Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Operator's Manual

Advertisement

Table of Contents

Summary of Contents for Westerbeke 12C-TWO

- Page 2 USE EXTREME CARE WHEN HANDLING ENGINE FUEL (A constant danger of explosion or fire exists) Do not fill fuel tank(s) while the engine is running. Do not smoke or use an open flame near the engine or fuel tanle Westerbeke Engines...

- Page 3 Make sure all attaching hardware is properly tightened. Keep protective shields and guards in their respective place at all times. Do not check fluid levels or the drive belt's tension while the unit is operating. Do not work on the equipment when mentally or physically incapacitated by fatigue. Westerbeke Engines...

- Page 4 Westerbeke must depend on such software for the design of Westerbeke's own product software. Such software may be outdated and no longer accurate. Routine changes made by Westerbeke's suppliers, of which Westerbeke rarely has notice in advance, are frequently not reflected in the supplier's software until after such changes take place.

- Page 5 FOREWORD Thank you for selecting a Westerbeke marine product for your use. We at Westerbeke are pleased to have you as a customer. Read this manual carefully and observe all safety precautions included throughout. Operating procedures, periodic preventive maintenance procedures, installation checks, system descriptions and minor...

-

Page 6: Table Of Contents

ENGINE TROUBLESHOOTING ....61 MAINTENANCE AND ADJUSTMENTS ..............64 LAY-UP AND RECOMMISSIONING ..............67 TABLE OF STANDARD HARDWARE TIGHTENING TORQUES ...... 71 TORQUE SPECIFICATIONS ....72 SPARE PARTS LIST ................. 73 Westerbeke Engines... -

Page 7: General

Westerbeke engine sets are thoroughly checked and given a final run under various load conditions before leaving the factory. This is done to ensure dependable operation, long service, and a satisfied owner. -

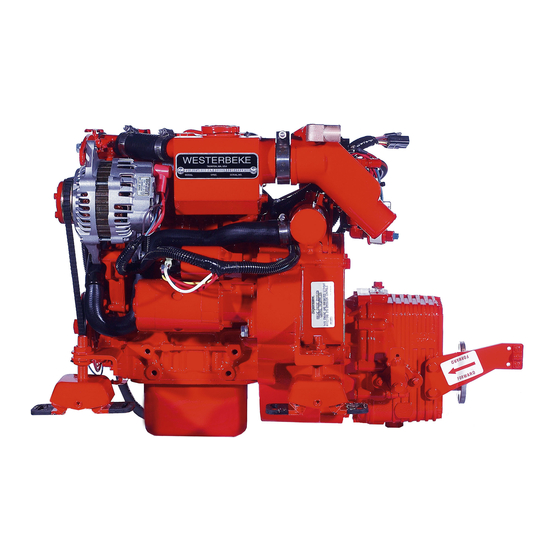

Page 8: Engine Callout Photo, Right Side

Fresh Water Coolant Fill . Intake Silencer Water Heater Flow Control Control Panel Connections - -_____ "," ..,Idi Fresh Water Circulating Pump Fuel Filter. _________ ..... Preheat Solenoid - _ _ _ _ _ _ _ ..Zinc Anode - - - - - - - - - - - - - Oil Pressure Switch Gear Shift Lever... -

Page 9: Engine Callout Photo, Lefr Side

Fresh Water Coolant Fill Unit D. Plate 20 Amp DC Circuit Breaker DC Charging Alternator Fuel Pump Lift Exchanger Fresh Water Drain (l> V> (l> (l> " C!9, V> Starter with Solenoid DC Battery Ground Connection Marine Transmission Drain ~TWO _.-'T SIDE... -

Page 10: Two General Specifications

225 LBS ( 102.13 kgs) Fuel Consumption: 0.7 gph (2.65 Iph) at 2500 rpm (approx.) Inclination Continuous 14° Temporary 25° (not to exceed 30 min) Idle Speed 1000-1200 rpm Cruise RPM 2000-2500 RPM Maximum RPM 2900 - 3000 RPM Westerbeke Engines... -

Page 11: 12 C Two System Specifications

(measured before discharging into exhaust elbow) System Capacity (fresh water) 2.9 qts (2.7 liters) LUBRICATION SYSTEM General Pressure fed system, gear type, enclosed in gear case, direct drive by crankshaft, forced lubrication. Oil Filter Full flow, paper element, spin-on type. Westerbeke Engines... - Page 12 Internal regulator, built into alternator TRANSMISSION (HBW 35) Standard Gear Ratio 2.05:1 Direction of Rotation Right Handed - standard transmission Lubrication Fluid Automatic Transmission Fluid (ATF) Type A or Dexron II Sump Capacity 0.32 S. quarts (0.3 liters) approx. Westerbeke Engines...

