Table of Contents

Advertisement

Quick Links

NAVSEA 0941·Lp·014·8010 WITH CHANGE #3,

NAVSEA 0941·014·8013

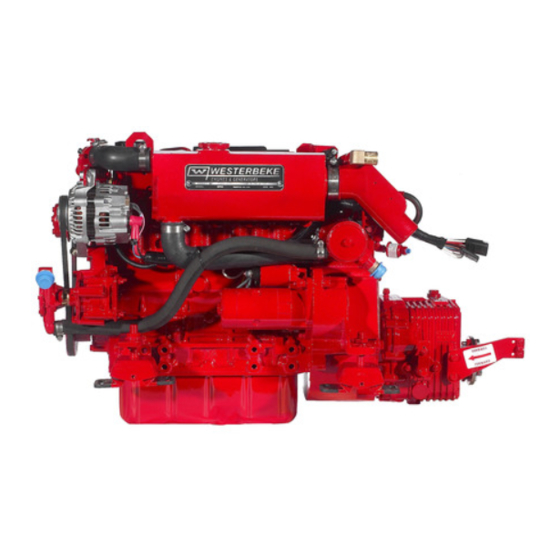

WESTERBEKE DIESEL

MODEL 14088

ENGINE SERVICE MANUAL

DEPARTMENT OF THE NAVY

NAVAL SEA SYSTEMS COMMAND

l~rWESTERBEKE

~

WESTERBEKE CORPORATION

•

MYLES STANDISH INDUSTRIAL PARK

150 JOHN HANCOCK ROAD, TAUNTON, MA 02780-7319

23 FEBRUARY 1967

CHANGE 3, 1 JUNE 1980

NAVSEA 0941-LP-014-8013

Advertisement

Table of Contents

Summary of Contents for Westerbeke 14088

- Page 1 NAVSEA 0941·Lp·014·8010 WITH CHANGE #3, NAVSEA 0941·014·8013 WESTERBEKE DIESEL MODEL 14088 ENGINE SERVICE MANUAL DEPARTMENT OF THE NAVY NAVAL SEA SYSTEMS COMMAND l~rWESTERBEKE WESTERBEKE CORPORATION 23 FEBRUARY 1967 • MYLES STANDISH INDUSTRIAL PARK 150 JOHN HANCOCK ROAD, TAUNTON, MA 02780-7319...

- Page 2 NAVSEA 0941·Lp·014·8010 WITH CHANGE #3, NAVSEA 0941·014·8013 WESTERBEKE DIESEL MODEL 14088 ENGINE SERVICE MANUAL DEPARTMENT OF THE NAVY NAVAL SEA SYSTEMS COMMAND l~rWESTERBEKE WESTERBEKE CORPORATION 23 FEBRUARY 1967 • MYLES STANDISH INDUSTRIAL PARK 150 JOHN HANCOCK ROAD, TAUNTON, MA 02780-7319...

- Page 4 APPROVAL AND PROCUREMENT RECORD BASIC APPROVAL DATA FOR: NAVSHIPS 0941-014-8010 TECHNICAL MANUAL WESTERBEKE DIESEL MODEL FOUR-107 APPROVAL AUTHORITY: Letter, 23 February 1967, BuShips NObs-4989, Sere 6146-157 Letter, 1 May 1967, SPCC Contract N104-18261A Letter, 18 July 1967, SuShips Jacksonville, Sere 240-1383...

- Page 6 LIST OF EFFECTIVE PAGES PAGE NO. CHANGE IN EFFECT COMMENTS Change 3 New Text Blank Change 3 New Text 6-11 Change 3 Renumbered pages Blank Change 3 Dwg. No. Changed Blank Change 3 15-18 Renumbered pages 19-20 Change 3 Revised Text 21-28 Change 3 Renumbered pages...

- Page 8 INDEX SECTION PAGE Titl e Page Approval and Procurement Record List of Effective Pages Index Sectional Index-General Section Software Notice Introduction Photographs Installation Drawing Installation of Engine Starting Engine the First Time Operating Engine Precautions Fault Diagnosis Do and Do Not's Periodical Attention Maintenance ENGINE OVERHAUL...

- Page 10 SECTION INDEX GENERAL Introduction Operation Installation Maintenance ENGINE OVERHAUL OTHER OVERHAUL Marine Engine Electrical System Cooling System (External) Transmissions SERVICE BULLETINS PARTS LIST...

- Page 11 Routine operator's and workshop manuals, parts changes made by Westerbeke's suppliers, of which Westerbeke rarely has notice lists and parts price lists, and other information, instructions and specifi- in advance, are frequently not reflected...

- Page 12 INTRODUCTION This manual describes the operation, adjustment and maintenance of the Westerbeke Whaleboat Marine Diesel Engine and is designed to be a guide for those concerned with the operation and maintenance of these diesels. This engine incorporates a basic engine model known variously as 4-99, 4-107 and 4-108.

- Page 13 FUEL OIL LIFT PUMP SECONDARY FUEL FILTER CONNECTION FOR GENERATOR CYLINDER BLOCK WATER DRAIN SHIELDED CONDUIT T ACHOMEHR DRIVE CONNECTOR LUBE OIL DIPSTICK ' - - - OIL COOLER LUBE OIL LINES TO IPI: FOR SUMP PUMP HOSE AND FROM TRANSMISSION Fig.

- Page 14 ..--cAnAu"T MANIFOLD EXHAUST ELBOW THERMOSTAT UNDER T WATER TANK _ - REVERSE GEAR SHIFTING LEVER FUEL INJECTION PUMP REVERSE GEAR DIPSTICK LUBE OIL FILTER STARTING MOTOR SOLENOID MOUNTING RAIL STARTING MOTOR LUBE OIL IN-OUT FITTING Fig. 2-Port View of Engine...

- Page 15 HEAT EXCHANGER ' - - - - HYDRAULIC REVERSE GEAR REDUCTION GEAR Fig. 3-Rear Starboard View Looking at Transmission...

- Page 16 _---INJECTION NOZZLES REAR LIFTING RING FUEL PIPES- FILTER TO PUM HEA T EXCHANGER DRAIN Fig. 4-Rear Port View Looking at Transmission...

- Page 17 FRESH WATER FILLER CAP FRESH WATER PUMP BILGE PUMP - - - Fig- 5-Front Starboard View Engine...

- Page 18 r------ FRESH WATER PUMP FRONT LIFTING RING FRESH WATER LINE CRANKSHAFT PULLEY SEA WATER LINE BilGE PUMP Fig. 6-Front Port View of Engine...

- Page 21 INSTALLATION FOREWORD to the rings and the engine lifted by means Since the boats in which these engines are used of a tackle attached to this short sling. The lifting have been designed by engineers of the U.S. rings have been designed to carry the fullweight Navy, every detail of the engine installation is of the engine, therefore auxiliary slings are not provided for in the plans, and checked by U.S.

- Page 22 It is therefore very important PROPELLER COUPLING to check the engine alignment at frequent inter- Each Westerbeke Diesel engine is regularly fitted vals and to correct any errors when they may with a suitable coupling for connecting the prop- appear.

- Page 23 slipped backwards and forward into the counter- bore very easily and when a feeler gauge in- dicates that the flanges come exactly together at all points. The two halves of the propeller coupling must be parallel within .002 inch. an .003" feeler gauge can be inserted, align- ment is unsatisfactory.

- Page 24 COOLING WATER PIPING A fuel filter is mounted on the engine between the fuel lift pump and the in- The Westerbeke Four-107 Diese I is fresh water jection pump. It contains a replaceable cooled, utilizing what is known as a "closed sys- cartridge (see Maintenance Schedule).

- Page 25 tween the fuel tank and engine should be of the fuel oil type, and it is important that all joints be free of pressure leaks. K~ep fuel lines as far as possible from exhaust pipe for minimum temperature, to eliminate "vaDor lock".

- Page 26 .24- V ACe. .5'TA£T£.e BUTTO/J ---I:L - ----------~ (}D.J. "'/0 lIt) ..l). \ ,7 1 " j ___ ' 1 _ .., SlAET£.e. ~------~ ~---====- 12 V. - 8ATT£R'I MTT££Y Fig. ll-Wiring Diagram (Delco-Remy Generator) Solenoid relay starting switch is mounted on The current and voltage regulator (supplied with cranking motor.

- Page 27 The water temperature gauge, is connected by capillary tubing with its recording element in- serted in 1/2" I.P.S. tapped hole in front of cylinder head. The oil pressure gauge should be connected to the take-off fitting on the side of the block. 1/4"...

- Page 28 STARTING ENGINE THE FIRST TIME The engine is shipped "dry", that is with lubrica- ting oil drained from crankcase and transmis- CRANKCASE OIL FILLER USE NAVY SYMBOL 9250, S.A.E, 30 sion. The following items should be checked methodically before starting engine the firsttime. Check Lubricating Oil in Engine: Fill crankcase with Diesel lubricating oil, S.A.E.

