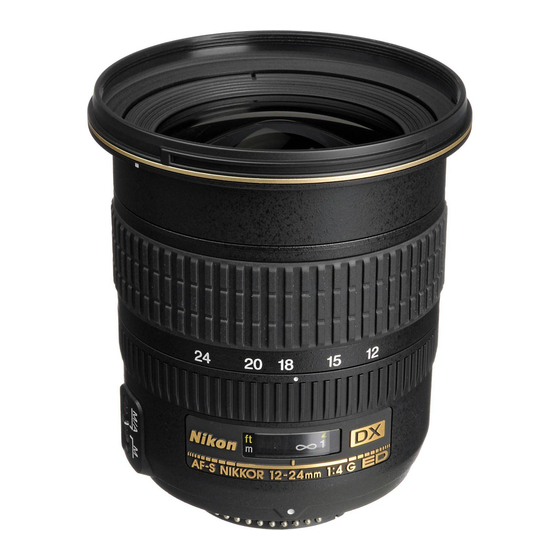

Nikon AF-S DXZoom-NIKKOR ED 12-24mm f/4G IF Repair Manual

Hide thumbs

Also See for AF-S DXZoom-NIKKOR ED 12-24mm f/4G IF:

- Instruction manual (87 pages) ,

- Instruction manual (19 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Instruction Manual

Advertisement

Table of Contents

Summary of Contents for Nikon AF-S DXZoom-NIKKOR ED 12-24mm f/4G IF

- Page 1 JAA78451-R.3596.A 配布許可印 作成承認印 AF-S DXZoom-Nikkor ED 12-24mm f/4G IF REPAIR MANUAL NIKON CORPORATION Tokyo, Japan Copyright c 2003 by Nikon Corporation. Recycled paper All Rights Reserved. Printed in Japan March 2003...

-

Page 2: Specifications

This lens can be used for Nikon digital SLR camera only. Type of lens G-type AF Zoom- Nikkor lens having built-in CPU and Nikon F bayonet mount Focal length 12mm - 24mm (18 - 36 mm in 35 mm format) -

Page 3: 1St Lens Group

JAA78451-R.3596.A Disassembly 1ST LENS GROUP #101 FILTER RING #103 Filter ring #104×4 ・Remove the rubber ring (#35). ・Remove the blindfolding-cover (#103). ・Unscrew #79. ・Take out 4 screws (#104). ・Remove the filter ring. - L1・ AF-S DX12-24/4G -... -

Page 4: Rear Cover Ring

JAA78451-R.3596.A REAR COVER RING - L2・ AF-S DX12-24/4G -... - Page 5 JAA78451-R.3596.A BAYONET #110 #100 #109×3 Index ring Index ring M/A change-over Focus ring Fig. 1. M/A change-over Fig. 2. - L3・ AF-S DX12-24/4G -...

- Page 6 JAA78451-R.3596.A MAIN PCB Zoom encoder FPC Distance encoder FPC ・ Remove the FPCs (positioned at 4 parts) from the connecter. Main PCB ・ Unscrew #89. ・ Remove the main PCB. SWM - FPC MR sensor FPC SWM UNIT - L4・ AF-S DX12-24/4G -...

- Page 7 JAA78451-R.3596.A - L5・ AF-S DX12-24/4G -...

- Page 8 JAA78451-R.3596.A Cam ring ・Take out the cam ring by turning the 1st sliding ring in the direction indi- cated by the arrow. ・Detach the 2nd and 3rd units from the cam ring. 1st sliding ring 2nd and 3rd units Can ring 1st sliding ring - L6・...

-

Page 9: 2Nd Lens Group

JAA78451-R.3596.A 2ND LENS GROUP - L7・ AF-S DX12-24/4G -... - Page 10 JAA78451-R.3596.A Assembly - L8・ AF-S DX12-24/4G -...

- Page 11 JAA78451-R.3596.A 2ND LENS GROUP #96×3 - L9・ AF-S DX12-24/4G -...

