines ENGLISH 49 / 195 Version 08/2004... -

Page 50: Idler Gear Removal

Do not cause damage to the lobes or bearing journals when removing the camshaft. Figure 47 Removing camshaft 15.11 Fuel injection pump camshaft removal Remove the stopper bolt. Figure 48 Removing camshaft stopper bolt 50 / 195 50 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 51: Gear Removal (When Required)

15.14 Front plate removal Remove four bolts that hold the front plate in position. Tap the plate lightly with a plastic hammer to separate the gasket. Figure 51 Removing front plate Service Manual Mitsubishi SL-Series diesel engines ENGLISH 51 / 195 Version 08/2004... -

Page 52: Cylinder Block, Crankshaft, Pistons And Oil Pan

Connecting rod 16. Cylinder block NOTE: When the cylinder block is to be discarded, remove the components (pressure relief valve, etc.) from the block for reuse. 52 / 195 52 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 53: Oil Pan Removal

Limit Thrust clearance for 0.10 to 0.35 0.50 connecting rod big (0.003 9 to 0.013 8) (0.019 7) Figure 54 Measuring thrust clearance for connecting rod big end ENGLISH 53 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 54: Connecting Rod Cap Removal

Standard Limit End play for 0.050 to 0.175 0.500 (0.019 crankshaft end (0.001 97 to 0.006 89) play Figure 57 Measuring end play for crankshaft 54 / 195 54 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 55: Main Bearing Cap Removal

16.9 Piston separation from connecting rod Use Piston Pin Setting Tool (31A91-00100) (special tool) to separate the piston from the connecting rod. Figure 60 Piston pin setting tool ENGLISH 55 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 56 Do not attempt to remove the piston pin by tapping. Replace a piston pin which needs a greater force for removal. Figure 62 Removing piston pin (2) 56 / 195 56 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 57: Inspection

INSPECTION ENGLISH 57 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 58: Cylinder Head And Valve Mechanism

Check ends for wear or damage Check for cracks, Check for bend oil or coolant leaks. Remove gasket, scale and carbon deposits Figure 63 Inspection points 58 / 195 58 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 59: Cylinder Head

18.880 to — for arm (0.744) 18.898 (0.743 31 to 0.744 01) Clearance — 0.012 to 0.200 between rocker 0.050 (0.007 arm and shaft (0.000 47 to 0.001 97) ENGLISH 59 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 60: Valve Springs

Figure 68 Measuring valve stem stem (0.258 46 to 0.259 05) 6.500 (0.255 91) Exhaust 6.530 to valve (0.260) 6.550 (0.257 09 to 0.257 87 60 / 195 60 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 61 After the valve guide has been replaced, check the valve contact with its seat. Figure 70 Height to top of valve guide ENGLISH 61 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

- Page 62 Valve margin and sinkage Item Standard Limit Valve sinkage 0.5 ± 0.25 (dimension from top (0.020 ± 0.009 8) (0.059) of closed valve to face of head) 62 / 195 62 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

- Page 63 After refacing the valve seat, put lapping compound on the valve face and lap the valve in the valve seat. Figure 76 Valve seat width and valve face angle ENGLISH 63 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 64: Combustion Jet Replacement

Combustion jet Figure 78 Removing combustion jet 64 / 195 64 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 65 The new jet must be flush with the cylinder head surface. Figure 79 Installing combustion jet ENGLISH 65 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 66: Timing Gears And Flywheel

Check clutch contact face for scores or ridges. Check ring gears for damage or wear. Check for wear, damage or aging. Figure 80 Inspection points 66 / 195 66 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 67: Camshaft

Remove the oil pan. Using a “remover” end of the Installer, push out the bushing into the cylinder block. Crush and take out the bushing from the block. Camshaft Bushing Installer Figure 83 Removing camshaft bushing Service Manual Mitsubishi SL-Series diesel engines ENGLISH 67 / 195 Version 08/2004... -

Page 68: Fuel Injection Pump Camshaft

.Unit: mm (in.) Item Standard Limit Lobe height of fuel injection pump (1.73) (1.69) camshaft Figure 86 Measuring lobe height of fuel injection pump camshaft 68 / 195 68 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 69: Tappets