- Page 29 Fuel Tank Primary Fuel Filte .. Fuel Lift Pump Secondary Fuel Filter S. Fuel Injedion Pump Injection Nozzles Fig. 17-- Fuel System Final Check-Over: Loosen one of the two hydraulic head locking Make a careful overall in- screws (8) on the side of the pump body. spection.

- Page 30 DAILY ROUTINE BEFORE STARTING ENGINE 1. Check Fuel Supply. Best time to fill fuel tank is at end of day's operation, to prevent condensation from forming in the tank. Check Water Level in fresh water tank. Note: An air space of about 2 inches below top of tank is normal.

- Page 31 MAINTENANCE OF EQUIPMENT IN COLD WEATHER the fuel, otherwise this may freeze and stop the Certain maintenance operations must be checked fuel flow. more carefully in cold weather. For instance, the thermostats and water temperature control Lubricating oil must be watched more carefully must be maintained so that the engine iswarmed during cold weather to be sure that dilution is up as qUickly as possible and remains at normal...

- Page 32 FAULT DIAGNOSIS WILL NOT RUN OTHER FAULTS --~I----_ LOSS Of POWII WIll NOI SIART SIOPPID IN US! WIll NOI IURN OVII OIL PlmU11 HISfIRING IlIOCrl" LOW 01 NIL ,--L---, IAmlY CAPACITY IIHING lUll IDL"6 IOIIRNAI IAHHID lURING OR INlEI 01 INIICIION CO"!PRISSIONS SnTlNC.

- Page 33 FAULT FINDING Difficult Starting. Sticking Rockers. No Fuel at Injection Nozzles: If the rockers stick, the cause may be: the use of unsuitable oil, shortage of oil, or sludging. Use (a) No fuel in tank. only oil of an approved type. If there is a (b) Fuel lift pump not working.

- Page 34 DO AND DO NOT DO KEEP THE ENGINE CLEAN. DO make sure that the pressurised filler cap is removed when draining the cooling system. DO keep this book where it is conveniently DO close these drain cocks and refill with water accessible.

- Page 35 PERIODICAL ATTENTION POST-DELIVERY CHECKOVER. It is recommended, therefore, that the following procedure be adopted and applied immediately After a customer has taken delivery of his en- the unit is withdrawn from service. gine, it is advisable, in his own interests, that a gp.neral check over of the engine be carried out 1.

- Page 36 If this occurs, the fuel oil may become con- gUidance of all users of the'above engines, and should be followed when putting the engine taminated with a wax-like substance which will back into service follOWing the winter lay-up qUickly clog the fuel filtering arrangement once period, or at any time the fresh water cooling the engine is returned to service.

- Page 37 FROST PRECAUTIONS (b) locking of the seal through the freezing of globules of moisture between the seal and Precautions against damage by frost should be the gland. taken if the engine is to be left exposed to in- clement weather either by adequately draining Operators are therefore advised to take these the water system or where this is not convenient precautions when operating in temperatures be-...

- Page 38 GENERATOR HAS TWO GREASE . . . - - - CUPS, TURN DOWN ONE TURN EVERY 100 HOURS CHANGE CARTRIDGE IN FUEL OIL FILTER EVERY 250 HOURS CHANGE CRANKCASE OIL EVERY 100 HOURS Fig. 21-Points of Lubrication, Starboard Side CRANKCASE OIL FILLER USE NAVY SYMBOL 9250, S.A.E, 30 TRANSMISSION OIL DEPTH GAUGE...

- Page 39 MAINTENANCE SCHEDULE DAILY EVERY 200 HOURS ~train'er, Check sea water if there is one. Change oil in transmission. Check water level in cool ing system. Check lubricating oil level in crankcase and transmission EVERY 250 HOURS Wash element in primary fuel oil strainer. EVERY 50 HOURS Change element in secondary fuel oil filter.

- Page 40 Fig_ 22A-lnstallation in 26' Motor Whale Boat...

- Page 41 FILTER MAINTENANCE AIR FILTER The time period for cleaning the air filter de- pends on operating conditions, therefore, under extremely dirty conditions, the time limits rec- ommended hereafter for cleaning should be decreased. The correct maintenance of the filter will greatly assist in reducing bore wear, thereby extending the life of the engine.

- Page 42 LUBRICATING OIL FILTERS To insure cleanliness of the lubricating oil, filters are fitted to the engine. If the periodical atten- tions relating to these filters are carried out, and the correct grade of clean oil is used, a very long life can be obtained from the engine. The first filter is in the sump and is also a gauze strainer.

- Page 43 Additional operating characteristics are included in the Operation Section of this manual. Any replacements should be made only with genuine Westerbeke parts. CONTENTS SECTION ENGINE DESCRIPTION..... • . • . • • • • ..•...

- Page 45 SECTION A Engine Description uniform heat distribution. Intimate mixing of the fuel The 4.108, 4.107 and 4.99 Series Diesel Engines with and air over a wide speed range is ensured, ,which in- which this manual is concerned is an indirect injection, creases the engines performance, efficiency and flexi- four cylinder, four stroke power unit.

- Page 46 ENGINE DESCRIPTION-A.2 Camshaft maintains an intermittent feed by drillings in the spigot and idler gear lubricate the timing gear arrangement. and to the centre camshaft bearing where due to The special cast iron alloy camshaft which has chill special machining on the centre camshaft journal an hardened cams.

- Page 47 SECTION B Technical data Engine Data Westerbeke 4.108 and 4.107 4.99 Bore (nominal- See Page B.3) 3.125 in (79,37 mm) 3.00 in (76,2 mm) Stroke ... 3.5 in (88,9 mm) 3.5 in (88,9 mm) No. of Cylinders Four Four Cubic Capacity ...

- Page 49 TECHNICAL DATA-B.3 MANUFACTURING DATA AND DIMENSIONS The data regarding clearances and tolerances is given for personnel engaged upon major overhauls. CYLINDER BLOCK Total Height of Cylinder Block 4.108.4.107.4.99 between Top & Bottom Faces 9.936/9.939 in (252,374/252,451 mm) 4.108 Parent Bore Dia. for Cylinder Liner 3.249/3.250 in (82,525/82,550 mm) Parent Bore Dia.

- Page 50 TECHNICAL DATA-B.4 Piston Rings 4.108 Top-Compression Parallel Faced Second and Third Compression Internally Stepped Fourth-Oil Control Laminated Segment Fifth-Oil Control Slotted Scraper Top Compression Ring Width 0.0771/0.0781 in (1,958/1,984 mm) Ring Clearance in Groove 0.0024/0.0044 in (0,061/0,112 mm) Second and Third Compression Ring Width ... 0.0615/0.0625 in (1,562/1,587 mm) Ring Clearance in Groove 0.00210.004 in (0,051/0,102 mm)

- Page 51 TECHNICAL DATA-B.S Small End Bushing 4.107 and 4.99 Type Steel Backed, Lead Bronze Lined Length of Small End Bushing 0.865/0.885 in (22,00/22,48 mm) Outside Dia. of Small End Bushing on later 4.99 and all 4.107 engines 1.065/1.066 in (27,05/27,08 mm) Early 4.99 engines 1.0025/1.0035 in (25,46/25,49 mm) Inside Dia.

- Page 52 TECHNICAL DATA-B.6 Crankshaft 4.108, 4.107, 4.99 21.125 in (536.575 mm) Overall Length 2.248/2.2485 in (57.099/57.112 mm) Main Journal Dia. Nos. 1 and 2 2.2475/2.248 in (57.086/57.099 mm) Main Journal Dia. No. 3 1.40625 in (35.719 mm) Main Journal Length No. 1 1.496/1.504 in (37.998/38.202 mm) Main Journal Length No.

- Page 53 TECHNICAL DATA-B.7 Camshaft 4.108, 4.107, 4.99 Journal Length 1.347/1.351 in (34,214/34,315 mm) Journal Dia. 1.791/1.792 in (45,491/45,517 mm) Cylinder Block Camshaft Bore Dia 1.794/1.7955 in (45,568/45,606 mm) Journal Running Clearance 0.00210.0045 in (0,051/0,114 mm) No. 2 Journal Length 1.250 in (31,750 mm) NO.2 Journal Dia.

