Fluke DTX-1800 Technical Reference Handbook

Dtx series cable analyzer

Hide thumbs

Also See for DTX-1800:

- Technical reference handbook (320 pages) ,

- User manual (62 pages) ,

- User manual (56 pages)

Summary of Contents for Fluke DTX-1800

- Page 1 DTX Series CableAnalyzer ™ Technical Reference Handbook April 2004, Rev. 11 1/11 ©2004-2011 Fluke Corporation. All rights reserved. All product names are trademarks of their respective companies.

- Page 2 90 days, unless otherwise stated. Ni-Cad, Ni-MH and Li-Ion batteries, cables or other peripherals are all considered parts or accessories. The warranty extends only to the original buyer or end user customer of a Fluke Networks authorized reseller, and does not apply to any product which, in Fluke Networks’...

- Page 3 SOFTWARE NOTICE This notice applies to portions of the software used in this product. Copyright © 1982, 1986, 1990, 1993 The Regents of the University of California. All rights reserved. Redistribution and use in source and binary forms, with or without modification, are permitted provided that the following conditions are met: 1.

- Page 5 Chapter Page Getting Acquainted Overview of Features ............................1-1 Registration ..............................1-2 Additional Resources for Cable Testing Information ..................1-2 Contacting Fluke Networks ..........................1-3 Unpacking ................................ 1-4 DTX-1800 ..............................1-4 DTX-1200 ..............................1-4 DTX-LT ................................. 1-4 DTX-ELT ............................... 1-5 DTX-CLT ...............................

- Page 6 Enabling or Disabling the Beeper ......................1-29 Overview of Memory Features ........................1-29 Inserting and Removing the Memory Card ....................1-29 Formatting the Memory Card (DTX-1800 and DTX-1200) or Internal Memory ........1-29 Creating Folders ............................1-30 Setting the Storage Location (DTX-1800 and DTX-1200) ................. 1-31 Options for Entering Cable IDs ........................

- Page 7 Step 1: Checking the Memory Space Available ..................2-1 Step 2: Entering Job Information ....................... 2-1 Step 3: Setting the Storage Location (DTX-1800 and DTX-1200) ............. 2-2 Step 4: Setting Up a Job Folder ........................2-2 Step 5: Selecting a Cable ID Source ......................2-4 Certifying Twisted Pair Cabling ........................

- Page 8 DTX Series CableAnalyzer Technical Reference Handbook Creating a List of Sequential IDs ........................ 2-23 About ANSI/TIA/EIA-606-A Cable IDs ......................2-25 Certifying Twisted Pair Cabling Setting the Reference ............................3-1 Testing Twisted Pair Patch Cords ........................3-2 Twisted Pair Test Settings ..........................3-3 Autotest on Twisted Pair Cabling ........................

- Page 9 Contents Using the Tone Generator ..........................3-37 Testing Twisted Pair Through a PoE Device Enabling the AC Wire Map Test ........................4-1 Autotest Through a PoE Device ........................4-1 AC Wire Map Results ............................4-4 Running the AC Wire Map Test as a Single Test .................... 4-7 Certifying Coaxial Cabling Setting the Reference ............................

- Page 10 DTX Series CableAnalyzer Technical Reference Handbook Running the HDTDX Analyzer ........................6-7 Recognizing Faults on HDTDX Plots ......................6-9 The HDTDR Analyzer ............................6-10 Running the HDTDR Analyzer ........................6-10 Recognizing Faults on HDTDR Plots ......................6-10 Using the OTDR Module Overview of Features ............................

- Page 11 Contents OTDR Details Screens ..........................7-42 Bi-Directional Testing ............................7-47 Using Manual OTDR Mode ..........................7-48 Certifying Fiber Optic Cabling Overview of Features ............................8-1 Safety Information ............................8-2 Installing and Removing Fiber Modules ......................8-4 Installing the Connector Adapter ........................8-6 Verifying Operation ............................

- Page 12 DTX Series CableAnalyzer Technical Reference Handbook Loopback Mode Autotest Results ......................8-36 Autotest in Far End Source Mode ........................8-38 Setting the Reference in Far End Source Mode ..................8-40 Testing Your Test Reference Cords in Far End Source Mode ..............8-42 Running the Autotest in Far End Source Mode ..................

- Page 13 Contents Software Requirements ........................... 11-1 Installing and Removing the Network Module and Optional SFP Module ..........11-2 Verifying Network Connectivity ........................11-4 Network Connectivity Test Settings ......................11-4 Entering Ping Addresses ..........................11-4 Running the Connectivity Test ........................11-6 About Testing for PoE (Power Over Ethernet) ..................11-6 Pinging Network Devices ..........................

- Page 14 Creating a New Folder ..........................13-4 Changing Folders ............................13-4 Deleting Folders ............................13-5 Viewing and Managing Saved Results ......................13-6 Moving or Copying Results to a Memory Card (DTX-1800, DTX-1200) ............ 13-7 Deleting Results ............................13-7 Renaming Results ............................13-8 Sorting Results ............................. 13-8 Formatting a Memory Card (DTX-1800, DTX-1200) or Internal Memory ............

- Page 15 Contents Replacing the Battery Pack ......................... 14-7 Replacing the Internal Battery ........................14-7 Fiber and OTDR Module Maintenance ...................... 14-7 Storage ................................14-8 Options and Accessories ..........................14-8 If Something Seems Wrong ..........................14-9 Specifications ..............................14-11 Feature Comparison of DTX Models ......................14-11 Environmental and Regulatory Specifications ..................

- Page 16 DTX Series CableAnalyzer Technical Reference Handbook Visual Fault Locator Specifications ......................14-35 Power ................................14-36 Electromagnetic Compatibility ........................14-36 Input Ratings ............................... 14-36 Certification and Compliance ........................14-36 CSA Standards ............................. 14-37 Safety ................................14-37 Laser Classification and Safety for DTX-MFM2, DTX-GFM2, and DTX-SFM2 Fiber Modules ....14-37 Regulatory Information ..........................

- Page 17 Contents Fiber Test Method Names Loss Test Methods for Fiber Cabling Introduction ..............................C-1 1 Jumper Method ............................. C-2 2 Jumper Method ............................. C-4 3 Jumper Method ............................. C-6 Modified 1 Jumper Method ..........................C-8 Index xiii...

- Page 18 DTX Series CableAnalyzer Technical Reference Handbook...

-

Page 19: List Of Figures

List of Figures Figure Page 1-1. Tester Front Panel Features..........................1-10 1-2. Tester Side and Top Panel Features ......................... 1-12 1-3. Smart Remote Features ............................ 1-14 1-4. Charging and Removing the Battery ......................1-17 1-5. Remote Battery Status Shown After Power-up....................1-18 1-6. - Page 20 Testing a Fiber Link in Smart Remote Mode (1 Jumper Method) ..............2-20 2-13. Summary Results Screen for an Autotest on Fiber ..................2-21 3-1. Twisted Pair Reference Connections for the DTX-1800, DTX-1200, and DTX-LT........... 3-2 3-2. Twisted Pair Reference Connections for the DTX-ELT and DTX-CLT.............. 3-2 3-3.

- Page 21 List of Figures Figure Page 3-21. Return Loss Plot..............................3-27 3-22. Far-End Crosstalk (FEXT) ........................... 3-29 3-23. ACR-F Plot................................3-31 3-24. Causes and Effects of Noise ..........................3-34 3-25. Impulse Noise Test Results..........................3-36 3-26. Using the Tone Generator..........................3-38 4-1.

- Page 22 DTX Series CableAnalyzer Technical Reference Handbook Figure Page 7-8. Launch/Receive Events in the Event Table ....................... 7-15 7-9. OTDR Trace with Launch Compensation Enabled................... 7-16 7-10. OTDR Port Connection Quality Gauge......................7-21 7-11. Progress Screen for Extended Test Times......................7-22 7-12.

- Page 23 List of Figures Figure Page 8-15. Testing the Test Reference Cords in Loopback Mode ..................8-33 8-16. Testing a Fiber in Loopback Mode (1 Jumper Method) ................. 8-35 8-17. Loopback Mode Summary and Loss Result Screens (single-directional)............8-36 8-18. Equipment for Testing in Far End Source Mode (1 Jumper Method) ............8-39 8-19.

- Page 24 DTX Series CableAnalyzer Technical Reference Handbook Figure Page 11-8. Identifying Links with Optional LinkRunner Cable ID Locators ..............11-16 13-1. Memory Status Screen Features ........................13-2 13-2. View Results Screen............................13-6 14-1. Twisted Pair Connections for Updating the Software with a PC ..............14-3 14-2.

-

Page 25: List Of Tables

List of Tables Table Page 1-1. International Electrical Symbols ......................1-8 3-1. Twisted Pair Test Settings ........................3-3 3-2. dB Rules for Permanent Link Test Limits ........................3-14 3-3. dB Rules for Channel Test Limits ..........................3-14 3-4. Smart Remote Requirements for Twisted Pair Single Tests..............3-33 5-1. - Page 26 DTX Series CableAnalyzer Technical Reference Handbook Table Page 11-1. Network Connectivity Test Settings ...................... 11-5 11-2. Diagnosing Low-Level Network Problems .................... 11-17 12-1. Settings for Custom OTDR Limits ......................12-8 14-1. Troubleshooting the Tester........................14-9 14-2. Level IV Accuracy Performance Parameters per IEC Guidelines*............14-16 14-3.

