Kval 990-H Service Manual

Pre-hanging door system

Hide thumbs

Also See for 990-H:

- Service manual (66 pages) ,

- Operation manual (88 pages) ,

- Operation manual (80 pages)

Summary of Contents for Kval 990-H

- Page 1 Innovation, Quality & Honesty 990-H Pre-Hanging Door System Service Manual Published: 6/6/16...

- Page 2 Proprietary Notice This Manual is confidential and contains proprietary information and intellectual property of KVAL Inc., and is to be used solely by Customer as an operating manual for KVAL Inc. machines. Neither this Manual nor any of the information contained herein may be reproduced or disclosed under any circumstances without the express written permission of KVAL Inc.

- Page 3 KVAL 990-H Service Manual Your Feedback is Welcome: To help us design products that make your job easier and your business more successful, we'd like to gain your perspective about your user experience with our product - that is, the manual, the machinery, the software, etc.

- Page 4 KVAL 990-H Service Manual...

-

Page 5: Table Of Contents

Table of Contents Introduction to the 990-H Door Hanging System Chapter 1 Chapter 1 at a Glance.............. 1-1 Overview of the 990-H Door Hanging System ......1-2 Operation ....................1-2 Features....................1-2 Options and Specials Available ............1-4 About this Manual .................1-5 Safety First!................1-6 Safety Sheet Sign-Off Sheet..............1-6... - Page 6 Connections to Servo Drives ..............2-5 High Frequency Panel Node Connections..........2-6 Frame Node Connections..............2-7 Back Section Node ................2-7 Screw Driver Nodes 1-3................2-8 Maintenance of the 990-H Chapter 3 Maintenance Schedule ............3-2 300 Cycle Maintenance Steps ..........3-4 Clean, Clean, Clean!................3-4 600 Cycle Maintenance Steps ..........

- Page 7 Ball Screws (If Applicable) ..............3-19 Description of Air Input System ............3-19 Adjusting the Air Line Lubricator............3-20 Priming the Air Line Lubricator ............3-20 Lubrication Points on the 990-H ..........3-21 Feed System Lube Points..............3-21 Screw Driver Lube Points ..............3-22 Back Section Lube Points..............3-23 Head Lube Points ................3-24...

- Page 8 Adjusting Cylinder Extend Speed ............4-17 Adjusting Cylinder Retraction Speed ..........4-17 Using Sensors to Trouble Shoot ..........4-18 Location of Sensors on 990-H ............4-18 Troubleshooting Electrical Problems ........4-19 If the Power Stops During Normal Operation........4-19 Troubleshooting with the Status Light Panel ......4-21 Network System Overview............

-

Page 9: Chapter 1 At A Glance

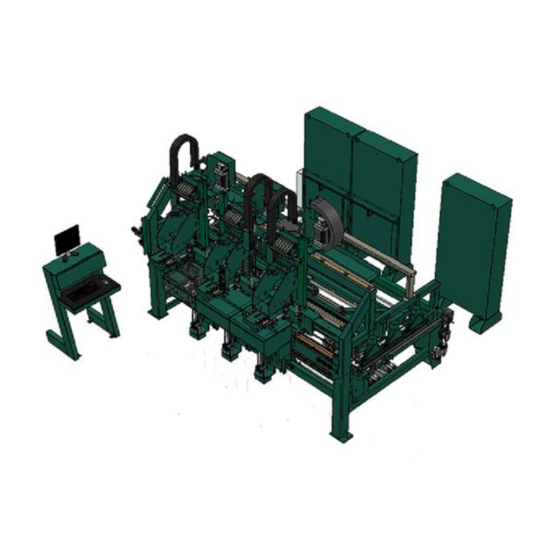

Chapter 1 at a Glance CHAPTER 1 Introduction to the 990-H Door Hanging System This chapter provides an overview of the KVAL 990-H Door Hanging System and important safety information to follow when operating the machine. Chapter 1 at a Glance Section Name... -

Page 10: Overview Of The 990-H Door Hanging System

Overview of the 990-H Door Hanging System Overview of the 990-H Door Hanging System The Kval Model 990-H will rout a door and jamb for two or three hinges, drill pilot holes for the hinge screws, rout and bore for the lock and apply hinges. - Page 11 Overview of the 990-H Door Hanging System Face bore; side drill and bolt plate router will be capable of shifting up to 300mm (11.811) off of center line of length of door in either direction. Total movement of 600mm. (23.622) Face bore drills will accommodate a three stage drill bit both top and bottom for drilling differ- ent diameter holes.