- Page 54 TECHNICAL DATA-B.S Valves (Inlet) 4.10S, 4.107, 4.99 Valve Stem Dia. 0.312/0.313 in (7.92517.950 mm) Clearance fit of Valve Stem in Guide 0.0015/0.0035 in (0.038/0.089 mm) Valve Head Dia. 1.410/1.414 in (35.814/35.916 mm) Valve Face Angle 45° Valve Head Depth Below Cylinder Head Face 0.028 in (0.711 mm)/0.039 in (0.991 mm) Overall Length of Valve 4.592/4.608 in (116.637/117.043 mm)

- Page 55 TECHNICAL DATA-B.9 TIMING GEARS 4.108,4.107,4.99 Camshaft Gear Number of Teeth Inside Dia. of Gear Boss 1.750/1.7514 (44.450/44.486 Outside Dia. of Camshaft Hub 1.7496/1.7509 (44.430/44.473 Transition Fit of Gear and Hub 0.0009/0.0018 (0.023/0.046 Fuel Pump Gear Number of Teeth Inside Dia. of Cylinder Block Bore for Fuel Pump Drive Hub Bearing 1.8125/1.8141 (46.037/46,078...

- Page 56 TECHNICAL DATA-B.10 Pump Clearances Inner Rotor to Outer Rotor 00005/0.0025 (0.013/0.063 mm) Outer Rotor to Pump Body 0.011/0.013 in (0.28/0.33 mm) Inner Rotor End Clearance 0.0015/0.0003 in (0.0380.076 mm) Outer Rotor End Clearance 0.0005/0.0025 in (0.013/0.063 mm) Inside Dia. of Bore for Pump Shaft 0.50010.501 in (12.700/12.725 mm) Outside Dia.

- Page 57 TECHNICAL DATA-B.11 Water Pump Type Centrifugal-Belt driven from Crankshaft 0.5905/0.5908 in (14,999/15,006 mm) Outside Oia. of Shaft for Pulley Inside Oia. of Pulley Bore 0.58810.589 in (14,935/14,961 mm) Interference Fit of Pulley on Shaft 0.0015/0,0028 in (0,038/0,071 mm) Outside Oia. of Shaft for Impeller. 0.49810.499 in (12,649/12,675 mm) 0.497/0.4975 in (12,624/12,636 mm Inside Oia.

- Page 58 TECH NICAL OAT A-B.12 Fuel Lift Pump Type AC Delco Diaphragm 'YJ' Series Spring Colour Code Green Method of Drive From Eccentric on Camshaft via Push rod Total Stroke of Operating Lever 0.192 in (4,877 mm) 4-7 Ibflin 2 (0,28-0,49 kgf/cm2) Static Pressure-No Delivery Pump to Distance Piece Gasket Thickness ...

- Page 59 TECHNICAL DATA-B.13 Electrical System Nominal Voltage . . 24 V. Type ..Ungrounded Battery (not supplied with engine) Terminal Voltage . . Nominal 24 Volts Recommended Capacity . . . 130 Ampere Hours terna tor Make . . . Motoro Mode MA24-900G...

- Page 61 SECTION C APPROVED ENGINE SERVICE TOOLS & Co. Ltd., Available from V. Churchill Daventry, Northamptonshire, England PO 1 C Valve Guide Remover and Replacer. PO 41 B Piston Height Gauge. With this tool all valve gUides can be removed Used for checking piston height. and replaced provided puller bars are available.

- Page 62 355 Connecting Rod Alignment Jig. P06118-1 Valve Spring Compressor Adaptor. Enablss a quick check to be made on the align- The adaptor is fitted to one of the rocker shaft ment of connecting rods-various adaptors are securing studs. required. See Below. PO 130 Fuel Pump Allen Screw Wrench.

- Page 63 SECTION D Fault Diagnosis Fault Possible Cause Low cranking speed 1.2. 3. 4. 5.6 7.8 9 10 12 13 14 15 16 17 18 19 20 22 31 32 33 Will not start 5.7.8.9.10.11.12.13.14.15.16.18.19.20.21.22.24.29. 31. 32. 33. Difficult starting 8. 9. 10. 11. 12. 13. 14. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 31. 32. 33. Lack of power 8.

- Page 65 SECTION E Cylinder Head To Remove the Cylinder Head Completely drain the cooling system. Before commencing to overhaul the cylinder head Disconnect the battery terminals. ensure that all joints. gaskets and any other parts ex- Remove the securing nuts and detach the exhaust pected to be required are available.

- Page 66 CYLINDER HEAD-E.2 Remove the cylinder head cover together with the breather pipe. Uncouple the water outlet connection on the front of the cylinder head. Unscrew the oil feed pipe to the rocker shaft at the cylinder head end. (Refer to Fig. E.2 for its Remove the air cleaner and place somewhere level ready for servicing.

- Page 67 CYLINDER HEAD-E.3 10. Remove the eight push rods and place somewhere 16. Remove the cylinder head securing nuts and lift safe (possibly in the cylinder head cover) off the. cylinder head complete with inlet and ex- avoid the possibility of any being accidentally bent. haust manifolds.

- Page 68 CYLINDER HEAD-E.4 COMBUSTION CHAMBER INSERTS These can be gently tapped out of their locations by means of a short length of curved bar through the injector bore. When refitting they must be located by means of expansion washers in the recesses provided. as shown in Figs.

- Page 69 CYLINDER HEAD-E.S EXHAUST INLET VALVE VALVE j''''- GRAD ..:tL. Inlet A-1.530 in to 1.531 in 8-0.3125 in to 0.3175 in C-0.015 in chamfer at 45° (Max.) Exhaust A-1.296 in to 1.297 in 8-0.3125 in to 0.3175 in C-0.015 in chamfer at 45 (Max.) VALVES AND VALVE SEATS The valves should be checked in their respective...

- Page 70 (Refer to Fig. E.1?). Valve seat inserts are not fitted to production engines. but may be litted in service. To Re-Assemble the Rocker Shaft Assembly When fitting inserts ensure that only genuine Westerbeke Refit the oil feed banjo and locate with parts are used.

- Page 71 CYLINDER HEAD-E.7 • 1J--1-t1 NOTE: Valve springs incorporate a damper coil and care should be taken to ensure that this damper coil is to the bottom of the spring. i.e .. nearest the cylinder head when fitted. Inner valve springs are not required for engines rated at 3,000 rev/min and below.

- Page 72 CYLINDER HEAD-E.8 Fit the push rods in their locations then carefully Adjust the· valve clearances to 0.012 in (0,3 mm) fit the rocker shaft assembly, noting that the valve as follows:- adjusting screw ends locate in their respective Turn the engine so that the valves of No.1 cylinder push rod cups and the oil feed to the rocker shaft are in the position of 'valve overlap', i.e ..

- Page 73 CYLINDER HEAD-E.9 Replace the injectors (Refer to Page P.?) but do Replace the rocker shaft as previously described and not tighten the securing nuts. set the valve clearances to 0.012 in (0,30 mm) COLD. Replace the leak off pipe assembly and four high Start engine and check oil flow to rocker levers, if satisfactory refit cylinder head cover and air cleaner.

- Page 75 SECTION F Pistons and Connecting Rods To Remove Pistons and Connecting Rods Remove the cylinder head assembly. (Refer to suitable piston ring tool. such a tool is shown in Page E.1). Fig. F.3. Remove the oil sump. (Refer to Page M.1). NOTE: The laminated segments or spring loaded NOTE: Any ridges or carbon deposits around the rings fitted in the fourth ring groove should be...

- Page 76 PISTONS AND CONNECTING RODS-F.2 it from its location. Remove the circlip retaining the piston pin and push out the piston pin to release the connecting rod. NOTE: Should difficulty be experienced in re- moving the piston pin, warm the piston in a suit- able clean liquid (usually water) to a temperature of 100-120°F.

- Page 77 PISTONS AND CONNECTING RODS-F.3 Hold No. 1 connecting rod with the small end between the piston pin bores so that the word "FRONT" cast on the rod is towards the same side. Push the piston pin into the piston thus locating the connecting rod in position.

- Page 78 PISTONS AND CONNECTING RODS-F.4 PISTON CROWN SECOND AND FOURTH SEGMENTS FIRST AND THIRD SEGMENTS Laminated Segment Rings Fit the second segment on top of the first, so that when compressed as described above the ends The procedure for fitting the laminated type is different. point upwards.

- Page 79 PISTONS AND CONNECTING RODS-F.5 The gaps of the remaining rings should stag- gered alternately along the piston pin axis_ Liberally lubricate the rings in their grooves and see that they can move freely in their locations. this does not apply to the laminated type in the fourth groove.

- Page 80 PISTONS AND CONNECTING RODS-F.6 It will of course be appreciated that grade F pistons are suitable for topping to give other grades where these are not to hand. After fitting pre-topped pistons, the distance between the cylinder block face and piston crowns should be checked to ensure the limit is as already quoted (See Fig.