-

Page 27: Overview Of Features

• The DTX-1800 certifies twisted pair and coaxial cabling • The DTX-1800 and DTX-1200 store up to 4,000 Autotest to Class F limits (600 MHz) in less than 25 seconds and results, including graphical data, on a 128 MB Category 6 cabling in less than 10 seconds. The removable memory card. -

Page 28: Registration

Fluke Networks products and provides service. articles on cable testing techniques and technology. To The DTX-1800 also supports the optional DTX 10 Gig kit. access the Knowledge Base, log on to This lets you test and certify Cat 6 and Augmented Cat 6 www.flukenetworks.com, then click Customer Support >... -

Page 29: Contacting Fluke Networks

Getting Acquainted Contacting Fluke Networks Contacting Fluke Networks Note If you contact Fluke Networks about your tester, have the tester's software and hardware version numbers available if possible. www.flukenetworks.com support@flukenetworks.com +1-425-446-4519 • Australia: 61 (2) 8850-3333 or 61 (3) 9329 0244 •... -

Page 30: Unpacking

DTX-1800 • Two carrying straps • DTX-1800 CableAnalyzer with lithium-ion battery pack • USB cable for PC communications • DTX-1800 Smart Remote with lithium-ion battery pack • Two ac adapters • Two Cat 6A/Class E permanent link adapters • •... -

Page 31: Dtx-Elt

Getting Acquainted Unpacking • USB cable for PC communications DTX-CLT • • DTX-CLT CableAnalyzer with lithium-ion battery pack Two ac adapters • • DTX-CLT SmartRemote with lithium-ion battery pack DTX Series CableAnalyzer Users Manual • Two 6A/Class E channel adapters •... -

Page 32: Dtx-Clt Certifiber

DTX Series CableAnalyzer Technical Reference Handbook • DTX-CLT CertiFiber DTX-CLT CertiFiber Getting Started Guide • DTX-CLT CertiFiber Product Manuals CD DTX-CertiFiber-M Multimode Kit • LinkWare Software CD • DTX-CLT CertiFiber with lithium-ion battery pack • DTX-CertiFiber-MS Multimode/Singlemode Kit DTX-CLT CertiFiber SmartRemote with lithium-ion battery pack •... -

Page 33: Dtx-Mfm2 Multimode Fiber Modules (Optional)

50 /125 µm fiber. Many are available as • DTX-MFM2/GFM2/SFM2 Fiber Modules Users Manual accessories from Fluke Networks. DTX-GFM2 Multimode Fiber Modules (optional) DTX Compact OTDR Optical Time Domain • Two DTX-GFM2 Fiber Modules for testing at 850 nm... -

Page 34: Safety Information

Do not modify the tester. Warning: Risk of fire, electric shock, or personal injury. • Use only ac adapters approved by Fluke Networks for use with the DTX tester to charge the battery Warning or Caution: Risk of damage or or power the tester. - Page 35 Memory cards may be lost, damaged, or adapter’s jack. Inserting other connectors, such as accidentally formatted, resulting in data loss. RJ11 (telephone) connectors, can permanently Therefore, Fluke Networks recommends saving no damage the jack. more than one day’s worth of test results on a •...

-

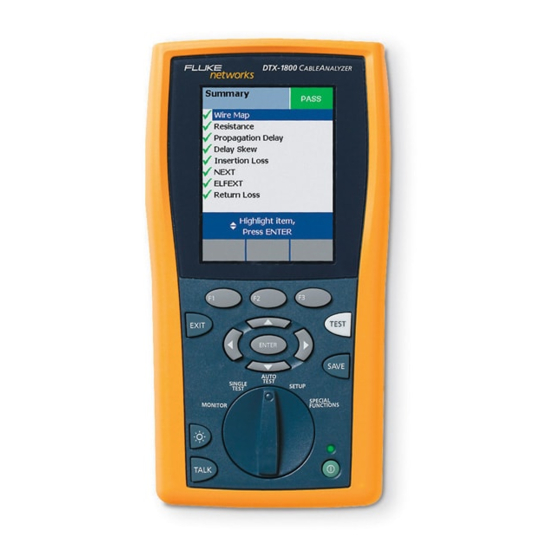

Page 36: Basic Features

DTX Series CableAnalyzer Technical Reference Handbook Basic Features Physical Features Figures 1-1 and 1-2 describe the tester’s features. Figure The following sections introduce the tester's basic features. 1-3 describes the smart remote’s features. EXIT TEST ENTER SAVE AUTO TEST SINGLE SETUP TEST SPECIAL... - Page 37 Getting Acquainted Basic Features LCD display with backlight and adjustable brightness. : Press to switch the backlight between bright and dim settings. Hold for 1 second to adjust the display : Starts the currently selected test. Activates the tone contrast. generator for twisted pair cabling if no smart remote is B C A D detected.

- Page 38 DTX Series CableAnalyzer Technical Reference Handbook amd33f.eps Figure 1-2. Tester Side and Top Panel Features 1-12...

- Page 39 • Green: Battery is charged. • DTX-1800 and DTX-1200: Slot and activity LED for the Flashing red: Charge timeout. The battery failed to removable memory card. To eject the card, push in then reach full charge within 6 hours. See “If Something release the card.

- Page 40 DTX Series CableAnalyzer Technical Reference Handbook amd30f.eps Figure 1-3. Smart Remote Features 1-14...

- Page 41 Getting Acquainted Basic Features Caution Low battery LED lights when the battery is low. All the LEDs flash if the smart remote detects : Starts the test currently selected on the main unit. excessive voltage on the cable. Unplug the cable Activates the tone generator for twisted pair cabling if no main tester is detected.

-

Page 42: Changing The Language

DTX Series CableAnalyzer Technical Reference Handbook Changing the Language Charging the Battery To charge the battery, connect the ac adapter to the To change the tester’s language: battery pack, as shown in Figure 1-4. Turn the rotary switch to SETUP. You may charge the battery when it is attached or detached from the tester. - Page 43 Getting Acquainted Basic Features amd124f.eps Figure 1-4. Charging and Removing the Battery 1-17...

- Page 44 DTX Series CableAnalyzer Technical Reference Handbook Checking the Battery Status The Time Remaining value tells you approximately how long the main tester’s battery will last based on the last The battery status icon ( ) near the upper-right corner of 3 minutes of use.

- Page 45 Getting Acquainted Basic Features amd102f.eps Figure 1-6. Connections for Using the Battery Status Function 1-19...

-

Page 46: About Link Interface Adapters And Modules

Cat 6. Optional coaxial adapters let you test coaxial cabling. For information on other adapter types, contact Fluke Networks or visit the Fluke Networks website. The adapter’s Autotest counters are helpful for gauging wear on the adapter’s jack or plug and for tracking the... - Page 47 Getting Acquainted Basic Features Modules provide optional testing capabilities. For example, the DTX-MFM2, DTX-GFM2, and DTX-SFM2 modules let you certify fiber optic cabling. The DTX-NSM module lets you verify network service. See Chapters 8 and 11 for details on these modules. EXIT TEST EXIT...

- Page 48 DTX Series CableAnalyzer Technical Reference Handbook amd36f.eps Figure 1-8. Handling Guidelines for Permanent Link Adapters 1-22...

- Page 49 The optional DTX-PLCAL automated calibration kit lets you calibrate your permanent link adapters to compensate for physical changes that occur over time to the adapter’s cable and other components. Contact Fluke Networks for more information. 1-23...

-

Page 50: Verifying Operation

DTX Series CableAnalyzer Technical Reference Handbook Verifying Operation If fiber modules are installed in addition to twisted pair adapters, select Mainframe. The tester performs a basic self test when you turn it on. To run a more thorough self test for an acceptance test or as Press part of a routine equipment check: If the tester reports an error, refer to “If Something Seems... -

Page 51: Checking The Hardware And Software Versions

Basic Features Checking the Hardware and Software To determine if your tester needs a software update, visit the Fluke Networks website to see if an update is available. Versions See Chapter 14 for details on updating the tester's To see information about the tester’s hardware and software. - Page 52 DTX Series CableAnalyzer Technical Reference Handbook Outlet Configuration: The wire mapping used for testing twisted pair cabling. Press to check the memory status. Press to view the results of the previous test. If a copper adapter and a fiber module are installed, press to change the type of media you will test.