-

Page 12: Options And Specials Available

410mm in width, but without lock pro- cessing (Option includes complete secondary feed fence attached to the lock section of the 990-H that will nest under doors when not in use) Opt P... -

Page 13: About This Manual

Overview of the 990-H Door Hanging System Option Title Description Corner Square Feature Adds automatic corner squaring to the hinge rout- ing sequence, and fastening of square hinges. Price includes replacing x,y,z motion air cylinders on each of the hinge router head with ball screws and AC servo motor (9 total), as well as corner square chisel assemblies. -

Page 14: Safety First

See “Safety Sign-Off Sheet” on page 1-20. Safety Terminology of Labels In addition to the nameplate, KVAL machines may have other warning labels or decals that pro- vide safety information to operators. Safety labels should be clearly visible to the operator and must be replaced if missing, damaged, or illegible. - Page 15 Before performing any mainte- nance or repairs on this machine turn off the main air disconnect. Lockout and tagout this connection. See “Lockout Tagout Procedure” on page 1-11. KVAL 990-H Service Manual...

- Page 16 This should be done in accordance with applicable state and/or federal code requirements. Laser Warnings On some machines, laser indicators are used to set boundaries. Follow the manufacturers safety precautions. KVAL 990-H Service Manual...

- Page 17 Safety First! Compliance with Codes and Regulations KVAL advises that you request an on-site state safety review of your installation of this machine. This is to ensure conformance to any additional specific safety and health regula- tions which apply in your geographic area.

-

Page 18: Lockout-Tagout Guidelines

O..OFF! Shut off all power sources and isolating devices P..Place lock and tag E..ENERGY: Release stored energy to a zero-energy state R ..Recheck controls and test to ensure they are in the “OFF” state KVAL 990-H Service Manual 1-10... -

Page 19: Lockout Tagout Procedure

Turn Switch to the Lock and Tag out Insert Lock into hole. OFF position Note: When multiple people are working on the machine, each person needs to have a lock on the handle in the extra holes provided. KVAL 990-H Service Manual 1-11... -

Page 20: Lockout Tagout Air Supply

The lock and tag can now be removed (only by the person(s) who placed them), and the machine can be re-energized. The tags must be destroyed and the locks and keys returned to the lockout center. KVAL 990-H Service Manual 1-12... -

Page 21: Zero-Energy To Start-Up

Replace Guards Replace all equipment guards. If part of equipment cannot be properly adjusted after start-up with guard on, contact the KVAL Service team. See “Getting Help from KVAL” on page 1-15. Check Controls Confirm that all switches are in the “OFF”... - Page 22 Be sure to follow the P-R-O- P-E-R lockout/tagout procedures, and that those around you do also. Close the Cage Gate Verify all cage gates are securely closed. Ensure all safety protocols are in effect. KVAL 990-H Service Manual 1-14...

-

Page 23: Getting Help From Kval

Ask about this procedure when calling are service team Product Return Procedure If you’ve contacted Kval for help and it is determined that a return is necessary, use the procedure below to return the machine or part. - Page 24 • With what equipment is the unit interfaced? • What was the application? • What was the system environment (temperature, spacing, contaminants, etc.)? Call Kval customer support for a Return Material Authorization (RMA). When you call: • Have the packing slip or invoice numbers available.

-

Page 25: How To Download The Service Application

Download Application To download the application, go the KVAL website ( http:// www.kvalinc.com At the KVAL website, select the tab. Follow the instruc- Support tions on the Support web page. Click the Download button to download the application that... - Page 26 Session code: An internal number to track this machine. It is auto filled. Your Name Field: Enter your name. The KVAL tech- nician will use this field to identify this machine. Description: Enter machine Serial number and issue.

- Page 27 How to Download the Service Application Page Intentionally Left Blank KVAL 990-H Service Manual 1-19...