-

Page 12: Zoom Encoder Fpc

JAA78451-R.3596.A ZOOM ENCODER FPC Attach the FPC along the groove. ・Apply the grease (GE-8) to the cam grooves (3 transversal grooves and 2 longitudinal grooves.). Attach with Super glue ・Apply the grease (GE-8) to 3 inside cam grooves. Inside cam groove Do not let the FPC run off downwards. - Page 13 JAA78451-R.3596.A ・Turn the 1st sliding ring in the direction indicated by the arrow. 1st sliding ring - L11 ・ AF-S DX12-24/4G -...

-

Page 14: Position Adjustment Of Limit Plate

JAA78451-R.3596.A POSITION ADJUSTMENT OF LIMIT PLATE Limit plate - L12 ・ AF-S DX12-24/4G -... -

Page 15: Inspection And Adjustment For The Waveform Output From Mr Encoder

JAA78451-R.3596.A MR HEAD MR head #541 × 2 #534 MR sensor FPC ・Attach the MR head so that it is aligned parallel to the magnetic tape. ・Attach the MR sensor FPC so that it goes alongside the inside groove of the SWM unit. - Page 16 JAA78451-R.3596.A - L14 ・ AF-S DX12-24/4G -...

- Page 17 JAA78451-R.3596.A ・Connections Power supply Self-made tool Set values 5. 0V 100mA (GND) ( + ) Oscilloscope(2ch) Oscilloscope(1ch) Power supply(+) Power supply(-) Self-made tool Oscilloscope (2ch) ・How to conduct inspection and adjustment ① Make sure that the current and voltage of the connected rated voltage power supply are set values. ...

- Page 18 JAA78451-R.3596.A ④ In the case of smaller amplitude, for adjustment, loosen MR head the two screws #541 and then shift the MR head position as shown in the right figure. # 541 × 2 Note:During adjustment, prevent the magnetic tape and MR head from touching the magnetized driver bit, or the magnetic Magnetic tape data may be damaged.

- Page 19 JAA78451-R.3596.A SWM UNIT - L17 ・ AF-S DX12-24/4G -...

-

Page 20: Index Ring, Focus Ring

JAA78451-R.3596.A MAIN PCB Distance encoder FPC Zoom encoder FPC ・Attach the main PCB. ・Screw #89. Main PCB ・ Connect the FPC (at 4 parts) to the connector. SWM - FPC MR sensor FPC INDEX RING, FOCUS RING Index ring On the sliding surface with focus ring. - Page 21 JAA78451-R.3596.A Index ring ・ Slide the M/A change-over SW and assemble into the index ring. M/A change-over SW BAYONET A #100 #110 #109×3 ・ Put the aperture lever (#55) in A of the above. J18004-1 #93×2 Aperture lever - L19 ・ AF-S DX12-24/4G -...

- Page 22 JAA78451-R.3596.A REAR COVER RING ZOOM RING All-round 3 convexities #105 ・Attach #105 to the zoom ring, and Zoom ring apply the oil barrier to the overall #105. Groove Zoom ring ・Put the convexities (at 3 parts) inside the zoom ring in the notches (at 3 parts) of #22, to assemble together.

- Page 23 JAA78451-R.3596.A FILTER RING All-round Grease: GE-8 Filter ring Convesity (on backside) Notch ・Put the convexity of the fileter ring in the notch of the above, and attach the filter ring with 4 screws (#104). Filter ring #104×4 - L21 ・ AF-S DX12-24/4G -...

