Table of Contents

Advertisement

Quick Links

Applied Thermal Control Ltd

39 Hayhill Industrial Estate

Installation, Operation & Service Manual

Barrow-upon-Soar, Loughborough

LE12 8LD, United Kingdom

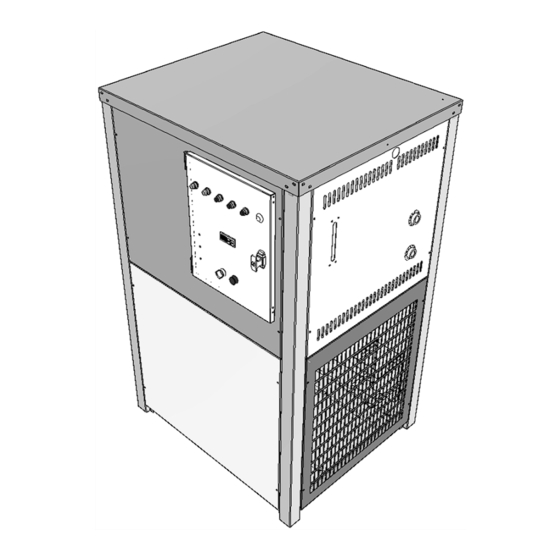

W-Series

+44 (0) 1530 839 998

Service@thermalexchange.co.uk

Support@app-therm.com

DOCUMENT DETAILS

Date 14/JUN/2022

Author(s) MJH

Page 1 / 5

Revision 1

Opening section W-Series

1

Advertisement

Table of Contents

Summary of Contents for ATC W Series

- Page 1 Applied Thermal Control Ltd 39 Hayhill Industrial Estate Installation, Operation & Service Manual Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom W-Series +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 14/JUN/2022 Author(s) MJH Page 1 / 5 Revision 1 Opening section W-Series...

-

Page 2: Change Log

Applied Thermal Control Ltd 39 Hayhill Industrial Estate Installation, Operation & Service Manual Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom W-Series +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 14/JUN/2022 Author(s) MJH Page 2 / 5 Revision 1 CHANGE LOG Date Revision Page ref... -

Page 3: Product Specifications

Applied Thermal Control Ltd 39 Hayhill Industrial Estate Installation, Operation & Service Manual Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom W-Series +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 14/JUN/2022 Author(s) MJH Page 3 / 5 Revision 1 PRODUCT SPECIFICATIONS Enclosure no. -

Page 4: Safety Notices

Warning symbols can be found on the unit. Ensure you have read through all warnings before starting the unit. The safe operation of ATC products always remains the responsibility of the operator. This equipment is intended to be used as a liquid temperature conditioning device – it requires no external pump, nor any further manipulation of temperature. - Page 5 Annex J-9 220406 EU DoC W-Series Annex J-10 201111 EU Compliance Statement RoHS Annex J-14 211124 UKCA DoC W-Series Annex K-1 200623 Standard warranty terms of ATC Annex L-12 220610 Volt Free Contacts Annex L-23 220614 On-off fan control Annex L-51 220614 Remote Stop-Start...

- Page 6 Please check that both the packaging and the unit are undamaged. If there is any doubt, it is vital that you inform both ATC and the carrier. If possible, unpack the unit before signing. Once you have signed for the goods, ATC cannot be held responsible for any transit damage subsequently found.

- Page 7 Current consumption quoted is based on nominal pump sizes described in product specification table. ATC cannot make recommendations for power supply wire gauge nor supply capacity. Follow local regulations and consult trained electricians. The product rating label contains the necessary information.

- Page 8 Caution: Always use ATC recommended fluids in your chiller – many sealing compounds and materials are present and unapproved fluids have the potential to corrode your application and damage seals.

-

Page 9: Hose Recommendations

ATC can offer commercial-grade cleaning solutions – contact us for information. Opaque, ideally black – to inhibit light passing through the tube and algae building up. Alternatively, solid ABS or copper pipe can be used where application chemistry allows. - Page 10 Applied Thermal Control Ltd Operating Manual; Installation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex C-5 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 9/MAR/2022 Author(s) MJH Page 2 / 2 Revision 2 BACKFILLING In situations where the chiller is situated physically lower than the application being cooled, fluid will apply pressure to the water circuit of the product.