- Page 13 (0.96 cmm) Cooling Air Engine Block Cooling 100.0 CFM (2.8 cmm) FRONT CRANKSHAFT LOADING Maximum Side Load 5 - 5.5 hp Maximum Distance 4.7 inches at crankshaft shives (measured from engine block) Maximum Allowable Thrust Load 9.5 hp Westerbeke Engines...

-

Page 14: Installation Checks

INSTALLATION CHECKS GENERAL Since the crafts in which Westerbeke engines are installed vary in design, installation procedures will vary accordingly. The intent of this section is not to advise boatyards or installers on procedures already well developed and well understood. However, it is important that the owner/operator realize there are details of the installation which require periodic checks to ensure the best operating conditions for the equipment and safe operating conditions for the personnel on board. - Page 15 Special rigging work is best done by someone experienced and competent in handling heavy machinery. Westerbeke Engines...

- Page 16 (refer to illustration). Supports between the bed stringers, and extending from the stringers to the hull, may be required for proper support and to aid in the absorption of vibration. GOOD NOTE: Avoid excessive height, use solid stringer construction (Al· Westerbeke Engines...

- Page 17 The best time to perform the propeller shaft/transmission coupling alignment is with the fuel and water tanks about half full and all the usual equipment on board, and after the main mast has been stepped and the final rigging has been accomplished. Westerbeke Engines...

- Page 18 This does not mean that the work has been done improperly at first; rather, it means that the boat has taken some time to take its final shape and that the engine's bed and stringers have probably absorbed some moisture. may even be necessary to realign the coupling halves again at a later time. Westerbeke Engines...

- Page 19 The illustration shows a siphon break installed. Westerbeke Engines...

- Page 20 Refer to the figures shown above for recommended exhaust system installations. The exhaust through-hull discharge fitting must not be restrictive so as to create unwanted back-pressure in the system. Westerbeke Engines...

- Page 21 NOTE: Other gauges may be available to test for exhaust back-pressure. Contact your local Westerbeke dealer. A water column can be made by taking a clear plastic tube and taping one end of the...

- Page 22 • Dizziness • Vomiting • Intense Headache • Muscular Twitching • Weakness and Sleepiness • Throbbing in Temples If you experience any of the above symptoms, get out into fresh air immediately. Westerbeke Engines...

- Page 23 Exhaust Elbow Installation Westerbeke Corporation offers a 45° and 90° exhaust elbow as well as an exhaust riser that you can install on your propulsion engine. Refer to the instructions below when installing the exhaust elbow you purchased for your engine.

- Page 24 COOLING SYSTEM Westerbeke engines are fresh water cooled by an engine mounted heat exchanger. Sea water is used as the heat exchanger's cooling medium. Sea water is pumped into the exchanger by a sea water pump and is then injected into the exhaust discharge, carrying with it the heat removed from the engine's fresh water cooling system.

- Page 25 Check to ensure that all engine harness connections are right and that they are made to the appropriate terminals. WARNING Do not smoke or allow an open flame near the batteries. Lead acid batteries emit hydrogen, a highly-explosive gas. Tum off the emergency switch in the battery's positive line. Westerbeke Engines...

- Page 26 Refer to the "SYSTEM SPECIFICATIONS" section of this manual for your engine's airflow requirements. Westerbeke Engines...

-

Page 27: Preparation For Starting

Follow the procedures as presented, for the conditions indicated, and your Westerbeke engine will give you reliable performance and long service life. Fill your engine with oil up to or near the upper limit on the dipstick (the installation angle may have an effect on the dipstick reading). - Page 28 DESCRIPTION OF STARTING SYSTEM All Westerbeke diesel engines use electric starters assisted by glow plugs for both normal and cold weather starting. The figure below shows a cross-sectional view of one cylinder. The glow plug is located in the combustion chamber so that its tip is in the injector nozzle's spray path. When the glow plug is energized by the PREHEAT button, the plug glows red at the tip and assists in igniting the fuel.