.Unit: mm (in.) Item Standard Limit Clearance between 0.03 to 0.07 0.20 idler gear and shaft (0.001 2 to 0.002 8) (0.007 9) Figure 89 Measuring idler gear and shaft Service Manual Mitsubishi SL-Series diesel engines ENGLISH 69 / 195 Version 08/2004... -

Page 70: Flywheel And Ring Gear

Heat a new ring gear up to a temperature of 150°C (302°F) with a piston heater and install it to the flywheel with its unchamfered side foremost. Figure 92 Removing ring gear 70 / 195 70 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 71: Cylinder Block, Crankshaft, Pistons And Oil Pan

CAUTION Do not reuse crankshaft if it shows evidence of overheating. Scratches Loss of overlay Defect due to poor installation Figure 93 Points à inspecter ENGLISH 71 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 72: Pistons, Piston Rings And Piston Pins

0.20 (0.001 2 to 0.002 8) (0.007 9) If the clearance still exceeds the limit after new piston rings have been installed, replace the piston. 72 / 195 72 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 73 0.15 to 0.35 between 1.50 compression (0.005 9 to ends of (0.059 1) ring 0.013 8) piston ring Oil ring 0.20 to 0.40 (0.007 9 to 0.015 7) ENGLISH 73 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 74: Connecting Rods

To check the rod for bend, install the cap to the connecting rod and tighten the cap nuts to the specified torque. Figure 99 Check connecting rod on a connecting rod aligner 74 / 195 74 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 75: Crankshaft

If the clearance still exceeds the limit, grind the crankpin to 0.25 mm (0.0098 in.), 0.50 mm (0.0197 in.) or 0.75 mm (0.0295 in.) undersize and use undersize connecting rod bearing. ENGLISH 75 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 76 Tightening torque 5.25 ± 0.25 kgf·m (38 ± 1.8 lbf·ft) [51.5 ± 2.5 N·m] Figure 104 Measuring bore in main bearing 76 / 195 76 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

- Page 77 Figure 106 Journal fillet radius • Grind all the journals of one crankshaft to the same undersize. • Finish the journal fillets to a radius of 2 mm (0.08 in.). ENGLISH 77 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

- Page 78 Install the gear in position with its keyway in alignment with the key as shown in the illustration. To be aligned Figure 109 Installing crankshaft gear 78 / 195 78 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 79: Cylinder Block

Figure 111 Checking cylinder block top face for .Unit: mm (in.) warpage Item Standard Limit Warpage of cylinder 0.05 (0.002 0) 0.10 block top face maximum (0.003 9) ENGLISH 79 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 80 CYLINDER BLOCK, CRANKSHAFT, PISTONS AND OIL PAN INSPECTION 80 / 195 80 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 81: Assembly

ASSEMBLY ENGLISH 81 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 82: Cylinder Block, Crankshaft, Pistons And Oil Pan

[27.5 ± 3 N m] Plate oil pan: 1.15 ± 0.15 kgf m (8.3 ± 1.1 lbf ft) [11.3 ± 1.5 N m] Figure 112 Inspection points 82 / 195 82 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 83: Main Bearing Installation

(arrow head) on the main bearing cap is toward the front of the engine. Tighten the main bearing cap bolts finger tight only. Figure 115 Main bearing caps installed ENGLISH 83 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 84 (page 42). If the end play is incorrect, loosen the bolts holding the main bearing caps once and tighten them again. Figure 118 Checking crankshaft for rotation 84 / 195 84 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 85: Side Seal Installation

Put the connecting rod on the Tool and lubricate the bore in the rod for the piston pin with engine oil. Figure 121 Connecting rod on Piston Setting Tool ENGLISH 85 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 86 Figure 123 Pressing piston pin After assembling the piston and connecting rod, make sure the connecting rod moves freely. Figure 124 Checking piston and connecting rod 86 / 195 86 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 87: Piston Ring Installation

(arrow head) on the top of the piston toward Figure 127 Relative location of piston ring end gaps the front (timing gear case side) of the engine. ENGLISH 87 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 88: Connecting Rod Cap Installation

(25.7 ± 2 lbf·ft) Tightening torque [34.8 ± 2.5 N·m] Figure 130 Tightening connecting rod cap nuts Check the thrust clearance for the connecting rod big end. 88 / 195 88 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 89: Oil Screen Installation