-

Page 28: Safety Sign-Off Sheet

Note: It is recommended you make a copy of this sheet for new operators. If a copy is needed, you may download a PDF at the KVAL website (http://www.kvalinc.com). You may also contact our Service Department at (800) 553-5825 or email at service@kvalinc.com. - Page 29 Safety Sign-Off Sheet KVAL 990-H Service Manual 1-21...

- Page 30 CHAPTER 2 System IT Administration This chapter describes the KVAL 990-H controller. The controller is an on board computer that supplies the user interface and controls the operation of the machine. With the controller, KVAL can remotely help troubleshoot your machine.

-

Page 31: About The 990-H Computer

Support will be able to access your machine through your company’s Intranet and help solve any issues that may occur. Connection to the Intranet is achieved by interfacing with the 990-H con- troller. The location of the Intranet connection is identified in the figure below (RJ45 to Intranet.) About the 990-H Computer ®... -

Page 32: Backing Up The Computer

About Remote Connection to KVAL Service Remote access is a powerful tool to help fix issues that occur with the 990-H machine. With the remote access, our KVAL service technician is able to observe your user screen in real time, read ®... -

Page 33: Network System Overview

Figure 2- 1 below, shows the PLC connections in the 990-H. The PLC is located in the Main Elec- trical Panel. From the PLC, connections are made to coupler interfaces located near the sections they control. -

Page 34: Connections To Servo Drives

Servo Drive 4 Servo Drive 3 Servo Drive 1 Servo Drive 2 2 High Voltage Outputs 2 High Voltage Outputs 2 High Voltage Outputs 2 High Voltage Outputs 2 High Voltage Outputs Servo Drives FIGURE 2- 2. KVAL 990-H Service Manual... -

Page 35: High Frequency Panel Node Connections

OK for hinge and plate routers, hinge P2P, and door width outputs to the stacker. For detailed wiring information, see your machine’s electrical drawings. Outputs Inputs Ether CAT Input (From Frame Node) Ether CAT Output (To E-Stop Circuitry) Coupler PLC Interface High Frequency Node FIGURE 2- 3. KVAL 990-H Service Manual... -

Page 36: Frame Node Connections

This node includes back section related inputs and outputs including, back section servos, face plate, boring, and door widths. For detailed wiring information, see your machine’s electrical draw- ings. Inputs Outputs 24 VDC PS 1 and PS 2 Back Section Node FIGURE 2- 4. KVAL 990-H Service Manual... -

Page 37: Screw Driver Nodes 1-3

For general information, refer to Figure 2- 5 . For detailed wiring information, see your machine's electri- cal drawings. Inputs Screw Screw Screw Driver Driver Driver Node # 3 Node # 2 Node # 1 Outputs Screw Driver Nodes FIGURE 2- 5. KVAL 990-H Service Manual... - Page 38 Network System Overview KVAL 990-H Service Manual...

- Page 39 CHAPTER 3 Maintenance of the 990-H This chapter describes preventative maintenance steps for KVAL 990-H. The content is geared to guide technicians to keep a regular maintenance schedule for your KVAL machine. Keeping your KVAL machine maintained is an important piece for successful operation of your door production process.

-

Page 40: Maintenance Schedule

This should be done in accor- dance with applicable state and/or federal code requirements To view a video of the maintenance process, visit the KVAL website. Select the Video Tab to view videos. http://www.kvalinc.com/... - Page 41 Inspect Inspect all airlines for kinks or rubbing. Lubricate Refill all lubricators. Replace fluid if milky or discolored. Use ab ISO 32 stan- dard hydraulic oil (KVAL PN:SYS-LUBEG). Lubricate Grease ball screw bearings (if applicable). Clean Clean all bearing shafts with clean, dry cloth.