-

Page 53: Setting User Preferences

Getting Acquainted Setting User Preferences Setting User Preferences Changing the Length Units Turn the rotary switch to SETUP, use The following sections describe how to change settings you highlight Instrument Settings; then press may want to adjust when you first start using the tester. Press to go to the tab with the Length Units selection. -

Page 54: Adjusting The Display Contrast

DTX Series CableAnalyzer Technical Reference Handbook Adjusting the Display Contrast To set the power down timer: Press and hold Turn the rotary switch to SETUP, use highlight Instrument Settings; then press for coarse adjustments and Fine Fine for fine adjustments. Press to go to the tab with the Power Down Time- Out setting;... -

Page 55: Enabling Or Disabling The Beeper

The DTX-1800 and DTX-1200 testers can also store up to 500 Press Format. Cat 6 Autotest results, including graphical data, on a 16 MB card. The testers can also use cards with higher capacity and secure digital (SD) memory cards. -

Page 56: Creating Folders

Technical Reference Handbook Creating Folders You can organize your test results by saving them in folders. To create a folder: DTX-1800, DTX-1200: Insert a memory card into the tester. Turn the rotary switch to SETUP. to highlight Instrument Settings; then press Press to highlight Current Folder;... -

Page 57: Setting The Storage Location (Dtx-1800 And Dtx-1200)

Options for Entering Cable IDs 1200) When you save a test, you enter a name for the test. At a To set the destination for saved results on a DTX-1800 or job site, you usually name each test with the identification DTX-1200 tester: code assigned to the link tested. -

Page 58: Automatically Saving Results (Dtx-1800, Dtx-1200, Dtx-Lt, Dtx-Clt, Dtx-Clt Certifiber)

DTX Series CableAnalyzer Technical Reference Handbook • Auto Sequence: Lets you select IDs from a list of Automatically Saving Results (DTX-1800, DTX- sequential IDs generated from a template in SETUP. 1200, DTX-LT, DTX-CLT, DTX-CLT CertiFiber) The horizontal, backbone, and campus templates... -

Page 59: Saving Different Types Of Results In The One Record

Getting Acquainted Using the Talk Mode Saving Different Types of Results in the One Using the Talk Mode Record The talk mode lets you talk to the person at the other end of a twisted pair or fiber link. Two-way communication over You can save results from different types of DTX modules in twisted pair requires one good wire pair. -

Page 60: About Linkware And Linkware Stats Software

Help on the LinkWare menu. ™ The LinkWare Cable Test Management software included Updates to LinkWare software are available on the Fluke with your tester lets you do the following: Networks website. • Upload DTX test results to PC. See page14-2. -

Page 61: Preparing To Save Tests

2-1 Turn the rotary switch to SETUP. Step 1: Checking the Memory Space Available 2-2 Use to highlight Instrument Settings; then press 1-1 DTX-1800, DTX-1200: Insert a memory card into the tester. 2-3 Press to go to the tab with the Operator Name 1-2 Turn the rotary switch to SPECIAL FUNCTIONS. -

Page 62: Step 3: Setting The Storage Location (Dtx-1800 And Dtx-1200)

Step 3: Setting the Storage Location (DTX-1800 and DTX-1200) 4-2 Turn the rotary switch to SETUP. To set the destination for saved results on a DTX-1800 or 4-3 Use to highlight Instrument Settings; then press DTX-1200 tester:... - Page 63 Tutorials on Setup and Test Procedures Preparing to Save Tests The characters available for use. To select a character to enter in the text box, use to highlight the character; then press . The character is entered to the left of the cursor. The text you are entering.

-

Page 64: Step 5: Selecting A Cable Id Source

DTX Series CableAnalyzer Technical Reference Handbook Step 5: Selecting a Cable ID Source Certifying Twisted Pair Cabling Cable IDs are names you enter for tests you save. You can This tutorial familiarizes you with testing twisted pair select IDs from a pre-generated list, or enter them manually cabling by guiding you through the following tasks: after each test. - Page 65 Tutorials on Setup and Test Procedures Certifying Twisted Pair Cabling PASS TEST FAIL TALK TONE LOW BATTERY EXIT TEST ENTER SAVE AUTO SINGLE TEST TEST SETUP SPECIAL MONITOR FUNCTIONS TEST TALK TALK amd40f.eps Tester and smart remote with battery packs For testing channels: two channel adapters Note Memory card (optional)

-

Page 66: Step 1: Checking The Battery Status And Verifying Operation With Twisted Pair Adapters

DTX Series CableAnalyzer Technical Reference Handbook Step 1: Checking the Battery Status and Verifying Operation with Twisted Pair Adapters You should check the tester and smart remote’s battery status and verify all equipment is in good working order before going to the job site. 1-1 Connect the main and remote testers using one of the Permanent link methods shown in Figure 2-3. -

Page 67: Step 2: Selecting A Test Limit, Cable Type, And Outlet Configuration

Tutorials on Setup and Test Procedures Certifying Twisted Pair Cabling Step 2: Selecting a Test Limit, Cable Type, and 2-6 The first Test Limit screen shows the most recently-used limits. To see the list of test limit groups, press Outlet Configuration More. -

Page 68: Step 3: Running The Autotest

DTX Series CableAnalyzer Technical Reference Handbook Step 3: Running the Autotest 3-1 Attach the correct adapters to the tester and smart remote. 3-2 Turn on the tester and smart remote; then connect them to the cabling. Figures 2-4 and 2-5 show connections for permanent link and channel installations. - Page 69 Tutorials on Setup and Test Procedures Certifying Twisted Pair Cabling Horizontal cabling Optional consolidation point Work area Patch panel Wall outlet Start permanent permanent link link PASS TEST FAIL TALK TONE Tester with permanent Smart remote with LOW BATTERY link adapter permanent link adapter EXIT TEST...

- Page 70 DTX Series CableAnalyzer Technical Reference Handbook Horizontal cabling Hub or switch Optional consolidation point Patch cord from hub or Work area switch Patch Wall panels outlet Start Patch channel cord channel from PC PASS TEST FAIL TALK TONE LOW BATTERY Tester with Smart remote with EXIT...

-

Page 71: Step 4: Viewing The Autotest Results

Tutorials on Setup and Test Procedures Certifying Twisted Pair Cabling Step 4: Viewing the Autotest Results The Summary screen, shown in Figure 2-6, tells you if the test results met the selected test limit. This screen also shows a status for each measurement: : PASS : FAIL : The results are for informational purposes only. -

Page 72: Step 5: Saving The Results

DTX Series CableAnalyzer Technical Reference Handbook Step 5: Saving the Results Certifying Fiber Cabling 5-1 Press Note 5-2 Use the text editing screen to enter a name for the The fiber modules are not compatible with the results. See Figure Figure 2-1 on page 2-3 for details on DTX-ELT. - Page 73 Tutorials on Setup and Test Procedures Certifying Fiber Cabling amd46f.eps Tester and smart remote with fiber modules. Use Two singlemode adapters of the appropriate type DTX-MFM2 modules for testing multimode fiber. Use Two mandrels. Recommended when testing multimode DTX-GFM2 modules for testing multimode fiber for fiber with DTX-MFM2 modules.

-

Page 74: Step 1: Installing The Fiber Modules

DTX Series CableAnalyzer Technical Reference Handbook Step 1: Installing the Fiber Modules Caution 1-1 Turn off the tester and smart remote. Leave the module bay covers in place when the fiber modules are not installed. 1-2 Remove the cover from the back of each unit and install a DTX-MFM2, DTX-GFM2, or DTX-SFM2 module in each Step 2: Checking the Battery Status and Verifying unit, as shown in Figure 2-8. -

Page 75: Step 3: Selecting A Fiber Type And Test Limit

Tutorials on Setup and Test Procedures Certifying Fiber Cabling 3-3 On the Fiber menu use to select Fiber Type. Fiber types are organized in groups: • Generic: Generic types of fiber • Custom: Fiber types entered by a DTX user •... -

Page 76: Step 4: Configuring The Fiber Test

DTX Series CableAnalyzer Technical Reference Handbook Step 4: Configuring the Fiber Test Step 5: Setting the Reference 4-1 Turn the rotary switch to SETUP. 5-1 Clean the connectors on the tester and the two test reference cords. 4-2 Use to highlight Fiber Loss; then press 5-2 Turn the rotary switch to SPECIAL FUNCTIONS. - Page 77 Tutorials on Setup and Test Procedures Certifying Fiber Cabling amd145f.eps Figure 2-10. Setting the Reference in Smart Remote Mode (1 Jumper Method) 2-17...

-

Page 78: Step 6: Testing The Test Reference Cords

(The limits are different because fiber has more loss at Note 850 nm than at 1300 nm.) Fluke Networks recommends that you use this procedure to make sure your test reference cords Singlemode test reference cord: are good before you test each fiber link. - Page 79 Tutorials on Setup and Test Procedures Certifying Fiber Cabling amd175.eps Figure 2-11. Testing the Test Reference Cords in Smart Remote Mode 2-19...

-

Page 80: Step 7: Running The Test

DTX Series CableAnalyzer Technical Reference Handbook Step 7: Running the Test 7-3 Turn the rotary switch to AUTOTEST. If a copper adapter is attached, verify that the media type is set to Fiber. 7-1 Clean the connectors on the cabling to be tested. Press Change Media to change it if necessary. -

Page 81: Step 7: Viewing The Results

Tutorials on Setup and Test Procedures Certifying Fiber Cabling Step 7: Viewing the Results The Summary screen, shown in Figure 2-13, tells you if the test results met the selected test limit. This screen also shows a status for each measurement: : PASS : FAIL : The results are for informational purposes only. -

Page 82: Using The Auto Increment And Sequential Cable Id Features

DTX Series CableAnalyzer Technical Reference Handbook Using the Auto Increment and Letters increment through the alphabet shown on the text editing screen: Sequential Cable ID Features 1A, 1B, 1C…1Y, 1Z, 1Ç…1Û, 1Ü, 1A The auto increment and sequential ID features generate To use the auto increment ID feature: cable IDs automatically. -

Page 83: Creating A List Of Sequential Ids

Tutorials on Setup and Test Procedures Using the Auto Increment and Sequential Cable ID Features Creating a List of Sequential IDs These IDs produce the following ID list: The tester includes templates for creating a list of ROOM A DROP#1 sequential IDs. - Page 84 DTX Series CableAnalyzer Technical Reference Handbook to highlight Auto Sequence, then press 13 Press to leave the sample list. If the tester shows an error message, check your Start to highlight Template, then press and Stop IDs for the problems listed below. 14 Press when you are done setting up the list.

