Summary of Contents for SIGLENT SDS1000D

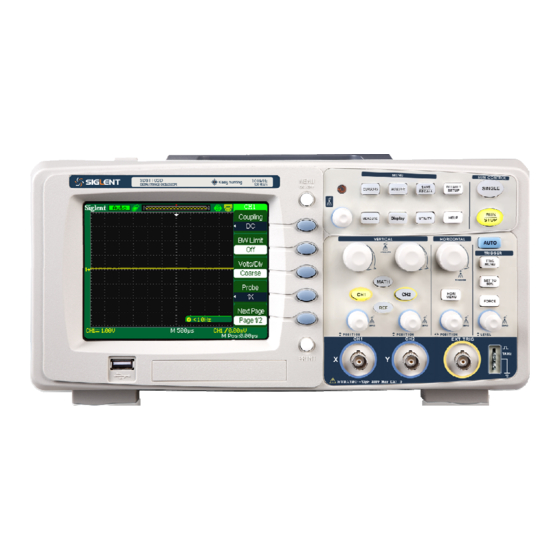

- Page 1 Service Manual SDS1000D Digital Storage Oscilloscope June 2011 SIGLENT Technologies Co., Ltd. Service Manual...

- Page 2 Declaration Copyright © SIGLENT Technologies Co.,Ltd. All rights reserved. Contents in this Manual are not allowed to copy, extract and translate before being allowed by SIGLENT Company. Service Manual...

-

Page 3: General Safety Summary

General Safety Summary Review the following safety precautions to avoid injury and prevent damage to this product or any products connected to it. To avoid potential hazards, use this product only as specified. Only qualified personnel should perform service procedures. 1. - Page 4 ● ● ● ● Avoid Exposed Circuitry. Do not touch exposed connections and components when power is present. ● ● ● ● Do Not Operate With Suspected Failures. If you suspect there is damage to this product, have it inspected by qualified service personnel. ●...

-

Page 5: Document Summarize

Document Summarize Chapter 1 Specifications List the specifications and general specifications of SDS1000D series digital oscilloscope. Chapter 2 Prepare for Use Introduce the preparatory work should be done before using the oscilloscope. Chapter 3 Performance Test Introduce how to execute the performance test to understand current performance status of the oscilloscope. -

Page 6: Table Of Contents

Catalogue Document Summarize........................6 Chapter 1 Specifications ........................8 Specifications..........................8 Generic Specifications ......................12 Chapter 2 Prepare for Use.......................13 General Inspecting ........................14 Power-On Inspection.......................15 Probe Compensation .......................16 Auto Setup ..........................17 Chapter 3 Performance Test ......................19 Interface Test...........................20 USB Host Test........................20 USB Device Test ......................21 RS-232 Test........................22 Pass/Fail Test........................24 Specification Test ........................25... -

Page 7: Chapter 1 Specifications

Chapter 1 Specifications All specifications apply to 10X probe and SDS1000D Digital Storage Oscilloscopes. To verify that the oscilloscope meets specifications, the oscilloscope must first meet the following conditions: The oscilloscope must have been operating continuously for thirty minutes within the ●... - Page 8 100MHz(SDS1102D) 60MHz(SDS1062D) 40MHz(SDS1042D) 25MHz(SDS1022D) Single-shot 200MHz(SDS1202D) Bandwidth 150MHz(SDS1152D) 100MHz(SDS1102D) 60MHz(SDS1062D) 40MHz(SDS1042D) 25MHz(SDS1022D) Lower frequency ≤10Hz(at input BNC) limit (AC -3dB) DC Gain Accuracy <±3.0%: 5mv/div to 10V/div in Fixed Gain Ranges <±4.0%:typical for 2mv/div and Variable Gain Ranges Measurement ±[3%X(reading+offset)1% of offset +0.2div+2mv] Accuracy: All Gain settings≤...

