Westerbeke 12C- TWO Operator's Manual

Marine diesel engines

Hide thumbs

Also See for 12C- TWO:

- Operators manual and installation manual (75 pages) ,

- Operator's manual (59 pages)

Table of Contents

Advertisement

Quick Links

OPERATORS MANUAL'

MARINE D'IESEL ENGINES·

12C~TWO

a

120-TWO,

PUBLICATION NO.039717

REVISION 3

JANUARY 2011

..

~

WESTERBEKE

WESTERBEKE CORPORA TlON • 150 JOHN HANCOCK ROAD

,

MyLES STANDISH INDUSTRIAL PARK' TAUNTON MA 02780

, W.B,SITE: WWW.WESTERBEKE.COM

.

. L;r

Member National Marine Manu/acturers Association

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Westerbeke 12C- TWO

- Page 1 OPERATORS MANUAL' MARINE D'IESEL ENGINES· 12C~TWO 120-TWO, PUBLICATION NO.039717 REVISION 3 JANUARY 2011 WESTERBEKE WESTERBEKE CORPORA TlON • 150 JOHN HANCOCK ROAD MyLES STANDISH INDUSTRIAL PARK' TAUNTON MA 02780 , W.B,SITE: WWW.WESTERBEKE.COM . L;r Member National Marine Manu/acturers Association...

- Page 2 Shut down the unit and do not restart until it has belln inspected and repaired. A WARNING DECAL is provided by WESTERBEKE and should be fixed to bulkhead near your engine or generator. 14'!'!"i!O:!!~~~ WESTERBEKE also recommends installing N·...

- Page 3 • In case of an engine overheat, allow the engine to cool Extinguishers rated ABC by the NFPA are appropriate before touching the engine or checking the coolant. for all applications encountered in this environment. WESTERBEKE Engines & Generators •...

- Page 4 Acid may splash on the skin or into the eyes ing parts and hot exhaust system components. inadvertently when removing electrolyte caps. WESTERBEKE Engines & Generators...

- Page 5 E-9 DC Electrical Systems Avon Industrial Park All installations must comply with the Federal Code of Avon, MA 02322 Regulations (FCR). USCG· (United States Coast Guard) "USCG 33CFR183" Order from: U.S. Government Printing Office Washington, D.C. 20404 WESTERBEKE Engines & Generators...

- Page 6 Carefully review the Marine Installation manual provided with your WESTERBEKE Engine or Generator. Additional manuals are available from your WESTERBEKE dealer. Engines & Generators...

-

Page 7: Table Of Contents

Lay-up and Recommissioning ......56 Changing the Oil ........... 20 Remote Oil Filter (Optional) ......21 Torque Specifications ........57 Water Heater ............. 22 Metric Conversions Oata ........58 Tachometer ............24 Suggested Spare Parts ........60 ...v- WESTERBEKE Engines & Generators... -

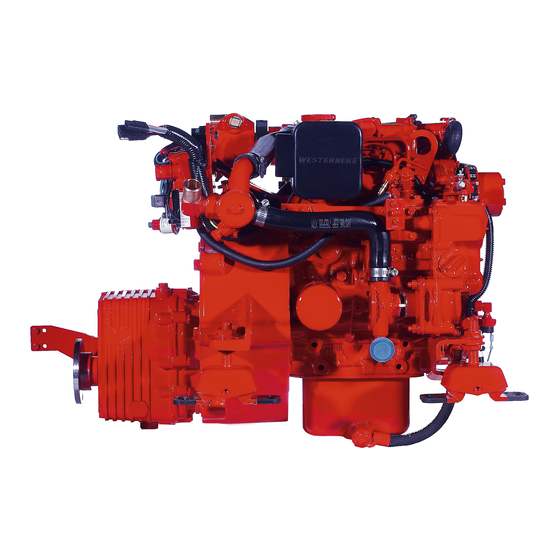

Page 8: Parts Identification

PARTS IDENTIFICATION AIR INTAI!E/SIILENCIER, U'~'" PRESSURE CAP .•• "iI~~:3r--- ENGINE SERIAL NUMBER OIL DRAIN HOSE MOTOR FRONT ALTE~NATOR FILL CAP COOLANT PRESSURE INTAKEJSILENCE~ PLUG -.LIJ"~ UHIUN OIL FILL PUNIP-,lbi~f: FUEL WATER PUMP . J ___ , 'RAW INLET FUEL FILTER OIL DIPSTICK DRAIN HOSE SUMP... -