-

Page 24: Zoom Encoder Brush

JAA78451-R.3596.A ZOOM ENCODER BRUSH Position to attach the encoder brush #127 ・ Turn the zoom to the TELE side. ・ Attach the encoder brush (B4) in the above position and fix it with screw (#66). After adjusting,fix #66 with the Screw Lock. -

Page 25: Adjustment (Division) Of Focus Movement (T, W)

JAA78451-R.3596.A ADJUSTMENT (DIVISION) OF FOCUS MOVEMENT (T, W) 1.Fit the infinity ( ∞ ) mark of the focus ring to the index. 2.Fix the aperture lever to make the aperture "full". 3.Read the values of the Wide and Tele sides. 4.Carry out the following calculations. - Page 26 JAA78451-R.3596.A Lens alignment Note: This adjustment is required when the 3rd lens groups is removed. (1) Preparation of Lens to be examined ・Remove the main PCB on Page L2-L4. ・Remove the aperture lever of the bayonet mount. ・Remove the solder of wires (blue and black) of M/A change SW from the main PCB. ・Assemble the other parts, but exclude the main PCB, aperture lever, and rear cover ring.

- Page 27 JAA78451-R.3596.A (2) Preparation of Lens optical alignment equipment ・ Fix the attachment holder for the 3rd lens group (J19127J) in the lens equipment for center alignment. How to fix: Move down the holder-moving lever slowly so that the holder touches the stage. Then tighten 4 screws to fix it.

- Page 28 JAA78451-R.3596.A Back view of Lens optical alignment equipment for center and periphery ④ Power cable for CCD camera ① VIDEO cable ‘ ① VIDEO IN ② VIDEO OUT ‘‘ ③ Pinhole chart ‘ ③ Cross line chart ‘ ② "VIDEO IN"...

- Page 29 JAA78451-R.3596.A (3)3rd lens group temporary alignment ① Mount the (self-made) center positioning tool on the lens alignment equipment (for periphery) by setting the groove in place slightly to the left (in a counterclockwise direction) from the below 12 o’clock position . Then turn the tool clockwise all the way to the right, and move the fixing-lever to the left to fix it.

- Page 30 JAA78451-R.3596.A (4) 3rd lens group alignment (Center alignment) ① Set the zoom ring by turning it all the way to TELE-end (24 mm), and loosen the one screw of the 3rd lens-group chamber. (If the lens to be examined remains to be set in the equipment, the alignment screwdriver touches the side surface, resulting in a failure of turning the screw.) Screw ※...

- Page 31 JAA78451-R.3596.A ⑤ Turn the "LIGHT CONT." knob of MEGALIGHT 100 to adjust brightness, and turn the focus ring to adjust the shape of the pinhole on the monitor. (ref. Pic.1 for the image of the pinhole.) Pic.1 LIGHT CONT.knob ⑥ Check the pinhole shape on the monitor. In case of Fig.1-A, set the zoom ring to WIDE-side (12 mm) and check the shape.

- Page 32 JAA78451-R.3596.A ⑧ Adjust the micrometers (X and Y) by turning them so that the shape on the monitor becomes like Fig.1-A. Note) When the holder is raised, the image on the monitor is changed in its shape. So make an adjustment by considering this change.

- Page 33 JAA78451-R.3596.A (5) Chart shooting for the 3rd lens-group alignment ① Prepare a camera (D100). Set the shutter speed to “M1/80” and the focus mode to “M”. On the shooting menu, set the Image Quality mode to “RAW”, the WB to “Preset” and the ISO to “200”. ②...

- Page 34 JAA78451-R.3596.A ⑤ Fit the lens to be examined in the camera. Set the zoom to TELE-end (24 mm). ⑥ By looking through the viewfinder, adjust the height and tilt based on the 4 point sources of light of the center. ⑦...

- Page 35 JAA78451-R.3596.A ⑬ Looking through the viewfinder, turn the focus ring of the lens slowly from close-side to infinity-side. Stop turning it at the position where the in-focus indicator is switched from blinking to lighting. ⑭ Slide the tripod to the front by 18±0.1 cm. ⑮...

- Page 36 JAA78451-R.3596.A ⑱ Again, slide the tripod to the back by 6 ± 0.1 cm and make a remeasurement. Repeat this operation 4 more times, totalling in 7 measurements. (The total sliding distance is 36 cm.) Note 1: When the below warning is given, there may be some defects in the brightness of the viewers and/or parallelism of the chart and camera, etc.

