Summarization of Contents

Foreword

Machine Identification

Details on identifying the machine model, item number, serial number, and nameplate.

Expectations for Information in This Manual

Explains what information to expect and the manufacturer's rights regarding modifications.

Manufacturer's Approval

Defines approved parts, attachments, and modifications and their consequences.

Usage

Intended Use

Specifies the intended purpose and applications for de-watering clear water or water with solids.

Unintended Use

Lists examples of misuse that can damage the machine or cause injury.

Residual Risks

Identifies potential risks that remain even after protective measures are taken.

Safety

Signal Words Used in This Manual

Explains the meaning of DANGER, WARNING, CAUTION, and NOTICE signal words in the manual.

Safety Guidelines for Operating the Machine

Provides essential guidelines for safe operation, including training and environmental awareness.

Safety Guidelines for Using Internal Combustion Engines

Details on PPE, safe operation, and practices when using internal combustion engines.

Description of the Machine

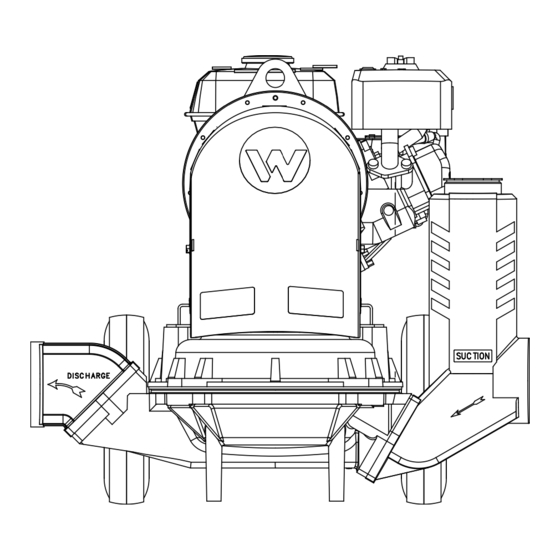

Machine Description

Overview of the diaphragm pump's components and functionality.

Overview of the Labels

Illustrates the location and types of labels found on the machine.

Safety Label Meanings

Explains the hazards and meanings associated with various safety labels on the machine.

Information Label Meanings

Defines the meaning of informational labels, such as stroke rate and sound levels.

Transportation

Lifting and Transporting

Guidelines and requirements for safely lifting and transporting the machine.

Commissioning

Preparing the Machine for First Use

Steps to take before operating the machine for the first time, including checks and fluid additions.

Hoses and Clamps

Recommendations for selecting and using hoses and clamps for proper pump connection.

Recommended Fuel

Information on the type of fuel required and guidelines for using oxygenated fuels.

Operation

Refueling the Machine

Safety precautions and procedures for refueling the machine's engine.

Before Installing the Pump

Lists requirements and procedural steps to perform before installing the pump.

Installing the Pump

Detailed procedure for setting up the pump, including checks and connections.

Starting, Operating, and Stopping the Machine

Step-by-step instructions for starting, operating, and safely shutting down the machine.

Clearing Jams

Procedure for clearing jams and addressing issues when the pump does not prime.

Emergency Shutdown Procedure

Steps to take in case of a breakdown or accident requiring an immediate shutdown.

Maintenance

General Maintenance

Highlights the importance of a well-maintained machine for safety and longevity.

Maintaining the Emission Control System

Information on maintenance and warranty repairs for emission control systems.

Periodic Maintenance Schedule

A schedule detailing maintenance tasks based on operating hours or time intervals.

Servicing the Air Cleaner

Instructions for inspecting, cleaning, and replacing air cleaner elements.

Greasing the Connecting Rod Bearing

Procedure for lubricating the connecting rod bearing at specified intervals.

Changing the Engine Oil

Detailed steps for changing the engine oil, including safety and environmental precautions.

Cleaning the Sediment Cup

Procedure for cleaning the engine sediment cup to maintain engine performance.

Maintaining the Spark Plug

Instructions for inspecting, cleaning, and replacing the spark plug for optimal engine function.

Checking and Changing the Gearbox Oil

Procedure for checking the gearbox oil level and changing the oil.

Cleaning the Pump

Guidelines for cleaning the pump, especially when pumping solids or dirt.

Checking and Adjusting Valve Engine Clearances

Task to be performed by a qualified technician for engine valve clearance adjustments.

Checking and Adjusting the Idle Speed

Task to be performed by a qualified technician for adjusting the engine's idle speed.

Replacing the Fuel Filter

Task to be performed by a qualified technician for replacing the fuel filter.

Storage

Long-Term Storage

Procedures for preparing and storing the machine for extended periods of non-operation.

Shutdown

Decommissioning

Steps for responsibly decommissioning and disposing of the machine at its end of service life.

Troubleshooting

Troubleshooting Guide

Common problems, their causes, and recommended remedies for pump operation.

Technical Data

Engine Data

Technical specifications related to the engine, including power, displacement, and oil type.

Machine Data

Specifications for the pump itself, such as hose diameter, flow rate, and discharge head.

Dimensions

Physical dimensions of the machine, including length, width, height, and hose sizes.

Emission Control System Information and Warranty

Limited Defect Warranty for Exhaust Emission Control System

Details on the limited defect warranty for the exhaust emission control system.

Need help?

Do you have a question about the PDI3A I and is the answer not in the manual?

Questions and answers