Table of Contents

Advertisement

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

Artisan Technology Group

new and certified-used/pre-owned equipment

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

View

Instra

REMOTE INSPECTION

SM

Remotely inspect equipment before purchasing with

www.instraview.com

our interactive website at

Contact us:

(888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

is your source for quality

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at

information on price quotations, drivers, technical

specifications, manuals, and documentation

www.artisantg.com

for more

Advertisement

Table of Contents

Summarization of Contents

Safety Information

Obligation to Provide Information

User must read and follow operating instructions for safe operation.

Safety Level Definitions

Defines DANGER, WARNING, CAUTION, NOTICE for hazard communication.

0 Important Safety Information

0.1 Mechanical Hazards

Details hazards related to mechanical aspects of the pump system.

0.2 Electrical Hazards

Details hazards related to electrical connections and components.

0.3 Hazards Caused by Materials and Substances

Details hazards from handling specific materials and substances.

0.4 Danger of Damages to the Pump System

Details potential damages to the pump system and how to avoid them.

Description

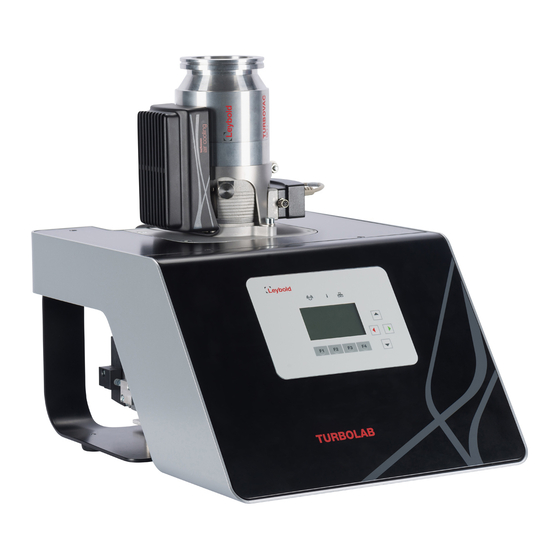

1 Description

Introduces the TURBOLAB pump systems as vacuum units.

1.1 Design

Details the components that make up the TURBOLAB pump systems.

1.2 Standard Specification

Outlines the standard components supplied with the pump system.

1.3 Technical Data

Provides technical specifications for pumps and systems.

1.3.1 Backing pumps

Provides technical data for various backing pump types.

1.3.2 Pump systems

Provides technical data for different TURBOLAB pump system configurations.

1.4 Ordering Information

Lists part numbers for various TURBOLAB system configurations.

1.5 Accessories

Lists available accessories and their part numbers.

Transport and Storing

2 Transport and Storing

Instructions for safe handling, transport, and storage of the pump system.

Installation

3 Installation

General guidance on installing the TURBOLAB pump system.

3.1 Placement

Guidance on selecting an appropriate location for installing the pump system.

3.2 Conforming Use

Defines the intended applications and limitations of the pump systems.

3.3 Ambient Conditions

Specifies environmental conditions suitable for pump operation.

3.4 Installing the Backing Pump

Instructions for connecting and installing the backing pump.

3.5 High Vacuum Connection

Instructions for establishing the high vacuum connection to the pump.

3.5.1 Removing the TURBOVAC Pump from the Pump System

Procedure for detaching the TURBOVAC pump from the system.

3.6 Connecting the Exhaust Line

Guidance on connecting the exhaust line from the backing pump.

3.7 Connect the Cooling

Instructions for connecting cooling systems (air/water) for the pump.

3.7.1 Cooling Water

Specifications and guidelines for cooling water quality and connection.

3.8 Connect a Power Failure Venting Valve or a Venting Valve

Instructions for connecting venting valves.

3.9 Connect Purge Gas

Instructions for connecting purge gas systems.

3.10 Connect a Flange Heater

Instructions for connecting a flange heater for bakeout.

3.11 Connect a Gauge

Instructions for connecting vacuum gauges.

3.12 Connect a PC/Mobile Device

Instructions for connecting a PC or mobile device for control.