- Page 37 JAA78451-R.3596.A ⑲ After the 7 measurements, point the cursor to the confirmation screen of the software. Click it 3 times, and if "END" is displayed on the Result, the lens optical alignment is completed. If "END" is NOT displayed, go to "(4) 3rd lens group alignment (center alignment)", and make readjustment.

- Page 38 JAA78451-R.3596.A How to create positioning tool of Rear lens-group holder for lens alignment (It is the same tool with AF-S ED 24-85/3.5-4.5G) 1: Summary 1-1: This is a positioning tool of the rear lens group holder for lens alignment, in order to secure the position for attaching the rear lens group temporarily.

- Page 39 JAA78451-R.3596.A 3-6: Attach the mount rotation stopper screw at the appropriate position. - L23-14 ・ AF-S DX12-24/4G - Added page July. 01. 2005...

- Page 40 JAA78451-R.3596.A How to create Setting board of "Lens alignment chart" and "Viewer" 1. Summary 1-1: In order to get necessary data for lens alignment, this board is created to use for setting a special chart and light viewers (for chart illumination), while taking pictures of the special chart with a digital camera. 2.

- Page 41 JAA78451-R.3596.A (Fig. 1- Prepare 2 package cardboard boxes, and (Fig. 2 - As for the 1st flattened cardboard box, cut out the flatten them as below.) <154 x 245 mm sized> shape at 5 locations.) (Fig. 3- Package cardboard boxes) (Fig. 4- As for the 2nd flattened cardboard box, cut Put the 2nd flattened cardboard boxe and the1st out the shape in the same way as Fig.2.

-

Page 42: Preparation For Inspection And Adjustment Of Main Pcb

JAA78451-R.3596.A PREPARATION FOR INSPECTION AND ADJUSTMENT OF MAIN PCB ● In case of replacing the main PCB, SWM unit or MR encoder unit, be sure to adjust the following items due to a necessity on the operation. 1.Items to adjust ・Adjustment of MR duty ・Adjustment of driving frequency and motor control 2.Equipment and tools to be required... - Page 43 JAA78451-R.3596.A 【System configuration diagram】 By using the DC/DC converter, 1 unit of rated voltage power supply can be energize this system fully. The following figure shows the system using the DC/DC converter for F100. The system will be explained hereafter on the assumption that this modification has been done.

-

Page 44: Adjustment For Mr Duty

JAA78451-R.3596.A ADJUSTMENT FOR MR DUTY ● In case of replacing the main PCB, SWM unit or MR encoder unit, be sure to make this adjustment. How to adjust ① Make sure that the current and voltage of the connected rated voltage power supply are the set values. ... -

Page 45: Adjustment Of Driving Frequency And Motor Control

JAA78451-R.3596.A ADJUSTMENT OF DRIVING FREQUENCY AND MOTOR CONTROL ● In case of replacing the main PCB, SWM unit and MR encoder unit, be sure to make adjustments. ① The method of connetion of the rated voltage power supply and measuring tools is the same as "ADJUSTMENT OF MR DUTY". - Page 46 JAA78451-R.3596.A ⑥ Manual adjustment In case the motor does not stop or automatic adjustment cannot be made, “Fig. 1” is displayed on the screen. At this moment, pressing “1” performs the automatic adjustment again. If the adjustment cannot be made even after making several automatic adjustments, press “2” for manual adjustment in the following screen.

- Page 47 JAA78451-R.3596.A e.g.) Oscilloscope (DL1540) setting As shown in Fig. 2, “div” value within standard is displayed on PC screen. As shown in Fig. 3, it becomes easy to judge if the standard range of cycle of waveform is set by cursor. The standard value, TIME/DIV, and CURSOR(T1,T2) varies according to the conditions of low-speed adjust- ment, high-speed adjustment, and other lenses, etc, so check by Fig.