Page 9: Introductl "On

INTRODUCTION PRODUCT SOFTWARE This WESTERBEKE Diesel Engine is a product of WESTERBEKE's long years of experience and advanced Product software, (tech data, parts lists, manuals, technology. We take great pride in the superior durability and brochures and catalogs), provided from sources other than dependable performance of our engines and generators. -

Page 10: Serial Number Location

INTRODUCTION SERIAL NUMBER LOCATION ORDERING PARTS The engine's model and serial number are located on Whenever replacement parts are needed, always provide the a nameplate mounted on the side of the engine's water engine model number and serial number as they appear on jacketed exhaust manifold. - Page 11 DIESEL FUEL, ENGINE OIL AND ENGINE COOLANT DIESEL FUEL ENGINE COOLANT WESTERBEKE recommends a mixture of 50% antifreeze USE A DIESEL FUEL WITH A CETANE RATING OF #45 OR HIGHER. and 50% distilled water. Distilled water is free from the (No.

-

Page 12: Admiral Control Panel

THEENGiNE'S Oil GALLERY. THIS SWITCH MONITORS THIS BUTTON WILL NOT OPERATE ELECTRICALLY t~E5 E~~rp~~(g~ !~.~S~~C~;)~~~~~~T~M~?~~~~E~~6~~~~~~\fteLL UNLESS THE PREHEAT BUTTON IS PRESSED AND HELD AT THE SAME TIME. ALARM. IN THIS EVENT. THE ALARM WILL EMIT A PULSATING SIGNAL WESTERBEKE Engines & Generators... -

Page 13: Captain Control Panel

PREHEAT BUTTON IS PRESSED.AND HELD ATTHE SAME SOLENOID ON THE INJECTION PUMP, AND THE ENGINE'S TIME. GLOW PLUGS, AND BYPASSES THE ENGINE'S OIL PRES- SURE ALARM SWITCH. IN ADDITION, THIS BUTTON ENER- GIZES THE START BUTTON. ·"IIY'WESTERBEKE . Engines··& Generators... -

Page 14: Preparations For Initial Start-Up

(this location is tagged). Check the coolant level in both the plastic recovery tank and at the manifold. TOP 'OIL FILTER CHECK ENGINE OIL LEVEL . I . CHECK TRANSMISSION FLUIO. CHECK COOLANT LEVEL WESTERBEKE Engines & Generators... -

Page 15: Starting/Stopping Procedure

STARTING/STOPPING PROCEDURE FAILURE TO START CHECKLIST the engine fails to start when the start button is pressed for Follow this check list each day before starting your engine. 5 seconds, wait for at least 30 seconds and repeat the starting Visually inspect the engine for fuel, oil, or water leaks. -

Page 16: Engine Break-In Procedure

ENGINE BREAK-IN PROCEDURE DESCRIPTION 3. While using the vessel, run the engine at various engine speeds for the first 25 hours. Avoid prolonged pedods of Altliough your engine experienced a minimum of one idling. hour of test operations at the factory to make sure accurate 4. -

Page 17: Warning Lights, Alarms And Circuit Breaker

WARNING LIGHTS, ALARMS & CIRCUIT BREAKER ALTERNATOR WARNINGS COOLANT TEMPERATURE SWITCH The Captain Control Panel indicates alternator low discharge A coolant temperature switch is located on the thermostat with a warning light. housing; This switch will activate a continuous alarm if the ~J!Ff coolant's operating temperature reaches approximately The Admiral Control Panel uses a voltmeter to monitor the... -

Page 18: Maintenance Schedule

MAINTENANCE SCHEDULE order use this Maintenance Schedule, it will be necessary WARNING: Never attempt to perform any service to log your engine hours. Use your engine hourmeter or record your engine hours by running time. while the engine is running. Wear the proper safety NOTE: Many of the following maintenance procedures are equipment such as goggles and gloves, and use the... - Page 19 Lubricate at 50 hours, then at least once a season. Lubricate Panel Key Switch with LDckeze" Initial change at 25 hours, then at least once a Transmission Fluid season. 'WESTERBEKE recommends this service be performed by an authorized mechanic. Engines & Generators...