3.13 Electrical Connection

Instructions for making the main electrical connections to the pump system.

Operation

4 Operation

Overview of operating the TURBOLAB pump system.

4.1 Media Compatibility / Purge Gas

Information on compatible media and purge gas usage.

4.2 Interfaces

Details the available interfaces and their functions.

4.3 Switching On

Steps to safely switch on the pump system.

4.4 Operation

Detailed operational procedures and system controls.

4.4.1 Menu

Overview of the main menu structure and navigation.

Turbopump menu

Details on configuring turbopump start functions and parameters.

Gauges menu

Details on configuring vacuum gauges and their settings.

Parameter menu

Information on accessing and changing system parameters.

System menu

Details on system settings like language, clock, and network.

4.4.2 Function Codes of the Accessory Connections

Explains function codes for accessory outputs (e.g., Fan).

Function X204 Purge gas valve

Details function codes for the purge gas valve.

Function X203 Venting valve

Details function codes for the venting valve.

Functions 24VDC Output backing pump (X206, X210, X211)

Explains function codes for 24VDC backing pump outputs.

Function pressure dependent switch-on of the turbo pump

Details pressure-dependent start-up for the turbo pump.

4.4.3 Relay Functions

Explains normal operation, error, and warning relay functions.

4.4.4 Parameter list

Lists and defines various operational parameters.

4.4.5 Monitoring of the Operation Conditions

Explains how to interpret LED status indicators for operation monitoring.

4.5 Shut-down

Procedures for safely shutting down the pump system.

4.6 Venting

Methods and considerations for venting the pump system.

4.7 Bakeout

Instructions for performing bakeout procedures on the pump.

4.8 Webserver

Instructions for connecting and using the webserver interface.

Start Screen

Overview of the start screen for pump operation and control.

LCD View

How to view pump system information via the web server.

Error Memory

How to access and interpret the pump's error log.

DataViewer

Tool for analyzing and visualizing recorded pump data.

Establishing the Link

Steps to establish a connection with the pump system via IP address.

Configuration Menu

How to change accessory functions and save settings.

X1 Interface (Menu I/O X1)

How to configure relay functions and analog outputs for the X1 interface.

Gauges

Details on selecting gauge units, types, and correction factors.

Turbomolecular pump (Menu TMP)

Options for starting the turbomolecular pump based on command or pressure.

Parameters

How to select and change parameters using the menu.

System Menu

User profile management for the web server.

File Upload

Instructions for loading or removing files, including software updates.

Data List

How to view and interpret recorded data points.

Logging Cycle

Information on setting the data logging interval.

Maintenance

5 Maintenance

Recommendations for maintenance and service of the pump system.

Rotor exchange

Information on rotor unit exchange and Leybold Service.

Purge gas filter

Maintenance for the purge gas filter, including exchange intervals.

Adsorption trap

Maintenance for adsorption traps, including regeneration and renewal.

5.1 Cleaning

Instructions for cleaning the pump system surfaces.

Cleaning the frequency converter internally

Internal cleaning of the frequency converter by Leybold Service.

Cleaning the TURBOVAC internally

Internal cleaning of the TURBOVAC, including bakeout.

5.2 Oil of the Rotary Vane Pump

Guidelines for checking and changing the rotary vane pump oil.

5.3 Removing the Backing pump

Steps for detaching and removing the backing pump.

5.4 Leybold Service

Procedures for sending equipment for service, including contamination declaration.

Troubleshooting

6 Troubleshooting

Guidance for diagnosing and resolving pump system issues.

Error Code Reference

Lists error codes, designations, possible causes, and remedies.

Disposal

7 Waste Disposal

Information and procedures for waste disposal of the equipment.

Contamination

Procedures for decontaminating equipment before disposal or service.

Disposal of Waste Oil

Guidelines for the proper disposal of waste oil.

EU Declaration of Conformity

EU Declaration of Conformity

States compliance with EU directives and harmonized standards.

Sales and Service Locations

Global Sales and Service Network

Lists contact information for Leybold offices worldwide.

Need help?

Do you have a question about the TURBOLAB 90 and is the answer not in the manual?

Questions and answers