Table of Contents

Advertisement

Quick Links

Applied Thermal Control Ltd

39 Hayhill Industrial Estate

Installation, Operation & Service Manual

Barrow-upon-Soar, Loughborough

LE12 8LD, United Kingdom

R05

+44 (0) 1530 839 998

Service@thermalexchange.co.uk

Support@app-therm.com

DOCUMENT DETAILS

Date 23/JUN/2022

Compiled by MJH

Page 1 / 5

Revision 1

Opening section R05

1

Advertisement

Table of Contents

Summarization of Contents

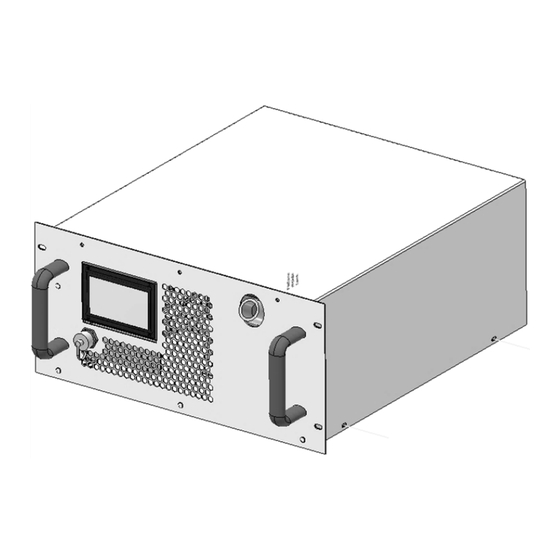

R05 Operation and Service Manual

Manual Introduction and Overview

Provides an introduction to the R05 Installation, Operation & Service Manual.

Document Control and Change Log

Details document revision history and any changes made.

Product Specifications

Lists detailed technical specifications for the R05 chiller.

Safety Notices and Warnings

Crucial safety precautions, cautions, and warnings for operating the R05.

Included Annexes Summary

Lists all supplementary annexes providing detailed technical information.

Annex A-1: Shipping & Unpacking

Unpacking Procedures

Step-by-step guide for safely removing the equipment from its packaging.

Manual Handling Recommendations

Guidelines for safe lifting and handling, including weight limits and best practices.

Annex B-12: Site & Environmental Requirements

R05 Installation Site Requirements

Covers rack mounting, clearance, and indoor use for the R05 unit.

Environmental Conditions for Operation

Specifies acceptable ambient temperature, humidity, and air quality.

Electrical Supply and Plumbing Guidelines

Details required electrical specifications and fluid connection guidelines.

Annex C-6: Installation Guide

Air-Cooled Unit Installation

Guidance for installing air-cooled refrigerated units.

Hose and Fitting Recommendations

Best practices for fluid lines, hoses, and adapter connections.

Backfilling Procedures

System Filling and Pressure Considerations

Steps for filling the system with fluid, considering potential pressure issues.

Annex D-1: Fluid Handling & Startup

Filling and Starting Procedures

Step-by-step guide for filling the chiller and initiating operation.

Draining Procedures

Instructions on how to safely drain the chiller system.

Annex E-1: Controller Operation

Controller Interface Views

Explains different display screens and their functions on the controller.

Program Mode and Management

Guides users through setting up and managing operational programs via the controller.

Software Management and Updates

Procedures for managing software, logs, and performing updates on the controller.

Engineering and Error Views

Accessing engineering parameters, system status, and troubleshooting error codes.

Maintenance Prompts and Passcode Entry

Managing maintenance schedules and accessing settings via passcode.

Factory and User Settings Configuration

Configuring various operational parameters through factory and user settings.

Measurement Units and Modbus Communication

Setting units of measurement and configuring Modbus communication.

System Configuration Settings

Adjusting compressor, fan, calibration, and default setpoint parameters.

Display and Clock Settings

Customizing display, theme, real-time clock, and file path settings.

PID Control Settings

Configuring Proportional-Integral-Derivative (PID) control loops for cooling and heating.