-

Page 85: About Ansi/Tia/Eia-606-A Cable Ids

Tutorials on Setup and Test Procedures Using the Auto Increment and Sequential Cable ID Features To use an ID from the auto sequence list: Horizontal Link Identifier Horizontal links run between telecommunications closets Verify that the Cable ID Source in SETUP is set to Auto and work areas. - Page 86 DTX Series CableAnalyzer Technical Reference Handbook Campus Cable Identifier Campus cables are backbone cables that run between buildings. Format: [b1-f s1]/[b2-fs2]-n.d Example: LBRY-01A/AUD-01A-5.16 The cable tested is in the backbone cable that runs between the library (LBRY), floor 1, telecom room A and the auditorium (AUD), floor 1, telecom room A.

-

Page 87: Setting The Reference

Chapter 3: Certifying Twisted Pair Cabling Setting the Reference Attach permanent link and channel adapters and make the connections shown in Figure 3-1. The reference procedure sets a baseline for insertion loss, ACR-F, and dc resistance measurements. For the DTX-ELT and DTX-CLT, which do not include permanent link adapters, use the reference module Run the tester’s reference procedure at the following times: included to connect the main and remote testers, as... -

Page 88: Testing Twisted Pair Patch Cords

Figure 3-1. Twisted Pair Reference Connections for the a network. DTX-1800, DTX-1200, and DTX-LT Patch cord testing requires the optional DTX-PCU6S Patch Cord Adapter Set. Contact Fluke Networks or visit the Fluke Networks website for more information. Note The DTX-PCU6S Patch Cord Adapter Set is not... -

Page 89: Twisted Pair Test Settings

Certifying Twisted Pair Cabling Twisted Pair Test Settings Twisted Pair Test Settings To access the settings, turn the rotary switch to SETUP, use to highlight Twisted Pair; then press Table 3-1 describes the settings that apply to twisted pair cabling tests. Table 3-1. - Page 90 DTX Series CableAnalyzer Technical Reference Handbook Ethernet and M12 T568A T568B USOC Single-Pair Two-Pair USOC Two-Pair Ethernet and M12 Two-Pair Crossed ATM/TP-PMD ATM/TP-PMD Token Ring Straight Crossed Crossover 1000BASE-T Crossover Rollover amd180.eps Figure 3-3. Outlet Configurations...

- Page 91 You should also set the reference every 30 days. See “Setting the Reference” on page 3-1. SETUP > Instrument Cable ID Source, Current Folder, Result Storage Location (DTX-1800, DTX-1200), Operator, Site, Settings Company, and Auto Save Results setting. See “Preparing to Save Tests” on page 2-1 and Settings for saving tests “Automatically Saving Results”...

-

Page 92: Autotest On Twisted Pair Cabling

DTX Series CableAnalyzer Technical Reference Handbook Autotest on Twisted Pair Cabling To run the Autotest on twisted pair cabling: Verify that the settings listed in Table 3-1 are Figure 3-4 shows the equipment needed for certifying appropriate. twisted pair cabling. Attach adapters appropriate for the job to the tester and the smart remote. - Page 93 Certifying Twisted Pair Cabling Autotest on Twisted Pair Cabling Horizontal cabling Optional consolidation point Work area Patch panel Wall outlet Start permanent permanent link link PASS TEST FAIL TALK TONE Tester with permanent Smart remote with LOW BATTERY link adapter permanent link adapter EXIT TEST...

- Page 94 DTX Series CableAnalyzer Technical Reference Handbook Horizontal cabling Hub or switch Optional consolidation point Patch cord from hub or Work area switch Patch Wall panels outlet Start Patch channel cord channel from PC PASS TEST FAIL TALK TONE LOW BATTERY Tester with Smart remote with EXIT...

-

Page 95: Twisted Pair Autotest Results

Certifying Twisted Pair Cabling Twisted Pair Autotest Results • Twisted Pair Autotest Results Return loss • ACR-N (attenuation to crosstalk ratio at the near end) The tests listed below apply to twisted pair cabling. and ACR-N at the smart remote Note •... - Page 96 DTX Series CableAnalyzer Technical Reference Handbook PASS: All parameters are within limits. FAIL: One or more parameters exceed the limit. PASS*/FAIL*: One or more parameters are within the tester’s accuracy uncertainty range, and the “*” notation is required by the selected test standard.

-

Page 97: Automatic Diagnostics

Certifying Twisted Pair Cabling Twisted Pair Autotest Results Automatic Diagnostics A failed test may produce more than one diagnostic screen. ADBC In this case, press to see additional If an Autotest fails, press Fault Info for diagnostic screens. information about the failure. The diagnostic screens show Figure 3-8 shows examples of diagnostic screens. -

Page 98: Pass*/Fail* Results

DTX Series CableAnalyzer Technical Reference Handbook PASS*/FAIL* Results A PASS* may be considered a passing result. A FAIL* should be considered a failure. A result marked with an asterisk means that measurements are in the tester’s accuracy uncertainty range (Figure 3-9) and the “*”... -

Page 99: About Db Rules

If insertion loss is less than 12 dB at 450 MHz, a relaxed 3 dB Rule NEXT limit is used. See the Knowledge Base on the Fluke Networks website for details. This rule applies to all test limits where return loss is measured. - Page 100 DTX Series CableAnalyzer Technical Reference Handbook 70 dB Rule Table 3-3. dB Rules for Channel Test Limits This rule applies to any channel or permanent link test limit Class for Channel Test Limit where ACR-F is measured. Test At frequencies where FEXT is less than 70 dB, ACR-F cannot NEXT fail.

-

Page 101: Wire Map

Certifying Twisted Pair Cabling Twisted Pair Autotest Results Wire Map examples of wire map screens. For information on AC wire map screens, see Chapter 4. Wire map results show the connections between the main Tip: The wire map test in Single Test mode features a and remote testers. - Page 102 DTX Series CableAnalyzer Technical Reference Handbook amd82i.bmp amd83i.bmp amd84i.bmp Split pair Reversed pair Crossed pairs A wire in the 3,6 pair is crossed with a Wires 1 and 2 are crossed. Pairs 1,2 and 3,6 are crossed. wire in the 4,5 pair. Figure 3-10.

-

Page 103: Resistance

Certifying Twisted Pair Cabling Twisted Pair Autotest Results Resistance Resistance results show the dc loop resistance for each cable pair. The smart remote shorts the end of each pair to create the loops. A pair’s resistance depends on the integrity of the contacts in the connector, the length of the pair, and its wire gauge. -

Page 104: Length

This is the 10 % rule Length for length, as given in the ANSI/TIA standard. See the Fluke Networks Knowledge base for details. Length results show the length of each cable pair. The PASS/FAIL result is assigned based on the shortest measured length. -

Page 105: Propagation Delay And Delay Skew

Certifying Twisted Pair Cabling Twisted Pair Autotest Results Propagation Delay and Delay Skew Delay skews are the differences in propagation delays between the shortest delay and the delays of the other Propagation delay is the time taken for a test pulse to travel cable pairs. -

Page 106: Insertion Loss

DTX Series CableAnalyzer Technical Reference Handbook Insertion Loss At higher frequencies, signals tend to travel only near the surface of a conductor. This “skin effect”, along with the Note cabling’s inductance and capacitance, cause insertion loss to Insertion loss is also known as attenuation. increase with frequency. - Page 107 Certifying Twisted Pair Cabling Twisted Pair Autotest Results The overall insertion loss result. “PASS*/FAIL* Results” on page 3-12 describes results marked with an asterisk. Horizontal and vertical magnification levels for the plot. To change the magnification, press Change To Zoom; then to zoom horizontally or vertically.

-

Page 108: Next (Near-End Crosstalk)

DTX Series CableAnalyzer Technical Reference Handbook NEXT (Near-End Crosstalk) For NEXT failures, the tester's diagnostic screens ( Fault Info) may show more than one possible cause for the NEXT results show the crosstalk attenuation between cable failure. In this case, you can use the HDTDX analyzer results pairs. - Page 109 Certifying Twisted Pair Cabling Twisted Pair Autotest Results The location of the NEXT results. Press to switch between the tester and smart remote. The overall NEXT result. “PASS*/FAIL* Results” on page 3-12 describes results marked with an asterisk. Horizontal and vertical magnification levels for the plot. To change the magnification, press Change To Zoom;...

-

Page 110: Acr-N (Attenuation To Crosstalk Ratio At The Near End)

DTX Series CableAnalyzer Technical Reference Handbook ACR-N (Attenuation to Crosstalk Ratio at the between NEXT and attenuation (insertion loss). Higher Near End) ACR-N values mean received signals are much larger than crosstalk signals. Higher ACR-N values correspond to better Note cabling performance. - Page 111 Certifying Twisted Pair Cabling Twisted Pair Autotest Results The location of the ACR-N results. Press to switch between the tester and smart remote. The overall ACR-N result. “PASS*/FAIL* Results” on page 3-12 describes results marked with an asterisk. Horizontal and vertical magnification levels for the plot. To change the magnification, press Change To Zoom;...

-

Page 112: Return Loss

DTX Series CableAnalyzer Technical Reference Handbook Return Loss interpret strong reflected signals as incoming data, resulting in data errors. Return loss is the difference between the power of a A return loss plot indicates how well a cable’s impedance transmitted signal and the power of the signals reflected matches its rated impedance over a range of frequencies. - Page 113 Certifying Twisted Pair Cabling Twisted Pair Autotest Results The location of the return loss results. Press to switch between the tester and smart remote. The overall return loss result. “PASS*/FAIL* Results” on page 3-12 describes results marked with an asterisk. Horizontal and vertical magnification levels for the plot.

