Summary of Contents for EFD 800

- Page 1 Operating Guide Model 800 Dispenser ® US: 800-556-3484 In the UK: 0800 585733 In Mexico: 001-800-556-3484 A NORDSON COMPANY...

- Page 2 Most questions you will have are answered in this Guide. However, x 2 " 3 lb 4 oz if you need assistance, please do not hesitate to contact EFD or your (18.4 x 21.6 x 6.7 cm) (1.48 kg) authorized EFD distributor.

-

Page 3: Table Of Contents

You are then assured of complete protection for two years. US, call 800-556-3484. This manual is for the express and sole use of EFD dispenser purchasers In Mexico, call 001-800-556-3484. and users, and no portion of this manual may be reproduced in any form. - Page 4 Plant air, 125 psi maximum to regulator. Output from regulator Power cord should be a minimum of 80 psi, maximum 100 psi. Check voltage label on dispenser Air input hose Foot pedal assembly Adapter assembly Blue test fluid Male quick-connect, insert and twist to lock...

-

Page 5: Dispenser Hookup

Attach the 10cc barrel prefilled with blue, Set plant air supply within 80 to 100 psi (5.5 to 6.9 nontoxic test fluid (included with the bar). Where required, use an EFD five-micron dispenser) to the 10cc adapter head. filter regulator #2000F755 (see Warranty). -

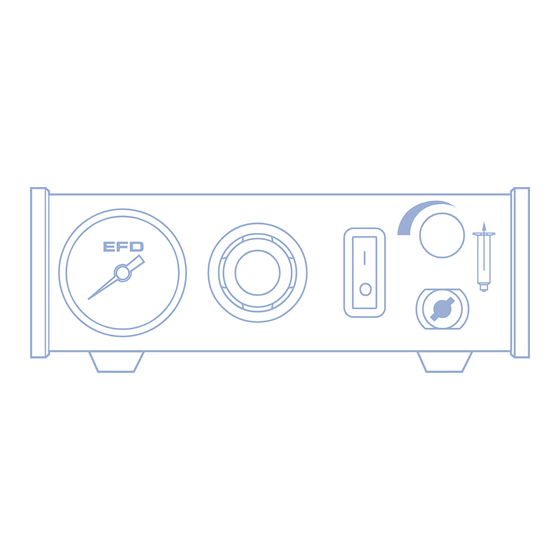

Page 6: Controls & Connections

Controls & Connections Air pressure Power Barrel Air gauge regulator switch vacuum control Air output quick-connect Voltage selector and Foot pedal Vacuum fuse cartridge receptacle transducer Air input Power input receptacle... -

Page 7: Setup For Testing

Push knob in to lock. Be sure barrel vacuum control is turned off (turn clockwise) for initial tests. Press power switch to turn on the dispenser. It will light green. Please continue to page 8 for test procedures. model 800... -

Page 8: Testing The Dispenser

Testing the Dispenser You are now ready to test the dispenser using the prefilled barrel of blue, nontoxic test material. Begin with the following settings: Thick fluid (blue) Thin fluid (clear) Air gauge 10 psi (0.7 bar) 5 psi (0.4 bar) Dispense tip 18 gage (green) 25 gage (red) -

Page 9: Using The Vacuum Control

Remove the tip cap and attach the 25 gage (red) tip. Use an EFD filter trap Closed 3. Set air pressure at 5 psi (0.4 bar). (#1000FLT-Y). This filter trap will impede the flow should the 4. -

Page 10: Ultra Dispensing System

Advanced Dispensing System If you dispense thick fluids, several problems may For Thick Fluids occur. First, the repetitive air cycles can bore tunnels through non-leveling fluids, causing spitting and inconsistent deposits. Second, thick fluids contain Air Pressure Air Pressure trapped air that leads to drooling and oozing. ™... - Page 11 For Thinner Fluids If you use low to medium viscosity fluids, the white SmoothFlow ™ piston has several advantages. First, vacuum adjustment is much less sensitive. Second, the piston prevents fumes from the fluid being exhausted into the work environment. Third, the piston prevents fluid backflow into the dis- penser if the barrel is inadvertently turned upside down.

-

Page 12: Loading The Barrel Reservoirs

Loading the Barrel Reservoirs Caution: Do not completely fill barrels. The optimum fill is a maxi- mum 2/3 of the barrel capacity and 1/2 of the barrel capacity when using the LV Barrier ™ If the fluid you are dispensing is pourable, take the barrel, twist on a tip cap and pour your fluid in. - Page 13 Here are a few suggestions that can help keep your work area clean, save time and reduce the chance of entrapped air in the fluid. 1. You could use the EFD #920BL barrel loader. Pack the fluid into the 12 ounce cartridge as shown. Then place the pre-filled cartridge into the barrel loader.

-

Page 14: Suggestions & Reminders

Suggestions & Reminders 1. Always use an EFD piston to make your barrel loading, dispensing and handling cleaner, safer and more accurate. Caution: If you dispense watery-thin fluids and choose to use ™ SmoothFlow pistons – do not increase vacuum pressure rapidly and do tip the barrel. -

Page 15: Components Reorder

™ ULTRA System Dispensing Components For complete selection and technical details, please refer to EFD Catalog and price list. General purpose precision tips Barrel adapter assemblies All EFD dispensing tips incorporate the unique Molded one-piece, yellow, SnapLok ™ adapter head ™... -

Page 16: Two Year Limited Warranty

All components of EFD dispensers are warranted to the original end user for two years from date of purchase. Within the period of this warranty, EFD will repair or replace free of charge any defective component on return of the part, or the complete dispenser, prepaid to the factory.

Need help?

Do you have a question about the 800 and is the answer not in the manual?

Questions and answers