- Page 11 Applied Thermal Control Ltd Operating Manual; Installation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex C-6 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 9/MAR/2022 Author(s) MJH Page 1 / 2 Revision 2 INSTALLATION FOR AIR-COOLED UNITS WITH 1/2" BSPPF FITTINGS This guide applies to the following product groups;...

- Page 12 Applied Thermal Control Ltd Operating Manual; Installation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex C-6 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 9/MAR/2022 Author(s) MJH Page 2 / 2 Revision 2 BACKFILLING In situations where the chiller is situated physically lower than the application being cooled, fluid will apply pressure to the water circuit of the product.

- Page 13 ATC can offer commercial-grade cleaning solutions – contact us for information. Opaque, ideally black – to inhibit light passing through the tube and algae building up. Alternatively, solid ABS or copper pipe can be used where application chemistry allows.

- Page 14 Applied Thermal Control Ltd Operating Manual; Installation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex C-8 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 9/MAR/2022 Author(s) MJH Page 2 / 2 Revision 2 BACKFILLING In situations where the chiller is situated physically lower than the application being cooled, fluid will apply pressure to the water circuit of the product.

- Page 15 Applied Thermal Control Ltd Operating Manual; Fluid Handling & Startup Procedures 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex D-7 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 29/NOV/2021 Author(s) MJH Page 1 / 1 Revision 1 FILLING, STARTING &...

-

Page 16: General Navigation

Push the return button for more than 5 seconds. The upper display will show PASS while the lower display will show 0. Using up and down buttons set the programmed password – full access is granted by entering ‘40’. ATC are not responsible for damage either to the chiller or the connected equipment as a result of changing parameters without ATC’s oversight. - Page 17 Applied Thermal Control Ltd Operating Manual; Controller Operation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex E-15G +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 6/APR/2022 Author(s) MJH Page 1 / 2 Revision 2 W-SERIES PROGRAM PURPOSE Internal part number EA902 (24V) &...

- Page 18 Applied Thermal Control Ltd Operating Manual; Controller Operation 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex E-15G +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 6/APR/2022 Author(s) MJH Page 2 / 2 Revision 2 Group ‘tin’ Group ‘PrG’...

- Page 19 Without any relief, it is critical to ensure the pump is not deadheaded (no flow, and no relief). From many years of experience, ATC have found this method of maintaining a high head pressure on the pump to extend the service life and all but eliminate pump leaks. The valve is closed slowly until the desired flowrate or maximum pressure is met for the application, read from the panel- mounted pressure gauge.

- Page 20 Where pressure or flow is too high, the throttling valve can be closed down – where pressure or flow is too low, it can be opened. Typically ATC size pumps to provide some excess pressure availability. Ensure the service pressure gauge is always at a minimum of 2bar.

- Page 21 Applied Thermal Control Ltd Operating Manual; Troubleshooting & Functional Explanations 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex G-15 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 14/JUN/2022 Author(s) MJH Page 1 / 1 Revision 1 TROUBLESHOOTING –...

-

Page 22: Document Details

Always clean with power supply isolated. Caution; Never blow out the condenser with compressed air. Caution; If the mains lead is lost or damaged, contact ATC who will be able to supply a replacement of the correct specification. - Page 23 Applied Thermal Control Ltd Operating Manual; Maintenance for Technicians 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex I-1 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 30/AUG/2021 Author(s) MJH Page 1 / 1 Revision 3 GENERIC MAINTENANCE FOR TECHNICIANS Warning;...

- Page 24 Applied Thermal Control (ATC) adheres to and embraces the ethical values that support our everyday activities. As an expression of these principles and ethical values, ATC adheres to the principle of responsible sourcing of components containing precious and non-precious metals and metal salts in compliance with applicable laws and regulations.

- Page 25 Applied Thermal Control Ltd Operating Manual; Declarations & Approvals 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex J-7 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 03/FEB/2021 Author(s) MJH Page 1 / 1 Revision 01 WHAT IS THE REACH REGULATION 1907/2006? REACH is a regulation of the European Union, adopted to improve the protection of human health and the environment from the risks that can be posed by chemicals, while enhancing the competitiveness of the EU...