- Page 20 ,,1' 0 ,nsure,cleanfuel-into the fuel pump, there is a small in- line, fuel filter connected to the fuel lift pump elbow. This filter should be replaced every 250 hours of operation or once a season, which ever occurs first. WESTERBEKE "IIY' ~,?gines & Generators...

- Page 21 ENGINE COOLING CIRCUIT exhaust system where finally it is discharged overboard. In OEseRIPTION other words, the engine is cooled by fresh water coolant, this Weslerbeke marine diesel generators are designed and coolant is cooled by raw water, and the raw water carries the ¢quipped for fresh water cooling.

-

Page 22: Cooling System

CHANGING COOLANT ENGINE COOLANT The engine's coolant must be changed according to the WESTERBEKE recommends a mixture of 50% antifreeze MAINTENANCE SCHEDULE. If the coolant is allowed to and 50% distilled water. bistilled water is free from the become contaminated, it can lead to overheating problems. -

Page 23: Thennostat

COOLING SYSTEM THERMOSTAT thennosta~ located near the manifold at the' front of the engine, controls the coolant temperature as the coolant continuously flows through the closed cooling circirit. When the engine is first started, the closed thennostat prevents . THERMOSTAT coolant from flowing (some coolant is by-passed t)rrough a 'ASSEMBLY hole in the thermostat... -

Page 24: Raw Water Intake Strainer

FI~TER NOTE: Never allow the pump to rnn dry. Even a short period , of dry rnnning may destroy the impeller. INSPECT AND SEACOCK;,..· """'''''''''' GLEAN EVERY ~WESTERBEKE 100HOURS Engl!J~-4~en!Jrators... - Page 25 REPAIR PARTS ARE AVAILABLE FROM YOUR WESTERBEKE DEALER KEY NO. PART NUMBER AND'PART NAME QUANITY ' 48080 RAW WJ!(fER PUMP' ,49172 SHAFT NOTE 49170 IMPELLER COVER THE PUMP-REPAIR KIT (49000) 48500 IMPELLER KIT (O·RING & GLYCERIN) , I INCLUDES ALL THE USTED...

-

Page 26: Heat Exchanger

. COOLING SYSTEM Zinc Anode . If the zinc anodes need replacement, hold the hex boss into #011885 loos~ which the zinc anode is threaded with a wrench while A zinc anode, or pencil, is located in the raw water cooling erung the anode with another wrench. - Page 27 ENGINE LUBRICATING OIL 2. Replacing the Oil Filter. When removing the used oil filter; you may find it helpful and cleaner to punch a hole TYPI.CAL LUBRICATION .O!A_GRAM • in the upper and lower portion of the old filter to ~ain "il from it into a container before removing it.

-

Page 28: Remote Oil Filter (Optional)

REMOTE OIL FILTER (OPTIONAL) PN# 040078 INSTALLATION NOTE: Westerbeke is not responsiblefor engine failure due to incorrect installation of the Remote ail Filter. . , reloc~te popular accessory ·is used to the engine's oil fil- This ter from the engine to a more convenient location such as an engine room bulkhead. -

Page 29: Water Heater

DOMESTIC HOT WATER TANK CONNECTIONS DESCRIPTION PREVIOUS MODEL ENGINES Bothihe two mid three cylinder models are equipped with connections to send engine coolant to a domestic water heater. ,HEATER BELOW ENGINE REMOVE THE [fthe owner/operator wishes to connect a water heater, remove BY-PASS HOSE' , the bypass hose and connect a water heater as described in the instructions presented below. - Page 30 DOMESTIC HOT WATER TANK CONNECTIONS HOT WATER HEATER ABOVE THE ENGINE any portion of the heating circuit rises above the engine's PRESSURE CAP IS RATED own pressure cap, the a pressurized (aluruinum) remote LOWER THAN MANIFOLD. CAP expansion must be installed in the circuit to become the tank highest point.

