Endress+Hauser Cerabar S PMP75 Brief Operating Instructions

Process pressure measurement

Hide thumbs

Also See for Cerabar S PMP75:

- Operating instructions manual (238 pages) ,

- Technical information (136 pages) ,

- Manual (96 pages)

Table of Contents

Advertisement

Quick Links

Brief Operating Instructions

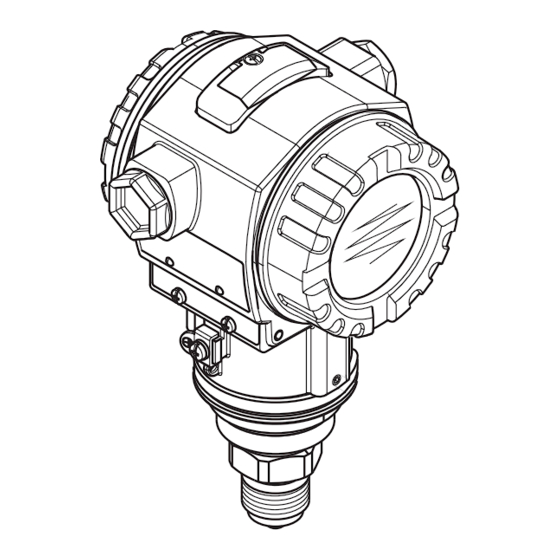

Cerabar S

PMC71, PMP71, PMP75

Process pressure measurement

These Instructions are Brief Operating Instructions; they do not replace the

Operating Instructions included in the scope of supply.

For detailed information, refer to the Operating Instructions and other

documentation on the CD-ROM provided or visit

"www.endress.com/deviceviewer".

KA01025P/00/EN/15.14

71254315

Advertisement

Table of Contents

Summary of Contents for Endress+Hauser Cerabar S PMP75

- Page 1 Brief Operating Instructions Cerabar S PMC71, PMP71, PMP75 Process pressure measurement These Instructions are Brief Operating Instructions; they do not replace the Operating Instructions included in the scope of supply. For detailed information, refer to the Operating Instructions and other documentation on the CD-ROM provided or visit "www.endress.com/deviceviewer".

-

Page 2: Table Of Contents

6.6 Scaling the OUT parameter ..............34 Endress+Hauser... -

Page 3: Safety Instructions

Safety Instructions listed in this Ex document must be observed. The documentation number of the related Safety Instructions is also indicated on the additional nameplate. Return Follow the instructions on returning the device as outlined in the Operating Instructions on the CD-ROM provided. Endress+Hauser... -

Page 4: Safety Icons

For an overview of the technical documentation provided, enter the serial number from the nameplates in the W@M Device Viewer (www.endress.com/deviceviewer). Installation General installation instructions Warning! The process seal is not allowed to press on the process isolating diaphragm as this could affect the measurement result. Endress+Hauser... -

Page 5: Installation Instructions For Devices Without Diaphragm Seals Pmp71, Pmc71

• To ensure optimal readability of the onsite display, it is possible to rotate the housing up to 380°. • The onsite display can be rotated in 90° stages. • Endress+Hauser offers a mounting bracket for installing on pipes or walls. Installation instructions for devices without diaphragm seals PMP71, PMC71 Cerabar S without diaphragm seal are mounted as per the norms for a manometer (DIN EN 837-2). - Page 6 In the fill flow, in the tank outlet or at a point in the container which could be affected by pressure pulses from an agitator. • The calibration and functional test can be carried out more easily if you mount the device after a shutoff device. Endress+Hauser...

-

Page 7: Installation Instructions For Devices With Diaphragm Seals Pmp75

• vibration-free (in order to avoid additional pressure fluctuations) • not in the vicinity of heating or cooling lines • insulate if the ambient temperature is below ore above the reference temperature • with a bending radius of 100 mm. Endress+Hauser... - Page 8 Cerabar S FOUNDATION Fieldbus 3.3.1 Vacuum application For applications under vacuum, Endress+Hauser recommends mounting the pressure transmitter underneath the diaphragm seal. A vacuum load of the diaphragm seal caused by the presence of filling oil in the capillary is hereby prevented.

