ATC R Series Installation, Operation & Service Manual

Hide thumbs

Also See for R Series:

- Installation, operation & service manual (51 pages) ,

- Assembly instruction manual (9 pages) ,

- Assembly instruction manual (11 pages)

Table of Contents

Advertisement

Quick Links

Applied Thermal Control Ltd

39 Hayhill Industrial Estate

Installation, Operation & Service Manual

Barrow-upon-Soar, Loughborough

LE12 8LD, United Kingdom

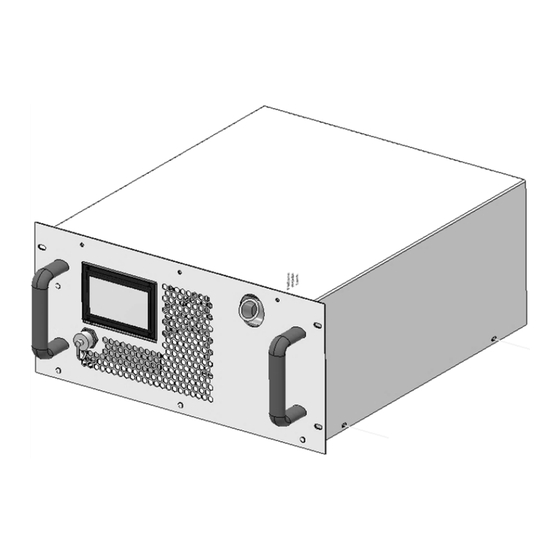

R05

+44 (0) 1530 839 998

Service@thermalexchange.co.uk

Support@app-therm.com

DOCUMENT DETAILS

Date 23/JUN/2022

Compiled by MJH

Page 1 / 5

Revision 1

Opening section R05

1

Advertisement

Table of Contents

Summary of Contents for ATC R Series

- Page 1 Applied Thermal Control Ltd 39 Hayhill Industrial Estate Installation, Operation & Service Manual Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 23/JUN/2022 Compiled by MJH Page 1 / 5 Revision 1 Opening section R05...

-

Page 2: Change Log

Applied Thermal Control Ltd 39 Hayhill Industrial Estate Installation, Operation & Service Manual Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 23/JUN/2022 Compiled by MJH Page 2 / 5 Revision 1 CHANGE LOG Date Revision Page ref... -

Page 3: Product Specifications

Applied Thermal Control Ltd 39 Hayhill Industrial Estate Installation, Operation & Service Manual Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 23/JUN/2022 Compiled by MJH Page 3 / 5 Revision 1 PRODUCT SPECIFICATIONS Attribute 25kg Weight... -

Page 4: Safety Notices

For your safety, we draw your attention to the following warning and caution marks throughout the manual; the safe operation of an ATC chiller always remains the responsibility of the operator. This equipment is intended to be used as a liquid temperature conditioning device – it requires no external pump, nor any further manipulation of temperature. - Page 5 Annex J-10 201111 EU Compliance Statement RoHS Annex J-12 210830 UKCA DoC R-series Annex J-13 220406 EU DoC R-series Annex K-1 200623 Standard warranty terms of ATC Annex M-1 220623 Recommended spares, M-, EM-, R05-Series Annex R-1 170621 SDS Refrigerant HFC-R134a Annex R-3 200203 SDS Hexid A4 v6.4...

- Page 6 Please check that both the packaging and the unit are undamaged. If there is any doubt, it is vital that you inform both ATC and the carrier. There are no hidden shipping bolts or other fixings. You should inspect the packaging for signs of transit damage before signing for the unit, and if possible, unpack the unit before signing.

- Page 7 5U high unit, 500mm deep. It must be secured with 4-off end user-supplied M6 bolts for rack cabinet upright rails. ATC strongly recommends the use of support guides that run from the front upright rail to the back upright rail of the rack cabinet to support the weight of the chiller.

