Endress+Hauser Cerabar S PMP72 Operating Instructions Manual

Process pressure measurement

Hide thumbs

Also See for Cerabar S PMP72:

- Technical information (84 pages) ,

- Brief operating instructions (25 pages) ,

- Brief operating instructions (36 pages)

Summary of Contents for Endress+Hauser Cerabar S PMP72

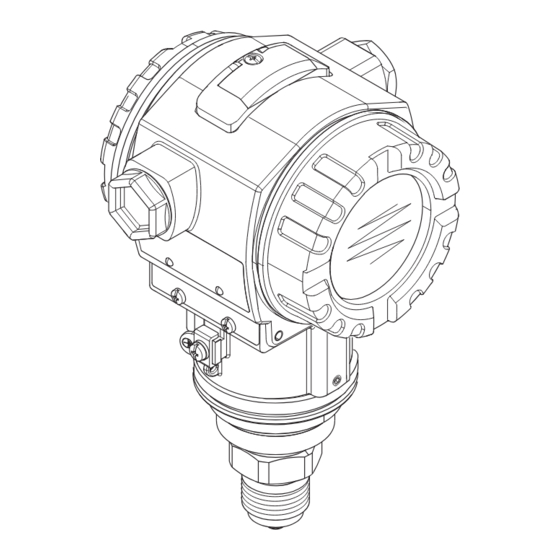

- Page 1 Operating Instructions Cerabar S PMC71, PMP71, PMP72, PMP75 Process pressure measurement BA271P/00/EN/05.10 71111792 valid from Software version: 02.10.zz...

- Page 2 "E" in feature 100 "Additional – Commissioning and iterative tests options 1" or in feature 110 "Additional – Settings options 2". See also Technical Information TI383P, – Technical safety characteristic quantities – Management Summary chapter "Ordering information". Endress+Hauser...

-

Page 3: Table Of Contents

Messages ....... . 55 Response of outputs to errors ....62 Endress+Hauser... -

Page 4: Safety Instructions

The documentation number of the related Safety Instructions is also indicated on the additional nameplate. • Ensure that all personnel are suitably qualified. 1.3.2 Functional Safety SIL3 (optional) If using devices for applications with safety integrity, the Functional Safety Manual (SD190P) must be observed thoroughly. Endress+Hauser... -

Page 5: Notes On Safety Conventions And Icons

A connection made to the plant grounding system which may be of type e.g. neutral star or equipotential line according to national or company practice. Safety instruction For safety instructions refer to the manual for the appropriate instrument version. Endress+Hauser... -

Page 6: Identification

ID number of notified body with regard to Pressure Equipment Directive (optional) ID number of notified body with regard to ATEX (optional) GL-symbol for GL marine certificate (optional) SIL-symbol for devices with SIL3/IEC 61508 Declaration of conformity (optional) Layout identification of the nameplate Endress+Hauser... - Page 7 Devices suitable for oxygen applications are fitted with an additional nameplate. Bei Sauerstoffeinsatz/ for oxygen service Pmax Tmax P01-xxxxxxxx-18-xx-xx-xx-000 Fig. 3: Additional nameplate for devices suitable for oxygen applications Maximum pressure for oxygen applications Maximum temperature for oxygen applications Layout identification of the nameplate Endress+Hauser...

- Page 8 Maximum temperature for devices suitable for oxygen applications Maximum pressure for devices suitable for oxygen applications 2.1.2 Identifying the sensor type See parameter "Sensor Meas.Type" in Operating Instruction BA274P. The Operating Instruction BA274P can be found on the supplied documentation CD. Endress+Hauser...

-

Page 9: Scope Of Delivery

The device complies with the applicable standards and regulations as listed in the EC declaration of conformity and thus complies with the statutory requirements of the EC Directives. Endress+Hauser confirms the successful testing of the device by affixing to it the CE mark. -

Page 10: Installation

• To ensure optimal readability of the on-site display, it is possible to rotate the housing up to 380°. See Page 19, Section 3.3.5 "Rotating the housing". • Endress+Hauser offers a mounting bracket for installing on pipes or walls. See Page 16, Section 3.3.4 "Wall and pipe mounting". - Page 11 Pressure measurement in gases ➀ ➁ P01-PMx7xxxx-11-xx-xx-xx-001 Fig. 5: Measuring arrangement for pressure measurement in gases Cerabar S Shut-off device • Mount Cerabar S with shut-off device above the tapping point so that any condensate can flow into the process. Endress+Hauser...