-

Page 31: Tachometer

TACHOMETER NOTE: Current model tachometers use a coarse adjustment' TACHOMETER/HOUR METER rpms. dial to set the tachometer to the crankshaft pulley The tachometerlhour meter used in propulsion engine instru- calibrating screw then usedior fine tuning. ment panels contains two separate electrical circuits with a common ground. -

Page 32: Alternator Testing/Troubleshooting

WARNING: A working alternator hot. A failed The following information applies to the standard alternators' altemator can become very hot. 00 not touch the that are supplied with WESTERBEKE'S Engines_ and Generators. until altemator has cooled. ELECTRICAL CHARGING CIRCUIT... - Page 33 If the voltage' output is 13-14 volts, . then the alternator is OK . . MEASURING ;--:-,-/~q • BAITelIY VOLTAGE TESTING THE OUTPUT ENGINE RUNNING CIRCUIT ENGINE RUNNING EXCITER '~,\ 'TERMINAL "R .WESTERBEKE , . y ' Engi,;e~ Generators &...

-

Page 34: Battery Care

Any good alternator service shop can do the job. NIiTE: WESTERBEKE'S service Manual has detailed instructions for the disa"sembly repair of their staridard alternators. · BATTERY CARE The minimum recommended capacity of the battery used in ·... -

Page 35: Glow Plugs

GLOW PLUGS DESCRIPTION Re-install the plugs in the engine and test them again. The plugs should get very hot (at the terminal end) within 20. to The glow plugs are wired through the preheat solenoid. 25 seconds. the plugs don't heat up quiCkly, check for a When PREHEAT is pressed at the control panel this solenoid short circuit. -

Page 36: Starter Motor

There will be arching and sparks will fly. when jumping terminals. Be certain the engine space Is free of potentially BJi#lloslve fumes, especially gasoline, and tirat there are NO flammable solvents or materials stored nearby. -..v WESTERBEKE Engines & Generators... - Page 37 SERVICE If the starter fails to spin, the motor is probably faulty. WESTERBEKE uses a standard starter motor which can be If no arching occurred, tbere is no jnice reaching the serviced or rebuilt at any starter motor automotive service solenoid.

-

Page 38: Engine Wiring Diagram (#39144)

ENGINE WIRING DIAGRAM (#39144) r - - - - It:: 12 VDC >AIill:( "~ " ADMIRAL ,,"U,, PANEL IUZIU '-==, ___ ' ___ _ r-=-:~::::-:-=-'J '-'="----'-----'--'-'_ - - - -- - - - \ "\ " " f' CAPTAIN LU1l PANEL ---.J I "'-... -

Page 39: Engine Wiring Schematic (#39144)

.14 LT . • 4 "~FT~"i~~ r:M~'I\W 1' .. JJN I VERSA! PROP!!I PRESTOI I Tf AI T ® OPT I DNA! AI IERNAIORS "U. IIO~. LU~. ~EHU ~lT[RnTO.$ "0 AYAlL",!" IM( In • IUS n 001' WESTERBEKE .Engines G.enerators &... -

Page 40: Admirals Panel Wiring Diagram (#36844)

~!lLI': TACHOMETER START PREHEAT ~TCH S~CH I" KEY SWITCH VOL.TMETER "'OIlLK. , " o e l " ! _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ J WESTERBEKE Engines. & Generators... -

Page 41: Captains Panel Wiring Diagram (#36467)

CAPTAINS PANEL WIRING DIAGRAM (#36467) .---f-"~---..., WATER TEM". G!.OwPLuGS SWITCH 11",4,Q011;. otllf.II!)IIIG 011 IlUNalA Cll.llIOEIiSl "'fG T.II.U( ,.NEHEt.T SOI..EN')IO .,. T. !ll.IIE " _-=q ,,-.J PRESSURE' _ _ _ SWITCH -1__ _ --mL !U.f.~E't- _ _ _ _ _ IUSED c<... - Page 42 ENGINE TROUBLESHOOTING The following troubleshooting table describes certain problems NOTE: The engine's electrical system is protected a 20 relating to engine service, the probable causes of these prob- ampere manual reset circuit breaker located all a bracket at lems, and the recommendations overcome these problems, the back of the engille.

- Page 43 ENGINE JROQBLESHOOTING Problem Probable Cause VerilicationJRemedy Engine slows and stops. 1. Fuel lift pump failure. 1. Fuellift pump should make a distinct ticking sound. Replace pump with spare. 2. Switches and/or wiring loose 2. Inspect wiring for short circuits and loose connections. or disconnected, Inspect switches for proper operation.