-

Page 42: 300 Cycle Maintenance Steps

Check vertical bearings for loose screws. Loose screws could cause bearing damage. High Dust Accumulation Areas Lock Bore Area: build up can occur and stop Bolt drill from extending. Front Section: Underneath Car- riage Heads Jamb Clamp area. KVAL 990-H Service Manual... -

Page 43: 600 Cycle Maintenance Steps

Reverse action when installing trap. Inspect Tooling Inspect the Tooling for wear, (Drill Bits, Cutting Tools, Screw Driver Bits) See “Replacing Tooling in the Front Section” on page 3-25 see “Replacing Tooling in the Back Section” on page 3-30 KVAL 990-H Service Manual... -

Page 44: Lubricate Inside Of Hopper

Check and empty any dust collection units. Clean any dust filters. Dust collection systems vary from machine to machine. Follow manufacturers directions to empty dust collection units. Filters Dust Collection Containers Typical Dust Collection Unit FIGURE 3- 6. KVAL 990-H Service Manual... -

Page 45: 3,000 Cycle Maintenance Steps

• cracks • wear from rubbing • Ensure tube clamps are tight Inspect all Photo Eyes Inspect all photo eyes secure and tight. Check Nut that attaches Photo Eye to Machine Check Connection to Photo Eye KVAL 990-H Service Manual... -

Page 46: Inspect Limit Switches

5 or 20 degrees before the limit switch actuates. Inspect Screw Receiver Parts Inspect screw receiver parts on six shooters for cracks or breaks. Inspect: Screw Receiver Spring Split Shell Steel Ring Rubber Ring Steel Ring Replace any parts that are broken. KVAL 990-H Service Manual... -

Page 47: Inspect Airlines

Refill Lubricators Ensure Air is turned off. Refill all lubricators. Replace fluid if milky or discolored. Use ab ISO 32 stan- dard hydraulic oil (KVAL PN: SYS- LUBEG). Slide locking switch down twist bowl and remove. Refill bowl. Reverse action when installing trap. -

Page 48: Grease Ball Screw Bearings

Grease ball screw bearings (if applicable). For a table of lubrication types to use, Lubrication Schedule. For locations to lubricate, See Ball Screws (If Applicable) Clean Bearing Shafts Clean all bearing shafts with clean, dry cloth. Spray shaft with silicone oil and clean build up grime and dirt. KVAL 990-H Service Manual 3-10... -

Page 49: 12,000 Cycle Maintenance Steps

Cylinders not holding their position. Inspect Hydraulic Lines Inspect hydraulic lines for loose fittings, leaks and cracks. Inspect hydraulic lines from the source to the end assembly. KVAL 990-H Service Manual 3-11... -

Page 50: Inspect Ball Rail Shafts

Clean and lubricate all slides and cylinder rods with dry silicone spray. Clean inside Hopper Clean inside hopper with dry sili- cone oil and a 3M ScotchBrite pad (or equivalent). Wipe dry with a clean dry rag KVAL 990-H Service Manual 3-12... -

Page 51: 72,000 Cycle Maintenance Steps

Wash filter and lubricator bowls with soapy water. • Slide lock down to unlock. • Twist bowl to remove it. • Remove filter from Air filter assembly. Inspect and clean or replace if necessary. • Clean bowls and reas- semble. KVAL 990-H Service Manual 3-13... -

Page 52: Tool Changing Schedule

Changing and inspecting the tooling on a regular basis keeps the door machining process running accurately and efficiently. KVAL recommends using the tables below for reference to change or inspect the machine tooling. Note: Depending on Machine or Option, some of these tools may vary. - Page 53 Tool Changing Schedule Screw Receiver and 6-Shooter Tooling Screwdriver Bits 1,500 cycles Steel Rings 7,500 cycles Rubber Rings 7,500 cycles Screw Receivers 30,000 cycles Split Shells 30,000 cycles Springs 30,000 cycles KVAL 990-H Service Manual 3-15...

-

Page 54: Maintenance No-Goes

• Do not adjust any and all flow controls from factory settings • Do not remove shim stock • Do not Change or Alter any safety assemblies (E-Stops, Gate Locks, etc) • Do not Change programs in PLC’s or PC’s • Do not Alter Electrical Components KVAL 990-H Service Manual 3-16... - Page 55 Notes:...