- Page 12 • Fill the siphon with fluid before commissioning. Pressure measurement in liquids ➀ ➁ P01-PMx7xxxx-11-xx-xx-xx-003 Fig. 7: Measuring arrangement for pressure measurement in liquids Cerabar S Shut-off device • Mount Cerabar S with shut-off device below or at the same level as the tapping point. Endress+Hauser...

- Page 13 • vibration-free (in order to avoid additional pressure fluctuations) • not in the vicinity of heating or cooling lines • insulate if the ambient temperature is below ore above the reference temperature • with a bending radius of 100 mm (3.94 in). Endress+Hauser...

- Page 14 115 P01-PMx7xxxx-11-xx-xx-xx-005 Endress+Hauser recommends the use of temperature separators in the event of constant extreme fluid temperatures which lead to the maximum permissible electronics temperature of +85°C (+185°F) being exceeded. To minimise the influence of rising heat, Endress+Hauser recommends the device be mounted horizontally or with the housing pointing downwards.

- Page 15 Seal for flange mounting ➀ ➁ P01-FMD7xxxx-11-xx-xx-xx-002 Fig. 11: Mounting the versions with flange or diaphragm seal Process isolating diaphragm Seal Warning! The seal is not allowed to press on the process isolating diaphragm as this could affect the measurement result. Endress+Hauser...

- Page 16 Depending on the diaphragm seal filling oil used ( see Technical Information TI383P Cerabar S) 3.3.5 Wall and pipe-mounting (optional) Endress+Hauser offers a mounting bracket for installing on pipes or walls. P01-xMx5xxxx-06-xx-xx-xx-001 Please note the following when mounting: • Devices with capillary lines: mount capillaries with a bending radius of 100 mm (3.94 in).

- Page 17 Mount the housing on a wall or pipe using the mounting bracket (item 7). When mounting on a pipe, tighten the nuts on the bracket uniformly with a torque of at least 5 Nm (3.69 lbs ft). Mount the cable with a bending radius (r) 120 mm (4.72 in). Endress+Hauser...

- Page 18 For the "U1 Prepared for diaphragm seal mount" version in feature 70 "Process connection; Material" in the order code of up to including 40 bar (600 psi)-sensors, Endress+Hauser recommends welding on the diaphragm seal as follows: the total welding depth of the fillet weld is 1 mm (0.04 in) at an external diameter of 16 mm (0.63 in).

-

Page 19: Post-Installation Check

These screws should be finger-tightened (2 Nm (1.48 lbf ft)) to the stop to ensure that the covers sit tightly. Post-installation check After installing the device, carry out the following checks: • Are all screws firmly tightened? • Are the housing covers screwed down tight? Endress+Hauser... -

Page 20: Wiring

Minimum supply voltage = 10.5 V DC, jumper is inserted in accordance with the illustration. Minimum supply voltage = 11.5 V DC, jumper is inserted in "Test" position. Devices with integrated overvoltage protection are labelled OVP (overvoltage protection) here. Endress+Hauser... - Page 21 Left: electrical connection for devices with Harting plug Han7D Right: view of the plug connector at the device 4.1.2 Connecting devices with M12 plug + – – – P01-xxx7xxxx-04-xx-xx-xx-000 Fig. 19: Left: electrical connection for devices with M12 plug Right: view of the plug at the device Endress+Hauser...

-

Page 22: Connecting The Measuring Unit

– minimum supply voltage: 10.5 V DC 4.2.2 Cable specification • Endress+Hauser recommends using twisted, screened two-wire cables. • Terminals for wire cross-sections 0.5 to 2.5 mm (20 to 14 AWG) • Cable external diameter: 5 to 9 mm (0.2 to 0.35 in) - Page 23 • When using in hazardous areas, you must observe the applicable regulations. Separate Ex documentation with additional technical data and instructions is included with all Ex systems as standard. Endress+Hauser...

- Page 24 • In the case of Ex d type of protection, do not connect the handheld terminal in the hazardous area. • Do not replace the battery of the handheld terminal in the hazardous area. • For devices with FM or CSA certificates, establish electrical connection as per Installation or Control Drawing (ZD) supplied. Endress+Hauser...

- Page 25 The Commubox FXA195 connects intrinsically safe transmitters to a computer's USB port using the HART protocol. This allows remote operation of the measuring transmitter using Endress+Hauser's operating program FieldCare. The Commubox is supplied with power through the USB port. The Commubox is also suitable for connection to intrinsically safe circuits.