- Page 26 Applied Thermal Control Ltd Operating Manual; Declarations & Approvals 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex J-8 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 03/FEB/2021 Author(s) MJH Page 1 / 1 Revision 01 WHAT IS THE POPs REGULATION 2019/1021? POPs stands for persistent organic pollutants.

- Page 27 Applied Thermal Control Ltd Operating Manual; Declarations & Approvals 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex J-9 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 6/APR/2022 Author(s) MJH Page 1 / 1 Revision 1 EU DECLARATION OF CONFORMITY Document layout;...

- Page 28 (EEE). RoHS compliance has been required for many years, however in 2014 it became a mandatory requirement under CE Marking. ATC products do not clearly fall within any of the existing categories of equipment, but as of 23/JUL/2019, all EEE not covered falls within scope of the directive. In contrast to RoHS 1, RoHS 2 is a CE marking Directive, and requires, for finished EEE, the use of the CE mark on the product to show compliance.

- Page 29 Applied Thermal Control Ltd Operating Manual; Declarations & Approvals 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex J-14 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 24/NOV/2021 Author(s) MJH Page 1 / 1 Revision 1 UKCA DECLARATION OF CONFORMITY (DoC) Demand The Product Safety and Metrology etc.

-

Page 30: Warranty Terms

ATC’s technical guidance on the web and in the product manual. On occasion, at the discretion of ATC, goods may be serviced on site FOC or a service loan unit may be supplied. - Page 31 (see below left) OR direct connection to terminal blocks (see below right). Where a D connector is provided, the female gender (ATC PN EA096) is supplied in all cases. If male pins are required, we recommend using a male-to-male gender-changer connector (ATC PN EA853). Pin numbers are clearly marked on the molding.

- Page 32 (that would be used to communicate a refrigerant leak), except the switching pressures are much higher. In the graphic right, ATC’s standard fan speed switch is disengaged below 190psi / 13bar / +31’C (in R407C-type refrigerants). Upon raising the pressure (by starting the compressor or increasing ambient temperature) the high side pressure starts to climb.

- Page 33 Applied Thermal Control Ltd Operating Manual; Standard Options 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex L-51 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 14/JUN/2022 Author(s) MJH Page 1 / 1 Revision 1 SA00051 REMOTE STOP-START This guide may apply to your product if you purchased standard option SA00051.

- Page 34 Applied Thermal Control Ltd Operating Manual; Recommended Spares 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex M-10 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 14/JUN/2022 Author(s) MJH Page 1 / 2 Revision 2 RECOMMENDED SPARES FOR W-SERIES Recommended spares include all rotating machinery (i.e.

- Page 35 Applied Thermal Control Ltd Operating Manual; Recommended Spares 39 Hayhill Industrial Estate Barrow-upon-Soar, Loughborough LE12 8LD, United Kingdom Annex M-10 +44 (0) 1530 839 998 Service@thermalexchange.co.uk Support@app-therm.com DOCUMENT DETAILS Date 14/JUN/2022 Author(s) MJH Page 2 / 2 Revision 2 W32-SPECIFIC W40-SPECIFIC W32N408-SPECIFIC EA882...

-

Page 36: Safety Data Sheet

SAFETY DATA SHEET According to Regulation (EC) No.1907/2006 ® HARP R407C Version: CLP01 Date: July 2012 Page 1 of 8 1. Identification of the substance / preparation and company / undertaking Product name R407C REACH registration numbers 1,1,1,2-Tetrafluoroethane 01-2119459374-33 Pentafluoroethane 01-2119485636-25 Difluoromethane Deadline not yet expired... -

Page 37: Composition / Information On Ingredients

SAFETY DATA SHEET According to Regulation (EC) No.1907/2006 ® HARP R407C Version: CLP01 Date: July 2012 Page 2 of 8 3. Composition / information on ingredients Concentration Substance name CAS No. EC No. Concentration 1,1,1,2-Tetrafluoroethane (R134a) 811-97-2 212-377-0 ca. 52% Pentafluoroethane (R125) 354-33-6 206-557-8... -

Page 38: Accidental Release Measures

SAFETY DATA SHEET According to Regulation (EC) No.1907/2006 ® HARP R407C Version: CLP01 Date: July 2012 Page 3 of 8 Specific hazards arising from the The product is not flammable. Chemical Hazardous decomposition products formed under fire conditions. Special protective actions for Fire- Wear self-contained breathing apparatus and protective suit Fighters Wear chemical resistant oversuit... -

