Table of Contents

Advertisement

Available languages

Available languages

Quick Links

Operating Instructions and Replacement Parts List

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect

yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage!

Retain instructions for future reference.

Description

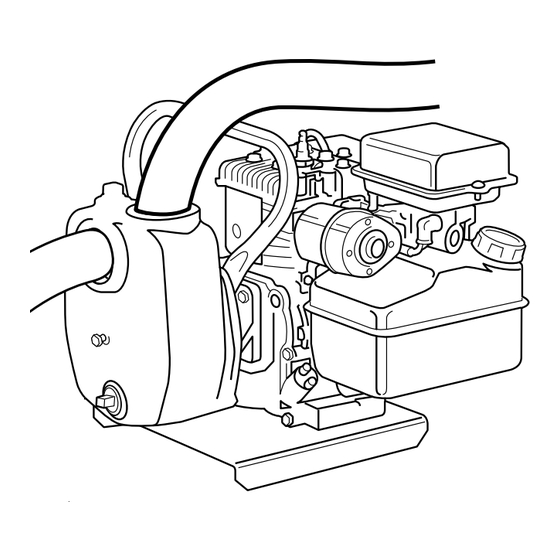

The WAYNE pumps are general use

centrifugal water pumps. The pump

is equipped with EPDM seals that are

intended for water use only.

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates an

imminently hazardous

situation which, if NOT avoided, WILL

result in death or serious injury.

Warning indicates a

potentially hazardous

situation which, if NOT avoided, COULD

result in death or serious injury.

Caution indicates a

potentially minor or

moderate injury, if NOT avoided, MAY

result in serious injury.

Notice indicates

important

information, that if NOT followed, MAY

cause damage to equipment.

General Safety

Information

CALIFORNIA PROPOSITION 65

This product may

contain chemicals

known to the State of California to

cause cancer and birth defects or other

reproductive harm. Wash hands after

handling.

1. Know the pump application,

limitations, and potential hazards.

Read these rules and the instructions

carefully. Failure to follow them could

cause serious bodily injury and/or

property damage.

REMINDER: Keep your dated proof of purchase for warranty purposes!

© 2011, WAYNE/Scott Fetzer Company.

Engine Driven

Centrifugal Pump

an enclosed area. Exhaust

gases contain deadly

poisonous carbon monoxide,

which has no odor or taste.

flammable or explosive fluids

such as gasoline, fuel oil,

kerosene, etc. Do NOT use in

flammable and/or explosive atmospheres.

Pump SHOULD only be used with liquids

compatible with pump component materials.

Failure to follow this warning CAN result in

personal injury and/or property damage.

2. Observe all safety precautions for the

handling of the fuel.

hot engine. Fuel spilled on a

hot engine could result in a

fire or explosion. Do NOT

refuel a running engine.

3. Pump should be located and should

rest on a level solid foundation. Do

NOT suspend pump by means of the

discharge pipe.

doesn't fall over.

4. Do NOT use torches or apply excessive

heat, fire or flames to this pump as an

explosion may result.

5. Before working on the unit, insulate

the wire from the spark plug, by

disconnecting the spark plug wire from

the spark plug.

MUST be protected against below freezing

temperature. Failure to do so COULD cause

serious damage and WILL void the warranty.

6. Do NOT run pump dry. Water is

required to lubricate the shaft seal.

Attach it to this manual or fi le it for safekeeping.

For parts, product & service information

visit www.waynepumps.com

NEVER run

7. Pumping chemicals or corrosive liquids

engine in

8. Personal Safety:

Do NOT use

to pump

9. This pump is designed for non-abrasive

Do NOT

refuel a

Installation

This pump is designed to be self-priming

when installed and operated as specified

below.

Be sure pump is on

1. The pump should be placed as close as

secure footing so it

Complete pump and

piping system

Figure 1

GPB400

with this pump will shorten the life of

the pump and may be hazardous to the

operator and void the warranty.

a. Wear safety glasses at all times when

working with pumps.

b. Keep work area clean, uncluttered

and properly lighted; replace all

unused tools and equipment.

c. Keep visitors at a safe distance from

the work area.

d. Make workshop child-proof with

padlocks, master switches, and by

removing starter keys.

fluid transfer; do NOT use as a trash

pump. ALWAYS use a suction strainer

with this pump to filter abrasive

material. Abrasive materials such as sand

and gravel will shorten the life of the

pump.

possible to the water being pumped.

A pump with 20 foot suction lift will

not remove water as quickly as a pump

with 5 foot suction lift (Figure 1).

20 FT. SUCTION LIFT

5 Ft.

SUCTION

LIFT

320605-001 8/11

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Wayne GPB400

- Page 1 NEVER run 7. Pumping chemicals or corrosive liquids engine in with this pump will shorten the life of The WAYNE pumps are general use an enclosed area. Exhaust the pump and may be hazardous to the centrifugal water pumps. The pump gases contain deadly operator and void the warranty.