-

Page 26: Potential Matching

FieldCare Connecting Commubox FXA291 The Commubox FXA291 connects Endress+Hauser field instruments with CDI interface (= Endress+Hauser Common Data Interface) to the USB interface of a personal computer or a notebook. For details refer to TI405C/07/en. Note! For the following Endress+Hauser instruments you need the "ToF Adapter FXA291" as an additional accessory: •... -

Page 27: Overvoltage Protection (Optional)

• Are all screws firmly tightened? • Are the housing covers screwed down tight? As soon as voltage is applied to the device, the green LED on the electronic insert lights up for a few seconds or the connected on-site display lights up. Endress+Hauser... -

Page 28: Operation

• rapid and safe commissioning with the Quick Setup menus Parameter Measured value display Identification Function name Value number Header line Main line Unit Information line Symbol – Bargraph Bargraph Editing modes Operating keys Selection options Value that can be edited Current measured value P01-xMx7xxxx-07-xx-xx-xx-001 Endress+Hauser... -

Page 29: Operating Elements

Operating keys on the exterior of the device under Operating keys the protective flap Slot for optional display ® Slot for optional HistoROM /M-DAT DIP-switch for locking/unlocking measured-value- relevant parameters DIP-switch for damping on/off Green LED to indicate value being accepted Endress+Hauser... - Page 30 /M-DAT module to the device. ® Copy the configuration data from the device to the optional HistoROM /M-DAT module. – DIP-switch 1: for locking/unlocking measured-value-relevant parameters τ Factory setting: off (unlocked) – DIP-switch 2: damping on/off, Factory setting: on (damping on) P01-xxxxxxxx-19-xx-xx-xx-057 Endress+Hauser...

- Page 31 – You are in a menu at a selection level. Each time you press the keys simultaneously, you go up a level in the menu. Note: The terms function group, level and selection level are explained in Section 5.4.1, Page 35. Endress+Hauser...

-

Page 32: On-Site Operation - On-Site Display Not Connected

Observe the input Observe the input Observe the input limits. limits. limits. Observe "Warning" on page 45 in Chapter 6 "Commissioning". Endress+Hauser... - Page 33 • See also Page 50, Section 6.5 "Level measurement". For parameter description see Operating Instructions BA274P. • LEVEL SELECTION, CALIBRATION MODE, LEVEL MODE, EMPTY CALIB., FULL CALIB, SET LRV and SET URV are parameter names used for on-site display or remote operation such as FieldCare, for instance. Endress+Hauser...

- Page 34 (EMPTY (FULL CALIB. CALIB. Observe "Warning" on page 45 in Chapter 6 "Commissioning". Parameter name used for the on-site display or remote operation such as the FieldCare. Endress+Hauser...

-

Page 35: On-Site Operation

1st selection level. In the digital communication, the LANGUAGE parameter is displayed in the DISPLAY group and the MEASURING MODE parameter is displayed in the QUICK SETUP menus or in the BASIC SETUP function group. See also Section 10.1 "Operating menu for on-site display and digital communication". Endress+Hauser... - Page 36 The decimal point is highlighted in black, i.e. you can now edit it. P01-xxxxxxxx-19-xx-xx-xx-029 1. Keep pressing "+" or "–" until "0" is displayed. 2. Confirm "0" with "E". The cursor jumps to the next position. is displayed and is highlighted in black. See next graphic. P01-xxxxxxxx-19-xx-xx-xx-030 Endress+Hauser...

-

Page 37: Historom®/M-Dat (Optional)

• Recording diverse events, such as alarms, configuration changes, counters for measuring range undershooting and exceeding for pressure and temperature, exceeding and undershooting the user limits for pressure and temperature, etc. Warning! ® Detach HistoROM /M-DAT from the electronic insert or attach it to the insert in a deenergised state only. Endress+Hauser... - Page 38 Press "E" and "-"-keys (for at least 3 seconds) until the LED on the electronic insert lights up. ® Wait approx. 20 seconds. Configuration data are loaded from the device to the HistoROM M-DAT. The device is not restarted. Disconnect device from the supply voltage again. Detach memory module. Reestablish supply voltage to the device. Endress+Hauser...

- Page 39 (Menu path: GROUPSELECTION OPERATING MENU OPERATION) ® Wait approx. 20 seconds. Configuration data are loaded from the device to the HistoROM M-DAT. The device is not restarted. Disconnect device from the supply voltage again. Detach memory module. Reestablish supply voltage to the device. Endress+Hauser...

