Summarization of Contents

INTRODUCTION

MANUAL USE MODES

Explains technical terms for installers, assuming end-user knowledge.

LIMITATIONS

Refers to general Virtual Terminal assembly; specific models are not mentioned unless installation is specific.

RESPONSIBILITY

Outlines installer's duties for proper installation and component compatibility.

5 POSITION ON FARMING MACHINE

5.1 System recommended composition

Guides on selecting correct connection cables based on system variants and nozzle count.

6 WIRING CONNECTIONS

6.1 General precautions for a correct harness position

Guidelines for securing and routing cables to prevent damage and water infiltration.

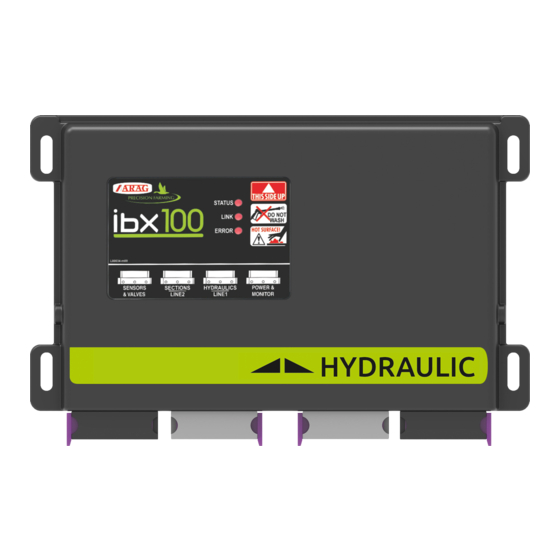

6.2 Control unit (ECU) connection

Instructions for connecting the ECU, emphasizing ISOBUS connection timing and connector handling.

7 ISOBUS SYSTEM CABLE CONNECTION

7.1 In-cab cable connection

Instructions for connecting the in-cab cable, including ring nut tightening.

7.2 ISOBUS cable connection

Instructions for connecting the ISOBUS cable, ensuring proper connection and locking.

8 INTRODUCTION

8.1 "OBJECT POOL" loading

Explains how to display the OP selection page and load the ECU OP.

9 SETUP

9.1 Tests and checks before programming

Lists checks to perform before programming: component installation, power, and connections.

9.2 Command location

Explains the function of menu navigation buttons and confirmation actions.

10 IMPLEMENT SETTINGS > BASIC SETTINGS

Sprayer technology

Defines options for sprayer technology: electric-activated valves or Seletron valves.

Main valve type

Specifies options for the main control valve: None, 2-way, or 3-way.

Spraying spot type

Defines the type of Seletron units: single, twin, or fourfold.

Flowrate reference sensor

Explains the role of flowmeter and pressure sensor in calculating application rate.

Terminal nozzle type

Describes "Buffer zone" and "Fence" functions for enabling specific nozzle types.

Tank level source

Specifies the device used for reading tank level: manual, filling flowmeter, or level sensor.

11 IMPLEMENT SETTINGS > ADVANCED SETUP

Access to Implement Settings Menu

Shows how to navigate to the Implement Settings menu.

Implement Settings - Menu Structure

Outlines the structure of the Implement Settings menu, showing editable and non-editable items.

11.9 Device calibration

11.9.1 Press. sensor zero value

Procedure for zero calibration of the pressure sensor to ensure accurate readings.

12 DATA AND SETTINGS

12.1 Manage presets

Allows setting and activating up to 20 different treatment configurations (Presets).

12.7 System status

12.7.1 Device status

Displays detailed system information, including sensor signals, power consumption, and versions.

13 SELETRON CONNECTION

Seletron status

Displays Seletron status and connection diagnostics, with color legend for operation status.

Connection sequence for single and twin Seletron devices

Step-by-step guide for connecting single and twin Seletron devices sequentially.

Connection sequence for fourfold Seletron devices

Step-by-step guide for connecting fourfold Seletron devices sequentially.

NOZZLES FOR "Buffer zone"

Instructions on connecting Seletron units for "Buffer zone" applications.

"Fence" NOZZLES

Instructions on connecting Seletron units for "Fence" nozzle applications.

13.2 SELETRON REPLACEMENT

13.2.1 Preliminary Operations

Prepares the system for Seletron replacement, ensuring safety and activating specific settings.

13.2.2 Replacement procedure

Procedure for replacing Seletron devices, including disconnection of incorrectly paired units.

14 USE

14.1 "HOME" main screen

Overview of the "HOME" main screen, its buttons, and displayed items.

15 JOB FUNCTIONS

15.1 Output temporary increase and decrease - Change target rate

How to change the spray rate value for the job on the "Home" screen.

15.2 Alarms

Displays a summary of active alarm notifications for operators.

15.3 Automatic functions

15.3.1 Application rate regulation

Enables/disables automatic output adjustment based on speed and boom status.

15.3.2 Test speed

Allows enabling/disabling speed simulation for regulation tests with a stopped machine.

15.5 Main control and section management

15.5.1 Controls WITH Auxiliary Input

Refers to user manual for controls with Auxiliary Input.

15.5.2 Controls WITHOUT Auxiliary Input

Explains how valves are controlled directly via the monitor touch-screen panel without Auxiliary Input.

16 MAINTENANCE / DIAGNOSTICS / REPAIRS

16.1 Cleaning rules

Guidelines for cleaning the control unit using a soft cloth and avoiding direct water jets.

16.2 Key to LED status

Explains the meaning of LED colors (green, yellow, red) and their flashing patterns for status indication.

Need help?

Do you have a question about the IBX100 4679005 and is the answer not in the manual?

Questions and answers