Page 39: Exposure Controls / Personal Protection

SAFETY DATA SHEET According to Regulation (EC) No.1907/2006 ® HARP R407C Version: CLP01 Date: July 2012 Page 4 of 8 8. Exposure controls / personal protection Control parameters Exposure limit values Substance Harp acceptable exposure limit EH40 workplace exposure limits 1,1,1,2-Tetrafluoroethane TWA = 1000 ppm TWA = 1000 ppm / 4240 mg/m... -

Page 40: Stability And Reactivity

SAFETY DATA SHEET According to Regulation (EC) No.1907/2006 ® HARP R407C Version: CLP01 Date: July 2012 Page 5 of 8 Explosive properties Not explosive Vapour pressure 10.35 bar at 20 21.94 bar at 50 C (Pentafluoroethane) Vapour density 3.45 Density Not applicable Relative density 1.17 at 20... -

Page 41: Ecological Information

SAFETY DATA SHEET According to Regulation (EC) No.1907/2006 ® HARP R407C Version: CLP01 Date: July 2012 Page 6 of 8 12. Ecological information Toxicity Fishes Brachydanio rerio LC50 96 h >200 mg/l 1,1,1,3,3- pentafluorobutane Fishes Brachydanio rerio LC50 96 h Ca. -

Page 42: Regulatory Information

SAFETY DATA SHEET According to Regulation (EC) No.1907/2006 ® HARP R407C Version: CLP01 Date: July 2012 Page 7 of 8 IMDG UN number UN 3340 Class IMDG-Labels 2.2 - Non-flammable, non-toxic gas HI/UN No. 3340 F-C, S-V Proper shipping name REFRIGERANT GAS R407C UN number UN 3340... -

Page 43: Other Information

SAFETY DATA SHEET According to Regulation (EC) No.1907/2006 ® HARP R407C Version: CLP01 Date: July 2012 Page 8 of 8 16. Other information Full text of H-Statements referred to under section 3 H220 Extremely flammable gas H280 Contains gas under pressure; may explode if heated This datasheet was prepared in accordance with Regulation (EC) No. - Page 44 Issue 6.4, January 2022 Page 1 of 4 SAFETY DATA SHEET HEXID A4 HEAT TRANSFER FLUID Conforming to Directive 1907/2006/EC SECTION 1: IDENTIFICATION OF THE SUBSTANCE/MIXTURE AND OF THE COMPANY/UNDERTAKING 1.1. Product Name Hexid A4 1.2. Supplier Applied Thermal Control Limited 39 Hayhill Industrial Estate, Barrow upon Soar, Leicestershire, LE12 8LD.

- Page 45 Issue 6.4, January 2022 Page 2 of 4 SAFETY DATA SHEET HEXID A4 HEAT TRANSFER FLUID Conforming to Directive 1907/2006/EC SECTION 6: ACCIDENTAL RELEASE MEASURES 6.1. Personal precautions Use personal protective equipment. Avoid contact with skin and eyes. Keep unnecessary and unprotected personnel from entering the area.

- Page 46 Issue 6.4, January 2022 Page 3 of 4 SAFETY DATA SHEET HEXID A4 HEAT TRANSFER FLUID Conforming to Directive 1907/2006/EC 9.10 Specific Heat Capacity 3.78kJ/kg °K 9.11 Viscosity, Kinetic, at 25°C 3.51mPa.s SECTION 10: STABILITY AND REACTIVITY 10.1. Reactivity Stable under recommended storage conditions. No dangerous reaction known under conditions of normal use.

- Page 47 Issue 6.4, January 2022 Page 4 of 4 SAFETY DATA SHEET HEXID A4 HEAT TRANSFER FLUID Conforming to Directive 1907/2006/EC SECTION 12: ECOLOGICAL INFORMATION 12.1. Acute toxicity Fish - LC50 : 40613 mg/l (Oncorhynchus mykiss; 96 h) (static test) Daphnia and other aquatic invertebrates - LC50 : 18340 mg/l (Ceriodaphnia Dubia (water flea); 48 h) (static test) Algae - ErC50 : 19000 mg/l (Pseudokirchneriella subcapitata (green algae);...

Need help?

Do you have a question about the W Series and is the answer not in the manual?

Questions and answers