- Page 9 Modes Time base ±50ppm measured over 1ms interval Accuracy Horizontal Scan 2.5nS/DIV - 50S/DIV Range Roll: 100mS/DIV ~50S/DIV (1-2.5-5 order) Measure System Auto Vpp, Vmax, Vmin, Vamp, Vtop, Vbase, Vavg, Mean,Crms, Vrms, Measure ROVShoot, FOVShoot, RPREShoot, FPREShoot, Rise time, Fall time, (32 Types) Freq, Period,+ Wid,-Wid, +Dut, -Dut, BWid, Phase, FRR, FRF, FFR, FFF, LRR, LRF, LFR, LFF...

- Page 10 Hard Ware Frequency Counter Reading resolution 6 Bytes Range DC Couple, 10Hz to MAX Bandwidth Signal Types Satisfying all Trigger signals(Except Pulse width trigger and Video Trigger) Control Panel Function Auto Set Auto adjusting the Vertical, Horizontal system and Trigger Position Save/Recall Support 2 Group referenced Waveforms,20 Group setups,20...

-

Page 11: Generic Specifications

Generic Specifications Display System Display Mode Color TFT 5.7in.(145mm)diagonal Liquid Crystal Display Resolution 320 horizontal by 234 vertical pixels Display Color 64K color Display Contrast 150:1 (Typical state) Backlight Intensity 300nit (Typical state) Wave display range 8 x 12 div Wave Display Mode Point, Vector Persist... -

Page 12: Chapter 2 Prepare For Use

Chapter 2 Prepare for Use This chapter includes the following contents: ● General Inspecting ● Power-On Inspecting ● Connect the Probe ● Probe Compensation ● Auto Setting Service Manual... -

Page 13: General Inspecting

General Inspecting After receiving a new SDS1000D series oscilloscope, please inspect the instrument as follows: 1. . . . Inspect the shipping container for damage. Keep the damaged shipping container or cushioning material until the contents of the shipment have been checked for completeness and the instrument has been checked mechanically and electrically. -

Page 14: Power-On Inspection

Power-On Inspection Normal operating voltage for DS1000CA series digital oscilloscope is the range of 100-240VRMS with the frequency from 45Hz to 440Hz. Connect one terminal of the power cord to the socket in left side of the oscilloscope and the other to the power source. Picture 2-1 Connect power line Press the button on top of oscilloscope, some keys on the front panel will be lighted for about 6 seconds until the normal display appears. -

Page 15: Probe Compensation

Probe Compensation You are suggested to compensate probe before first using so as to match it to the input channel. Measurement error may generate without the compensation or because of deviation compensation. To compensate the probe, follow the steps below. 1.Set the probe option attenuation in the channel menu to 10X. -

Page 16: Auto Setup

Auto Setup SDS1000D Series Digital Storage Oscilloscopes have auto setup function, which can identify the type of waveform and adjust controls to produce a usable display of the input signal. AUTO is the auto setup button. Table2-1 Auto setup function menu:... - Page 17 Bandwidth Limit Off(full) V/div Adjusted VOLTS/DIV Coarse adjustability Signal inverted Horizontal position Center S/div Adjusted Trigger type Edge Trigger source Auto detect the channel which has the input signal Trigger slope Rising Trigger mode Auto Service Manual...

-

Page 18: Chapter 3 Performance Test

Chapter 3 Performance Test This chapter includes the following contents: ■ Interface Test USB Host USB Device RS-232 Pass/Fail ■ Specification Test Service Manual... -

Page 19: Interface Test

USB Host Test Purpose: Test if the USB Host interface works normally through U disc. Tools: ● An Unit SDS1000D digital oscilloscope ● An U disc Steps: 1.Insert a U disc into the interface of USB Host on the front panel of the oscilloscope. -

Page 20: Usb Device Test

USB Device Test Purpose: Test if the USB Device interface works normally through EasyScope for SDS1000D series oscilloscope. Tools: ● An Unit SDS1000D digital oscilloscope ● A computer with USB interface ● A standard USB cable(Type AB) ● EasyScope software for SDS1000D series Steps:... -