-

Page 9: Assembling And Mounting The "Separate Housing" Version

Mount the housing on a wall or pipe using the mounting bracket (item 7). When mounting on a pipe, tighten the nuts on the bracket uniformly with a torque of at least 5 Nm. Mount the cable with a bending radius (r) 120 mm. Endress+Hauser... -

Page 10: Wiring

• Remove housing cover of the terminal compartment. • Guide cable through the gland. Preferably use twisted, shielded two-wire cable. • Connect device in accordance with the following diagram. • Screw down housing cover. • Switch on supply voltage. Endress+Hauser... -

Page 11: Connecting The Measuring Unit

15.5 mA ±1 mA, switch-on current corresponds to IEC 61158-2, Clause 21. 4.2.3 Cable specification • Use a twisted, shielded two-wire cable, preferably cable type A • Terminals for wire cross-sections: 0.5 to 2.5 mm • Outer cable diameter: 5 to 9 mm Endress+Hauser... - Page 12 Cerabar S must be grounded, for example by means of the external ground terminal. Different grounding and shielding installation methods are available for FOUNDATION Fieldbus networks such as: • Isolated installation (see also IEC 61158-2) • Installation with multiple grounding • Capacitive installation Endress+Hauser...

-

Page 13: Operation

Parameter Measured value display Identification Function name Value number Header line Main line Unit Information line Symbol – Bargraph Bargraph Editing modes Operating keys Selection options Value that can be edited Current measured value P01-xxxxxxxx-07-xx-xx-xx-011 Endress+Hauser... - Page 14 The primary value of the Transducer Block is increasing. Tendency symbol (decreasing) The primary value of the Transducer Block is decreasing. Tendency symbol (constant) The primary value of the Transducer Block has remained constant over the past few minutes. Endress+Hauser...

-

Page 15: Operating Elements

Operating key or position adjustment (zero Green LED to indicate value is accepted point-correction) or total reset Operating key for position adjustment (zero point-correction) Slot for optional display ® Slot for optional HistoROM /M-DAT DIP-switch for locking/unlocking measured-value-relevant parameters DIP switch for simulation mode Endress+Hauser... - Page 16 – You are in a menu at a selection level. Each time you press the keys simultaneously, you go up a level in the menu. Note: The terms function group, level and selection level are explained in ä 17, Section 5.3.1. Endress+Hauser...

-

Page 17: Onsite Operation Via Onsite Display

MEASURING MODE ➀ ➁ SETTINGS DISPLAY POSITION ADJUSTMENT BASIC SETUP EXTENDED SETUP POS. ZERO ADJUST ➂ ➃ POS. INPUT VALUE CALIB. OFFSET P01-xxxxxxxx-19-xx-xx-xx-145 Fig. 7: Structure of the operating menu 1. Selection level 2. Selection level Function groups Parameter Endress+Hauser... - Page 18 The onsite display shows the parameter to be changed. The value highlighted in black can be changed. The "s" unit is fixed and cannot be changed. P01-xxxxxxxx-19-xx-xx-xx-023 Press "+" or "–" to get to the editing mode. The first digit is highlighted in black. P01-xxxxxxxx-19-xx-xx-xx-027 Endress+Hauser...

- Page 19 Use "E" to save the new value and exit the editing mode. See next graphic. P01-xxxxxxxx-19-xx-xx-xx-031 The new value for the damping is now 30.0 s. – Jump to the next parameter with "E". – You can get back to the editing mode with "+" or "–". P01-xxxxxxxx-19-xx-xx-xx-032 Endress+Hauser...

- Page 20 Use "E" to assign the value (3.9 mbar) to the POS. ZERO ADJUST parameter. The device confirms the calibration and jumps back to the parameter, here POS. ZERO ADJUST (see next graphic). P01-xxxxxxxx-19-xx-xx-xx-037 Switch to the next parameter with "E". P01-xxxxxxxx-19-xx-xx-xx-160 Endress+Hauser...

-

Page 21: Locking/Unlocking Operation

Menu path: OPERATING MENU OPERATION INSERT PIN No. To lock operation, enter "0" for the parameter. Unlocking operation Operation via FF configuration program: select SWLOCK parameter in the Resource Block. Operation via FieldCare: select INSERT PIN No. parameter. To unlock operation, enter "100" for the parameter. Endress+Hauser... -

Page 22: Commissioning

Load Cff and device description files into the host system or the configuration program. Make sure you are using the right system files. Identify the device using the DEVICE_ID. Assign the desired tag name to the device by means of the PD_TAG parameter. Endress+Hauser... - Page 23 – CHANNEL = 2: Secondary value, here the sensor temperature Factory setting: – Analog Input Block 1: CHANNEL = 1: Primary Value (pressure measured value) – Analog Input Block 2: CHANNEL = 2: Secondary Value (sensor temperature) Endress+Hauser...