Software Update Procedure

Step-by-step guide for updating the controller software using a USB drive.

Annex F-5: Pressure & Flow Adjustment

Centrifugal/Turbine Pump Operation

Explanation of pump types and their characteristics in the system.

Component Layout and Functions

Identifies key components and their functions within the pump and fluid circuit.

Annex G-1: Troubleshooting Guide

Mini & R05 Common Issues

Addresses common symptoms and potential causes for system issues.

Annex H-1: End-User Maintenance

Periodic Maintenance Schedule

Outlines weekly, monthly, and annual maintenance tasks for end-users.

Annex I-1: Technician Maintenance

Generic Maintenance for Technicians

Procedures and safety warnings for technicians performing maintenance.

Annex J-5: Conflict Minerals Compliance

Conflict Minerals Compliance Statement

ATC's statement on sourcing materials responsibly regarding conflict minerals.

Annex J-7: REACH Compliance

REACH Regulation Overview

Explanation of the European REACH chemical regulation.

REACH Compliance Statements

ATC's compliance statements regarding REACH Annexes and SVHC substances.

Annex J-8: POPs Compliance

POPs Regulation Overview

Explanation of the European POPs (Persistent Organic Pollutants) regulation.

POPs Compliance Statement

ATC's certification of product compliance with POPs regulations.

Annex J-10: RoHS Compliance

RoHS Directive Overview

Explanation of the Restriction of Hazardous Substances (RoHS) directive.

RoHS Compliance Statements

ATC's compliance statements for different versions of the RoHS directive.

Annex J-12: UKCA Declaration

UKCA Declaration of Conformity

UK conformity assessment declaration for the R-Series machinery.

Machinery Identification and Regulations

Details machinery identification and applicable UK regulations.

Annex J-13: EU Declaration of Conformity

EU Declaration of Conformity

EU conformity declaration for the R-Series machinery, listing directives and standards.

Machinery Identification and Directives

Details machinery identification and relevant EU directives.

Annex K-1: Warranty Terms

ATC Product Warranty Information

Explains the warranty period, fulfillment, shipping charges, and procedures.

Annex M-1: Recommended Spares

Recommended Spares Overview

Lists recommended spare parts categorized by chiller series and type.

R05-Specific Spares

R05 Model Spare Parts

Lists spare parts specifically recommended for the R05 model.

Harp® 134a Safety Data Sheet

Product Identification and Supplier Details

Identifies the product, supplier, and contact information for Harp® 134a.

Hazard Identification and First Aid

Details hazards, classifications, label elements, and essential first-aid measures.

Composition and Firefighting Measures

Information on chemical composition and appropriate firefighting procedures.

Release Measures and Handling/Storage

Guidelines for accidental release, safe handling, and storage of the substance.

Exposure Controls and Physical Properties

Personal protection, exposure limits, and physical/chemical properties of Harp® 134a.

Stability, Reactivity, and Toxicology

Information on chemical stability, reactivity, hazardous decomposition, and toxicological effects.

Ecological and Disposal Information

Data on environmental impact, biodegradability, and proper disposal methods.

Transport and Regulatory Information

Guidelines for transporting Harp® 134a and relevant safety regulations.

General Information and Hazard Statements

Additional information, SDS source, and hazard statements for Harp® 134a.

Hexid A4 Heat Transfer Fluid Safety Data Sheet

Product Identification and Hazards

Identifies Hexid A4 fluid and its hazard classification according to regulations.

Composition, First Aid, and Firefighting

Details chemical composition, first-aid measures, and firefighting guidance for the fluid.

Exposure Controls and Physical Properties

Outlines personal protective equipment, exposure limits, and physical characteristics.

Stability, Reactivity, and Toxicology

Information on chemical stability, potential hazards, and toxicological effects of Hexid A4.

Ecological, Disposal, and Transport Information

Data on environmental impact, disposal, and transport regulations for the fluid.

Regulatory and Other Information

Details regulatory compliance and additional information sources for Hexid A4.

Need help?

Do you have a question about the R05 and is the answer not in the manual?

Questions and answers