- Page 81 SECTION G Cylinder Block and Liners CYLINDER LINERS (4.108 ENGINES) The cylinder liners fitted to the 4.108 series engines are centrifugally cast alloy iron, they are an interference fit in the cylinder block parent bore and of the thinwall dry type. Reboring of these liners is not possible and new liners should be fitted when a rebore would normally be con·...

- Page 82 CYLINDER BLOCK AND L1NERS-G.2 Earlier 4.99 engines had only one sealing ring at the All 4.107 and later 4.99 engines have four small holes bottom of the liner. drilled along the fuel pump side of the cylinder block. 4.107 and 4.99 cylinder liners have pre-finishsd bores. each one breaking through into the area between the Under normal circumstances, the liner would only two sealing rings at the bottom of...

- Page 83 SECTION H Crankshaft and Main Bearings (0,19 mm oversize) thrust washers are available which if used on one side of the rear main bearing only will reduce crankshaft end float by 0.0075 in (0,19 mm) and by 0.Q15 in (0,38 mm) if used on both sides The limits for the crankshaft end float are given on Page B.6.

- Page 84 CRANKSHAFT AND MAIN BEARINGS-H.2 To Renew Main Bearings and Thrust Washers Removal of the main bearings and thrust washers can Rotate the bearing shell on the crankshaft until it be carried out without removing the crankshaft by the locates correctly with the tag in the machined slot. following procedure:- Locate the lower half bearing shell in the main Remove the engine from its application.

- Page 85 CRANKSHAFT AND MAIN BEARINGS-H.3 Check that the crankshaft end float is within the limits given on Page B.6 by means of feeler gauges as shown in Fig. H.7. If incorrect, oversize thrust washers are available to give an overall reduction of 0.015 in (0,38 mm). (Refer to Page H.2).

- Page 86 CRANKSHAFT AND MAIN BEARINGS-H.4 Fit new sealing strips to the rear main bearing oil seal housings and refit the housings as described under the heading "Crankshaft Rear End Oil Seal" on Page H.4. 10. Liberally oil the crankpins, locate the connecting rod bearing shells, again ensuring their correct relative positions, then fit the connecting rod caps as described on Page F.5.

- Page 87 SECTION Flywheel and Housing Alignment of the Adaptor Plate, Flywheel Housing and Flywheel. It is most important that the adaptor plate, flywheel housing and flywheel be correctly aligned with the crankshaft. If the plate and housing have been removed as is necessary for a complete overhaul, the greatest care must be taken on replacement to insure accuracy of alignment.

- Page 88 FLYWHEEL AND HOUSING-J.2 See that the face of the housing is perfectly clean and free from burrs. Secure the housing to the adaptor plate with setscrews and spring washers, but not overtight so as to allow adjustment. Attach the indicator gauge to the flywheel centre and set the needle of the gauge to the interior of the bored hole in the flywheel housing (See Fig.

- Page 89 0941-LP-014-8012 0941-014-8010 CHANGES TO TM Installation of Flywheel Ring Gear Care shoul"d be exercised in replacing flywheel ring gears. Too high a temperature (above 15000F) during replacement installation may leave the steel ring gears fully annealed. If a press of sufficient capacity (about 10 tons) is available, ring gears should be installed without heating.

- Page 91 SECTION K Timing Case and Drive tion taking care not to damage the rubber lip of the oil seal on the crankshaft pulley key. Loosely fit the front cover securing setscrews and nuts. Fit the crankshaft pulley to centralise the seal. then tighten the securing setscrews and nuts.

- Page 92 TIMING CASE AND DRIVE-K.2 NOTE: If the cylinder head assembly has not been disturbed, then the cylinder head cover and rocker shaft should be removed in order to allow the camshaft to be turned to facilitate the aligning 01 the timing marks. Insert the hub as shown in Fig.

- Page 93 TIMING CASE AND DRIVE-K.3 To Refit the Fuel Pump Gear Refit the low and high pressure fuel pipes to the fuel pump. Refit the fuel pump gear so that the timing marks Refit the fuel pump drive gear. idler gear and hub. on the gear and hub respectively are in alignment timing case front cover etc.

- Page 94 TIMING CASE AND DRIVE-K.4 Remove the fuel lift pump. tappet inspection cover and fuel lift pump operating push rod. Turn the engine over so that the sump is now uppermost. NOTE: At this stage if it is not possible to turn the engine over then the tappets should be lifted to the top of their locations and secured with suitable clips ..

- Page 95 TIMING CASE AND DRIVE-K.S Drive Hub Lubricating Oil Pump Drive Gear Groove for reduced oil pressure feed to Rocker Shaft Bearing Journals...

- Page 96 TIMING CASE AND DRIVE-K.6 Before the camshaft is pushed fully home locate Turn the engine over so that the cylinder block top the two thrust plates (Refer to Fig. K.12) (one of face or cylinder head (if fitted) is uppermost. which locates on the dowel in the recess) in posi- Refit the timing gears, timing case front cover etc ..

- Page 97 SECTION L Timing General crankshaft is uppermost as shown in Fig. l.1. (This will bring Nos. 1 and 4 pistons to T.D.C.) As timing gears are employed, the factory setting remains constant. It is also worth remembering that Fit the camshaft gear to its hub ensuring that the the removal of the cylinder head in no way effects 'D' marks are correctly aligned.

- Page 98 TIMING-L.2 Checking Fuel Pump Timing-See Page P.S Checking Valve Timing To check the valve timing proceed as follows: Turn the crankshaft until the valves of No. 4 cylinder are 'on overlap. In this position set the valve clearance of No. 1 inlet valve to 0.039 in (1 mm).

- Page 99 SECTION M Lubrication System To Refit the Sump Lightly apply a coating of a suitable sealing com- pound to the crankcase and sump faces, position the gaskets so that all the holes align. NOTE: When the gaskets are being placed in posi- tion it is important that the mitred ends go right up into the recesses in the front and rear main bearing caps.

- Page 100 ~HMT ROCKER ASSEMBLY SPLASH MIST VALVt GlJlDt ASStMBLIES REDUCED PRESSURE FEED -< SPLASH AND OIL MIST SPLASH AND OIL MIST SPLASH AND OIL MIST SPLASH AND OIL MIST \ t / , t I SPLASH MAIN GALLERY DRAIN' )UMP GRAVITY BACK - - I + - - - - - .

- Page 101 LUBRICATION SYSTEM-M.3 Relief Valve Housing Rotor Housing Install the drive shaft complete with inner rotor, Hole for Locating Screw then the outer (driven) rotor ensuring that the face Pump Drive Gear which carries the chamfered edge enters the pump body first (Refer Fig.

- Page 102 LUBRICATION SYSTEM-M.4 1.· \ " Outlet to Main Oil Filter Relief Valve Plunger Plunger Spring Spring Cap Retaining Cotter Pin. NOTE: The relevant clearances for these dimen- sional checks are given on Page B.10. they are the clearances applicable to a new pump and are in- tended to be used as a guide.

- Page 103 LUBRICATION SYSTEM-M.S is given on Page B.9. The pressure will drop whilst NOTE: Caution should be exercised when restart- ing the engine, as it will take a moment or two for the engine is idling and also a slight drop will be ex- perienced when the oil is hot, this is quite normal.

- Page 105 SECTION N Internal Cooling System ALTERNATOR BELT To Adjust the Alternator Belt Alternator belt adjustment is achieved by altering the position of the alternator as detailed below. Slacken the alternator adjusting lever setscrew. Slacken the two alternator-to-bracket mounting bolts. Move the alternator either towards or away from the engine to either slacken or tighten the belt.

- Page 106 COOLING SYSTEM-N.2 Pivot the alternator towards the cylinder block. Turn the engine slowly by hand and work the alter- nator belt off the water pump pulley. The belt can now be lifted from the alternator and crankshaft pulleys and removed from the engine. Examine the belt for signs or fraying or cracks in the rubber and renew if necessary.

- Page 107 COOLING SYSTEM-N.3 Fit the two bearings (3) and spacer (6) onto the shaft (5) and pack the space between the two bear- ings approximately % full of high melting point grease. Press the bearings and shaft assembly into the pump body. impeller end first and locate with the circlip (4).

- Page 109 SECTION P Fuel System FUEL OIL FILTERS The element in this filter is of the paper type and therefore no attempt should be made to clean it. Its life will be governed by the quality and condition of the fuel passing through it. but under average con- ditions the element should be renewed in accordance with the recommendations in Operator Section.

- Page 110 FUEL SYSTEM-P.2 To Remove the Lift Pump To Re-Assemble the Lift Pump Disconnect the pipes from the inlet and outlet Examine casting ensure that there ports. Seal the ends of the pipes to prevent the sufficient material to provide a sound staking when entry of foreign matter.