-

Page 56: Lubrication Schedule

Lubrication Schedule Lubrication Schedule KVAL recommends the following lubrication schedule to ensure that the machine operates prop- erly. Recommended Lubrication Schedule TABLE 3- 3. Type of Assembly Recommended Schedule Recommended Lubrication Type Linear Bearing Pillow Block Bearing Every 250 Hours of Machine Operation... -

Page 57: Lubrication Requirements

If the bearing is equipped with a grease fitting (Zerk Fitting), it should receive 1 Gram (one pump from grease gun) of Dura-Lith Grease (KVAL P/N Lube EP-2) every 250 hours of operation. Note: Bearings without grease fittings have been pre-lubricated at the factory and do not require further lubrication. -

Page 58: Gear Motor Lubrication Requirements

MOBILUBE HD 80 W-90 or equivalent. Ball Screws (If Applicable) All ball screws should be lubricated Dura-Lith Grease (KVAL P/N Lube EP-2) for every 80 hours of operation. At each lubrication grease should be pumped into the fitting until clean grease comes out around the ball screw. -

Page 59: Adjusting The Air Line Lubricator

Repeat this same procedure for the back section and other trouble areas. It is recommended to check the lines every week to two weeks. KVAL 990-H Service Manual 3-20... -

Page 60: Lubrication Points On The 990-H

Lubrication Points on the 990-H Lubrication Points on the 990-H Feed System Lube Points Use Lube-EP2 (or similar) to Lubricate Chains Lubricate feed sys- tem hex shaft with Silicon Spray Feed System Lubrication Points FIGURE 3- 10. KVAL 990-H Service Manual... -

Page 61: Screw Driver Lube Points

Lubrication Points on the 990-H Screw Driver Lube Points Screw Drive Lubrication Points FIGURE 3- 11. KVAL 990-H Service Manual 3-22... -

Page 62: Back Section Lube Points

Lubrication Points on the 990-H Back Section Lube Points Back View Front View Back View 2 Bottom View FIGURE 3- 12. KVAL 990-H Service Manual 3-23... -

Page 63: Head Lube Points

Lubrication Points on the 990-H Head Lube Points Bottom Back 1.Assemblies shown transparent. FIGURE 3- 13. KVAL 990-H Service Manual 3-24... -

Page 64: Replacing Bits

Chisels: Chisels: Upper and Upper and Lower Left Lower Right Drill Motor Router Motor Location of Bits in the 990-H Heads FIGURE 3- 14. KVAL 990-H Service Manual 3-25... -

Page 65: How To Access To Bit Assemblies

Use a 17 mm shaft wrench and a 3/8 “collet wrench to remove the bit on the pre-drill or router assemblies. See Figure below. 3/ 8 “Collet Wrench (PN: PERER16W 17 mm Shaft Wrench (PN: WRENCH17MM) Removing Pre-Drill or Router Bit. FIGURE 3. 15. KVAL 990-H Service Manual 3-26... - Page 66 Set to 2.0” Set to 1 3/4 “ 1 3/4 ““ 2.0 “ Bit Depth Gauge (PN432C) Setting the Bit Depths FIGURE 3. 17. Tighten the collet assembly. Inspect and verify the work. Clean the work area. KVAL 990-H Service Manual 3-27...

-

Page 67: Remove And Replace The Chisels

Pull the Six-Shooter assembly toward the machine-it will move slightly. Locate the back slide near the air valves (see images); push slide away from you. This allows for movement of the Six-Shooter assembly away from the machine KVAL 990-H Service Manual 3-28... - Page 68 Release holder to secure bit. Move Six-Shooter assembly back toward machine and pull the back slide toward you; then move assembly away from machine to restore assembly to original start- ing position KVAL 990-H Service Manual 3-29...

-

Page 69: Replacing Tooling In The Back Section

Note: Make sure the arbor is not bottomed out in the back of the motor. If it is, the arbor will not tighten and will damage the collet or other machine parts. Note: The figure shows the cover off for training purposes. KVAL 990-H Service Manual 3-30... -

Page 70: Changing The Bolt Drill

Collet Torque Values Note: Make sure the arbor is not bottomed out in the back of the motor. If it is the arbor will not tighten and will damage the collet or other machine parts. KVAL 990-H Service Manual 3-31... -

Page 71: Collet Torque Values

Collet Torque Values Collet Torque Values KVAL recommends torquing the collets. Torquing adds consistency is important for repeatable machining. Follow the torque tool manufacturers method of torquing. Torque values. TABLE 3- 4. Collet Collet Nut Type Collet Inner Dia Over 1/16''... - Page 72 Collet Torque Values KVAL 990-H Service Manual 3-33...