-

Page 44: Control Panel Troubleshooting

2. Remove the wire attached to the sender tenninal at tlle terminals), the ground side will not necessarily be connected gauge and connect it to ground. See if the gauge reads full scale, which is the nonn.l reading for 11ris situation. to 11le block. WESTERBEKE "tIY' & Generators Engines... -

Page 45: Engine Adjustments

ENGINE ADJUSTMENTS NOTE: WESTERBEKE recommends that the following engine adjustments be peiformed by a competent engine mechanic. The information below is provided to assist the ENGINE IDLING SPEED The engine idling speed is pre-set at the factory but once the... - Page 46 ENGINE ADJUSTMENTS engin~ NOTE: WESTERBEKE ':;'commends that the/allowing adjust- . ments be peiformed by a competent engine mechanic. The information below is provided to assist the mechanic. ENGINE COMPRESSION DRIVE BELT ADJUSTMENT Check; the engine's compression pressure at 500 and 1250 Excessive drive belt tension can cause rapid wear of the belt openiting'houis or whenever engine perfonnance is reduced.

-

Page 47: Oil Pressure Switch

ENGINE ADJUSTMENTS NOTE: WESTERBEKE recommends that the following engine adjust- ments be peTjonned by a competent engine T(lechanic. infonnation below is provided to assist the mechanic. TESTING OIL PRESSURE OIL PRESSURE RELIEF VALVE To test oil pressure, remove the hex head plug from the oil pressuterelief valve is located. - Page 48 ENGINE ADJUSTMENTS NOTE: WEST.ERBEKE recommends that the fallowing engine adjustments be performed by a competimt engine mechanic. TIW information below is provided to assist the mechanic. CYLINDER HEAD BD,LT TIGHTENING SEQUENCE W\LVE CLEARANCE ADJUSTMENT The valve clearance must be adjusted every 500 operating hours or whenever the valve rocker is abnormally noisy.

-

Page 49: Valve Clearance Adjustment

ENGINE ADJUSTMENTS NOTE: WESTERBEKE recommends that the following engine adjustments .be petformed by a competent engine mechanic. information below is provided to assist the mechanic. VALVE CLEARANCE ADJUSTMENT (CDNT.) Rotate the engine's crankshaft in its normal direction of rotation to position piston No.1 at the beginning of its 5. -

Page 50: Fuel Injectors

ENGINE ADJUSTMENTS NOTE: WESTERBEKE recommends that the following engine adjustments be peifonned by a competent engine mechanic. The infonnatlon below is provided to assist the mechanic. FUEL INJECTORS INSPECTING THE SPRAY PATTERN Operate the hand lever of the nozzle tester at intervals of... -

Page 51: Js And Bwtransmissions

JS AND BW TRANSMISSION DESCRIPTION the throw distance (or travel) of the remote cable is too The transmission's gear ratio is 2.47 to I. This manual trans- short, .the gear box lever cannot fully engage the transmission mission rotates opposite to the engine when in forward gear. into .FORWARD or REVERSE. - Page 52 Disassembly of the transmission in the field is not recom- in NEUTRAL is just good sailing practice). mended, If an overhaul or repair is needed, the work should be done by an authorized WESTERBEKE service centel. COOLING MAINTENANCE The JS transmission is raw water-cooled. Raw water enters...

- Page 53 Refer to the WESTERBEKE parts list. SHIFT LEVER The transmission is suitable for single lever remote control.

-

Page 54: Hurth Hbw/Zf Transmissions

HURTH HBWJZF TRANSMISSIONS INITIAL OPERATION LOCKING THE PROPELLER All HBWIZF marine transmissions are test-run on a test Locking of the propeller shaft by an additional brake is not stand with the engine at the factory prior to delivery. For required: use the gear shift lever position opposite ·your safety reasons the fluid is drained before shipment. - Page 55 Look for corrosion of the end fittings, cracks or cuts in waters, maintenance, etc. it inight only last half that time. the conduit, and bendiug of the actuator rods. Lubricate WESTERBEKE recommends having a spare cooler aboard. all moving parts. NOTE: the transmission is to be stored for a long time ltwelve months or more), it should be topped offwith·...

- Page 56 NOTE: you suspect a major problem in your transmission, is stiff to operate, break the cable loose at the transmission immediately contact your WESTERBEKE dealer or an and try again. is still stiff, check the cable for kinks or If it authorized marine transmissioll[acility.