Squeeze out a 4 mm (0.2 in.) thick bar of sealing compound (Three Bond) from the tube and put it on the flange of the oil pan as shown. Figure 133 Oil pan for S4L and S4L2 engines ENGLISH 89 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 90 Cylinder Block, Crankshaft, Pistons and Oil pan ASSEMBLY Figure 134 Oil pan for S3L and S3L2 engines To squeeze out a 4 mm (0.2 in.) thick bar, cut the nozzle of the tube as shown. Cut nozzle here Figure 135 Cutting sealing compound tube nozzle...

-

Page 91: Timing Gears And Flywheel

Tightening torque: 13.5 ± 0.5 kgf m (98 ± 4 lbf ft) [132 ± 5 N m] Use a new gasket Use a new gasket Figure 137 Inspection points Service Manual Mitsubishi SL-Series diesel engines ENGLISH 91 / 195 Version 08/2004... -

Page 92: Front Plate Installation

Put a bar between the bolts and turn the crankshaft to bring No. 1 piston to the top center as shown in the illustration. Figure 140 Turning engine 92 / 195 92 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 93: Engine Turning

(38 ± 2 lbf·ft) Tightening torque [51.5 ± 2.5 N·m] Make sure the camshaft rotates freely. Check the end play for the camshaft. Figure 143 Installing thrust plate Service Manual Mitsubishi SL-Series diesel engines ENGLISH 93 / 195 Version 08/2004... -

Page 94: Idler Gear Installation

Tightening torque [172 ± 25 N·m] WARNING Figure 146 Tightening crankshaft pulley nut Check the strength of the bolts and bar used for holding the crankshaft. 94 / 195 94 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 95: Gear Installation

Figure 148 Installing speedometer driven gear 21.11 Tappet installation Lubricate the tappets with engine oil and put them in position in the cylinder block. Figure 149 Installing tappets Service Manual Mitsubishi SL-Series diesel engines ENGLISH 95 / 195 Version 08/2004... -

Page 96: Oil Seal Case Installation

Remove the safety bar. Install the last bolt in the flywheel and tighten it finger tight only. Figure 152 Safety bar 96 / 195 96 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 97 13.5 ± 0.5 kgf·m (98 ± 4 lbf·ft) Tightening torque [132 ± 5 N·m] WARNING Always signal each other to prevent possible personal injury. Figure 153 Tightening flywheel bolts Service Manual Mitsubishi SL-Series diesel engines ENGLISH 97 / 195 Version 08/2004...

-

Page 98: Cylinder Head And Valve Mechanism

9 ± 0.5 kgf m (65 ± 4 lbf ft) [88 ± 5 N m] Use a new part Use a new gasket Lubricate stem with engine oil Figure 154 Inspection points 98 / 195 98 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 99: Cylinder Head Bottom Face Cleaning

Figure 156 Installing valve stem seal 22.3 Valve spring installation White enameled Install the valve spring with the white enameled end up. Figure 157 Installing valve spring ENGLISH 99 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 100: Installing Valve Block

Put the cylinder head in position on the cylinder block, making sure the guide bolts are all in alignment with their respective bolt holes in the head. Figure 160 Installing cylinder head 100 / 195 100 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 101: Cylinder Head Bolt Tightening

Install the rocker arms, brackets and springs on the rocker shaft. Secure the brackets to the shaft by tightening the bolts. Bolt Make sure the rocker arms move freely. Figure 163 Assembling rocker arms ENGLISH 101 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 102: Rocker Shaft Assembly Installation

Tighten the bolts that hold the rocker cover to the specified torque. 1.15 ± 0.15 kgf·m (8.3 ± 1.1 lbf·ft) Tightening torque [11.3 ± 1.5 N·m] Figure 166 Installing rocker cover 102 / 195 102 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 103: Air Inlet System And Exhaust System

23.2 Exhaust manifold installation Tighten the bolts that hold the exhaust manifold to the specified torque. 1.85 ± 0.35 kgf·m (13.4 ± 2.5 lbf·ft) Tightening torque [18 ± 3.4 N·m] Service Manual Mitsubishi SL-Series diesel engines ENGLISH 103 / 195 Version 08/2004... -

