Advertisement

© 2011 Char-Broil, LLC Columbus, GA 31902

PRODUCT GUIDE

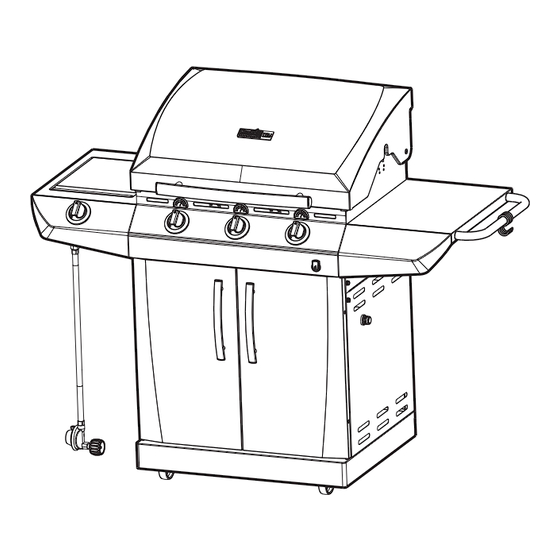

MODEL 463232012

Char-Broil Performance T-36G

IMPORTANT: Fill out the product record information below.

Serial Number

Date Purchased

For support and to register your

grill, please visit us at

www.charbroil.com

If you have questions or need

assistance during assembly,

please call 1-888-430-7870.

Printed in China

See rating label on grill for serial number.

Assembly instructions © 2011

09/22/11 • G519-001-230801

Advertisement

Table of Contents

Need help?

Do you have a question about the 463232012 and is the answer not in the manual?

Questions and answers