-

Page 114: Ps Next (Power Sum Near End Crosstalk)

DTX Series CableAnalyzer Technical Reference Handbook PS NEXT (Power Sum Near End Crosstalk) PS ACR-N is the difference (in dB) between each wire pair’s attenuation (insertion loss) and the combined crosstalk PS NEXT results show how much each cable pair is affected received from the other pairs. - Page 115 Certifying Twisted Pair Cabling Twisted Pair Autotest Results Signal source Crosstalk farther from the input Crosstalk near the input Far-end crosstalk amd94f.eps Figure 3-22. Far-End Crosstalk (FEXT) Because of attenuation, FEXT on longer cables is less than on all four wire pairs, so ACR-F is a critical parameter for FEXT on shorter cables of the same type.

-

Page 116: Ps Acr-F Test

DTX Series CableAnalyzer Technical Reference Handbook NEXT and ACR-F performance tends to be similar in cable, PS ACR-F Test but may differ greatly in connecting hardware. Some Note connectors achieve good NEXT performance by balancing PS ACR-F is also known as PSELFEXT (power sum the inductive and capacitive currents that cause crosstalk. - Page 117 Certifying Twisted Pair Cabling Twisted Pair Autotest Results The location of the ACR-F results. Press to switch between the tester and smart remote. The overall ACR-F result. “PASS*/FAIL* Results” on page 3-12 describes results marked with an asterisk. Horizontal and vertical magnification levels for the plot. To change the magnification, press Change To Zoom;...

-

Page 118: Running Single Tests

DTX Series CableAnalyzer Technical Reference Handbook Running Single Tests Single tests use the selected test limit to produce a PASS/ FAIL result for the test. Each single test also produces results The tester’s single test mode (SINGLE TEST on the rotary for other measurements. - Page 119 Certifying Twisted Pair Cabling Running Single Tests Table 3-4. Smart Remote Requirements for Twisted Pair Single Tests Test Smart Remote Requirements* HDTDX analyzer Recommended. Without a smart remote, results for short cables may be unreliable. HDTDR analyzer Optional. Without a smart remote, the plot shows large reflections at the end of the cabling. Recommended.

-

Page 120: Monitoring Impulse Noise

DTX Series CableAnalyzer Technical Reference Handbook Monitoring Impulse Noise Noise distorts the shape of digital signals, as shown in Figure 3-24. Too much noise can cause transmission errors, Impulse noise is electrical noise generated by fluorescent resulting in poor network performance. lights, electric motors, electric heaters and air conditioners, The impulse noise test lets you monitor noise on inactive photocopiers, refrigerators, microwave ovens, and other... - Page 121 Stop; then use to change the value. Press resume testing. Tip: Fluke Networks recommends a noise threshold of 30 mV with an average pulse rate below 0.01/sec for testing 1000BASE-T (Gigabit Ethernet) cabling. To stop the test at any time, press...

- Page 122 DTX Series CableAnalyzer Technical Reference Handbook The average number of noise hits per second. The highest number of noise hits per second since the start of the test. The time shows when the peak was recorded. The minimum level of noise considered to be a noise hit. To change the threshold, press Stop;...

-

Page 123: Using The Tone Generator

Note ™ a tone probe such as a Fluke Networks IntelliTone probe. The toner's signal may not be detectable along The tone probe converts the toner’s signal to audible tones... - Page 124 DTX Series CableAnalyzer Technical Reference Handbook Patch panel Tone probe, such as Volume control the Fluke Networks PASS TEST IntelliTone probe FAIL TALK TONE LOW BATTERY Tester or smart remote Press to start the toner TEST TALK amd96f.eps Figure 3-26. Using the Tone Generator...

-

Page 125: Enabling The Ac Wire Map Test

Chapter 4: Testing Twisted Pair Through a PoE Device Note The AC wire map test lets you test links connected through midspan PoE (Power over Ethernet) devices. When you Always disable the AC Wire Map test when not enable this test, the tester uses AC signals instead of DC testing through a PoE device. - Page 126 DTX Series CableAnalyzer Technical Reference Handbook amd24f.eps Figure 4-1. Testing a Permanent Link Through a PoE Device...

- Page 127 Testing Twisted Pair Through a PoE Device Autotest Through a PoE Device amd58f.eps Figure 4-2. Testing a Channel Through a PoE Device...

-

Page 128: Ac Wire Map Results

DTX Series CableAnalyzer Technical Reference Handbook AC Wire Map Results When the tester detects multiple wire map faults or cannot map the cable wiring, it may not display the wire map AC wire map results are similar to the wire map results screen, but may show a diagnostics screen instead. - Page 129 Testing Twisted Pair Through a PoE Device AC Wire Map Results amd52.bmp amd50.bmp amd45.bmp Open on pair 1,2. The open is 21.7 m Short between pairs 1,2 and 3,6. The Split pair on pairs 1,2 and 3,6. The from the tester and 61.4 m from the short is 1.7 m from the tester.

- Page 130 DTX Series CableAnalyzer Technical Reference Handbook amd44.bmp amd43.bmp The tester detected one or more wire map faults on pairs The tester detected multiple, complex faults on the 1,2 and 3,6 about 4 ft from the tester. The distance to cabling. faults may not be given for some types of complex faults.

-

Page 131: Running The Ac Wire Map Test As A Single Test

Testing Twisted Pair Through a PoE Device Running the AC Wire Map Test as a Single Test Running the AC Wire Map Test as a Single Test To run the AC Wire Map test as a single test, enable the test in SETUP, turn the rotary switch to SINGLE TEST;... - Page 132 DTX Series CableAnalyzer Technical Reference Handbook...

-

Page 133: Setting The Reference

Chapter 5: Certifying Coaxial Cabling Certifying coaxial cabling requires the optional DTX-COAX To set the reference, do the following: coaxial adapters. Note Note Turn on the tester and let it sit for 1 minute before setting the reference. Set the reference only after The DTX-COAX adapters are not compatible with the the testers have reached an ambient temperature DTX-CLT. -

Page 134: Verifying Operation

DTX Series CableAnalyzer Technical Reference Handbook Verifying Operation Connect the main and remote testers as shown for setting the reference in Figure 5-1. Turn the rotary switch to SPECIAL FUNCTIONS. to highlight Self Test; then press Press If the tester reports an error, refer to “If Something Seems Wrong”... - Page 135 Certifying Coaxial Cabling Coaxial Test Settings Table 5-1. Coaxial Cable Test Settings Setting Description Select the appropriate test limit for the job. SETUP > Coaxial > Test Limit Select a cable type appropriate for the type you will test. SETUP > Coaxial >...

- Page 136 You should also set the reference every 30 days. See “Setting the Reference” on page 5-1. Set Reference Cable ID Source, Current Folder, Result Storage Location (DTX-1800, DTX-1200), Operator, Site, Settings for saving tests and Company. See “Preparing to Save Tests” in on page 2-1.

-

Page 137: Autotest On Coaxial Cabling

Certifying Coaxial Cabling Autotest on Coaxial Cabling Autotest on Coaxial Cabling Figure 5-2 shows the equipment needed for certifying coaxial cabling. PASS TEST FAIL TALK TONE LOW BATTERY EXIT TEST ENTER SAVE AUTO TEST SINGLE SETUP TEST SPECIAL MONITOR FUNCTIONS TEST TALK TALK... - Page 138 DTX Series CableAnalyzer Technical Reference Handbook To run the Autotest on coaxial cabling: Press on the tester or smart remote. To stop the test at any time, press Verify that the settings listed in Table 5-1 are The tester shows the Autotest Summary screen when appropriate.

- Page 139 Certifying Coaxial Cabling Autotest on Coaxial Cabling PASS TEST FAIL TALK TONE LOW BATTERY EXIT TEST ENTER SAVE AUTO SINGLE TEST SETUP TEST SPECIAL MONITOR FUNCTIONS TEST TALK TALK amd139.eps Figure 5-3. Coaxial Network Cabling Test Connections...

- Page 140 DTX Series CableAnalyzer Technical Reference Handbook Connection to coaxial cabling Wall outlet Female to female Female to female F-connector adapter F-connector adapter PASS TEST FAIL TALK TONE LOW BATTERY Tester with coaxial Smart remote with EXIT TEST adapter coaxial adapter ENTER SAVE AUTO...

-

Page 141: Coaxial Autotest Results

Certifying Coaxial Cabling Coaxial Autotest Results Coaxial Autotest Results Note The Autotest runs some or all of the tests shown in Figure 5-5 describes the Autotest Summary screen, which Figure 5-5, depending on the selected test limit. lists the tests that apply to coaxial cabling. PASS: All parameters are within limits. -

Page 142: Hdtdr Analyzer

DTX Series CableAnalyzer Technical Reference Handbook HDTDR Analyzer Characteristic impedance is the impedance a cable would have if the cable were infinitely long. Good cabling has ™ The HDTDR (High-Definition Time Domain Reflectometry) relatively constant characteristic impedance throughout the analyzer plots the locations and magnitudes of reflections cable and connectors. -

Page 143: Insertion Loss

Certifying Coaxial Cabling Running Single Tests Insertion Loss Running Single Tests Insertion loss is the loss of signal strength over the cabling. The tester’s single test mode (SINGLE TEST on the rotary Insertion loss is caused by the resistance of the copper wire switch) lets you run individual tests for isolating cabling and connecting hardware and by leakage of electrical failures and quickly testing repairs. - Page 144 DTX Series CableAnalyzer Technical Reference Handbook Table 5-2. Smart Remote Requirements for Coaxial Single Tests Test Smart Remote Requirements* HDTDR analyzer Optional. Without a smart remote, the plot shows large reflections at the end of the cabling. Resistance Smart remote or terminator required for loop resistance measurement. Length Not required.