Page 104: Fuel System

3.6 ± 0.6 kgf·m (26 ± 4.3 lbf·ft) Tightening torque [35 ± 6 N·m] Figure 169 Installing flyweight assembly 104 / 195 104 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 105: Sliding Sleeve Installation

Put the fuel injection lines in position and connect them to the fuel injection pump. Install the clamps. Figure 172 Installing fuel injection lines Service Manual Mitsubishi SL-Series diesel engines ENGLISH 105 / 195 Version 08/2004... -

Page 106: Lubrication System

Put the sealant on the threads only. Do not over-tighten the oil pressure switch when To be coated with it is installed. thread sealant Figure 175 Installing oil pressure switch 106 / 195 106 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 107: Cooling System

Install the spacers in position in the fan as shown. Install the pulley in position on the water pump. Install the fan and spacer combination in position on the pulley. Figure 178 Installing cooling fan Service Manual Mitsubishi SL-Series diesel engines ENGLISH 107 / 195 Version 08/2004... -

Page 108: Thermoswitch And Thermounit Combination Installation

Coat the threads of the combination with Three Bond 1104. Put the combination in position and tighten it to the specified torque. Figure 179 Installing thermoswitch and thermounit combination 108 / 195 108 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 109: Electrical System

Figure 181 Installing alternator Adjusting plate bolt Apply 10 kgf (22 lbf) [98 N] force midway between crankshaft pulley and alternator pulley. Figure 182 Adjusting alternator and fan belt Service Manual Mitsubishi SL-Series diesel engines ENGLISH 109 / 195 Version 08/2004... - Page 110 Electrical System ASSEMBLY 110 / 195 110 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

- Page 111 ELECTRICAL SYSTEM ENGLISH 111 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 112: Electrical System General

-40 to +80 (-40 to 176) range °C (°F) Pre-glow time, second 6.2 ± 0.7 1. All specifications are subject to change without any prior notice. 112 / 195 112 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 113: Wiring Diagrams

ELECTRICAL SYSTEM GENERAL 28.2 Wiring diagrams < ETS type stop solenoid > Service Manual Mitsubishi SL-Series diesel engines ENGLISH 113 / 195 Version 08/2004... - Page 114 GENERAL ELECTRICAL SYSTEM < ETR type stop solenoid > 114 / 195 114 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 115: Starter

14. Internal gear 15. Overrunning clutch 16. Front bracket CAUTION The pinion must be removed before removal or replacement of the following parts: Front bracket Reduction gears Overrunning clutch Service Manual Mitsubishi SL-Series diesel engines ENGLISH 115 / 195 Version 08/2004... -

Page 116: Inspection

Coil Ground Test Check whether continuity exists between the commutator and shaft (or core). If continuity exists, the coil is grounded and the armature must be replaced. 116 / 195 116 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 117 Check whether continuity exists between the terminal lead and each brush. If continuity does not exists, the field coil has an open circuit and the yoke assembly must be replaced Service Manual Mitsubishi SL-Series diesel engines ENGLISH 117 / 195 Version 08/2004...

- Page 118 Brush Holder Insulation Test Check whether continuity exists between the (+) brush holder and the (–) brush holder plate. If continuity exists, replace the brush holder assembly. 118 / 195 118 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 119: Assembly

16 → 12 → 13 → 14 → 15 → 1 → 10 → 11 → 9 → 8 → 5 → 6 → 7 → 4 → 3 → 2 Service Manual Mitsubishi SL-Series diesel engines ENGLISH 119 / 195... -

Page 120: Inspection And Testing After Assembly

Switch Battery Voltmeter Starter (12V) Motor CAUTION Use the thickest wires possible, and tighten each terminal firmly. 120 / 195 120 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 121 Continuity should exists between the S- and M-terminals and between the S-terminal and ground (case). Test for Fused Contacts Continuity should not exist between the B- and M-terminals. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 121 / 195 Version 08/2004...