-

Page 29: Engine Control Panels

ENGINE CONTROL PANELS Westerbeke offers two types of control panels as optional equipment. Read the following instructions that apply to the panel you purchased with your engine. GENERAL This manually-operated control panel is equipped with a Key Switch; an RPM gauge; PREHEAT and START buttons;... - Page 30 OFF. The oil pressure gauge will fall to zero when the Key Switch is turned OFF. The temperature gauge will once again register the engine's true temperature once electrical power is restored to the gauge. Westerbeke Engines...

- Page 31 NOTE: Tbe alarm will sound when the Key Switch is turned ON. Tbis sounding is normal for the engines covered in this manual. Once the engine starts, and the engine's oil pressure will silence. reacbes 15 psi, the alarm Westerbeke Engines...

- Page 32 OFF. The oil pressure gauge will fall to zero when the Key Switch is turned OFF. The temperatnre gauge will once again register the engine's true temperature once electrical power is restored to the gauge. Westerbeke Engines...

-

Page 33: Starting Procedure

Never attempt to engage the starter while the engine is running. NOTE: Some unstable running may occur in a cold engine, but this condition should smooth out as the operating temperature of 170 - 190° F is reached. Westerbeke Engines... -

Page 34: Stopping Procedure

Key Switch OFF which turns OFF an electrically run Fuel Run Solenoid. This electrical shut off option is installed at the factory upon the specific request/order of the owner. THROTTLE CO'Trll LEVEl STD~ POSlTIIHI ST OP COlirtOl UV£II: Westerbeke Engines... - Page 35 Excessive speed or heavy overloading, especially with a cold engine, may cause scoring of the cylinder walls, producing similar results. As indicated above, operate the engine in moderation during the 50- hour break-in period. (Don't baby the engine, but do not abuse it.) Westerbeke Engines...

- Page 36 DOES NOT RISE ENOUGH - Allow the glow plugs to operate sufficiently to aid in starting during the preheat period whenever the temperature of the intake air is low and when the compression temperature does not rise enough. Refer to the preheat chart found in the "STARTING PROCEDURE" section. Westerbeke Engines...

-

Page 37: Fuel System

DO NOT allow any smoking, open flames, or other sources of fire near the fuel system when servicing. Ensure proper ventilation exists when servicing the fuel system. Westerbeke Engines... - Page 38 Engine damage resulting from this type of sea water entry is not a warrantable issue; the owner/operator should keep this in mind. Westerbeke Engines...

- Page 39 To obtain long and satisfactory service from the injection pump, always use fuel which is free from impurities and maintain a good filtration and water separation system between the fuel tank and engine. Service this system regularly: the injection pump it saves will be your own. Westerbeke Engines...

- Page 40 The Westerbeke fuel system is self-bleeding. While it is unlikely that the operator will be forced to service the system at sea, the possibility does exist. Therefore, we recommend that a replacement fuel filter be carried on board at all times. Each fuel filter comes with two O-ring gaskets. Select the part number for this fuel filter from your Parts List and purchase spares from your local Westerbeke Dealer or Distributor.

- Page 41 PLUNGER SPRING Sectional View of Pump Idle speed and timing adjustment are the only adjustments the servicing dealer can perform on the injection pump. Other types of adjustments or repairs must be performed by a qualified injection service shop. Westerbeke Engines...

-

Page 42: Electrical System

ELECTRICAL SYSTEM Engine 12-Volt DC Control Circuit The Westerbeke 12C-TWO propulsion engine has a 12-Volt DC electrical control circuit, as shown on the wiring diagrams which follow. Refer to these diagrams when troubleshooting or servicing electrical components on the engine. - Page 43 Illustrated below is a wiring harness for a three-cylinder engine electrical system. The wiring harness for the 12C-TWO's electrical system differs only in that it has one less glow plug terminal. Optional Fuel Run Solenoid Westerbeke Engines...

- Page 44 NOTE: Before removing the alternator for repair, make sure 12-volts excitation is present at the R terminal should the above test show only battery voltage at the B output terminal. Westerbeke Engines...