-

Page 48: Lens Operation Check

JAA78451-R.3596.A LENS OPERATION CHECK Check the lens operation by using a personal computer after assembling. ○ Check by using a personal computer ● Check items 1.Operation of MR encoder ・Drive the lenses for scanning and check the difference in pulses at start and at end. ・In case the MR encoder’s MR head is not properly attached on the magnetic tape, the difference in pulses is larger. - Page 49 JAA78451-R.3596.A ● Explanation of the AF-S zoom lens (New) inspection program (1)Menu display NIKON AF-S ZOOM LENS(NEW)INSPECTION / ADJUSTMENT PROGRAM. [J18342] 1.ADJUSTMENT FOR MR DUTY. 9. 2.ADJUSTMENT FOR FREQUENCY & CONTOROL. A. 3.READ AND REWRITING OF EEPROM DATA. B....

- Page 50 JAA78451-R.3596.A (2)Display of "OPERATION OF MR ENCODER" TYPE OF LENS: AF-S DX NIKKOR 12-24mm/4G CPU VERSION:4.00.04 OPERATION OF MR ENCODER. INSPECTING. PUSH ANY KEY TO FORWARD NEXT STEP. Note:If the MF ring is rotated during lens scanning, an error value is shown for the pulses. Don’t touch the MF ring during operation.

- Page 51 JAA78451-R.3596.A The difference between the pulses before and after inspection must be within the standard. Standard of difference between the pulses : 0±10 PULSE(S) Standard of all pulses : 2460±94 PLUSE(S) TYPE OF LENS: AF-S DX NIKKOR 12-24mm/4G CPU VERSION:4.00.04 OPERATION OF MR ENCODER. POSITION WHEN CHECK BEGINS.

- Page 52 JAA78451-R.3596.A (3)Display of "INSPECTION OF DRIVING STOP ACCURACY" TYPE OF LENS: AF-S DX NIKKOR 12-24mm/4G CPU VERSION:4.00.04 INSPECTION OF DRIVING STOP ACCURACY. NUMBER OF LENS GO-AND-RETURN OPERATIONS. : 5 / 5 TIME(S). ① LENS DRIVING TIMES. (DF0+DF1+DF2+DF3+DF4+DF5+DF6) : 85 TIME(S). MAXIMUM PULSE.(ABSOLUTE) (DF0+DF1+DF2+DF3+DF4+DF5+DF6) : 3 PULSE(S).

- Page 53 JAA78451-R.3596.A (4)Display of "INSPECTION OF LENS SERVO TIME" TYPE OF LENS: AF-S DX NIKKOR 12-24mm/4G CPU VERSION:4.00.04 INSPECTION OF LENS SERVO TIME. SERVO AMOUNT. STANDARD. 1. [ Df1 ] 93ms OR LESS. 2. [ Df2 ] 120ms OR LESS. 3. [ Df3 ] 146ms OR LESS.

- Page 54 JAA78451-R.3596.A (5)Display of "SWITCHES AND LENS CONDITION" TYPE OF LENS: AF-S DX NIKKOR 12-24mm/4G CPU VERSION:4.00.04 SWITCHES AND LENS CONDITION. :FOCUSING ENCODER ZOOMING ENCODER : : 0-1 17 0 20 : : 0-2 18-1 1 21 : FOCUSING ENCODER :...

- Page 55 JAA78451-R.3596.A Preparation for Inspection & Adjustment of Main PCB ● In case of replacing the main PCB, SWM unit or MR encoder unit, be sure to make the necessary adjustments as follows: 1. Adjustment item ・Adjustment for electrical device (MR duty adjustment, drive frequency/motor control adjustment) 2.

- Page 56 JAA78451-R.3596.A 【System configuration】 Constant-voltage power supply (Set voltage: 6V) (+) "E" terminal (-) "H" terminal Oscilloscope If the RS232C terminal of PC is a 9-pin type, connect it by using the 25-pin/9-pin conversion AF-I communication box connector. This connector is NOT supplied as RJ, (J15306-1) so use commercial products on the market.