- Page 111 FUEL SYSTEM-P.3 Stake the casting in six places (between the original stakings) round each valve. with a suitable punch. NOTE: Valves fitted to earlier lift pumps were held in position with a retaining plate and two screws. On no account should attempts be made to stake the valves of this earlier type pump.

- Page 112 FUEL SYSTEM-P.4 To Refit the Fuel Injection Pump Replace the fuel pump mounting flange gasket (where necessary). Fit pump as shown in Fig. P.8 ensuring that the master spline on its quill shaft is correctly posi- tioned to engage with the female splines within the fuel pump drive hub.

- Page 113 C.A.V. Distributor, or 11. When the fuel pump timing has been correctly set. Westerbeke. slowly turn the engine to T.D.C. in the normal direction of rotation, remove the indicator and refit NOTE: The engine must not be allowed to operate at the valve springs.

- Page 114 FUEL SYSTEM-P.6 INJECTORS 11' - ' " ' . . -----1 General 1-"----2 When replacing injectors in the cylinder head, it is essential that a new, correct type copper washer is fitted between the nozzle body and cylinder head. The first symptoms of atomiser trouble usually come under one or more of the following headings : - ..----3 0 ..

- Page 115 FUEL SYSTEM-P.7 Fuel Pipes (High Pressure) Slacken the vent screw on the top of the fuel filter When replacing the fuel pipes it should be noted that Operate the priming lever on the fuel feed pump no two pipes are the same, each is formed to suit an (Refer to Fig.

- Page 117 Q.O.l OTHER OVERHAUL CONTENTS SECTION PAGE . . . MARINE ELECTRICAL SYSTEM Delco Remy Generator and Regulator Motorola Alternator and Regulator Q.13 Delco Remy Starter Motor Q.17 COOLING SYSTEM TRANSMISSION . Westerbeke-Paragon P220 Hydraul S. 1...

- Page 119 SECTION Q ELECTRICAL SYSTEM Earlier engines were equipped with Delco- minerals. Do not overfill, and be sure the vents Remy electrical accessories operating on are kept open in filler caps: these are for the a nominal 24 volt system. The generator escape of gas from the electro-chemical action.

- Page 120 The armature is supported by double sealed ball Inspection - The commutator end frame must bearings at the drive end and the commutator be removed for periodic inspection of brush end. The commutator end bearing is protected and commutator condition. If the commuta- from water by a special cover and gasket.

- Page 121 CHECKING INOPERATIVE GENERATOR c.lnspect commutator for roughness, grease and dirt, high mica, out-of-round, Several conditions may require removal of the or burned bars. With any of these con'" generQtor from the engine and further checking ditions the commutator must be turned of the generator, as follows: down in a lathe and the mica undercut.

- Page 122 Shift brush plate ahead (direction of arma- I 18 The regulator shown in Fig. consists ot four ture rotation) until the inserted strip is units: an actuating relay, a circuit breaker relay, 3/32"-1/8" ahead of neutral marking on a current regulator and a voltage regulator, all 3/32- side of inspection hole.

- Page 123 Fig. 119-Regulator Terminals The actuating relay (Fig. 119A) contains two wind- ings and an upper and a lower set of contact points. One of the windings is a series winding Fig. 119P-Circuit Breaker of'a few turns of heavy wire (shown in solid lines in Fig.

- Page 124 series with a resistor, is connected between the ACTUATING RELAY field side of the contact points and ground. The ,.--- SHUNT WINDING windings and core are assembled into a frame. Above the core is an armature and a stationary ~---~ point which are identical in construction to those 1.L 1 _ _ .

- Page 125 CURRENT VOLTAGE ACTUATING RELAY REGULATOR REGULATOR IATTERY AMMETER GENERATOR FIELD ARMATURE Fig. 121-Generator Circuits Current Regulator - Description: The current where several paths for current flow are avail- regulator contains two windings on the same able. One path through a resistance unit, re- core - a series winding and an accelerator turns to the insulated side of the field coils, to...

- Page 126 UPPER ARMATURE STOP In addition to the regulating resistance in series resi~tance with the field coils, a parallel is used to absorb some of the inductive energy pro- duced when the regulator contact points open. POINT OPENING Inductive voltage, of course, causes current to continue to flow in the same direction as the original current flow.

- Page 127 BEND UPPER ARMATURE STOP TO ADJUST POINT OPENING POINT OPENING Fig. 122C-Checking and Adjusting Point Opening on Fig. 122B-Adjusting Air Gap on Circuit Breaker Relay Circuit Breaker Relay CLOSING VOLTAGE - To check the closing vol- SEALING VOLTAGE: The sealing voltage is the tage of the circuit breaker relay, the regulator voltage at which the armature seals against the must be connected in the proper manner to the...

- Page 128 Q.lO Fig. 122G-Actuating Relay Air Gap and Point Opening Chec:b and Adjushnents POINT OPENING - Check point opening of lower Fig. 122E-Adjustment of Circuit Breaker Relay Closing contact points with upper contact points justtouch- Voltage ing. Place finger on the center of the armature, push down until upper points open, release until AIR GAP - The air gap should be measured be- upper points just touch (Fig.

- Page 129 Q.ll OPERATING VOLTAGE - Connect a voltmeter from the regulator ARMATURE terminal to the ground screw on the end of the regulator. Slowly increase the generator speed and note the voltage at which the actuating relay closes. This will be indicated by a sharp click procuced as the circuit breaker contacts close in response to the closing of the actuating relay lower contacts.

- Page 130 Q.12 insulation. If less than two ounces is required, AIR GAP - The correct air gap for the current increase the tension by prying, lightly under regulatoris.084", and the adjustment procedure, one side and then the other side of the crease is the same as outlined for the voltage regulator in the spring.

- Page 131 Q.13 MOTOROLA ALTERNATOR SYSTEMS INSTALLATION Tighten pulley nut to 40 - 50 foot pounds. Tighten drive belts by applying pressure to the alternator front housing only. Do not apply pressure to the rear housing or stator. GEI\IERAL Set belt tension to engine manufacturer recommendations. If this information is not available, tighten belts to the CAUTION: OBSERVE PROPER POLARITY WHEN INSTAL- point where the alternator fan cannot be turned by hand.

- Page 132 Q.14 TROUBLESHOOTING & SERVICE DIAGNOSIS BATTERY The vehicle storage battery circuit represents a continuous, although variable, electrical load to the alternator. If the circuit, positive or negative, is opened or broken while the alternator is charging, the loss of the battery will result in the charging voltage rising to unsafe levels.

- Page 133 Q.15 SYMPTOM NO.2 - LOW OR UNSTEADY EL.:ECTRONIC VOLTAGE REGULATOR CHARGING RATE CHECK FOR: The Motorola all·electronic transistoriz::d voltage reg- ulator is an electronic device using no mechanical contacts Alternator belt loose. or relays to perform the only necessary regulation on the B.

- Page 134 Q.16 ELECTRICAL SYSTEM USING MOTOROLA ALTERNATOR 24vDC 35AMP Voltage Regulator-must be mounted on a 50 sq. in. metallic plate • Oil Pres sure Switch r-----E~~f-------/ Voltage Resistor protect:JJ 150 or r--- • Battery 24 Volt...

- Page 135 Q.17 SOLENOID COMMUTATOR Fig. 125-Sectional View of Cranking Motor CRANKING MOTOR The overrunning clutch (Fig. 126); consists of a sleeve shell assembly which is splined internal- The cranking motor used on this engine (Delco- ly to match splines on the armature shaft. Thus, Remy Model 1107579) is grounded type, opera- both the shell and sleeve assembly and the ting on nominal 24 volts, corresponding to the...

- Page 136 Q.18 LOCK WIRE Fig. 126-0verrunning Clutch The rollers jam between the pinion collar and 4. The drive assembly should be wiped clean. the shell so that the pinion is forced to rotate CAUTION: Do not clean in any degreasing with the armature and crank the engine. tank or with grease dissolving solvents;...

- Page 137 Q.19 the specified voltage 'by varying the resistance unit. Then read the current draw and the arma- VOLTMETER ture speed with the following specifications: BATTERY 23.5 Volts ....Minimum Amperes Maximum Amperes Minimum R.P.M ..

- Page 138 Q.20 AMMETER BATTERY " SECURELY LOCKED BRAKE ARM CRANKING MOTOR Fig. 128-Resistance Test Hookup 6. High free speed and high current draw indicate: shorted fields. If shorted fields Fig. 129-Removing Retainerfrom Snap Ring are suspected, replace the field coil assem- bly and check for improved performance.

- Page 139 Q.21 SPRING PLUNGER Fig. l30-Sectionai View Overrunning Clutch showing details of construction and Location of Ro"ers in Clutch COMPONENT INSPECTION AND REPAIR If the commutator is worn, dirty, out of rouna, or high insulation, the commutator should be A. Brushes and brush holders - Inspect the turn ed down and undercut as pre vi...