Page 21: Rs-232 Test

RS-232 Test Purpose: Test if the RS-232 interface works normally through EasyScope for SDS1000D series oscilloscope. Tools: ● An Unit SDS1000D digital oscilloscope ● A computer with RS-232 interface ● A standard RS-232 cable ● EasyScope software for SDS1000D series. - Page 22 Picture 3-6 EasyScope connect setting 4. Press “UTILITY” page3/4 IO Setting, select the Baud as 38400 5. Click “Connect”, if successful, the two point lamps at the top right corner of the software will be changed from red to green.; if failed, a prompt message will be appeared as below. Picture 3-7 RS-232 connect failed Service Manual...

-

Page 23: Pass/Fail Test

● A Probe Steps: 1. Power-On two oscilloscopes. 2. Connect the Pass/Fail interface of SDS1000D with the channel BNC of another oscilloscope using the BNC cable. 3. Connect the probe to channel 1 on SDS1000D, and press AUTO button. 4. Press “UTILITY” button... -

Page 24: Specification Test

Specification Test Purpose: Test if some specifications are in the specified range. Table 3-2 require instruments Description Minimum requirements Examples DC Voltage Source -6 mV to 30 V, ±0.1% accuracy FLUKE 9500B Standard sine wave 10Hz and 300MHz, ±1% amplitude generator accuracy DC to 1GHz... -

Page 25: Test Bandwidth

Volt/div setting DC voltage output level Accuracy limits for V diff 10v/div +30V, -30V 58.2 V~61.8 V 5v/div +15V, -15V 29.1 V~30.9 V 2v/div +6V, -6V 11.64 V~12.36 V 1v/div +3V, -3V 5.82 V~6.18 V 500mv/div +1.5V, -1.5V 2.91 V~3.09 V 200mv/div +600mV, -600mV 1.164 V~1.236 V... -

Page 26: Test Trigger Sensitivity

Test Trigger Sensitivity Steps: : : : 1、Press the button “DEFAULT/SETUP”, and set the VOLT/DIV to 500mv/div, set SEC/DIV to 25ns/div. 2、Connect the oscilloscope channel 1 to the standard sinewave generator 3、Set the standard sinewave generator frequency to 10 MHz 3、Set the generator output level so the Vpp measurement is about 500 mV. -

Page 27: Chapter 4 Calibration

Chapter 4 Calibration Self Calibration Self Calibration procedure can optimize the signal path at the most measurement precision. You can run this procedure at any time. If the operating temperature changes by more than 5℃ or the units run less than thirty minutes, you should do the self calibration. Steps:... - Page 28 Picture 4-2 Calibrating 4. After the calibration finished, Press “SINGLE” key to exit. Picture 4-3 Calibration succeed interface Generally speaking, the self calibration will take about 3-5 minutes, if the calibration does not Pass after this time, or the progress bar stop at one of the calibration item, there may be a trouble in the instrument.

-

Page 29: Chapter 5 Disassembly And Assembly

Chapter 5 Disassembly and Assembly This chapter includes the following topics: ● Notice ● Disassemble and Assemble the on-off and knobs ● Disassemble and Assemble back rind ● Disassemble and Assemble back cover board ● Disassemble and Assemble top cover board ●... -

Page 30: Notice

Notice Notices: : : : ● Don’t disassemble the products except the work need. ● Disassemble only can be done by qualified person. ● Cut the power before disassembling. ● Take static glove when disassembling. ● Use proper tools and follow the disassemble sequence. ●... -

Page 31: Disassemble And Assemble On-Off And Knobs

Disassemble and Assemble On-off and Knobs Picture 5-1 Disassemble and Assemble the on-off and knobs Disassemble steps: 1. Nip on-off 1 button by forceps, and then pull up. ○ 2. Cock knobs③、④ gently by forceps Assemble steps: Please operate as reverse orders. The same is as below. Service Manual... -