-

Page 145: Using The Automatic Diagnostics

• information about the location and likely cause of the fault. Keep the tester’s software current. The latest software is available on the Fluke Networks website. See page 14-2 for details on installing updates. • Set the reference for the twisted pair adapters every 30 days. -

Page 146: Common Causes Of Copper Cabling Failures

DTX Series CableAnalyzer Technical Reference Handbook Common Causes of Copper Cabling Failures Table 6-1 describes common causes of test failures on twisted pair and coaxial cabling. Table 6-1. Diagnosing Twisted Pair Test Failures Wire Map: open • Wires connected to wrong pins at connector or Tip: The wire map test in Single Test mode features a punchdown blocks scanning function that runs the wire map test... - Page 147 Diagnosing Copper Cabling Faults Common Causes of Copper Cabling Failures Table 6-1. Diagnosing Twisted Pair Test Failures (cont.) Wire Map: short • • Damaged connector Improper connector termination • • Damaged cable Wrong application for cable • Conductive material stuck between pins at connector. “Bad patch cord”...

- Page 148 If the length of the shortest pair does not exceed the limit by 10 %, then the length test passes even if other pairs exceed the limit. This is the 10 % rule for length, as given in the ANSI/TIA standard. See the Fluke Networks Knowledge base for details.

- Page 149 Diagnosing Copper Cabling Faults Common Causes of Copper Cabling Failures Table 6-1. Diagnosing Twisted Pair Test Failures (cont.) Return loss gives FAIL, FAIL*, or PASS* result • Patch cord or cable impedance not 100 Ω • Poorly matched plug and jack (6A/Class E applications) •...

- Page 150 DTX Series CableAnalyzer Technical Reference Handbook Table 6-1. Diagnosing Twisted Pair Test Failures (cont.) NEXT, PS NEXT, ACR-F, PS ACR-F gives FAIL, FAIL*, or PASS* result • Excessive untwisting of pairs at connector Note • Fixing NEXT problems usually corrects ACR-F Poor quality patch cords problems.

-

Page 151: The Hdtdx Analyzer

Diagnosing Copper Cabling Faults The HDTDX Analyzer The HDTDX Analyzer Turn on the smart remote; then connect the tester and remote to the cabling. ™ The HDTDX (High-Definition Time Domain Crosstalk) Turn the rotary switch to SINGLE TEST, select HDTDX analyzer plots the locations and magnitudes of crosstalk on Analyzer;... - Page 152 DTX Series CableAnalyzer Technical Reference Handbook Horizontal and vertical magnification levels for the plot. In zoom mode, use zoom in or out at the cursor’s location. The distance to the end of the cabling. The cursor and the distance to the cursor from the tester.

-

Page 153: Recognizing Faults On Hdtdx Plots

Diagnosing Copper Cabling Faults The HDTDX Analyzer Recognizing Faults on HDTDX Plots Figure 6-2 shows how some common faults appear on HDTDX plots. Bad section of cable Bad spool of cable Bad patch cord amd98f.eps A bad patch cord about 53 m from the tester. A spool of cable with poor NEXT performance. -

Page 154: The Hdtdr Analyzer

DTX Series CableAnalyzer Technical Reference Handbook The HDTDR Analyzer Turn on the smart remote; then connect the tester and remote to the cabling. ™ The HDTDR (High-Definition Time Domain Reflectometry) Turn the rotary switch to SINGLE TEST, select HDTDR analyzer plots the locations and magnitudes of reflections Analyzer;... - Page 155 Diagnosing Copper Cabling Faults The HDTDR Analyzer Horizontal and vertical magnification levels for the plot. In zoom mode, use zoom in or out at the cursor’s location. The distance to the end of the cabling. The cursor and the distance to the cursor from the tester.

- Page 156 DTX Series CableAnalyzer Technical Reference Handbook amd100f.eps Figure 6-4. Interpreting HDTDR Plots 6-12...

- Page 157 Diagnosing Copper Cabling Faults The HDTDR Analyzer Open on pair 1,2 near the smart remote. A positive A link with a section of cable that has higher impedance (120 Ω) than the rest of the cable. The bad section starts reflection indicates an increase in impedance.

- Page 158 DTX Series CableAnalyzer Technical Reference Handbook 6-14...

-

Page 159: Overview Of Features

Chapter 7: Using the OTDR Module • Note Displays OTDR results in summary format, as a table of events, or as an OTDR trace. PASS/FAIL results are based The DTX-OTDR module is not compatible with the on factory-installed limits or limits you specify. DTX-ELT, DTX-CLT, or DTX-CLT CertiFiber. -

Page 160: Safety Information

DTX Series CableAnalyzer Technical Reference Handbook Safety Information Caution To avoid damaging the tester or cables under test, Warning to avoid data loss, and to ensure maximum To avoid possible eye damage caused by accuracy of test results: hazardous radiation and to avoid possible fire, •... - Page 161 Using the OTDR Module Safety Information • • Avoid touching reflective surfaces (such as metal) Read the instructions for splice machines before using the OTDR to monitor splicing procedures. to the end of a fiber cable plugged into the OTDR The OTDR can interfere with the light injection when the OTDR is operating.

-

Page 162: Installing The Otdr Module

DTX Series CableAnalyzer Technical Reference Handbook Installing the OTDR Module To install the module, refer to Figure 7-1 and do the following: Caution Turn off the tester. To avoid damaging the DTX mainframe or the Remove and discard the standard bail. OTDR module and to ensure proper operation: Install the bail included with the DTX Compact OTDR •... - Page 163 Using the OTDR Module Installing the OTDR Module SAVE AUTO TEST SINGLE SETUP TEST SPECIAL MONITOR FUNCTIONS TALK amd157f.eps Figure 7-1. Installing the OTDR Module...

-

Page 164: Using The Cradle

Figure 7-2 shows how to use the cradle to stand the tester up The following software supports the DTX Compact OTDR on a flat surface when a DTX Compact OTDR module is module. Software upgrades are available on the Fluke attached. Networks website. -

Page 165: Otdr Module Features

Using the OTDR Module OTDR Module Features OTDR Module Features OTDR ports for singlemode (left) and multimode (right) fiber. The ports have removable SC connector adapters with protective caps. Visual fault locator (VFL) output with universal fiber connector and protective cap. The connector accepts 2.5 mm ferrules. Laser safety label (shown below): amd155f.eps Warning*... -

Page 166: Verifying Operation

The tester performs a basic self test on the mainframe and Inspect connectors with a fiber microscope, such as the OTDR module when you turn it on. To run the self test Fluke Networks FiberInspector Video Microscope before manually, select Self Test from the SPECIAL FUNCTIONS making connections. - Page 167 Using the OTDR Module Setting Up for OTDR Testing Always cover unused connectors with protective caps. Clean caps periodically with a swab or wipe and fiber optic solvent. Unlocking and removing the Cleaning the OTDR Ports adapter Use a dry, optical-grade wipe to clean the OTDR ports. Figure 7-4 shows how to remove the OTDR adapter to access the connector ferrule.

-

Page 168: Selecting Auto Or Manual Otdr Mode

DTX Series CableAnalyzer Technical Reference Handbook Selecting Auto or Manual OTDR Mode Manual OTDR mode lets you select the settings to optimize the OTDR for displaying specific events. See “Using Manual Note OTDR Mode” on page 7-48 for details. Typically, you should use Auto OTDR mode when certifying cabling with the OTDR. -

Page 169: About Launch And Receive Fibers

OTDR traces and labels these events in the event table. It enabled during the test. also removes these fibers’ losses, lengths, and attenuation Fluke Networks recommends that you use launch and coefficients from overall OTDR results. The losses of the receive fibers. You should also use launch compensation to... - Page 170 DTX Series CableAnalyzer Technical Reference Handbook Types of Compensation On the Set Launch Method screen highlight the type of compensation you want to do. The tester offers three types of compensation: • Launch Only: Lets you compensate for a launch fiber. Clean the tester's OTDR port and launch fiber connectors.

- Page 171 Using the OTDR Module Setting Up for OTDR Testing You should run the compensation function again if you Launch fiber end and change the launch or receive fiber used for a wavelength. receive fiber beginning Launch Viewing the Launch Compensation Settings fiber To view launch compensation settings that have been saved, turn the rotary switch to SPECIAL FUNCTIONS, select...

- Page 172 DTX Series CableAnalyzer Technical Reference Handbook Launch fiber Launch fiber end Receive fiber beginning Cabling to be tested Tester with OTDR module Receive fiber amd66f.eps Figure 7-7. Launch + Fiber + Receive Compensation Connections 7-14...

- Page 173 Using the OTDR Module Setting Up for OTDR Testing Launch/receive event, indicated by the launch/receive event icon shown for Launch + Receive compensation. Press View Trace to see the trace used for the launch compensation settings. If the launch or receive event is misidentified in the event table, use to select the correct event, then use the softkeys to remove or move the launch or receive event assignments.

- Page 174 DTX Series CableAnalyzer Technical Reference Handbook Launch fiber Receive fiber length length Beginning of End of receive fiber launch fiber Measurement is relative to the end of the launch fiber amd68f.eps Figure 7-9. OTDR Trace with Launch Compensation Enabled 7-16...