-

Page 122: Alternator

30.1 Disassembly Disassembly sequence Through bolt Pulley Rotor Rear bearing Bearing retainer Front bearing Front bracket Stator core Brush holder 10. Rectifier 11. Rear bracket 122 / 195 122 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 123 Unsolder the leads as quickly as possible to prevent damage to the diodes in the rectifier. Unsolder Remove the screws that hold the rectifier in position and remove the rectifier. Figure 186 Removing stator core Service Manual Mitsubishi SL-Series diesel engines ENGLISH 123 / 195 Version 08/2004...

-

Page 124: Inspection

Do the same step for the remainder of the diodes. If any diode is open or shorted, replace the rectifier. Diode lead wires Heat sink (+) Figure 188 Testing diode 124 / 195 124 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 125 Test for continuity between the leads as shown in the illustration. No continuity shows there is an open circuit in the stator core. Replace the stator core. Figure 191 Testing stator core for open circuit Service Manual Mitsubishi SL-Series diesel engines ENGLISH 125 / 195 Version 08/2004...

- Page 126 This will permit removal of the brushes and Unsolder springs. Brush holder Figure 194 Removing brushes for replacement 126 / 195 126 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 127: Assembly

Brushes bracket to lift the brushes off the slip rings. Remove the tooling after the rotor has been Wire-shaped installed in position. tooling Figure 196 Assembling alternator Service Manual Mitsubishi SL-Series diesel engines ENGLISH 127 / 195 Version 08/2004... -

Page 128: Key Shutoff System (Ets Solenoid Type)

Temporarily install the shutoff solenoid and nut in the governor case. Move the injection pump control rack all the way to the non-injection (shutoff) position. 128 / 195 128 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 129: Inspection After Assembly

NOTE It will take about 10 seconds to restart an engine which was shut down by the key shutoff device. ENGLISH 129 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 130: Key Shutoff System (Etr Solenoid Type)

The wires of the solenoid are identified by color as Blue follows: Color Remarks/Connection PULL (pull-in coil)/starter Stroke 13 ± 0.5 mm White HOLD (hold-in coil)/starter switch (0.51 ± 0.02 in.) Blue COM (earth)/ground 130 / 195 130 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 131: Shutoff Solenoid Installation

NOTE It will take about 10 seconds to restart an engine which was shut down by the key shutoff device. ENGLISH 131 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 132: Automatic Glow System

–40°C to +80°C range (–40°F to +176°F) Glow plug activating time 6.2 ± 0.7 seconds 1. All specifications are subject to change without any prior notice. 132 / 195 132 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 133: Glow Plug Relay Specifications (Standard)

If no continuity, replace with new one. Item Standard 0.55 Ω Resistance Figure 203 Testing glow plug 2. All specifications are subject to change without any prior notice. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 133 / 195 Version 08/2004... - Page 134 AUTOMATIC GLOW SYSTEM ELECTRICAL SYSTEM 134 / 195 134 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 135: Cooling System

COOLING SYSTEM ENGLISH 135 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 136: General

80°C (176°F): 29.5 ± 2.5 Ω Resistance in thermounit 120°C (248°F): 10 ± 0.3 Ω 1. All specifications are subject to change without any prior notice. 136 / 195 136 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 137: Inspection

Check for aging or damage Check for cracks or distortion. Use new gaskets. Check for cracks or leaks. Check for elongation, aging or wear. Figure 205 Inspection points Service Manual Mitsubishi SL-Series diesel engines ENGLISH 137 / 195 Version 08/2004... -

Page 138: Water Pump

95°C (203°F) valve lift is 8 mm (0.3 in.) Figure 207 Testing thermostat WARNING Water in the pan is hot. Any contact can cause severe burns. 138 / 195 138 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 139: Thermoswitch (Standard)

80°C (176°F): 29.5 ± 2.5 Ω 120°C (248°F): 10 ± 0.3 Ω Figure 209 Testing thermounit WARNING Antifreeze in the pan is hot. Any contact can cause severe burns. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 139 / 195 Version 08/2004... - Page 140 INSPECTION COOLING SYSTEM 140 / 195 140 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 141: Lubrication System

LUBRICATION SYSTEM ENGLISH 141 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 142: General

(7 ± 1.4 psi) [49 ± 10 kPa] closed (indicator light comes on) Oil filter Paper-element cartridge (full flow) type 1. All specifications are subject to change without any prior notice 142 / 195 142 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 143: Inspection