- Page 140 Q.22 BATTERY SNAP RING CRANKING GROOVE MOTOR Fig. 133-Connections for Checking Pinion Clearance Fig. 131-Forcing Snap Ring over Shaft b. Place the snap ring on the end of the shaft. With a piece of wood on top of it, PINION QEARANCE force the ring over the shaft with a light Pinion clearance should be checked after re- 131)

- Page 141 Q.23 Adjust the pInion clearance by loosening the screw on the serrated shaft lever inkage and moving it forward or backward. Press on clutch as shown in Figure 134 to take up movement. Fig. 134-Checking Roller Clutch Pinion Clearance...

- Page 143 SECTION R COOLING SYSTEM (EXTERNAL) This engine is fresh water cooled, utilizing what The heat rejected in combustion, as well as heat is known as a "closed system", wherein the cool- developed by friction, is absorbed by the fresh ing water is circulated from the water or surge water coolant moving through the heat exchang- tank (mounted over the thermostat at the front er, which has a flow of sea water exchanger...

- Page 144 Dismantling Heat is also conducted away from the bearings and other friction surfaces by the lubricating oil, To dismantle the pump, proceed as follows: which is circulated by a pressure pump and cooled by the flow of fresh water through the Remove front end cover.

- Page 145 SECTION S TRANSMISSION PARAGON HYDRAULIC TRANSMISSION- With the control I ever in the neutral position, MODEL "P220" the pressured oil is prevented from entering either the multiple disc clutch piston or the re- DESCRIPTION verse band piston. Therefore the planetary The Paragon Hydraulic transmission, model P220 gears run idle and the propeller shaft remains engin~...

- Page 146 LUBRICATION TROUBlE SHOOnNG The model P220 transmission is a self contained The trouble shooting charts on the following unit, independent of the engine lubricating sys- pages should be studied and the suggestions tems. The unit is lubricated by pressure and carried out prior to any disassembly, to deter- splash from its own oil.

- Page 147 TROUBLE SHOOTING CHART Chart 1 GEAR INOPERATIVE DRIVE SHAFT DOES NOT ROTATE WITH SELECTOR VALVE IN FORWARD OR REVERSE Check For 4. FAILURE OF PLANETARY ASSEMBLY 1. LOW OIL PRESSURE 2. HIGH OIL TEMP ERATURE 5. FAILURE OF REDUCTION GEAR 3.

- Page 148 TROUBLE SHOOTING CHART Chart 2 GEAR DRAGGING DRIVE SHAFT ROTATES EITHER FORWARD OR REVERSE WITH SELECTOR VALVE IN NEUTRAL POSITION Check For DEFECTIVE FORWARD CLUTOi PLATES BINDING IN PLANETARY ASSEMBLY --------------------------REMEDy--------------------------- 1. Forward clutch plates warped and sticking. a. Bearings and gears worn excessively in Remove clutch plates and replace.

- Page 149 TROUBLE SHOOTING CHART Chart 4 INTERNAL AND EXTERNAL LEAKS Check For 1. WATER IN LUBRICATING OIL 3. OIL ON EXTERIOR OF MARINE GEAR 2. EXCESSIVE OIL IN ENGINE CRANK- 4. LOSS OF OIL FROM TRANSMISSION CASE OR FLYWHEEL HOUSING ------------------------REMEDy--------------------------- Check the following items: 3.

- Page 150 DISASSEMBLY OF TRANSMISSION 2. Strike gear half coupling flange with a soft mallet to break reduction gear unit from the As in any servicing operation, cleanliness is a reduction adapter plate. Slide entire re- must and all rules for good workmanship apply. duction unit straight back approximately 3 Some of these rules are as follows: inches until reduction unit clears reduction...

- Page 151 Fig. 1Sl-Complete Assembly...

- Page 152 (70) Remove retaining ring from end of re- verse piston shaft pin (69) and remove reverse piston shaft pin (69) from reverse band lever (81) and reverse piston shaft. (70) Remove retaining ring from other end of reverse piston shaft pin. 7.

- Page 153 FRONT END PLATE Fig. 153-Front End Plate and Pump It is not necessary to remove two pump DISASSEMBLY OF FRONT END PLATE AND pins (17) from pump housing (18) for further PUMP servicing. However, if pump housing pins FIGURE 151 and 153. have become damaged and require re- placing, they may be removed by gripping I.

- Page 154 S .10 Fig. 154-Reverse Gear Housing Unless damaged and in need of replacing, Remove socket head capscrews that secure do not remove oil suction tube (79), oil reduction adapter plate (36) to reverse gear distributor tube (122), baffle (68), reverse housing (1).

- Page 155 S.l1 Fig. 155-Disassembly Gear Case 10. Bend sides of case clip (7) away from head Using spanner wrench T-439 I , remove screw collar (61) from end of gear case of capscrew (8) and remove capscrew (8), case clip (7) and pinion shaft locking tab (23) while clamping gear case.

- Page 156 S.12 15. Do not remove engine gear roller bearings 6. All gear teeth should be examined fo r (II) unless damaged and replacement is "pitch line pitting", uneven wear pattern or necessary. excessive wear. 16. Do not remove gear case needle bearing 7.

- Page 157 S.13 Vibration dampers should be checked at (e) Remove dU'mm shaft, insert second springs and splines for wear. thrust pad (24) between long pinion and rear wall of gear case and start pinion Check relief valve plug and relief valve shaft into rear wall of gear case.

- Page 158 S.14 (d) Smear ends of roller bearings with cup (b) Install remaining b'ronze clutch plates grease. (63) and steel clutch plates (65) alter- nating bronze and steel until all are in (e) Insert short pinion assembled with roll- place. er bearings, etc., into gear case, mesh- ing teeth on short pinion and long pin- NOTE: Make certain that all clutch plates ride...

- Page 159 S.lS ASSEMBLY OF GEAR CASE IN REVERSE GEAR Press needle th'rust bearing (35) into reduc- HOUSING tion adopter plate (36). Press reduction adopter plate assembly, FIGURE 154 Figure 154 over reduction pinion tailshaft (19) til 1. Assemble oil suction tube hole in assembly, Figure 154.

- Page 160 S.16 9. Make certain that control lever and control RELIEF VALVE ASSEMBLY valve rotate freely. FIGURE 154 Install ball detent (I 10) into hole in side of Place relief valve spring (120) in relief cover and rotate control valve until ball valve housing (121).

- Page 161 5.17 TRANSMISSION ASSEMBLY 10. Install six flat-head socket capscrews (91) to front end plate assembly and reverse FIGURE 151 gear housing and tighten securely. 1. Install pipe plug into drain hole of housing. Drain hole is located on the right hand 11.

- Page 162 S.18 (46) ASSEMBLY OF COMPLETE TRANSMISSION AS- Place coupling wosher over end of (47) shaft, insert lockwasher with tang on SEMBLY TO ENGINE inside of lockwasher in slot on shaft. Place Install two studs in opposite side holes in locknut (4S) onto shaft and secure using en~~ine engine adapting piate on so studs...

- Page 164 SECTION V SERVICE BULLETINS The following Bulletins contain supplementary and up- dated information about various components and service pro- cedures which are important to the proper functioning of your engine and its support systems. You should familiarize yourself with the subjects and make sure that you consult the appropriate Bulletin(s) whenever your engine requires service or overhaul.

- Page 165 SERVICE BULLETIN DATE: September 17, 1976 BULLETIN NUMBER: 10 MODEL: Westerbeke 40 and WPDS 10-15 SUBJECT: Sea Water Pump Clearance and Al ignment Clearance: Adequate longitudinal clearance between the sea water pump shaft and the driving shaft is established by the use of multiple pump gaskets.

- Page 166 SERVICE BULLETIN DATE: Apri 1 23, 1968 BULLETIN NUMBER: 11 MODEL: Westerbeke 40 and WPDS 10-15 SUBJECT: Instructions for Replacing Injection Pump Drive Hub Bushing (#0050323) 1. Remove cis Pulleys 2. Remove water pump 3. Remove timing cover 4. Mark idler gear and fuel pump gears before removing fuel pump gear (This is very important in order to retain proper relation of gears and eliminate re-timing of engine).

- Page 167 WESTERBEKE SERVICE BULLETIN #11 (Continued) 14. Axter bushing is in place recheck xor xree rotation making sure no binding is evident 15. Line up master spline drive hub with master spline xuel pump drive 16. Replace xuel pump drive shaxt by passing it through drive hub until it enters into pump drive.

- Page 168 Any fittings used to connect the hose to the gallery must be of steel or malleable iron. Brass must not be used for this purpose. H. WESTERBEKE CORP. AVON INDUSTRIAL PARK, AVON, MASS. OZ3ZZ '1817} 588-7700 CABLE: WESTCORP, AVON· TELE .Z -...