- Page 40 (Menu path: GROUP SELECTION OPERATING MENU OPERATION) ® Wait approx. 20 seconds. Configuration data are loaded from the device to the HistoROM M-DAT. The device is restarted. ® Before removing the HistoROM /M-DAT again from the electronic insert, disconnect the device from supply voltage. Endress+Hauser...

-

Page 41: Operation Via Hart Handheld Terminal

FieldCare FieldCare is an Endress+Hauser asset management tool based on FDT technology. With FieldCare, you can configure all Endress+Hauser devices as well as devices from other manufacturers that support the FDT standard. The following operating systems are supported: WinNT4.0, Win2000 and Windows XP. -

Page 42: Locking/Unlocking Operation

FIELD COMMUNICATION PROTOCOL HW-Version: SW-Version: – P01-xxxxxxxx-19-xx-xx-xx-133 Fig. 28: DIP-switch position "Hardware locking" on the electronic insert If necessary, remove on-site display (optional) DIP-switch is at "on": operation is locked. DIP-switch is at "off": operation is unlocked (operation possible) Endress+Hauser... -

Page 43: Factory Setting (Reset)

Any customer-specific configuration carried out by the factory is not affected by a reset (customer- specific configuration remains). If, after a reset, you wish the parameters to be reset to the factory settings, please contact Endress+Hauser Service. Reset code Description and effect... - Page 44 – Function group SYSTEM 2 – Any simulation which may be running is ended. – The device is restarted. 8888 HistoROM reset The measured value memory and event memory are cleared. During the reset, the HistoROM must be attached to the electronic insert. Endress+Hauser...

-

Page 45: Commissioning

Page, Section 5.4.1 "General structure of the operating menu". The following languages are available: • Deutsch • English • Français • Italiano • Español • Nederlands • Chinese (CHS) • Japanese (JPN) The following measuring modes are available: • Pressure • Level Endress+Hauser... - Page 46 Select the menu language for the FieldCare frame via the "Extra" menu "Options" "Display" "Language". The following languages are available: • Deutsch • English • Français • Italiano • Español • Nederlands • Chinese (CHS) • Japanese (JPN) Endress+Hauser...

-

Page 47: Position Adjustment

To correct the MEASURED VALUE to 0.0 mbar, you must enter the value 2.2 here. (MEASURED VALUE = MEASURED VALUE – CALIB. OFFSET) – MEASURED VALUE (after entry for calib. offset) = 0.0 mbar – The current value is also corrected. Factory setting: Endress+Hauser... -

Page 48: Pressure Measurement

VALUE via the POS. ZERO ADJUST parameter with the VALUE via the POS. ZERO ADJUST parameter with the "Confirm" option, i. e. you assign the value 0.0 to the "Confirm" option, i. e. you assign the value 0.0 to the pressure present. pressure present. Endress+Hauser... - Page 49 Note! For on-site operation, see also Page 31, Section 5.2.3 "Function of the operating elements" and Page 35, Section 5.4 "On-site operation". Endress+Hauser...

-

Page 50: Level Measurement

RESET parameter (menu path: (GROUP SELECTION ) OPERATING MENU OPERATION) using the reset code "7864". For further information see the Cerabar S (SD190P) Functional Safety Manual. • See the Operating Instructions BA274P "Cerabar S/Deltabar S/Deltapilot S, Description of device functions". See also Page 2, "Overview Documentation" section. Endress+Hauser... - Page 51 % must not be in direct proportion to the measured pressure. A linearisation table must be entered for the 2nd measured variable. The 2nd measured variable is assigned to the 1st measured variable by means of this table. Endress+Hauser...

- Page 52 Select MEASURING MODE. Select "Level" option. MEASURING MODE Select "Level" option. LEVEL SELECTION LEVEL SELECTION Select level mode. For an overview see Page 51. Select level mode. For an overview see Page 51. GROUP SELECTION Select QUICK SETUP menu. Endress+Hauser...

- Page 53 – LEVEL SELECTION "Level Easy Pressure" and CALIBRATION MODE "Wet" – LEVEL SELECTION "Level Standard", LEVEL MODE "Linear" and CALIBRATION MODE "Wet" Note! For on-site operation, see also Page 31, Section 5.2.3 "Function of the operating elements" and Page 35, Section 5.4 "On-site operation". Endress+Hauser...