- Page 73 Trouble Shooting of the 990-H This chapter describes troubleshooting steps to help technicians solve issues that may occur with your KVAL machine. If help is needed, call or contact our KVAL Service team at (800) 553-5825 or http://www.kvalinc.com. Refer to the Air and Electrical drawings provided with delivery of the machine.

-

Page 74: About Motion Control

KVAL Machinery. Sequencing: Sequencing is a series of events executed in a predetermined order. Most KVAL machines use a form of sequential motion control. A typical series of events for a KVAL machine are: Move the door into position. - Page 75 • Moves the load. Examples: A motor or a pneumatic cylinder. The Position Feedback. • Provides location information to the controller. Examples: A limit switch, a photo eye, or ferrous eye, a resolver or an encoder KVAL 990-H Service Manual...

-

Page 76: Troubleshooting Basics

When did the problem first start? • At first Start-Up? • During the Run? When was the last calibration? Is the door true? Use Router Bit Depth Gauge (PN: 432C) to check depth of Bits Check tools for wear. KVAL 990-H Service Manual... -

Page 77: Analyze The Sub Systems

Analyze the Sub Systems Check the Load for mechanical issues • Is the Load “bound up? • Is there sufficient lubrication? • Is it an alignment issue? • Is anything damaged? Check the Position Feed Back. KVAL 990-H Service Manual... - Page 78 • Bad Output: Relay may be stuck • Air Solenoid Valve: May be stuck or not working. Check the Positioning System Follow the circuit from the Controller output to the Load and check for compo- nent failures. KVAL 990-H Service Manual...

-

Page 79: About A Typical Contactor Control

Common DC - Thermal Control Coil for OverLoad 120 Vac. Should measure Line Voltage here Motor Schematic Drawing of Contactor and Thermal Overload Block Diagram of a Common Contactor Circuit FIGURE 4- 2. KVAL 990-H Service Manual... -

Page 80: About Contactor Troubleshooting

Rerun the machine and verify that motor runs without tripping the circuit. If the same overload keeps tripping, verify condition. Follow circuit path using the E-Drawing as a reference. a.Common issues: Check for bad wire, bad motor, or if load is too great for cur- rent draw. KVAL 990-H Service Manual... -

Page 81: About Typical Vfd Motor Drive Control

An adjustable-speed drive is used to control the motor speed and torque by varying motor input frequency and voltage. A variable-frequency drive (VFD) is used in KVAL machinery to accu- rately drive motors for machining or moving product through the machine. The figure below shows a block diagram of a typical motor drive circuit. -

Page 82: About The Vfd

Figure 4- 4 on page 4-9 VFD models vary in KVAL machines depending on where it is used, voltage requirements and type of PLC used. This is a general view on the VFD. See the machine’s Electrical Print for detailed information. -

Page 83: About Vfd Troubleshooting

Note: The number of reset buttons depends on the machine type and option. The fig- ure above shows a machine with 11 VFDs The VFD manuals are located in the Electrical Panels. On some machines, documentation can be found in the operation station in the documen- tation folder. KVAL 990-H Service Manual 4-11... -

Page 84: About A Typical Pneumatic Circuit

Note: In this sample set-up, Port A is nor- mally open and Port B is nor- mally closed. If power is OFF, air should be on Port B. Block Diagram of a Pneumatic Circuit FIGURE 4- 7. KVAL 990-H Service Manual 4-12... -

Page 85: Typical Pneumatic Assembly

About a Typical Pneumatic Circuit Typical Pneumatic Assembly Pneumatic assembly setups vary in KVAL machines depending on where it is used and air requirements.This is a general overview of a pneumatic assembly. See the machine’s Air Print for detailed information. -

Page 86: About Cylinder Operation

Router applies the control voltage to the which directs com- Control Valve pressed air to extend port of the Cylinder are extended deactivating the Cylinder Router Retract Sensor fully extends activating the Router Extend Sensor. KVAL 990-H Service Manual 4-14... - Page 87 Control Valve Cylinder. retract deactivating the Cylinder Router Extend Sensor When the are fully retracted, the is activated. Cylinder Router Retract Sensor senses the voltage from the completing the process Retract Sensor KVAL 990-H Service Manual 4-15...