Page 32: Disassemble And Assemble Back Rind

Disassemble and Assemble Back Rind Picture 5-2 Disassemble and Assemble back rind 1 图 5-3 Disassemble and Assemble back rind 2 Disassemble steps: 1. Back out the two bolts⑤ and two bolts⑥. 2. Back out the two bolts ○ 3. Remove the back rind. Service Manual... -

Page 33: Disassemble And Assemble Back Cover Board

Disassemble and Assemble Back Cover Board Picture 5-4 Disassemble and Assemble back cover board Disassemble steps: 1. Remove the back cover board by the forceps. Service Manual... -

Page 34: Disassemble And Assemble Top Cover Board

Disassemble and Assemble Top Cover Board Picture 5-5 Disassemble and Assemble top cover board Disassemble steps: 1. Back out the two bolts ○ 2. Pull on the top cover board. Service Manual... -

Page 35: Disassemble And Assemble Fan

Disassemble and Assemble Fan Picture 5-6 Disassemble and Assemble fan Disassemble steps: 1. Back out the four bolts 11 . ○ 2. Remove the fan ○ Service Manual... -

Page 36: Disassemble And Assemble Power Board

Disassemble and Assemble power board Picture 5-7 Disassemble and Assemble power board Disassemble steps: 1. Back out the four bolts 13 . ○ 2. Pull out the power line from the main board and remove the power board. Service Manual... -

Page 37: Disassemble And Assemble Metal Shelf

Disassemble and Assemble Metal Shelf Picture 5-8 Disassemble and Assemble metal shelf Disassemble steps: 1. Back out the four bolts 14 , and remove the metal shelf 15 . ○ ○ 2. Take off the silica gel key 16 . ○... -

Page 38: Disassemble And Assemble Main Board

Disassemble and Assemble Main board Picture 5-9 Disassemble and Assemble main board Disassemble steps: 1. Back out the five bolts 17 . ○ 2. Pull out the screen line and keyboard line from main board. 3. Back out the three big nuts from the BNC. 4.... -

Page 39: Disassemble And Assemble Lcd

Disassemble and Assemble LCD Picture 5-10 Disassemble and Assemble LCD Disassemble steps: 1. Break off the LCD 20 with fingers and thumb. ○ Service Manual... -

Page 40: Disassemble And Assemble Keyboard

Disassemble and Assemble Keyboard Picture 5-11 Disassemble and Assemble keyboard Disassemble steps: 1. Back out the four bolts 21 and remove the keyboard.. ○ Service Manual... -

Page 41: Chapter 6 Prompting Messages And Troubleshooting

Chapter 6 Prompting Messages and Troubleshooting Prompting messages: ■ Trig level at limit! : Mention you that the trigger Level is at a limit when you turn the Trig level knob. ■ Horizon position at limit! : Mention you that the horizontal position is at a limit when you turn the horizon position knob. - Page 42 Drive. ■ Store Data Success! : Save setup data, waveform data or picture data to the internal of the oscilloscope or USB flash successful. ■ Ready Data Success! : Read setup data or waveform data from the internal of the oscilloscope or USB flash successful.

-

Page 43: Troubleshooting

After the inspections above ,restart the oscilloscope. ⑶ ⑷ If the oscilloscope is still not used after the checking, please connect with SIGLENT company 2. If there is no signal wave in the screen after gathering the signal, please do as following steps: (1) Check whether the probe have connected with the signal cable or not. -

Page 44: Chapter 7 Updating Parts

Chapter 7 Updating Parts SIGLENT Provide some replaceable parts in order to maintain or update for users. Please see as the following table. Note that the numbers in the table. Table 7-1 Updating Parts Item Name Specification On-Off button Back Rind...

Need help?

Do you have a question about the SDS1000D and is the answer not in the manual?

Questions and answers