Summary of Contents for Kemppi MinarcMig Adaptive 150

- Page 1 Operation instructions • English 1910170E Gebrauchsanweisung • Deutsch 0550 Gebruiksaanwijzing • Nederlands Manuel d’utilisation • Français MinarcMig™ Adaptive 150...

- Page 2 MinarcMig™ Adaptive 150 OPERATION INSTRUCTIONS ENGLISH © Kemppi Oy 0550...

-

Page 3: Table Of Contents

4.1. DAILY MAINTENANCE ............. 15 4.2. MAINTENANCE OF THE WIRE FEED MECHANISM ....15 4.3. MACHINE DISPOSAL ............... 16 4.4. ORDERING NUMBERS ............. 17 5. TROUBLESHOOTING ............18 6. TECHNICAL DATA .............19 7. TERMS OF GUARANTEE ..........20 © Kemppi Oy 0550... -

Page 4: Introduction

Carbon dioxide or a mixture of carbon dioxide and argon is suitable for shielding gas. Some filler wires form a shielding gas from the wire’s filling as it melts thus eliminating the need for a separate shielding gas. © Kemppi Oy 0550... -

Page 5: Safety Instructions

fluids, from the vicinity of the welding site and supply the site with adequate fire-fighting equipment. Take into account dangers caused by special workplaces, such as fire risk and danger of explosion, when welding container-like pieces. © Kemppi Oy 0550... -

Page 6: Supply Voltage

2.6. WELDING FUMES Make sure ventilation is sufficient. Take special precautions when welding metals containing lead, cadmium, zinc, mercury or beryllium. Supply of sufficient clean air can also be ensured with the use of a fresh air mask. © Kemppi Oy 0550... -

Page 7: Machine Use

-20°C – +40°C. Place the machine in such a way that it does not come in contact with hot surfaces, sparks and spatters. Make sure the air flow in the machine is unrestricted. © Kemppi Oy 0550... -

Page 8: General View Of The Machine

Earthing The earthing cable is already connected to the machine. Clean the workpiece surface and fix the earthing cable clamp to the piece in order to create a closed and interference-free circuit needed for welding. © Kemppi Oy 0550... -

Page 9: Welding Gun

flow rate is 8-15 l/min. 3. Close the bottle’s valve after use. NOTE! Use a shielding gas suitable for the material’s welding. Fix the gas bottle securely in an upright position before installing the control valve. © Kemppi Oy 0550... -

Page 10: Filler Wire

6. Pull the feed roll from its shaft. 7. Turn the feed roll and reinstall it to its shaft all the way to the bottom making sure that the screw is on the shaft’s level. 8. Tighten the feed roll locking screw. © Kemppi Oy 0550... -

Page 11: Threading The Filler Wire

If the pressure is too high, it removes metal fragments from the wire surface and may damage the wire. On the other hand, if the pressure is too low, the feed gear slips and the wire does not run smoothly. © Kemppi Oy 0550... -

Page 12: Reversing Polarity

5. Install the washers in place and close the tightening nuts to spanner tightness. 6. Put the rubber cover of the earthing cable’s pole firmly in place. The rubber cover must always protect the earthing cable’s pole. © Kemppi Oy 0550... -

Page 13: Controls And Indicator Lights

The light switches off when the machine is ready for operation again. Make sure that there is enough space around the machine allowing air to freely flow and cool the machine. © Kemppi Oy 0550... -

Page 14: Welding Power Adjustment

You can also adjust the welding power, if need be. Once the arc has been trimmed, it usually does not need to be changed when the welded sheet thickness changes. © Kemppi Oy 0550... -

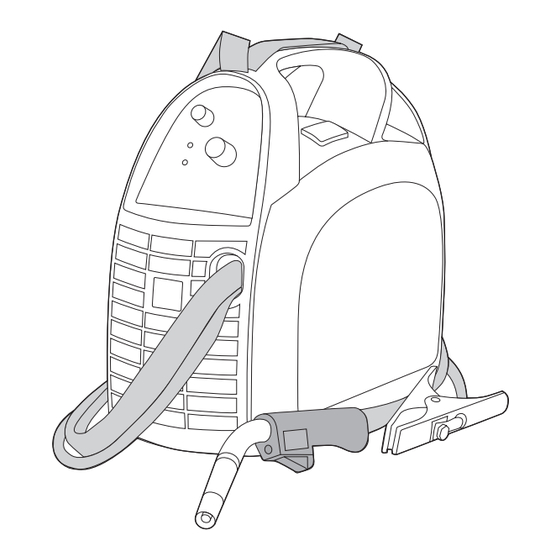

Page 15: Threading The Shoulder Strap

When servicing the machine, its utilization degree and environmental circumstances should be taken into account. If you use the machine appropriately and service it regularly, you will spare yourself from unnecessary malfunctions. CAUTION! Disconnect the machine from the mains before handling the electrical cables. © Kemppi Oy 0550... -

Page 16: Daily Maintenance

• Remove welding spatters from the welding gun’s tip and check the condition of the parts. Change damaged parts to new ones immediately. Only use original Kemppi spare parts. • Check that the insulating tips of the welding gun’s neck are undamaged and in place. -

Page 17: Machine Disposal

As the owner of the equipment, you should get information on approved collection systems from our local representative. By applying this European Directive you will improve the environment and human health. © Kemppi Oy 0550... -

Page 18: Ordering Numbers

Contact tip M6 ø 0,6 mm 9876634 Contact tip M6 ø 0,8 mm 9876635 Contact tip M6 ø 0,9 mm 9876633 Contact tip M6 ø 1,0 mm 9876636 Contact tip adapter 9580173 Neck insulating ring 9591079 Wire guide 0,6-1,0 mm 4307650 © Kemppi Oy 0550... -

Page 19: Troubleshooting

• Machine’s volume-capacity ratio has been exceeded; wait for the indicator light to switch off • The supply voltage is too low or too high If the machine’s malfunction can not be corrected with these measures, contact the KEMPPI maintenance service. © Kemppi Oy 0550... -

Page 20: Technical Data

Temperature class H (180°C) / F (155°C) Dimensions L 400 x W 180 x H 340 mm Weight 9,4 kg (incl. gun and cables 3,0 kg) Operating temperature range -20°C...+40°C Storage temperature range -40°C...+60°C Protection class IP23C © Kemppi Oy 0550... -

Page 21: Terms Of Guarantee

MinarcMig™ Adaptive 150 7. TERMS OF GUARANTEE Kemppi Oy provides a guarantee for products manufactured and sold by them if defects in manufacture and materials occur. Guarantee repairs must be carried out only by an Authorised Kemppi Service Agent. Packing, freight and insurance costs to be paid by orderer. - Page 22 Telefax 44 941 536 Telefax (06033) 72 528 Telefax (03) 899 428 e-mail: sales.dk@kemppi.com e-mail: sales.de@kemppi.com www.kemppi.com KEMPPI BENELUX B.V. KEMPPI SP. z o.o. KEMPPIKONEET OY Postbus 5603 UI. Piłsudskiego 2 PL 13 NL – 4801 EA BREDA 05-091 ZĄBKI FIN –...

Need help?

Do you have a question about the MinarcMig Adaptive 150 and is the answer not in the manual?

Questions and answers