-

Page 54: Maintenance

• The cleaning agents used should not attack the surface and the seals. • Mechanical damage to the process isolating diaphragm, e.g. due to pointed objects, must be avoided. • Observe degree of protection. See therefor nameplate if necessary (Page 6). Endress+Hauser... -

Page 55: Trouble-Shooting

• If the device detects a defect in the on-site display during initialization, special error messages are generated. For the error messages, see Page 62, Section 8.1.1 "On-site display error messages". • For support and further information, please contact Endress+Hauser Service. • See also Section 8.4, 8.5 and 8.6. - Page 56 Spans for the "Height linearized" option: LEVEL MAX – LEVEL MIN; TANK CONTENT MAX. – TANK CONTENT MIN. 613 (W613) Warning I>Simulation is active – Simulation is switched on, i.e. the – Switch off simulation. device is not measuring at present. Endress+Hauser...

- Page 57 – Carry out calibration again. (See limits. linearisation table is either below the also Operating Instructions BA274P, value for HYDR. PRESS MIN. or chapter 5 or these Operating MIN. LEVEL or above the value for Instructions, Page 2.) HYDR. PRESS. MAX. or LEVEL MAX. Endress+Hauser...

- Page 58 – At least on Y-VALUE in the – Carry out calibration again. (See limits linearisation table is below the MIN. also Operating Instructions BA274P, TANK CONTANT or above the chapter 5 or these Operating MAX. TANK CONTENT. Instructions, Page 2.) Endress+Hauser...

- Page 59 – Briefly disconnect device from the power supply. – Main electronics defect. – Replace main electronics. 729 (A729) Alarm B>RAM error – Fault in the main electronics. – Briefly disconnect device from the power supply. – Main electronics defect. – Replace main electronics. Endress+Hauser...

- Page 60 – Briefly disconnect device from the power supply. – Main electronics defect. – Replace main electronics. 739 (A739) Alarm B>Measurement error – Fault in the main electronics. – Briefly disconnect device from the power supply. – Main electronics defect. – Replace main electronics. Endress+Hauser...

- Page 61 748 (A748) Alarm B>Memory failure in signal – Electromagnetic effects are greater – Block off electromagnetic effects or processor than specifications in the technical eliminate source of disturbance. data. (See Section 9.) – Main electronics defect. – Replace main electronics. Endress+Hauser...

-

Page 62: Response Of Outputs To Errors

122 for "Sensor not number such as 613 for "Simulation is digit number such as 731 for "URV user connected". active". limits exceeded". Menu path: (GROUP SELECTION ) OPERATING MENU OUTPUT Menu path: (GROUP SELECTION ) OPERATING MENU MESSAGES Endress+Hauser... - Page 63 – Lower sensor limit undershot (E 120 "Sensor low pressure"): 3.6 mA – Upper sensor limit overshot (E 115 "Sensor overpressure") overshot: current output assumes the value set via the SET MAX ALARM parameter. Factory setting: • ALT. CURR. OUTPUT: normal Endress+Hauser...

-

Page 64: Confirming Messages

(see also Section 8.1). Once you have suppressed this message using the F-key, the message with the next highest priority is displayed. You can use the F-key to suppress each message, one after the other. The ALARM STATUS parameter continues to display all the messages present. Endress+Hauser... -

Page 65: Repair

Cerabar S PMC71, PMP71, PMP72, PMP75 with 4...20 mA HART Trouble-shooting Repair The Endress+Hauser repairs concept provides for measuring devices to have a modular design and also the customer may carry out repairs (see Chap. 8.6 "Spare Parts" on Page 66). Note! •... -

Page 66: Spare Parts

Select the required spare parts (You may also use the overview drawing on the right side of the screen.) When ordering spare parts, always quote the serial number indicated on the nameplate. As far as necessary, the spare parts also include replacement instructions. Endress+Hauser... -

Page 67: Returning The Device

• Please fill out completely and sign the "Declaration of Hazardous Material and De- Contamination". It is only then possible for Endress+Hauser to inspect or repair the returned device. • The chemical and physical properties of the fluid. • A description of the application. -

Page 68: Software History

– ToF Tool Field Tool Package version 3.00.00 or higher – FieldCare version 2.01.00, DTM Library version 2.06.00, DTM: Deltabar S/MD7x/V02.00 V 1.4.98.74* – HART Communicator 375 with Device Rev.: 20, DD Rev.: 1* * Menu languages Chinese and Japanese not selectable Endress+Hauser... - Page 69 BA274P/00/EN/05.08 – ToF Tool Field Tool Package version 4.0 71077559 71077544 71071855 – FieldCare version 2.02.00 – HART Communicator 375 with Device Rev.: 21, DD CD507P/00/A2/06.09 BA271P/00/EN/06.09 BA274P/00/EN/06.09 Rev.: 1 71095448 71095434 71095452 CD507P/00/A2/05.10 BA271P/00/EN/05.10 BA274P/00/EN/05.10 71111804 71111792 71118244 Endress+Hauser...