- Page 57 JAA78451-R.3596.A AF-S Zoom lens (New) inspection program ● (1) Menu screen ・Menu items Items 1. is used for adjustments. Items from 2. through to 5. are used for inspection Item 6. is used for confirming firmware Item from 7. through 9. are used for reading/writing EEPROM DATA. ・Selecting items Depending on selected items, screens appear such as the lens selection, the focal length selection, the voltage setting, the inspection mode entering, etc.

- Page 58 JAA78451-R.3596.A Adjustment for electrical device When the main PCB or SWM unit or MR encoder is replaced, be sure to make adjustments. ● When the main PCB is replaced, be sure to perform "Writing of EEP-ROM Fixed Values". ● How to adjust: ①...

- Page 59 JAA78451-R.3596.A ⑤ Confirm that the waveform on the oscilloscope has duty 50% and stop the MF ring at the close-end. (Fig.1) C H 1 = 5 V C H 2 = 5 V 5 m s / d i v ●...

- Page 60 JAA78451-R.3596.A Caution: If each waveform from "Infinity-end" to "Close-end", or "Close-end" to "Infinity-end" does not have duty 50%, perform "Inspection and adjustment of the MR encoder output waveform" on Page L13-L16 for readjustment. Standard H:L = 100:206 ~ 206:100(50% ±17.3%) H L...

- Page 61 JAA78451-R.3596.A ② When "Fig.1" screen appears, if the motor driving stands still, click "Close" to end the adjustment. Fig.1 Added page - L34-7 AF-S DX12-24/4G - May 17 2007...

- Page 62 JAA78451-R.3596.A Manual adjustment ① If the automatic adjustment failed, "Adjustment could not be completed" (Fig.1) will appear. So click "Yes" and make the manual adjustment. Fig.1 ② ② Low-speed adjustment 1. Set the oscilloscope to the set values of "Fig.2", and make the low-speed adjustment of lens. 2.

- Page 63 JAA78451-R.3596.A ③ ③ High-speed adjustment Make the high-speed adjustment of "Fig.4" by the same procedure as in the low-speed adjustment. (Be careful, however, that the setting values are different.) ・When the adjustment is completed, click "Write adj.value" of "Fig.5". If even the manual adjustment cannot be made, the SWM unit or MR head may be defective. Set values of oscilloscope (DL1540) Fig.4...

- Page 64 JAA78451-R.3596.A (2) Screen for inspecting MR encoder operation ① Click "Start insp." of "Fig.1". Caution: When the MR ring is roated during the lens-scan driving, the number of pulses shows an abnormal value. So do NOT touch the MF ring in operation. Fig.1 ②...

- Page 65 JAA78451-R.3596.A (3) Inspection screen of lens driving stop accuracy Make this inspection on both focal length 24mm (W) and 120mm (T) at the following five lens positions. ① (Lens position when inspecting) Tilt of Lens Position of index window Horizontal Up / Right / Left Front lens group 90°...

- Page 66 JAA78451-R.3596.A ③ During the lens driving, the screen of "Fig.1" appears. Caution: When the MR ring is roated during the lens-scan driving, the number of pulses shows an abnormal value. So do NOT touch the MF ring in operation. Fig.1 ④...

- Page 67 JAA78451-R.3596.A (4) Inspection screen of lens driving time ① Make the inspection on both focal length 12mm (W) and 24mm (T) Make the inspection on both focal length 12mm (W) and 24mm (T) at the five lens positions of "Fig.1". ②...

- Page 68 JAA78451-R.3596.A (5) Inspection screen of switches and lens conditions ・If there is no problem with each item, click "Close" to end. If there is some problem, make the readjustment by referring to Page L34-16. ① ② ③ Focus encoder signal ①...

- Page 69 JAA78451-R.3596.A Oscilloscope: Example of settings for DL1540 ・"Fig.2" on Page L34-8 shows setting values for low-speed adjustment, while "Fig.4" on Page L34-9 shows those for high-speed adjustment. ・Setting T1 (min. value) and T2 (max. value) of one cycle of waveform beforehand, as shown by the below dotted lines, facilitates the adjustment.