-

Page 88: Important Notice About Adjusting Cylinder Speed

However, sometimes machine settling, mechanics be “broken in” may be cause to slightly adjust extend and retraction speed. If more than 1/2 turn on adjustment knobs are needed, call in a specialist or check with KVAL customer service at 1-800-553-5825. KVAL 990-H Service Manual 4-16... -

Page 89: Adjusting Cylinder Extend Speed

Adjusting Cylinder Extend Speed Adjusting Cylinder Retraction Speed Tip: If Installing a new flow control assembly, shut down the flow control and back out 4 to 5 turns. this position is a good starting point for kine adjust. KVAL 990-H Service Manual 4-17... -

Page 90: Using Sensors To Trouble Shoot

• The distance from an eye to the door should be in range. Typically the range should be 3/4'' to 7/8'' from the top of all eyes to the door. Location of Sensors on 990-H Location and operation of sensors can be viewed by way of the Diagnostic Screen. -

Page 91: Troubleshooting Electrical Problems

Refer to Air and Electrical Schematics provided with delivery of the machine. Schematics are located in the Electrical Panel. If copies NOTE: are unavailable, contact the KVAL Service Department. Have model number and serial number of machine readily available. Warning The following checks require the electrical panel to be energized. - Page 92 Note: Most electrical problems are related to mechanical malfunction (e.g., stuck motors, jammed chain, blocked photo sensors etc.) Note: If a solenoid valve is suspected, and not cleared in the air checks section , it can be electrically jumped to check operation. KVAL 990-H Service Manual 4-20...

-

Page 93: Troubleshooting With The Status Light Panel

STEP 4: Stop (Amber) If light is OFF go to item page 4-23. STEP 5: Start (Amber) If light is OFF go to item page 4-24. STEP 6: 24VDC (Green light is OFF go to item page 4-24. KVAL 990-H Service Manual 4-21... - Page 94 X1 and X2. If no power is measured it is a bad transformer. b.If there is power at X1 and X2, check the other side of the fuse. If now power, replace the fuse. KVAL 990-H Service Manual 4-22...

- Page 95 Start button. If no voltage, check the Stop button to make sure it is all the way out and not stuck in, then check the contact to make sure it is closed. If still no voltage, check the wiring. KVAL 990-H Service Manual 4-23...

- Page 96 Check for +24VDC at between any –DC and +DC terminal on the DC Terminal block. Reinstall the (+ 24V positive) wires one by one, checking for +24VDC after installing each. If at any point no voltage is found trace the last reinstalled wire and check for shorts. KVAL 990-H Service Manual 4-24...

- Page 97 Troubleshooting with the Status Light Panel KVAL 990-H Service Manual 4-25...

- Page 98 15 programmable logic controller, PLC 2 gear box, maintenance schedule 17 remote operation, setting up machine for 17 return material authorization (RMA) 15 internet access returning the product to Kval 15 location of connection 2 KVAL 990-H Service Manual...

- Page 99 8, 29 screwdriver bits remove and replace 28 sensors location on frame 18 troubleshooting 18 service connecting your machine to KVAL Service 3 service center, contacting information 15 servo drives connections location 5, 26 start light description 24...

- Page 100 Notes: ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- -------------------------------------------------------------------------------------------------------------...

- Page 101 Notes: ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- -------------------------------------------------------------------------------------------------------------...

- Page 102 Notes: ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------- -------------------------------------------------------------------------------------------------------------...

- Page 103 Notes:...

- Page 104 Contacting KVAL Customer Service Phone and Fax: Mailing address: In the U.S and Canada, call (800) 553-5825 or fax Customer Support Department (707) 762-0485 Kval Incorporated Outside the U.S. and Canada, call (707) 762-7367 825 Petaluma Boulevard South or fax (707) 762-0485 Petaluma, CA 94952 Email: service@kvalinc.com...

Need help?

Do you have a question about the 990-H and is the answer not in the manual?

Questions and answers