-

Page 8: Hose Recommendations

Applied Thermal Control Ltd Operating Manual; Installation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex C-6 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 9/MAR/2022 Author(s) MJH Page 1 / 2 Revision 2 INSTALLATION FOR AIR-COOLED UNITS WITH 1/2" BSPPF FITTINGS This guide applies to the following product groups;... - Page 9 Applied Thermal Control Ltd Operating Manual; Installation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex C-6 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 9/MAR/2022 Author(s) MJH Page 2 / 2 Revision 2 BACKFILLING In situations where the chiller is situated physically lower than the application being cooled, fluid will apply pressure to the water circuit of the product.

- Page 10 Connect the chiller to the electrical supply and switch on at the rear rocker switch. The controller should begin to load and leave you on the splash screen with ATC logo in the middle. Check all application valves are open, including solenoid valves and variable position valves. The chiller will require an open water circuit to pump into.

- Page 11 1. Process-start will start fridge and water circuit. 2. Pump priming button runs pump without process starting. 3. Access to settings menu. 4. Service pack refers to software version installed. 5. Serial number is added by ATC during production. Process View 1. Process stop. 9. Condensing temperature.

- Page 12 Applied Thermal Control Ltd Operating Manual; Controller Operation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex E-1 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 10/DEC/2020 Author(s) MJH, AMI Page 2 / 10 Revision 1 Program Mode 1.

- Page 13 Applied Thermal Control Ltd Operating Manual; Controller Operation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex E-1 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 10/DEC/2020 Author(s) MJH, AMI Page 3 / 10 Revision 1 Software Management (incl.

- Page 14 Applied Thermal Control Ltd Operating Manual; Controller Operation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex E-1 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 10/DEC/2020 Author(s) MJH, AMI Page 4 / 10 Revision 1 Maintenance Prompt View 1.

- Page 15 Applied Thermal Control Ltd Operating Manual; Controller Operation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex E-1 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 10/DEC/2020 Author(s) MJH, AMI Page 5 / 10 Revision 1 Factory Settings (3) Scroll down from ‘Factory Settings’...

- Page 16 4. Select start address. 5. Direction of data, select read-write, or read-only. 6. Data transmission rate. 7. Select odd or even. 8. Select half or full; standard ATC wiring is 3-wire half duplex. Annex E-1 200707 XTD controller XTD043RB-K620G&F (Mini at SW v39.4)

- Page 17 5. Frequency issued to instruct the compressor to stop. Fan Settings Fan performance is closely linked to overall refrigeration system health. ATC caution users against making changes. 1. Return to ‘Factory Settings’ main menu. 2. To avoid stalling, the minimum duty default is 17%.

- Page 18 Applied Thermal Control Ltd Operating Manual; Controller Operation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex E-1 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 10/DEC/2020 Author(s) MJH, AMI Page 8 / 10 Revision 1 Display Settings 1.

- Page 19 Applied Thermal Control Ltd Operating Manual; Controller Operation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex E-1 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 10/DEC/2020 Author(s) MJH, AMI Page 9 / 10 Revision 1 PID Cooling Settings (1) 1.

- Page 20 Applied Thermal Control Ltd Operating Manual; Controller Operation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex E-1 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS 10 / Date 10/DEC/2020 Author(s) MJH, AMI Page Revision 1 XTD043RB-K620G / XTD043RB-K620F SOFTWARE UPDATE PROCEDURE 1/ Find an empty USB flash drive and ensure that its formatted to FAT32 (they usually are unless they are changed to something else).

- Page 21 This annex describes ATC’s default settings and how to adjust the system. REPRESENTATIVE COMPONENT LAYOUT & FUNCTIONS (IMAGE BELOW FROM EM05) It is important to understand the basic principle that all else being equal, higher flow results in a higher demand for pressure to overcome forces of friction and viscosity.

- Page 22 Applied Thermal Control Ltd Operating Manual; Pressure & Flow Adjustment 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex F-5 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 10/JUN/2022 Author(s) MJH Page 2 / 2 Revision 2 ADDITIONAL REPRESENTATIVE LAYOUT (IMAGE BELOW FROM XF050) With the following exceptions, the numbered descriptions apply as per page 1;...