-

Page 70: Technical Data

PRESS. ENG. UNIT parameter. These parameters are indicated with a "*". • For a description of the parameters, please refer to Operating Instructions BA274P "Description of device functions". The exact dependency of individual parameters on one another is explained here. See also Page 2, Section "Overview documentation". Endress+Hauser... - Page 71 Cerabar S PMC71, PMP71, PMP72, PMP75 with 4...20 mA HART Appendix Endress+Hauser...

- Page 72 There are parameters that are only displayed if other parameters are appropriately configured. For example the CUSTOMER UNIT P parameter is only displayed if the "User unit" option was selected for the PRESS. ENG. UNIT parameter. These parameters are indicated with a "*". P01-PMx7xxxx-19-xx-xx-xx-039 Endress+Hauser...

- Page 73 There are parameters that are only displayed if other parameters are appropriately configured. For example the CUSTOMER UNIT P parameter is only displayed if the "User unit" option was selected for the PRESS. ENG. UNIT parameter. These parameters are indicated with a "*". P01-PMx7xxxx-19-xx-xx-xx-040 Endress+Hauser...

- Page 74 There are parameters that are only displayed if other parameters are DAMPING VALUE appropriately configured. For example the CUST. UNIT FACT. H parameter is only displayed if the "User unit" option was selected for the HEIGHT UNIT parameter. These parameters are indicated with a "*". P01-xxxxxxxx-19-xx-xx-xx-140 Endress+Hauser...

- Page 75 EDITOR TABLE EDITOR TABLE LINE-NUMB ACTIVE LIN. TAB. Y EDITOR TABLE X-VAL. Y-VAL. TANK DESCRIPTION EDITOR TABLE TANK DESCRIPTION There are parameters that are only displayed if other parameters are appropriately configured. These parameters are indicated with a "*". P01-PMx7xxxx-19-xx-xx-xx-041 Endress+Hauser...

- Page 76 There are parameters that are only displayed if other parameters are 2) Display via appropriately configured. HART handheld terminal only These parameters are indicated with a "*". 3) Level measuring mode only 4) only LEVEL SELECTION = Level Easy Pressure See Safety Manual SD190P. P01-PMx7xxxx-19-xx-xx-xx-042 Endress+Hauser...

- Page 77 NR OF REMOTE SEAL 4 TH VALUE FILL FLUID 2) Display via FieldCare and HART handheld terminal only There are parameters that are only displayed if other parameters are appropriately configured. These parameters are indicated with a "*". P01-PMx7xxxx-19-xx-xx-xx-043 Endress+Hauser...

- Page 78 Pressure Level Tank content Current SIM. PRESSURE SIM. LEVEL SIM. TANK CONT. SIM. CURRENT SIM. ERROR NO. There are parameters that are only displayed if other parameters are appropriately configured. These parameters are indicated with a "*". P01-PMx7xxxx-19-xx-xx-xx-044 Endress+Hauser...

-

Page 79: Patents

• US 5,050,034 A1 i EP 0 445 382 B1 • US 5,005,421 A1 i EP 0 351 701 B1 • EP 0 414 871 B1 • EP 1 061 351 B1 • US 5,334,344 A1 i EP 0 490 807 B1 • US 6,703,943 A1 Endress+Hauser... - Page 80 Appendix Cerabar S PMC71, PMP71, PMP72, PMP75 with 4...20 mA HART Endress+Hauser...

- Page 81 Cerabar S PMC71, PMP71, PMP72, PMP75 with 4...20 mA HART Appendix Endress+Hauser...

-

Page 82: Index

Operating keys, function, without on-site display ..30 Operating keys, position ......29 Endress+Hauser... - Page 83 Erklärung zur Kontamination und Reinigung Please reference the Return Authorization Number (RA#), obtained from Endress+Hauser, on all paperwork and mark the RA# clearly on the outside of the box. If this procedure is not followed, it may result in the refusal of the package at our facility.

- Page 84 www.endress.com/worldwide BA271P/00/EN/05.10 71111792 CCS/FM+SGML6.0 71111792...