-

Page 45: Dc Control Circuit Wiring Diagram #39144

DC Control Circllit Wiring Diagram #39144 page 1 of2 it:-] $EE NOTE 2 ADMlrlAL PAN:::'" ' - - - - - - - - - - - - - - - - - - - - ' ~------------------------- Westerbeke Engines... - Page 46 WIRf.1 PtUG liS UNUSED SHOULD INSU,ATEO,CAPTAI>J='MJELOlJtV. "'" ~J.t" ""<~ ~T :J>JU~{)A>JC 'f,1JQi.J;P!3£ '>JSUUlT!D, .o\OMIJ<<l~ P~>JEL O!JL II. Go«.Y Z ;5 pt(X, e\" t" ~ 1. (.,u\~~~~ " '''8R' ~PBfSTQ"F AI T t" "*" ." II Bl" e"'N'V'RSAI PROP"I S IQll o~c<;.~QLUL...U..~ Westerbeke Engines...

-

Page 47: Cooling System

COOLING SYSTEM Description . Westerbeke marine diesel engines are designed and equipped for fresh water cooling. Heat produced in the engine by combustion and friction is transferred to fresh water which circulates throughout the engine. This circulating fresh water cools the engine block and its internal moving parts. The heat is transferred externally from the fresh water to sea water by means of a heat exchanger, similar in function to an automotive radiator. - Page 48 (SoC) lower than the actual atmospheric temperature e""pected. Filling the Fresh Water System A coolant recovery tank kit is supplied with each Westerbeke diesel engine. The purpose of this recovery tank is to allow for engine coolant expansion and contraction, during engine operation, without the loss of coolant and without introducing air into the cooling system.

- Page 49 Since 1980, each type of thermostat has a hole punched through it. The hole is a bypass to prevent the exhaust manifold from overheating during the engine's warm-up. Replacement thermostats must have this design characteristic. Westerbeke Engines...

- Page 50 Excessive slack or the presence of oil on the belt can cause belt slipping, resulting in high operating temperature, as well as insufficient alternator output. Westerbeke Engines...

- Page 51 A spare drive belt should be carried on board. Refer to the "SPARE PARTS" section of this manual. Cooling System Components. EXIJloded View The illustration shows the cooling system components for the 12C Two engine. Refer to the Parts List for ezch component's name and part number. Westerbeke Engines...

- Page 52 Domestic Hot Water The 12C-Two engine is equipped with a domestic hot water connection. If the owner/operator wishes to connect a hot water heater. remove the bypass hose and connect a heater as described in the instructions presented below. General: With the bypass hose...

- Page 53 The hose connection from the heater to the remote expansion tank should be routed and supported so as to rise continuously from the heater to the tank, enabling any air in the system to rise. Refer to the illustrations on the previous page. Westerbeke Engines...

-

Page 54: Lubrication System

NOTE: A newly started, cold engine can have an oil pressure reading upwards of 55 psi. A warmed engine can have an oil pressure reading as low as 15 psi. These readings may also vary depending upon the speed at which the engine is running. Westerbeke Engines... - Page 55 Immediately after an oil filter change and oil fill, run the engine for a few minutes to make sure the oil pressure is normal and that there are no oil leaks around the new oil filter. Westerbeke Engines...

- Page 56 The kit allows you to remove the oil filter off the engine and mount it on an adjacent bulkhead allowing better access for servicing. Contact your local dealer for information on purchasing a kit. H~ TIlRK H.lLR I..l..GlI.llN GASKET CONTACTS eASf Westerbeke Engines...

-

Page 57: The Hbw 35 Transmission

This transmission fluid may also be removed by inserting a small tube through the dipstick opening (where the transmission fluid is added) and attaching a pump onto the tube so the old fluid may be sucked out. Westerbeke Engines... - Page 58 The operating oil temperature must not exceed 266° F (l30°C). If this temperature is to be exceeded during normal operation, an optional transmission oil cooler should be installed. Consult your local Westerbeke Dealer for details on this cooler. NOTE: To check the transmission fluid level, remove the dipstick and wipe off all transmission fluid on the dipstick, and place the dipstick back in the hole where it was removed, making sure that the base of the dipstick's threaded portion rests on the transmission housing.