- Page 23 Fluid seen leaking from system Rapid changes in system temperature can cause some materials to change shape at a faster rate than others. Contact ATC to discuss alternative materials and parts in water circuit construction. Check for any error states on the compressor – the controller will indicate if an error has occurred –...

-

Page 24: Document Details

Always clean with power supply isolated. Caution; Never blow out the condenser with compressed air. Caution; If the mains lead is lost or damaged, contact ATC who will be able to supply a replacement of the correct specification. - Page 25 Applied Thermal Control Ltd Operating Manual; Maintenance for Technicians 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex I-1 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 30/AUG/2021 Author(s) MJH Page 1 / 1 Revision 3 GENERIC MAINTENANCE FOR TECHNICIANS Warning;...

- Page 26 Applied Thermal Control (ATC) adheres to and embraces the ethical values that support our everyday activities. As an expression of these principles and ethical values, ATC adheres to the principle of responsible sourcing of components containing precious and non-precious metals and metal salts in compliance with applicable laws and regulations.

- Page 27 Applied Thermal Control Ltd Operating Manual; Declarations & Approvals 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex J-7 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 03/FEB/2021 Author(s) MJH Page 1 / 1 Revision 01 WHAT IS THE REACH REGULATION 1907/2006? REACH is a regulation of the European Union, adopted to improve the protection of human health and the environment from the risks that can be posed by chemicals, while enhancing the competitiveness of the EU...

- Page 28 Applied Thermal Control Ltd Operating Manual; Declarations & Approvals 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex J-8 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 03/FEB/2021 Author(s) MJH Page 1 / 1 Revision 01 WHAT IS THE POPs REGULATION 2019/1021? POPs stands for persistent organic pollutants.

- Page 29 (EEE). RoHS compliance has been required for many years, however in 2014 it became a mandatory requirement under CE Marking. ATC products do not clearly fall within any of the existing categories of equipment, but as of 23/JUL/2019, all EEE not covered falls within scope of the directive. In contrast to RoHS 1, RoHS 2 is a CE marking Directive, and requires, for finished EEE, the use of the CE mark on the product to show compliance.

- Page 30 Applied Thermal Control Ltd Operating Manual; Declarations & Approvals 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex J-12 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 30/AUG/2021 Author(s) MJH Page 1 / 1 Revision 1 UKCA DECLARATION OF CONFORMITY (DoC) Demand The Product Safety and Metrology etc.

- Page 31 Applied Thermal Control Ltd Operating Manual; Declarations & Approvals 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex J-13 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 6/APR/2022 Author(s) MJH Page 1 / 1 Revision 1 EU DECLARATION OF CONFORMITY Document layout;...

-

Page 32: Warranty Terms

ATC’s technical guidance on the web and in the product manual. On occasion, at the discretion of ATC, goods may be serviced on site FOC or a service loan unit may be supplied. - Page 33 Applied Thermal Control Ltd Operating Manual; Recommended Spares 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex M-1 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 23/JUN/2022 Author(s) MJH Page 1 / 2 Revision 2 RECOMMENDED SPARES FOR M, EM- & R05-SERIES CHILLERS Recommended spares include all rotating machinery (i.e.

- Page 34 Applied Thermal Control Ltd Operating Manual; Recommended Spares 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex M-1 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 23/JUN/2022 Author(s) MJH Page 2 / 2 Revision 2 R05-SPECIFIC Description BULKHEAD FITTING –...

-

Page 35: Section 2: Hazards Identification

SAFETY DATA SHEET according to Regulation (EU) 2015/830 Page Harp® 134a Revision Revision date 2017-06-21 SECTION 1: Identification of the substance/mixture and of the company/undertaking 1.1. Product identifier Product name Harp® 134a REACH Registration Number 01-2119459374-33 CAS No. 811-97-2 EC No. 212-377-0 1.2. -

Page 36: Section 3: Composition/Information On Ingredients

Page Harp® 134a Revision Revision date 2017-06-21 2.2. Label elements Signal Word Warning Hazard Statement Compressed gas: H280 - Contains gas under pressure; may explode if heated. Precautionary Statement: P410+P403 - Protect from sunlight. Store in a well-ventilated place. Storage 2.3. -