- Page 169 (Note: Tighten bolt equally in sequence to pre- vent galling the bronze bushing block.) Continued H. WESTERBEKE CORP. AVON INDUSTRIAL PARK, AVON, ",ASS. 02322 '1817} 588-7700, CABLE: WESTCORP, AVON· TELEX: 112-4444...

- Page 170 SERVICE BULLETIN #21 - Contiuued REPLACING INJECTION PUMP DRIVE HUB 12. When the hub and bushing are removed pullout the pUJlp splined drive shaft which will now be visibleo 13. Remove circlip xrom old hub and transxer bushing to new hub using new circlip.

- Page 171 SERVICE BULLETIN DATE: November 3, 1970 BULLETIN NUMBER: 31 Westerbeke Diesel Model Four-107 (Whaleboat) MODEL: Lubricating Oil System Modification SUBJECT: PURPOSE: To reverse lube oil direction through system thereby utilizing high pressure by-pass valve in lube oil filter. APPLICABILITY: All referenced engine models whose lube oil fitting, located at oil attachment boss on engine, bears the casting number B-120.

- Page 172 Under its head are 1 to 3 washers. Remove one washer. This should stop forward boat movement. But under NO circumstances use fewer than one washer nor more than three. H. WESTERBEKE CORP. AIION INDUSTI/IAL PAI/", AIION, MASS. 01131111· (8171 588-7700 CABLE: WESTCOl/P, AIION·TELEX: .11-4444...

- Page 173 This alternator is driven from the engine's crankshaft pulley at a speed ratio of 2.19:1 with an output of 840 watts at 24 VDC. See diagram and parts list overleaf. J. H. WESTERBEKE CORP. AllaN INDUSTRIAL PARI<, AllaN, MASS. 02322· 1817} 588-7700 "2- •••• PIN: 22218...

- Page 174 ~SAAIP 215(06 ALTERNAToe. C/j~LE Z2../I~ ASSY. 24 'lOLl 2/611 I?EGt.lLATo.e • lTEM PART NO. DESCRIPTION H. WESTERBEKE CORP ..AHCD , •• a_ ... _ •••. AVON 02322 · D.eIM ..~ODEL FOUR-I07W'oc,~ .1°'171:'i NOM 'l"-..OVIED • ., .., ·...

- Page 175 BULLETIN NUMBER: MODEL: SUBJECT: Ammeter Wire Sizes Ammeters may be installed in conjunction with any Westerbeke marine diesel engine or diesel generator set. The range of the ammeter must be appropriate for the maximum output of the alternator. Additionally, the wire size for the alternator output circuit, including the ammeter, varies with the total length of that circuit.

-

Page 176: Table Of Contents

SECTION X PARTS LIST Page Contents Notes on using parts list Cylinder Block Cylinder Head - Valves Crankshaft - Rod - Pistons X.10 Timing System - Camshaft X.12 Rocker Shaft Fuel System X.14 X.16 Cooling System X.20 Water Pumps X.22 Lube Oil Sump X.24 Intake Manifold... -

Page 177: Notes On Using Parts List

NOTES ON USING THIS PARTS LIST 1. Unit of issue for all linear commodities is inches (not feet or yards). 2. To find the part number of a serviceable component: a) In the contents, find the page number of the system of which the component is most logically a member. - Page 179 FCUR 107 WHALEBOAT SPEC - CYLINDER BLOCK --"'" 69 70 Drawing No. 13905...

-

Page 180: Cylinder Block

FOUR 107 WHALEBOAT SPEC - CYLINDER 3LOCK QUAN ROIARKS Ar~E BLOCK ASSEMBLY ENGINE & 3J81C H~aD 1r1U LINER 2- 1 126(10 S/~' SIN le8U 19330 LI'JER 2- 2 RING LINER SEALING SIN 107U 12565 FLUG BLOCK WATER JACKET 12452 DOiJEL 12380 12469 BOLT... - Page 181 FOUR WHALEBOAT SPEC - CYLINDER HEAD - VALVES " ~f----17 © = - 2 2 Drawing No. 13904...

-

Page 182: Cylinder Head - Valves

FOUR WHALEBOAT SPEC CYLINDER HEAD - VAL \IE S NAME REMARKS QUAN 1234C HEAD ASSEMBLY SIN 107U 19939 HE4D 1Q8U ASS~MBLY PLUG HEAD-TOP -SIN 10BU 19979 & 19956 PLUG HEAD-Tap-SIN 108U 12452 PLUG HEAD-SIDE 12454 PLUG HEAD-REA R 12455 PLUG HEAD-RF"AR 12629 GUIDE... - Page 183 FOUR 101 WHALEBOAT SPEC - CRANKSHAFT - ROO - ST ON ~~=:---- No. 13903 awing...

- Page 184 FOUR 101 WHALEBOAT SPEC CRANKSHAFT PISTO~J r\AME QUliN REMARKS CRANKSHAFT ASSEMBLY SIN lG7U 12341 CRANKSHAFT 23105 ASSEMBLY SIN 108U & 12342 EEARING MAIN-KIT-STD 123'+9 BEARING 3- l MAI\J-KIT-.010 UNDER 12370 BEARING MAIN-KIT-.020 UNDER 3- 3 12373 BEARING MAIN-KIT-.030 UND:::~ 123'+3 BEARING R OD-K I T- STD 5- 1...

- Page 185 X.lO FOUR 107 IJHALEBOAT SPEC TIMING SYSTEM - CAMSHA FT SO 48 Drawi ng No. 13902...

- Page 186 X.l1 WHALEBOAT SPEC TIMING SYSTEM ~OUR CAMSHAFT REMARKS QUAN ~AME CAMSHAFT 12605 GEAR 12597 PLA TE 12625 BOLT 12474 PLATE 12654 DOWEL 1244 G GEAR IDLER WI TH BUSHING 126d9 BUSHING FOR IDLER GEAR 14685 12398 PLA TE 12551 BOLT 12481 TABWASHER 12541...

- Page 187 X.12 FOUR WHALEBOAT SPEC - R OCKER SHAFT ~-. ~--4 -===--__ --~o 17 20 • 20 17 2S--/J rf'I t34 3 Drawing No. 13901...

- Page 188 X.13 FOUR 107 WHALEBOAT SPEC - ROCKER SH~FT NAME REMARKS QJA\4 COVER ROCKER 12681 12'+ GASKET ROCKER COVER tl'+ STUD LONG 11--1/2 12'+94 12429 124S1 SEAL WASHER 12535 CAP ASSY SMALL DIA TO SIN 1C7U71G6766 7- 1 1'+lG9 1-3/4 CAP ASSY LARGE 12567 2-3/8...

- Page 189 X.14 FOUR 107 WHALEBOAT SPEC - FUEL SYSTEM DWG NO. 15704...

- Page 190 X.15 FOUR 107 WHALEBOAT SPEC - FUEL SYSTE~ NAME QUAN RE~ARKS PRACKET FUEL FILTER ~OU~TING 12lH: LINE LIFT PUMP TO FUEL FILTER 12,1:'0 13336 CCNNECTOR FUEL LINE TO FILTER ~UEL FILTER FUEL-ENGINE 5- 1 11614 ~OUNTED fLEMn.:T FlEL FILTER 5- 2 1641t 11700 PUMP...

- Page 191 >< ..'7--~~@ ...:: _ _ ." .., ,... ]> ,." ]> "0 ,." ,... -< ,." DRAWING NO. 13687...

-

Page 192: Cooling System

X.I? FCUR WHALEBOAT SPEC - COOLING SYSTEM REMARKS QUAN NAME RISER EXHAUST-SEA WATER JACKETED 15(117 GASKET EXHAUST MANIFOLD FLANGE 12661 PETCOCK 11471 MANIFOLD EXHAUST-FRESH WATER JACKETED 12411 HOSE FRESH WATER-INCHES REQUIRED 11501 PRESSURE 11499 SCREW EXPANSION TANK 14832 TANK FRESH WATER EXPANSION 1,.073 13131 BRACKET... - Page 193 >< :,:, .."TI 1> 1"'1 1> (.I) ""0 ,." ..(j') (.I) -< (.I) ,." DRAWING NO. 13687...

- Page 194 X.19 F CUR WHALEBOAT SPEC - COOLING SYSTEM QUAN NAME REMARKS PLUG TRANSMISSION OIL 11724 PLUG OIL COOLER 11'+9'+ EXHAUST RISER )RAIN 1112 ' + PLUG PLUG EXPANSION 11755 EL80W EXPANSION TANK OVERFLOW 13329 NAMEPLATE 11156 5& PLUG EXPANSION TANK CORE 11752 BRACKET LUBE OIL FILTER...