Also, check for air leaks. Any air leak is an indication of a ruptured diaphragm. In such a case, replace the switch. Figure 212 Testing oil pressure switch (2) Service Manual Mitsubishi SL-Series diesel engines ENGLISH 143 / 195 Version 08/2004... -

Page 144: Pressure Relief Valve

3.5 ± 0.5 kgf/cm Relief valve opening (50 ± 7 psi) Figure 213 Checking pressure relief valve pressure [343 ± 49 kPa] 144 / 195 144 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 145: Fuel System

FUEL SYSTEM ENGLISH 145 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 146: General

Fuel injection pipe Fuel injection pump Fuel injection nozzle To fuel tank Fuel filter overflow pipe Fuel pump Fuel filter From fuel tank Figure 214 Schematic overview 146 / 195 146 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 147: Specifications (Standard)

300 cc (18.3 cu in.)/min minimum or 400 cc (24.4 cu in.)/min PUMP 20°C (68°F)) minimum (remote) Table 3 Specifications 1. All specifications are subject to change without any prior notice. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 147 / 195 Version 08/2004... -

Page 148: Fuel Injection Nozzle

(go through) the skin and cause serious injury to the operator. Keep the tip of the nozzle pointed away from the operator and into the fuel collector. 148 / 195 148 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 149 When installing the new nozzle tip, remove synthetic resin film from the tip and slide the needle valve in the body in clean diesel fuel to wash off inhibitor completely. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 149 / 195 Version 08/2004...

-

Page 150: Disassembly And Assembly

Figure 219 Disassembly sequence and inspection Disassembly sequence points Retaining nut Nozzle tip assembly Piece Spring Washer Body 150 / 195 150 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 151: Fuel Injection Pump

10. Control rack 11. Delivery valve holder 12. O-ring 13. Delivery valve spring 14. Delivery valve gasket 15. Delivery valve 16. Plunger barrel 17. Pump housing Figure 220 Disassembly sequence Service Manual Mitsubishi SL-Series diesel engines ENGLISH 151 / 195 Version 08/2004... -

Page 152: Disassembly Procedure

Remove the upper spring seat and control sleeve. Do Steps (1) through (4) again for remainder of the plungers. Remove the control rack. Figure 223 Removing plungers 152 / 195 152 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 153 Keep them as clean as possible. Keep the plungers with their respective barrels for installation. Do not use plungers or barrels with other barrels or plungers. Figure 226 Removing barrels Service Manual Mitsubishi SL-Series diesel engines ENGLISH 153 / 195 Version 08/2004...

- Page 154 Pump Tester Cam Box is needed for measurement of injection quantity. Keep the disassembled injection pump parts in clean diesel fuel. Figure 227 Adjusting plates 154 / 195 154 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 155: Inspection

40.3 Inspection Check delivery valve for wear or damage Check plunger for wear, rusting or scoring. Check control rack for movement. Check tappet for wear. Figure 228 Inspection points Service Manual Mitsubishi SL-Series diesel engines ENGLISH 155 / 195 Version 08/2004... -

Page 156: Assembly

If the slot in the barrel is not aligned with the dowel of the housing, the O-ring will not seat correctly (still visible) after the delivery valve holder has been installed. Figure 230 Installing barrels 156 / 195 156 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 157 Figure 232 Installing control sleeves Put the plungers in position in the barrels. CAUTION Make sure the notch in the plunger is toward the adjusting plate. Figure 233 Installing plungers Service Manual Mitsubishi SL-Series diesel engines ENGLISH 157 / 195 Version 08/2004...

- Page 158 Disassemble and check the injection pump to locate the cause of the trouble. After the injection pump has been finally assembled, check the injection timing. Figure 236 Checking control rack movement 158 / 195 158 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 159: Governor

Spring pin Grooved pin Governor shaft (remove 7 thru 11 as an assembly) Governor lever Start spring Tension lever 10. Governor spring 11. Governor spring lever 12. Governor case Service Manual Mitsubishi SL-Series diesel engines ENGLISH 159 / 195 Version 08/2004... -

Page 160: Assembly

Install the grooved pin and spring pin in position spring with a hammer. Install the tie rod and tie rod spring in position. Tie rod Spring pin Figure 239 Assembling governor 160 / 195 160 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 161: Torque Spring Set Installation