Page 37: Section 6: Accidental Release Measures

Page Harp® 134a Revision Revision date 2017-06-21 5.3. Advice for firefighters exposed containers. SECTION 6: Accidental release measures 6.1. Personal precautions, protective equipment and emergency procedures Ensure adequate ventilation of the working area. Avoid contact with skin and eyes. Evacuate personnel to a safe area. - Page 38 Page Harp® 134a Revision Revision date 2017-06-21 8.2. Exposure controls 8.2.1. Appropriate engineering Ensure adequate ventilation of the working area. controls 8.2.2. Individual protection Wear protective clothing. measures Eye / face protection Approved safety goggles. Skin protection - Wear suitable gloves. Handprotection Skin protection - Other Wear suitable protective clothing.

- Page 39 Page Harp® 134a Revision Revision date 2017-06-21 9.2. Other information VOC (Volatile organic Not relevant compounds) Conductivity No data available Surface tension No data available Gas group No data available Benzene Content No data available Lead content No data available SECTION 10: Stability and reactivity 10.1.

-

Page 40: Section 13: Disposal Considerations

Page Harp® 134a Revision Revision date 2017-06-21 12.1. Toxicity No data available 12.2. Persistence and degradability Not readily biodegradable. 12.3. Bioaccumulative potential Does not bioaccumulate. Partition coefficient Harp® 134a No data available 12.4. Mobility in soil No data is available on this product. 12.5. - Page 41 Page Harp® 134a Revision Revision date 2017-06-21 14.5. Environmental hazards Environmental hazards Marine pollutant 14.6. Special precautions for user No data is available on this product. 14.7. Transport in bulk according to Annex II of MARPOL 73/78 and the IBC Code No data is available on this product.

- Page 42 Issue 6.4, January 2022 Page 1 of 4 SAFETY DATA SHEET HEXID A4 HEAT TRANSFER FLUID Conforming to Directive 1907/2006/EC SECTION 1: IDENTIFICATION OF THE SUBSTANCE/MIXTURE AND OF THE COMPANY/UNDERTAKING 1.1. Product Name Hexid A4 1.2. Supplier Applied Thermal Control Limited 39 Hayhill Industrial Estate, Barrow upon Soar, Leicestershire, LE12 8LD.

-

Page 43: Personal Precautions

Issue 6.4, January 2022 Page 2 of 4 SAFETY DATA SHEET HEXID A4 HEAT TRANSFER FLUID Conforming to Directive 1907/2006/EC SECTION 6: ACCIDENTAL RELEASE MEASURES 6.1. Personal precautions Use personal protective equipment. Avoid contact with skin and eyes. Keep unnecessary and unprotected personnel from entering the area. -

Page 44: Section 10: Stability And Reactivity

Issue 6.4, January 2022 Page 3 of 4 SAFETY DATA SHEET HEXID A4 HEAT TRANSFER FLUID Conforming to Directive 1907/2006/EC 9.10 Specific Heat Capacity 3.78kJ/kg °K 9.11 Viscosity, Kinetic, at 25°C 3.51mPa.s SECTION 10: STABILITY AND REACTIVITY 10.1. Reactivity Stable under recommended storage conditions. No dangerous reaction known under conditions of normal use. - Page 45 Issue 6.4, January 2022 Page 4 of 4 SAFETY DATA SHEET HEXID A4 HEAT TRANSFER FLUID Conforming to Directive 1907/2006/EC SECTION 12: ECOLOGICAL INFORMATION 12.1. Acute toxicity Fish - LC50 : 40613 mg/l (Oncorhynchus mykiss; 96 h) (static test) Daphnia and other aquatic invertebrates - LC50 : 18340 mg/l (Ceriodaphnia Dubia (water flea); 48 h) (static test) Algae - ErC50 : 19000 mg/l (Pseudokirchneriella subcapitata (green algae);...

Need help?

Do you have a question about the R Series and is the answer not in the manual?

Questions and answers