- Page 59 1200 rpm or below. The clutch pack within the transmission makes an audible "clunk" when engaging into gear. Moving the shift lever toward the output shaft (coupling end) of the transmission puts the transmission in FORWARD. Moving the shift lever toward the engine puts the transmission in REVERSE. Westerbeke Engines...

- Page 60 If any seal on the transmission shows signs of leaking, have the transmission looked at by an authorized Westerbeke Dealer or a Hurth Service Center. This problem, especially concerning the rear seal, is often contributed to an improper alignment of the transmission's coupling and the propeller shaft's coupling.

-

Page 61: Engine Troubleshooting

I terminal on the preheat solenoid. Check for 12 volts at the 10 breaker. Check for 12 volts at the R terminal on the alternator when the preheat button is pushed. Westerbeke Engines... - Page 62 6. Blockage in exhaust. 6. Remove exhaust hose from the engine and crank to start. Failure to stop. I. Mechanical Run Stop engine manually moving linkage disconnected. the RUN linkage to STOP. That failing, shut OFF fuel and air. Westerbeke Engines...

- Page 63 Make an output check with a voltmeter at the B terminal on the alternator. 2. Faulty alternator. 2. Voltage leak through the alternator when not operating. 3. Bad battery connections. 3. Connections are corroded or loose at the battery or/and at the engine. Westerbeke Engines...

-

Page 64: Maintenance And Adjustments

1. Change the engine's lubrication oil and oil filter. 2. Replace the fuel filter element in the on-engine filter and in the optional water/sediment separator, if a separator has been installed. *3. Torque the cylinder head hold-down bolts. *4. Adjust valve clearances. Westerbeke Engines... - Page 65 Replace worn components as needed. Check for leaks and repair as needed; DO NOT NEGLECT! 7. Check internal and external condition of water injected elbow. Remove any carbon or corrosion build- up. Replace the elbow should its condition be questionable. Westerbeke Engines...

- Page 66 NOTE: Operating in salty and/or tropical waters may require that a heat exchanger cleaning be performed more often than every 1000 hours. *2. Check the injection pump's timing. Mark on gear case TOC mark IT mark on pulley Westerbeke Engines...

-

Page 67: Lay-Up And Recommissioning

Fill the sump with the correct amount of oil for your engine model. (Refer to the "SYSTEM SPECIFICATIONS" section of this manual.) Use an oil which has an API specification of CC or CD. Run the engine and check for proper oil pressure and ensure that there are no leaks. Westerbeke Engines... - Page 68 Lubrication and cleaning of the starter drive pinion is advisable, if access to the starter permits its easy removal. Ensure that the battery connections are shut off before attempting to remove the starter. Take care in properly replacing any electrical connections removed from the starter. Westerbeke Engines...

- Page 69 Recommissioning The recommissiorting of your Westerbeke unit after a seasonal lay-up generally follows the same procedures as those presented in the "PREPARATIONS FOR STARTING" section, regarding preparation for starting and normal starts.

- Page 70 When the unit is put into operation, the system will self-flush in a short period of time with no adverse affects. 5. Start the unit in accordance with procedures in the "PREPARATIONS FOR STARTING" section of this manual. Westerbeke Engines...

-

Page 71: Table Of Standard Hardware Tightening Torques

3/8 UNC 28 - 33 3.7 - 4.6 3/8 UNF 30 - 35 4.1-4.8 7116 UNC 44 - 49 6.1- 6.8 7116 UNF 50 - 55 6.9 -7.6 1I2UNC 68 -73 9.4-10.1 112 UNF 73 - 80 10.1-1l.l Westerbeke Engines... -

Page 72: Torque Specifications

Wet indicates that the bolts removed) are to have a thin oil film wiped on them before ihey are retorqued. If the bolts have not been removed and need only to be retorqued, then no oil is needed Westerbeke Engines... -

Page 73: Spare Parts List

From the list provided directly above, and from these inquiries, you can determine what spare parts should be carried on board. In addition, if you are planning a long ocean voyage, consult your local Westerbeke distributor for a listing of the Westerbeke dealers located along your route. - Page 74 YOUR NOTES Westerbeke Engines...

Need help?

Do you have a question about the 12C-TWO and is the answer not in the manual?

Questions and answers