-

Page 2: Maintenance

Operating Instructions and Replacement Parts List 7. Fill the engine crankcase with oil. Installation PIPING (continued) Refer to the engine operating manual Always place the pump as close as possible for the specific grade of oil and 2. Suction hose and fitting must be to the water being pumped. -

Page 3: Performance Information

GPB400 Performance Information 2” Cast Iron Pump Performance CAPACITIES IN GALLONS PER HOUR Discharge Dynamic Suction Lift - Feet Head - Feet 6600 6420 6180 6000 5640 5220 6180 6000 5640 5220 4800 4380 5640 5220 4800 4380 4080 3660 4800 4380 4080... - Page 4 For Replacement Parts or Technical Assistance, call 1-800-237-0987 Please provide following information: Address parts correspondence to: - Model number WAYNE Water Systems - Serial number (if any) 101 Production Drive - Part description and number as shown Harrison, OH 45030 Item No.

- Page 5 GPB400 Notes www.waynepumps.com...

-

Page 6: Maintenance / Service Record

Operating Instructions and Replacement Parts List Maintenance / Service Record Date Maintenance Performed Replacement Components Required www.waynepumps.com... - Page 7 GPB400 Maintenance / Service Record Date Maintenance Performed Replacement Components Required www.waynepumps.com...

-

Page 8: Limited Warranty

Limited Warranty For one year from date of purchase, WAYNE Water Systems (”WAYNE Pumps“) will repair or replace, at its option, for the original purchaser any part or parts of its Sump Pumps or Water Pumps (”Product“) found upon examination by WAYNE Pumps to be defective in materials or workmanship. -

Page 9: Directives De Sécurité

NE JAMAIS l’arbre doit être lubrifié avec de Description faire l’eau. Les pompes WAYNE sont généralement fonctionner le moteur dans 7. Le pompage de produits chimiques ou un espace fermé. Les gaz qui utilisées pour les pompes à eau de liquides corrosifs avec cette pompe s’en échappent contiennent un... -

Page 10: Entretien

Mode d’emploi et Liste de Pièces de Rechange 7. Remplir le carter du moteur avec de Installation (suite) TUYAUTERIE l’huile. Se reporter au manuel de Toujours placer la pompe aussi près que fonctionnement du moteur pour possible de l’eau à pomper. Maintenir 1. - Page 11 GPB400 Informations sur le Rendement Performance de la pompe en fonte 5 cm (2 po) CAPACITÉS EN GALLONS PAR HEURE Décharge Aspiration Dynamique - Pied Tête-Pied 6600 6420 6180 6000 5640 5220 6180 6000 5640 5220 4800 4380 5640 5220 4800 4380 4080...

- Page 12 1-800-237-0987 Veuillez fournir l’information suivante : Adresser la correspondance à : - Numéro de modèle WAYNE Water Systems - Numéro de série (s’il y a lieu) 101 Production Drive - Description et numéro de pièces tel Harrison, OH 45030 qu’indiqué...

- Page 13 GPB400 Remarques 13 Fr...

-

Page 14: Garantie Limitée

Garantie limitée Pendant un an à compter de la date d’achat, WAYNE Water System («WAYNE Pumps») réparera ou remplacera, à sa discrétion, pour l’acheteur original toute pièce ou pièces de ces pompes de puisard ou pompes à eau («Produit») déterminées défectueuses, par WAYNE Pumps, en terme de matériaux ou de fabrication. -

Page 15: Guías De Seguridad

Descripción haga líquidos corrosivos con esta bomba funcionar el motor en un Las bombas WAYNE son bombas puede acortar la vida útil de la misma área cerrada. Los gases de centrífugas de agua de uso general. y puede ser peligroso para el operador salida contienen monóxido de... -

Page 16: Mantenimiento

Instrucciones de funcionamiento y Lista de piezas de repuesto 7. Llene la caja del cigüeñal del motor Instalación (cont.) TUBERÍAS con aceite. Consulte el manual de La bomba debe colocarse lo más 2. La manguera y las conexiones funcionamiento del motor para ver cerca posible del agua a bombear. - Page 17 GPB400 Información del rendimiento Desempeño de la bomba de hierro fundido de 5 cm (2 pulg.) CAPACIDADES EN GALONES POR HORA Altura de Altura de succión dinámica, en pies descarga, en pies 6600 6420 6180 6000 5640 5220 6180 6000 5640 5220 4800...

- Page 18 1-800-237-0987 Sírvase proporcionar la siguiente Dirija su correspondencia sobre información: repuestos a: - Número de modelo WAYNE Water Systems - Número de Serie (de haberlo) 101 Production Drive - Descripción y número del repuesto Harrison, OH 45030 como se indica Artículo N.º...

- Page 19 GPB400 Notas 19 Sp...

-

Page 20: Garantía Limitada

Garantía limitada Durante un (1) año a partir de la fecha de compra, WAYNE Water Systems (”WAYNE Pumps“) reparará o reemplazará, a su criterio, para el comprador original, cualquier pieza o piezas de sus Bombas para cloacas o Bombas de agua (el “Producto”) que después de un examen sea(n) hallada(s) por WAYNE Pumps como defectuosa(s) en su material o mano de obra.

Need help?

Do you have a question about the GPB400 and is the answer not in the manual?

Questions and answers