- Page 195 X.20 FOUR 197 WHALEBOAT SPEC - WATER PUMPS Drawi ng No. 13556...

-

Page 196: Water Pumps

X.21 FOUR WHALEBOAT SPEC - WATER PUMPS NAME REMARKS QJA~ PUMP RUBBER IMPELLER-NLA USE PUMP 11020 16423 10- 1 PUMP IMPELLER 1&423 RUBBE~ PUMP GASKET 16423 15153 PUMP IMPELLER 16423 11418 IMPELLER REPLACEMENT PUMP 11906 11020 11- l SEAL PUMP 14771+ 11020 12 - 1... - Page 197 X.22 DrOWing 13900...

- Page 198 X.23 FCUR WHALEEOAT SPEC LU8E CIL SUr-'P f\AME REP'ARKS GUM" SUMP 12680 FLUG DRAIN SUMP 13-951 GASKET SUP'P-LEFT AND RIGHT 12659 GASKET 12407 PLATE STIFFENER 12547 PLATE STIFFENER 12548 STIFFENER FLATE 12549 PLATE STIFFENER 1255El SCREW 12473 DRAIN PL'tG "ASHER 13952 SU~P DIPSTICK...

- Page 199 X.24 FOUR 107 SPEC - INTAKE MANIFOLD ~HALEBOAT Drawing No. 13569...

-

Page 200: Intake Manifold

X.25 WHALEBOAT SPEC INTAKE MANIFOLD \AME REMARKS QJAN FILTER 12556 COVER 12683 ELBOW BREA THER 12639 12688 ~ANIFOlD GASKET 20021 BUSHING 13392 PLUG 11615 14- h 14- 2 STAR TI NG -E THER TYPE 11688... - Page 201 X.26 FOUR 107 WHALEBOAT SPEC - ELECTRICAL SYSTEM...

- Page 202 X.27 FCLR 107 SPEC - ELECTRICAL ~~ALEBCAT SYSTE~ R;;:.F NAME REt'ARKS GUAN REGULATOR VCLTAGE FOR 21566 ALTERNATCR 21611 CABLE !O IN ALTERNATOR TO RErULATCR 2- 1 22119 CABLE 84 IN ALTERNATOR TO REGULATOR 23124 2- 2 ALTERNATOR AMP-24VDC-NEGATIVE GROU~C 21":66 RESISTOR.

- Page 203 X.28 FOUR 107 WHALEBOAT SPEC - BACK END ARRANGEMENT DWG NO. 15705...

- Page 204 X.29 WHALEBOAT SPEC - BACK END FCUR 101 ARRANGE~E~T t\AME GUAN REI"ARKS FCUSING FLYWHEEL 14D66 PLATE BACK 14065 DOWEL 11498 GEAR 13832 FLYWHEEL INCLUDES 13832 RING GEAR 24064 TABWASHER 1412(J CAMPER 11618 SCREW DA,..PER TO 24118 FLY~HEEL SPACER STARTING MOTOR 12101 STUD MeTeR-SHORT...

- Page 205 X.30 FOUR lQ7 WHALEBOAT SPEC - TRANSMISSION - PARAGON '~------~y~------~I DRWG 16058...

- Page 206 X.31 FOUR 101 WHALEBOAT SPEC - TRANSMISSION - PARAGON 105--- 51C,/ON DRWG 16058...

-

Page 207: Transmission - Paragon

X.32 WHALEBOAT SPEC FOUR - TRANSMISSION - PARAGON "JAME REMARKS QUAN 1& 235 I-'OUSING TRANSMISSION-TO SERIAL 6Al 1S227 HOUSING TRANSMISSION-FROM SERIAL SAL 16234 FLA TE FRONT-TO SERIAL 6Al 16226 PLATE 2- Z FRONT-FROM SERIAL 6Al 16231 PLATE FRONT PLATE ASSEMBLY-TO SERIAL 6Al 16229 PLATE FRONT PLATE ASSEMBLY-FROM SERIAL 6A1... - Page 208 X.33 FOUR WHALEBOAT SPEC - TRANSMISSION - PARAGON NAME QUAN REMARKS OUTPUT SHAFT 16101 161Q3 EEARING BALL-REDUCTION 1&157 RING RETAINING-BALL BEARING 5,.. 16108 RING PISTON-OIL DISTRIBUTOR BEARING 16217 THRUST-TAILSHAFT-NEEOLE f(ACE 16218 THRUST-TAILSHAFT BEARING 16163 TAILSHAFT REDUCTION PINION 16144 BEARING NEEDLE-SCREW COLLAR 15203 HOUSING REDUCTION GEAR...

- Page 209 X.34 FOUR lC7 WHALEBCAT SPEC TRANSMISSIO~ PA~AGC~ NAME REP'ARKS GUAN ItEF REVERSE GEAR 16173 ~OUSING RCLL REVERSE BAND 16172 11S1 BAND REVERSE BAND ASSEMBLY 1;)3- 1 16183 EAND LINING 1\13- 2 REVERSE-WITHO~T 16184 LINING REVERSE BAND-ONE PAIR 133- 3 16104 RIVET REVERSE BAND lu3- 4...

- Page 211 X.36 FOUR 107 wHALEBOAT SPEC - TRANSMISSION - WARNER...

-

Page 212: Transmission - Warner

X.37 FOUR 107 WHALEBOAT SPEC - TRANSMISSION - WARNER NAME REMARKS QUAN SEARING 163()4 COVER VALVE 16263 GASKET VALVE COVER 16264 VALVE VALVE AND SPRING ASSEMBLY 16284 O-RI NG 15291 BREATHER COMPLETE ASSEMBLY 16309 FLUG DRYSEAL 15299 DIPSTICK COMPLETE ASSEMBLY 16283 SPRING POPPET... - Page 213 X.38 - TRANSMISSION - ~ARNER FOUR 101 WHALEBOAT SPEC...

- Page 214 X.39 FOUR 101 WHALEBOAT SPEC TRANSMISSION - WARNER NAME REMARKS QJA\J PLATE REVERSE CLUTCH PR:::SSURE PLATE 1&274 PISTON REVERSE CLUTCH PISTON 16261 RING SEALING 16292 BEARING NEEDLE 16295 RING SEALING 16290 1£,2B1 GASKET CASE TO ADAPTER ADAPTER 16305 PUMP GASKET 16253 PUMP COMPLETE ASSEM8LY...

- Page 215 X.40 FOUR 107 WHALEBOAT SPEC - REDUCTION UNIT - SNOW NABSTEOT --/-..J..--..· DIA. BORE ~------------------ ---------------_/ DWG NO 15706...

-

Page 216: Reduction Unit - Snow Nabstedt

X.41 FOUR 107 WHALEBOAT SPEC - REDUCTION UNIT - SNOW NABSTEDT QUAN REMARKS ~AME ADAPTER TO TRANSMISSION SCRE 15518 ADAPTER REDUCTION HOUSING TO TRANSMISSION 15506 REDUCTION HOUSING TO ADAPTER GASKET 1550'+ REDUCTION 15508 ~OUSING SHI M .005 15515 5- 1 SHIM 6- 2 15516... - Page 218 WESTERBEKE MODEL 14088 SPEC B WHALEBOAT ENGINE SPEC B. INTRODUCED IN OCTOBER 1985. RELOCATES MODIFIES FOLLOWING COMPONENTS ORDER REDUCE ENGINE OVERALL WIDTH AND LENGTH: MOUNTING RAILS LUBE FILTER. BLOCK HEATER ALTERNATOR . THE ILLUSTRATION PARTSLIST FOLLOWING IDENTIFY PARTS CREATED BY SPEC B FOR SERVICE PURPOSES.

- Page 219 WESTERBEKE MODEL 14088 SPEC B WHALEBOAT ENGINE...

- Page 220 WESTERBEKE MODEL 14088 SPEC B WHALEBOAT ENGINE QUAN NAME REMARKS 35331 STRAP RIGHT FILTER BRACKET SUPPORT 35318 LUBE OIL FILTER BRACKET 35321 STRAP LEFT FILTER BRACKET SUPPORT 11613 FILTER LUBE OIL ELBOW COMPRESSION 13335 35324 LINE BLOCK OIL ADAPTER TO FILTER...

- Page 221 WESTERBEKE MODEL 14088 SPEC B WHALEBOAT ENGINE NAME QUAN REMARKS NOTE ALL REFERENCES ARE TO NAVSEA MANUAL 0941-014-8013 WITH CHANGE 3 PAGE X.17-19 DELETE THE FOLLOWING REF 13969 LINE OIL ADAPTER TO FILTER 14079 LINE OIL FILTER TO COOLER 11119...

Need help?

Do you have a question about the 14088 and is the answer not in the manual?

Questions and answers