Install the sealing cap over the torque spring set and stake the cap in position. Figure 241 Sealing cap for torque spring set Service Manual Mitsubishi SL-Series diesel engines ENGLISH 161 / 195 Version 08/2004... -

Page 162: Fuel Pump

Look outside the pump for defects and test its performance. Do not attempt to disassemble the pump. Figure 242 Fuel pump (plunger type) Figure 243 Fuel pump (diaphragm type) 162 / 195 162 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 163: Fuel Filter

Air vent screws Priming sequence To pump Replace every 400 service hours From Check for water and fuel tank sediment accumulation Figure 246 Fuel filter (cartridge type) Service Manual Mitsubishi SL-Series diesel engines ENGLISH 163 / 195 Version 08/2004... - Page 164 FUEL FILTER FUEL SYSTEM 164 / 195 164 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

- Page 165 AIR INLET SYSTEM AND EXHAUST SYSTEM ENGLISH 165 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 166: Air Inlet System And Exhaust System 44 General

Air breather pipe (for recirculation of blowby gases Blowby gases Air (from air cleaner) To exhaust muffler Air inlet cover Exhaust manifold Figure 247 Schematic overview 166 / 195 166 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 167: Inspection

Item Standard Warpage of manifold 0.15 (0.005 9) Table 5 Inspection, unit mm (in.) Figure 249 Checking manifold for warpage Service Manual Mitsubishi SL-Series diesel engines ENGLISH 167 / 195 Version 08/2004... - Page 168 INSPECTION AIR INLET SYSTEM AND EXHAUST SYSTEM 168 / 195 168 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 169: Maintenance

MAINTENANCE ENGLISH 169 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 170: Lubrication And Maintenance Chart

Check glow plugs Retighten nuts and bolts Check starter Every 1000 Service Hours Check alternator Check turbocharger See turbocharger manual Table 6 Lubrication and maintenance charts 170 / 195 170 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 171 Every 2 Years Change coolant See operation manual Prime fuel system When Required Clean air cleaner element Change air cleaner element See operation manual Table 6 Lubrication and maintenance charts Service Manual Mitsubishi SL-Series diesel engines ENGLISH 171 / 195 Version 08/2004...

-

Page 172: Engine Oil And Oil Filter

Start and run the engine for a few minutes. Then stop the engine and check the oil level again. 172 / 195 172 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 173: Oil And Oil Filter Change

Install the filter by hand until its gasket contacts the base. Tighten 3/4 turn more. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 173 / 195 Version 08/2004... - Page 174 Add 0.5 liter (0.5 qt) of oil. Start the engine and check for leaks around the filter. Stop the engine. Check the oil level and add oil if necessary. 174 / 195 174 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 175: Valve Clearance

Item Standard Valve clearance (both 0.25 (0.0098) inlet and exhaust valves) Table 8 Valve clearance, unit mm (in.) Hold the adjusting screw and tighten the lock nut. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 175 / 195 Version 08/2004... - Page 176 After the valve clearance on the valves for all cylinders has been adjusted, turn the crankshaft two or three times and make sure the valve clearance is correct. 176 / 195 176 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 177: Fuel Injection Timing

NOTE Turn the crankshaft in reverse direction just a little and do Step (2) again to verify the injection timing. Figure 258 Fuel stops coming from injection pipe Service Manual Mitsubishi SL-Series diesel engines ENGLISH 177 / 195 Version 08/2004... - Page 178 1° retarded. Take this 1° Figure 260 Disconnecting No. 1 fuel injection pipe retardation into account when making a shim adjustment. Figure 261 Timing mark 178 / 195 178 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 179: Adjustment

Close the fuel filter valve and restore the delivery valve and injection pipe to the original state. Increase Decrease shim shim thickness. thickness. Advanced Retarded Figure 263 Adjusting fuel injection timing Service Manual Mitsubishi SL-Series diesel engines ENGLISH 179 / 195 Version 08/2004... -

Page 180: Fuel Filter

50.2 Cartridge (air vent screw) type fuel filter Replace the filter as an assembly if water and sediment have been accumulated in it. Figure 265 Cartridge type fuel filter 180 / 195 180 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 181: Fuel System Priming