- Page 175 Using the OTDR Module Setting Up for OTDR Testing • Manually Selecting the Launch and Receive Events For Launch + Receive compensation, highlight the event that is the end of the launch fiber and the If necessary, you can manually select the launch and receive beginning of the receive fiber;...

-

Page 176: Settings For Otdr Tests

DTX Series CableAnalyzer Technical Reference Handbook Settings for OTDR Tests To see the settings used for an OTDR test: On the OTDR Results screen, press View Events. Table 7-1 describes the settings that apply to OTDR tests. To access the settings (except for job settings), turn the On the Event Table screen, press View Details. - Page 177 Using the OTDR Module Setting Up for OTDR Testing Table 7-1. OTDR Test Settings (cont.) Setting Description Fiber Characteristics When Fiber Characteristics is set to User Defined, the n and Backscatter values can be edited by the user. When the Fiber Characteristics is set to Default, the tester uses the values defined in the current Fiber Type.

- Page 178 DTX Series CableAnalyzer Technical Reference Handbook Table 7-1. OTDR Test Settings (cont.) Setting Description Wavelength You can test cabling at one or all the wavelengths supported by the installed module and the selected test limit. Note If you select the dual-wavelength setting, be sure to select a fiber type and test limit that supports both wavelengths.

-

Page 179: Otdr Port Connection Quality

If a connector on the tester is damaged, contact Fluke Networks for service information. A poor OTDR connection increases the connector’s deadzone, which can hide faults near the OTDR port. -

Page 180: Progress Screen For Extended Test Times

DTX Series CableAnalyzer Technical Reference Handbook Progress Screen for Extended Test Times When the test time per wavelength exceeds 21 seconds, the tester shows the developing trace along with the progress indicator. Figure 7-11 shows an example of this screen. The tester updates the trace as measurement averaging proceeds. -

Page 181: Running The Otdr Test

Using the OTDR Module Running the OTDR Test Running the OTDR Test Figure 7-12 shows the equipment needed for OTDR tests. EXIT TEST ENTER SAVE AUTO SINGLE TEST SETUP TEST SPECIAL MONITOR FUNCTIONS TALK amd152f.eps Tester with OTDR module Launch fiber and receive fibers. Match the fiber to be tested. - Page 182 DTX Series CableAnalyzer Technical Reference Handbook To run the OTDR test: To save the results, press ; then do one of the following: Verify that the settings described in Table 7-1 are appropriate. • To save the results in a new record, create an ID or select an unused ID from the Auto Sequence ID list or Select Auto OTDR mode: Turn the rotary switch to the List of downloaded IDs;...

- Page 183 Using the OTDR Module Running the OTDR Test Installed fiber Patch Patch panel panel Launch fiber Tester with OTDR module amd101f.eps Figure 7-13. Connecting the OTDR to Installed Fiber (no receive fiber) 7-25...

- Page 184 DTX Series CableAnalyzer Technical Reference Handbook Installed fiber Patch Patch panel panel Launch fiber Tester with OTDR EXIT TEST ENTER Receive SAVE module AUTO TEST SINGLE SETUP TEST fiber SPECIAL MONITOR FUNCTIONS TALK amd116f.eps Figure 7-14. Connecting the OTDR to Installed Fiber (with receive fiber) 7-26...

- Page 185 Using the OTDR Module Running the OTDR Test Pigtail patch cord and mechanical splice Tester with OTDR module Spooled cable amd122f.eps Figure 7-15. Connecting the OTDR to Spooled Cable 7-27...

-

Page 186: Looking At Otdr Test Results

DTX Series CableAnalyzer Technical Reference Handbook Looking at OTDR Test Results Reading the OTDR Results Screen The OTDR Results screen, which appears when the test is The tester offers four different views of OTDR test results: finished, is described in Figure 7-16. summary results, an OTDR trace, an event table, and detailed results. - Page 187 Using the OTDR Module Looking at OTDR Test Results Table 7-2. OTDR Results Screen Measurements Item Description Length The length of the fiber in the cabling. If the measured length seems wrong, check the Index of Refraction in Setup. The length does not include launch and receive fibers if launch fiber compensation is enabled.

-

Page 188: Viewing The Otdr Trace

DTX Series CableAnalyzer Technical Reference Handbook Viewing the OTDR Trace Figure 7-17 describes the readouts and navigational features on the OTDR screen. Figure 7-18 describes the To see the OTDR trace, press View Trace from the features of a typical OTDR trace. OTDR Results or Event Table screen. - Page 189 Using the OTDR Module Looking at OTDR Test Results Wavelength for the trace and the End setting selected in Press to see the Event Table. See page 7-35. Setup. If the test ran at two wavelengths, press Event information appears if the cursor is on an event. Next Trace to switch wavelengths.

- Page 190 DTX Series CableAnalyzer Technical Reference Handbook amd125f.eps Figure 7-18. Typical OTDR Trace Features 7-32...

- Page 191 Using the OTDR Module Looking at OTDR Test Results Reflective event caused by the OTDR port connection. Reflective event caused by the last connection in the cabling. The dotted line marks the end of the fiber under Reflective event caused by the first connection in the test and the beginning of the receive fiber.

-

Page 192: Using The Measurement Cursor

DTX Series CableAnalyzer Technical Reference Handbook BCAD Using the Measurement Cursor to move the cursor to the ending point for the measurement. You can use the cursor on the OTDR trace to measure distances and losses along the cabling. The following readouts appear on the screen: To make measurements with the cursor: •... -

Page 193: Zooming The Trace

Using the OTDR Module Looking at OTDR Test Results Zooming the Trace The Event Table The zoom function lets you magnify the trace horizontally To see a list of the events along the cabling, press or vertically. View Events from the OTDR Results screen or the OTDR Trace screen. - Page 194 DTX Series CableAnalyzer Technical Reference Handbook Overall result for the test. Events on the fiber, each event’s status, and the distance to each event. See Table 7-3 on page 7-37. : The event’s measured value is within the limit. A yellow checkmark means there is a warning for the result.

- Page 195 Using the OTDR Module Looking at OTDR Test Results Table 7-3. Event Types Event Possible Causes OTDR Port The tester identifies the OTDR port connection and grades its quality, as shown on the OTDR details screens. See “OTDR Port Connection Quality” on page 7-21. The tester’s OTDR port connector.

- Page 196 DTX Series CableAnalyzer Technical Reference Handbook Table 7-3. Event Types (cont.) Event Possible Causes Tip: On some traces with multiple ghosts, only the first ghost may be identified in the event Ghost Source table. You can usually determine that other reflections are ghosts because they occur at A reflective event that is multiples of distances to connectors and they show almost no loss.

- Page 197 Using the OTDR Module Looking at OTDR Test Results Table 7-3. Event Types (cont.) Event Possible Causes Hidden The event is detected, but not enough information is available to measure its loss separately from the previous event. Since the hidden event’s loss can’t be determined, it The event is within the is not shown.

- Page 198 DTX Series CableAnalyzer Technical Reference Handbook Table 7-3. Event Types (cont.) Event Possible Causes Weak Signal No fiber is attached to the OTDR port, the fiber is too short, or there is a bad connector or broken fiber somewhere near the tester. May also occur if the fiber has very high loss, or The signal is attenuated if the tester is in Manual OTDR mode and the Pulse Width is too narrow.

- Page 199 Check for bad connections and broken fibers within a few meters of the tester. No Signal If this continues to occur, contact Fluke Networks for assistance. There is a problem with the module. The tester identifies the end of the cabling as the point where the backscatter stops.

-

Page 200: Otdr Details Screens

DTX Series CableAnalyzer Technical Reference Handbook OTDR Details Screens Use the softkeys to move among the details screens. Table 7-4 describes the details that may appear on these screens. On the Event Table, you can highlight an event, then press View Details to see more information about the event. - Page 201 Using the OTDR Module Looking at OTDR Test Results Table 7-4. OTDR Measurement Details (cont.) Detail Description Segment The attenuation per kilometer for the fiber segment before the event. This value may not be shown if it Attenuation could not be measured accurately. This can occur on short segments or if the connector before the Coefficient segment has a large deadzone.

- Page 202 • The launch fiber is too short. No signal detected (also see page 7-41): There may be a problem with the module. If the error persists, contact Fluke Networks for assistance. Unable to find end of fiber due to weak signal (also see page 7-40): •...

- Page 203 Using the OTDR Module Looking at OTDR Test Results Table 7-4. OTDR Measurement Details (cont.) Detail Description Warnings Cannot measure overall loss: • Overall loss cannot be measured, either because no backscatter was detected or the fiber is too short for attenuation to be measured.

- Page 204 DTX Series CableAnalyzer Technical Reference Handbook Table 7-4. OTDR Measurement Details (cont.) Detail Description Warnings Negative loss value (a gainer) found in test result: • One or more loss value is significantly negative (-0.2 dB or more). • There is a bad connection on the fiber. •...

-

Page 205: Bi-Directional Testing

Using the OTDR Module Bi-Directional Testing Bi-Directional Testing To test cabling in both directions and save the bi-directional results: In Setup, enter names for End 1 and End 2 to identify the ends of the cabling. Name End 1 as the end you will test first. -

Page 206: Using Manual Otdr Mode

DTX Series CableAnalyzer Technical Reference Handbook Using Manual OTDR Mode Table 7-5 describes the settings you can change in manual OTDR mode and how the settings affect the trace. You can Note access these settings on the Fiber OTDR tabs in Setup. Typically, you should use Auto OTDR mode when Tip: To see the settings used for an OTDR test, press certifying cabling with the OTDR. - Page 207 Using the OTDR Module Using Manual OTDR Mode Table 7-5. Manual OTDR Settings (cont.) Setting Description and Selection Guidelines Averaging The averaging time sets the number of measurements averaged together to create the final trace. Time Longer times reduce noise on the trace which increases dynamic range and accuracy and reveals more details, such as smaller non-reflective events.