-

Page 24: Selecting The Language And Measuring Mode

ä 17, Section 5.3.1 "Structure of the operating menu". The following measuring modes are available: • Pressure • Level 6.2.2 Selecting the language and measuring mode via FieldCare The parameters for setting the measuring mode are displayed in the FieldCare "Measuring mode" menu. Endress+Hauser... -

Page 25: Position Adjustment

There are two options to choose from when performing position adjustment. • Onsite display menu path: GROUP SELECTION OPERATING MENU SETTINGS POSITION ADJUSTMENT • FieldCare menu path: OPERATING MENU SETTINGS POSITION ADJUSTMENT Endress+Hauser... - Page 26 To correct the MEASURED VALUE to 0.0 mbar, you must enter the value 2.2 here. (The following applies: MEASURED VALUE = MEASURED VALUE – CALIB. OFFSET) – MEASURED VALUE (after entry for calib. offset) = 0.0 mbar Factory setting: Endress+Hauser...

-

Page 27: Pressure Measurement

MEASURING MODE QUICK SETUP OPERATING MENU Pressure Level Absolut pressure sensors Gauge pressure sensors POS. ZERO ADJUST POS. INPUT VALUE DAMPING VALUE 1) On-site display only 2) FieldCare only P01-PMx7xxxx-19-xx-xx-en-078 Fig. 8: Quick Setup menu for the "Pressure" measuring mode Endress+Hauser... - Page 28 Input Block react to a change in the pressure. Note! For local operation see also ä 16, Section 5.2.3 "Function of the operating elements – onsite display connected" and ä 17, Section 5.3 "Onsite operation via onsite display". Endress+Hauser...

-

Page 29: Level Measurement

– Customer-specific units of level, volume and mass, or a linearization table, can only be entered in the "Level standard" level mode. • For a detailed description of the parameters and configuration examples, see Operating Instructions BA00303P "Cerabar S/Deltabar S/Deltapilot S, Description of Device Functions". Endress+Hauser... - Page 30 – Customer-specific BEFORE LIN. Linear – Level Operating units of level, parameter show – Volume Instructions volume and the measured – Mass BA00303P. mass are value. possible – Calibration without reference pressure – dry calibration, see Operating Instructions BA00303P. Endress+Hauser...

- Page 31 A Operating linearization table Instructions has to be entered BA00303P. for the 2nd measured variable. The 2nd measured variable is assigned to the 1st measured variable by means of this table. Endress+Hauser...

- Page 32 2) FieldCare only 3) – LEVEL SELECTION "Level Easy Pressure" and CALIBRATION MODE "Wet" – LEVEL SELECTION = "Level Standard", LEVEL MODE = "Linear" and CALIBRATION MODE = "Wet" P01-FMB70xxx-19-xx-xx-en-015 Fig. 9: Quick Setup menu for the "Level" measuring mode" Endress+Hauser...

- Page 33 – LEVEL SELECTION "Level standard", LEVEL MODE "Linear" and CALIBRATION MODE "Wet" Note! For local operation see also ä 16, Section 5.2.3 "Function of the operating elements – onsite display connected" and ä 17, Section 5.3 "Onsite operation via onsite display". Endress+Hauser...

-

Page 34: Scaling The Out Parameter

FieldCare. • Result: At a pressure of 350 mbar, the value 70 is output to a downstream block or to the PCS as the OUT value. L_TYPE: Indirect UNITS_INDEX: mbar EU_100 EU_0 UNITS_ INDEX: EU_0 EU_100 P01-xMx7xxxx-05-xx-xx-en-008 Endress+Hauser... - Page 35 • The L_TYPE, XD_SCALE and OUT_SCALE parameters can only be changed in the OOS block mode. • Make sure that the output scaling of the Pressure Transducer Block SCALE_OUT matches the input scaling of the Analog Input Block XD_SCALE. Endress+Hauser...

- Page 36 KA01025P/00/EN/15.14 71254315 CCS/FM+SGML 9.0 71254315...