Figure 267 Priming cartridge (air vent screw) type fuel filter The fuel system of the engine with an electric fuel pump can be primed by turning the starter switch key to ON position. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 181 / 195 Version 08/2004... -

Page 182: Idle Rpm Setting

Tighten the Idling set bolt lock nut. Lock nuts High-idle set bolt Figure 268 Idle speed setting 182 / 195 182 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 183: Fuel Injection Nozzles

Put the nozzle in position in the cylinder head and tighten it to the specified torque. 5.5 ± 0.5 kgf·m Tightening torque (40 ± 4 lbf·ft) [54 ± 5 N·m Figure 269 Installing fuel injection nozzles Service Manual Mitsubishi SL-Series diesel engines ENGLISH 183 / 195 Version 08/2004... -

Page 184: Fan Belt

(0.4 to 0.5) Deflection: 10 to 12 mm (0.4 to 0.5 in.) under 10 kgf (22 lbf) [98 N] force Figure 270 Installing fuel injection nozzles 184 / 195 184 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 185: Service Data

SERVICE DATA ENGLISH 185 / 195 Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 186: Specifications

0.10 (0.003 9) Repair. Bend (dial indicator reading) of valve push rod — 0.3 (0.012) Replace. 1. All specifications are subject to change without any prior notice. 186 / 195 186 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 187 (0.007 9 to 0.015 7) Hone out bore for 0.035 to 0.086 Clearance between piston and cylinder 0.300 (0.011 81) oversize piston or (0.001 38 to 0.003 39) replace cylinder block. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 187 / 195 Version 08/2004...

-

Page 188: Lubrication System

Change every Paper-element type air cleaner element 100 service hours 500 service hours. Warpage of mounting faces of manifolds — 0.15 (0.005 9) Repair or replace. 188 / 195 188 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 189: Cooling System (Standard)

Runout of commutator 0.03 (0.001 2) 0.10 (0.003 9) Repair or replace. Diameter of commutator 32 (1.26) 31 (1.22) Replace. Undercut of mica 0.5 (0.020) 0.2 (0.008) Repair. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 189 / 195 Version 08/2004... - Page 190 At 500 voltage tempe- rature) Current 47 A min. — Brush length — Wear limit line Replace. 0.55 Ω Resistance in glow plug — Replace. 190 / 195 190 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004...

-

Page 191: Tightening Torques

0.125 ± 0.025 (0.9 ± 0.2) [1.2 ± 0.2] Stop solenoid nut — 4.5 ± 0.5 (32.5 ± 4) [44 ± 5] Starter B terminal 1.25 — 1.1 ± 0.1 (8 ± 0.7) [10.8 ± 1] Service Manual Mitsubishi SL-Series diesel engines ENGLISH 191 / 195 Version 08/2004... -

Page 192: Torques For Bolts And Nuts With Standard Threads

PT 1/4, NPTF 1/4 (18 ± 4) (29 ± 4) [25 ± 5] [39 ± 5] 6.5 ± 1 PT 3/8 — (47 ± 7) [64 ± 10] 192 / 195 192 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... -

Page 193: Sealants

Three Bond 1212 Main bearing caps Apply to surfaces that come into (front and rear) contact with cylinder block. Cylinder block Oil pan Three Bond 1207C Apply to sealing surface. Service Manual Mitsubishi SL-Series diesel engines ENGLISH 193 / 195 Version 08/2004... -

Page 194: Special Tools

In addition to these special tools, commercially available tools such as bearing puller, valve seat cutting tool, valve guide installing tool, valve spring compressing tool, oil filter wrench, etc. are necessary. 194 / 195 194 / 195 ENGLISH Service Manual Mitsubishi SL-Series diesel engines Version 08/2004... - Page 195 BLANK PAGE Service Manual Mitsubishi SL-Series diesel engines ENGLISH 195 / 195 Version 08/2004...

Need help?

Do you have a question about the S3L and is the answer not in the manual?

Questions and answers

Timing of engine Mitsubishi s3l

The timing specification for the Mitsubishi S3L engine includes a firing order of 1–3–2 with a crankshaft rotation angle of 240°.

This answer is automatically generated