- Page 208 DTX Series CableAnalyzer Technical Reference Handbook Table 7-5. Manual OTDR Settings (cont.) Setting Description and Selection Guidelines Loss Threshold User Defined lets you set the threshold (in decibels) for reporting loss events. Events at or above the (Auto or User threshold are included in the event table.

-

Page 209: Overview Of Features

ISO standards for most SFF (small form factor) fiber connectors. The optional DTX-MFM2, DTX-GFM2, and DTX-SFM2 fiber modules are used with a DTX-1800, DTX-1200 or DTX-LT • Provides pass/fail results based on industry-standard CableAnalyzer to test and certify fiber optic cabling limits. -

Page 210: Safety Information

DTX Series CableAnalyzer Technical Reference Handbook • Safety Information Never look directly into the visual fault locator output. Momentary exposure to the locator’s output will not damage your eyes; however, Warning: Class 1 and Class 2 Laser direct, long-term exposure is potentially Products hazardous. - Page 211 • Leave the module bay covers in place when the • Use a Fluke Networks FiberInspector Video fiber modules are not installed. Microscope to periodically inspect the fiber • When using the fiber modules, use proper module’s OUTPUT connector for scratches and...

-

Page 212: Installing And Removing Fiber Modules

DTX Series CableAnalyzer Technical Reference Handbook Installing and Removing Fiber Modules Figure 8-1 shows how to install and remove the fiber modules. Caution To avoid damaging the DXT mainframe or the fiber module and to ensure proper operation: • Turn off the tester before removing or attaching modules. - Page 213 Certifying Fiber Optic Cabling Installing and Removing Fiber Modules Button for activating the visual fault locator (B) and output port (D). See Chapter 9 and “Autotest in Far End Source Mode” on page 8-18. Universal fiber connector (with dust cap) for the visual fault locator output. The connector accepts 2.5 mm ferrules.

-

Page 214: Installing The Connector Adapter

SC, ST, LC, and FC fiber connectors (Figure • 8-3). Additional adapter styles may be available. Check the Store the connector adapters for the fiber module Fluke Networks web site for updates. in the canisters provided. • Do not touch the photodiode lens (see Figure 8-4). - Page 215 Certifying Fiber Optic Cabling Installing the Connector Adapter amd99f.eps Figure 8-4. Installing the Connector Adapter...

-

Page 216: Verifying Operation

DTX Series CableAnalyzer Technical Reference Handbook Verifying Operation Clean the tester’s connectors and the connectors on two SC/SC test reference cords. Connect the tester and smart remote together, as shown in Figure 8-5. Turn the rotary switch to SPECIAL FUNCTIONS. to highlight Self Test;... -

Page 217: Essentials For Reliable Fiber Test Results

To get reliable fiber test results, you must follow proper cleaning and referencing procedures and, in some cases, Inspect connectors with a fiber microscope, such as the use mandrels during testing. Fluke Networks FiberInspector Video Microscope before making connections. Cleaning Connectors and Adapters Cleaning the Fiber Module's Input Connector Always clean and inspect fiber connectors before making connections. -

Page 218: About Setting The Reference

• Anytime the tester warns you that the reference is out Inspect connectors with a fiber microscope, such as the of date. Fluke Networks FiberInspector Video Microscope • Anytime you see a negative loss measurement (see before making connections. page 10-3). -

Page 219: Selecting Test Reference Cords

The DTX Fiber Modules come with high-quality test reference cords. To ensure that your measurements are accurate and repeatable, use test reference cords provided by Fluke Networks or cords of the same quality. See "Replacing Fiber Test Reference Cords" on page 14-8. -

Page 220: Using Mandrels For Testing Multimode Fiber

50 µm fiber with a 3 mm jacket. These mandrels are also with the DTX-MFM2 fiber modules. Mandrels can improve available from Fluke Networks. Refer to the appropriate measurement repeatability and consistency. They also allow standard for mandrel requirements if you follow other the use of LED light sources to certify 50 µm and 62.5 µm... - Page 221 Certifying Fiber Optic Cabling Essentials for Reliable Fiber Test Results Place top wrap in groove under retainer Wrap 5 times in grooves Right: no bends at retainer Wrong: bends at retainer amd67f.eps Figure 8-6. Wrapping a Test Reference Cord Around a Mandrel 8-13...

-

Page 222: Loss/Length Test Settings

DTX Series CableAnalyzer Technical Reference Handbook Loss/Length Test Settings To access the fiber test settings turn the rotary switch to SETUP; then select Fiber Loss. Use to see different tabs. Table 8-2 describes the test settings that apply to loss/length tests on fiber cabling. - Page 223 Certifying Fiber Optic Cabling Loss/Length Test Settings Table 8-2. Loss/Length Test Settings (cont.) Setting Description SETUP > Fiber Loss > If the selected limit uses a calculated loss limit, enter the number of adapters and splices that will Number of Adapters be added to the fiber path after the reference is set.

- Page 224 DTX Series CableAnalyzer Technical Reference Handbook amd65f.eps Figure 8-7. Example of How to Determine the Number of Adapters Setting (singlemode example; mandrels not used) 8-16...

- Page 225 Connections screen) TIA reporting requirements. SETUP > Instrument Cable ID Source, Current Folder, Result Storage Location (DTX-1800, DTX-1200), Operator, Site, Settings Company, and Auto Save Results setting. See “Preparing to Save Tests” on page 2-1 and “Automatically Saving Results” on page 1-32.

-

Page 226: About 1 Jumper Connections

DTX Series CableAnalyzer Technical Reference Handbook About 1 Jumper Connections Autotest in Smart Remote Mode Use Smart Remote mode to test and certify dual-fiber The reference and test connections shown in this manual cabling. produce 1 Jumper results. 1 Jumper results include the loss of the fiber plus the loss of the connections at both ends of In this mode, the tester measures loss, length, and the link. - Page 227 Certifying Fiber Optic Cabling Autotest in Smart Remote Mode amd46f.eps Tester and smart remote with fiber modules and Two singlemode adapters of the appropriate type connector adapters installed. Match connector adapters Two mandrels. Recommended when testing multimode to the connectors in the link. fiber with DTX-MFM2 modules.

-

Page 228: Setting The Reference For Smart Remote Mode

DTX Series CableAnalyzer Technical Reference Handbook Setting the Reference for Smart Remote Mode requirements, you can enter lengths for each test reference cord number after setting the reference. Turn on both testers and let them sit for 5 minutes. Press Allow additional time if the modules have been stored above or below ambient temperature. - Page 229 Certifying Fiber Optic Cabling Autotest in Smart Remote Mode amd145f.eps Figure 8-9. Setting the Reference in Smart Remote Mode (1 Jumper Method) 8-21...

-

Page 230: Testing The Test Reference Cords In Smart Remote Mode

Caution Note Fluke Networks recommends that you use this An overall result of PASS does not show that the test reference cords are good. You must procedure to make sure your test reference cords are good before you test each fiber link. - Page 231 Certifying Fiber Optic Cabling Autotest in Smart Remote Mode amd175.eps Figure 8-10. Testing the Test Reference Cords in Smart Remote Mode 8-23...

-

Page 232: Running The Autotest In Smart Remote Mode

DTX Series CableAnalyzer Technical Reference Handbook Running the Autotest in Smart Remote Mode 24 If Open or Unknown appears as the status, try the following: Caution • Verify that all connections are good. If the test reference cords have been disconnected •... - Page 233 Certifying Fiber Optic Cabling Autotest in Smart Remote Mode amd146f.eps Figure 8-11. Testing a Fiber Link in Smart Remote Mode (1 Jumper Method) 8-25...

-

Page 234: Smart Remote Mode Autotest Results

DTX Series CableAnalyzer Technical Reference Handbook Smart Remote Mode Autotest Results Figure 8-12 describes the Summary screen and loss results screen for an unsaved, single-directional Autotest in Smart The Summary screen appears when the test is finished. To Remote mode. see more detailed results, use to highlight a For bi-directional results in Smart Remote mode, see... - Page 235 Certifying Fiber Optic Cabling Autotest in Smart Remote Mode Note To see the propagation delay, select the length result. The results described here are for an unsaved test. Propagation delay is half the time taken for a signal to Unsaved tests for Smart Remote mode show results travel from the main tester to the remote and back again.

-

Page 236: Autotest In Loopback Mode

DTX Series CableAnalyzer Technical Reference Handbook Autotest in Loopback Mode Use Loopback mode to test spools of cable and segments of uninstalled cable. In this mode, the tester measures loss, length, and propagation delay at two wavelengths in one or both directions. Figure 8-13 shows the equipment required for testing fiber in Loopback mode. - Page 237 Certifying Fiber Optic Cabling Autotest in Loopback Mode amd49f.eps Tester with fiber module and connector adapter Two singlemode adapters of the appropriate type installed (match connector adapter to the connectors in Mandrel Recommended when testing multimode fiber the link) with DTX-MFM2 modules. See page 8-12. Memory card (optional) Fiber cleaning supplies AC adapter with line cord (optional)

-