- Page 57 5. Contact marlne repair, 6. Contact manufacturer. 6. 'Transmisslon malfunction. 7. Engine maHunction .. 7. Contact marine repair. NOTE: you suspect a major problem in your transmission, immediately contact your WESTERBEKE dealer or all authorized marine transmission facility, WESTERBEKE -..Y' Generators Engines &...

- Page 58 PRM HEWAGE TRANSMISSIONS MODELS aD-AND 120 . 120HASABREATHEti,~ . THE MODEL NOTE: When changing the'fluid, take care not to lose the FITTING ON THE TOP OF THE CASEr:::::::!!!!:I drain plug sealing washer. The drain plug will leak without this sealing washer. -':'DII'$m:K 112"...

- Page 59 Fax: 954-467-1525 Newage Transmissions, Limited. Website: www.Newage-PRM.co.uk If a major problem should occur, contact your WESTERBEKE dealer or a NEWAGE distributor. To avoid prejudicing walTanty rights, do not undeltake repair work on the gearbox without first contacting NEWAGE TRANSMISSIONS LTD.

- Page 60 . PRM NEWAGE TRANSMISSIONS TROUBLESHOOTING VerlllcationJReme~y Problem· Probable CaUse Excessive noise at low speeds. Engine idle speed too low. Increase.ldling speed. Defective coupling. Inspect/replace coupling if necessary. Excessive noise at all speeds. 2. Shaft misalignment. 2. Check alignment with feeler gauge. 3.

- Page 61 12 Volt DC, 50 Amps (Fresh Water) Regulator Internal regulator, built into alternator TRANSMISSIONS 2.47:1 reduction (See Transmission pages) JS Model 2.50:1 reduction PRMBO 2.47:1 reduction Propeller Rotation Right hand turning - Standard Transmission Propeller Shaft 3/4" diameter (minimum) WESTERBEKE Engines Generators &...

-

Page 62: Lay-Up And Recommissioning

Do not leave the engine's old engine oil ~ubricating in the sump over the lay-up period. oil and combustion depOSits combine to produce harmful chemicals which can reduce the -life of your engine's internal paris. I~--'WESTERBEKE --, Ergines & Generators... - Page 63 Lay-up time provides a good opportunity to inspect your if access to the starter permits its easy removal. Make sure the Westerbeke engine to see if external items such as drive belts battery connections are shut off before attempting to remove or coolant hoses need replacement.

-

Page 64: Torque Specifications

TORQUE SPECIFICATIONS FHB (M-KG) COMPONENT FHB (M-KG) COMPONENT Alternator Bracket ......27 - 38 (3.8 - 5.3) Injection Pump Hollow Screw M10 (14) ........7.2 - 10.8 (1.0 - 1.5) Back Plate ........24 - 35 (3.3 - 4.8) Injectors .......... 36 - 38 (5.0 - 6.0) Connecting Rod Cap M8 (14) .. - Page 65 DECIMAL TO METRIC EQUIVALENT CHART Fractions of Fractions of Decimal (in.) Metric (mm) Decimal (in.) Metric (mm) an inch an inch 1/64 0.015625 13.09687 0.39688 33/64 0.515625 1/32 0.03125 0.79375 17/32 0.53125 13.49375 3/64 0.046875 13.89062 1.19062 35/64 0.546875 1/16 0.0625 1.58750 9/16...

- Page 66 Miles Per Gallons US (MPG) x .425 = Kilometers Per Liter (Km/L) Kilometers Per Liter (Km/L) x 2.352 = US MPG TEMPERATURE Degree Fahrenheit (OF) (OC X 1.8) + 32 Degree Celsius (OC) (OF - 32) x .56 WESTERBEKE -.,.y' Englnf!s & Generators...

-

Page 67: Suggested Spare Parts

. ENGINE OIL (YOUR BRAND) FOR Alii OIL CHANGE (5 OTS.) AND A GALLON OF PREMIXED COOLANT. "'~ SP.ARE PARTS .•..WESTERBEKE also offers two Spare Pints Kits, BKit each packaged in rugged hinged toolbox. Kit "An includes the basic spares. - Page 68 WESTERBEKE Engines & Generators 1158·2/2011...

Need help?

Do you have a question about the 12C- TWO and is the answer not in the manual?

Questions and answers