- Page 70 JAA78451-R.3596.A Inspection of Lens operations Check the lens operations by using PC after assembling. ○ Check by PC ● Inspection item 1. MR encoder operations ・Activate the scanning drive of lens and check the difference in pulse no. when beginning and ending inspection.

- Page 71 JAA78451-R.3596.A Aberration compensation data writing adjustment ・ This adjustment uses the software which calculates the aberration compensation data according to the feature of lens aberration and writes in EEPROM of the lens, in order to improve the accuracy of autofocus. Note: This adjustment is necessary when the main PCB and/or each lens part (glass, lens chamber) is replaced or when each lens part is disassembled.

- Page 72 JAA78451-R.3596.A ( Target chart ) ( Resolution chart ) - L36 ・ AF-S DX12-24/4G - Additional page August. 9. 2005...

- Page 73 JAA78451-R.3596.A (3) Writing aberration compensation data ① Prepare a camera (D100). Set the "Exposure mode" to "A" for full aperture and "Focus mode" to "S". On the shooting menu, set the "Image quality mode" to "FINE", "Image size" to "L", "WB" to "Preset", and "ISO"...

- Page 74 JAA78451-R.3596.A "Lens select" window opens. Select "AFS DX 12-24/4G[IF]" and click "OK". ⑥ Click the "Defocus rectify..." button. ⑦ Click the "JPEG Shot" button. ⑧ The shutter is released after the AF operation. The shot image is automatically displayed on the PC screen. ⑨...

- Page 75 JAA78451-R.3596.A Input the value of the focused position into the entry field. ⑩ e.g. The below is the case when " - 100μm" of the front focus side is in focus. ⑪ Set the focal length of the lens to 12 mm, and the distance between the test chart and camera (CCD face) to 48 cm 2 cm.

- Page 76 JAA78451-R.3596.A ⑮ The reconfirmation screen is displayed. Click "OK". ⑯ An hourglass is displayed on the screen, and writing starts. The below screen is displayed after a few seconds. Turn camera OFF and turn it ON again. Click "OK", and the adjustment software restarts. Note: Unless the camera is turned off once, the value that was written in EEPROM is not reflected on the results of shooting.

-

Page 77: Adjustment Software

JAA78451-R.3596.A Tools ★:New tool RJ No. Name Note MZ-800S DRY SURF MZ-800S GE-8 GREASE GE8 EDC0021 ADHESIVE EDB0011 SCREW LOCK 1401C J18004-1 STANDARD GAUGE FOR J18004 J19002 BACK FOCUS COLLIMATER LT-500S J18028 LENS ADAPTER FOR FOCUS TESTER J18342 AF-S ZOOM LENS (NEW)INSPECTION AND Use the version date after ADJUSTMENT SOFTWARE May 10 ,2003. - Page 78 JAA78451-R.3596.A Making of self-made tool ● It is necessary to make a self-made tool by using the main PCB of repair part. The self-made tool will be used for "INSPECTION AND ADJUSTMENT FOR THE WAVEFORM OUTPUT FROM MR ENCODER". ...

- Page 79 JAA78451-R.3596.A 外観図 Sketch drawings - F1・ AF-S DX12-24/4G -...

- Page 80 JAA78451-R.3596.A 組立図 Structure of the Lens - F2・ AF-S DX12-24/4G -...

- Page 81 JAA78451-R.3596.A - F3・ AF-S DX12-24/4G -...

-

Page 82: Wiring Diagram

JAA78451-R.3596.A 実体配線図 WIRING DIAGRAM ズームエンコーダー FPC Zoom encoder FPC 接点 FPC Contact FPC M/A スイッチ M/A Switch Blue Black MR センサー付き FPC FPC with MR sensor M/A 基板 M/A Base plate はんだブリッジ Solder bridge メイン基板 Main PCB 磁気テープ Magnetic tape 絶対距離...

Need help?

Do you have a question about the AF-S DXZoom-NIKKOR ED 12-24mm f/4G IF and is the answer not in the manual?

Questions and answers