ARAG IBX100 Installation - Use - Maintenance

Electronic control unit

Hide thumbs

Also See for IBX100:

- Installation, use and maintenance manual (76 pages) ,

- Installation - use - maintenance (60 pages) ,

- Directions for installation, use and maintenance (56 pages)

Subscribe to Our Youtube Channel

Summary of Contents for ARAG IBX100

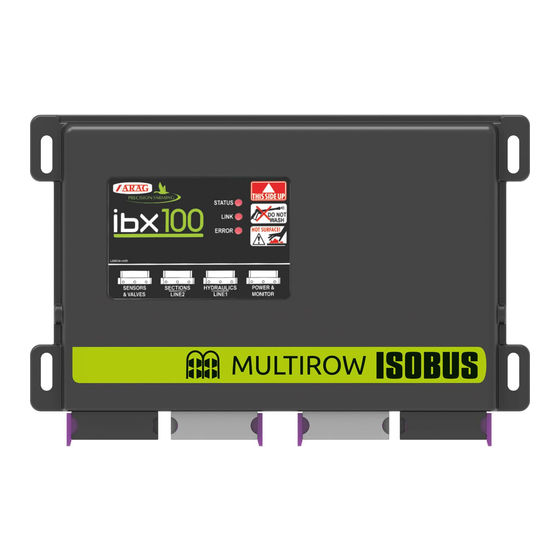

- Page 1 IBX100 ELECTRONIC CONTROL UNIT 4679006 Object Pool rel. 2.5.x INSTALLATION, USE AND MAINTENANCE...

- Page 2 This manual is an integral part of the equipment to which it refers and must accompany the equipment in case of sale or change of ownership. Keep it for any future reference; ARAG reserves the right to modify product specifications and instructions at any moment and without notice.

-

Page 3: Table Of Contents

18.4.4 Restore config from last import ........53 6 Wiring connections ..........12 18.4.5 Import configuration ............53 General precautions for a correct harness position ..12 18.4.6 Reset to Arag factory defaults ......... 54 Control unit (ECU) connection ........12 18.5 Registration..............54 Sensor connection ............13... -

Page 4: Risks And Protections Before Assembly

• RESPONSIBILITIES The installer must carry out "workmanlike" installations and ensure to the end user the perfect operation of the whole system both with ARAG components only and other brands' components. ARAG always recommends using its components to install control systems. -

Page 5: Position On Farming Machine

INSTALLATION POSITION ON FARMING MACHINE System recommended composition WARNING: DO NOT CONNECT ISOBUS CONNECTOR (Chap. 7 on page 15) THIS CONNECTION MUST BE CARRIED OUT LATER, ONLY AFTER INSTALLING ALL THE COMPONENTS. WARNING: DO NOT CONNECT THE MOTOR ENABLING CABLE (BLUE WIRE CONNECTION). THIS CONNECTION SHOULD ONLY BE MADE LATER DURING THE MOTOR ID ASSIGNMENT PHASE. - Page 6 INSTALLATION 5.1 System recommended composition > > > WARNING: DO NOT CONNECT ISOBUS CONNECTOR (Chap. 7 on page 15) THIS CONNECTION MUST BE CARRIED OUT LATER, ONLY AFTER INSTALLING ALL THE COMPONENTS. WARNING: DO NOT CONNECT THE MOTOR ENABLING CABLE (BLUE WIRE CONNECTION). THIS CONNECTION SHOULD ONLY BE MADE LATER DURING THE MOTOR ID ASSIGNMENT PHASE.

- Page 7 INSTALLATION 5.1 System recommended composition > > > WARNING: DO NOT CONNECT ISOBUS CONNECTOR (Chap. 7 on page 15) THIS CONNECTION MUST BE CARRIED OUT LATER, ONLY AFTER INSTALLING ALL THE COMPONENTS. WARNING: DO NOT CONNECT THE MOTOR ENABLING CABLE (BLUE WIRE CONNECTION). THIS CONNECTION SHOULD ONLY BE MADE LATER DURING THE MOTOR ID ASSIGNMENT PHASE.

- Page 8 THIS CONNECTION MUST BE CARRIED OUT LATER, ONLY AFTER INSTALLING ALL THE COMPONENTS. WARNING: DO NOT CONNECT IBX100 ADAPTER CABLE FOR SEED SENSOR SMART CABLE TO IBX100. THIS CONNECTION SHOULD ONLY BE MADE LATER DURING THE SEED SENSOR ID ASSIGNMENT PHASE.

- Page 9 INSTALLATION 5.1 System recommended composition > > > WARNING: DO NOT CONNECT ISOBUS CONNECTOR (Chap. 7 on page 15) THIS CONNECTION MUST BE CARRIED OUT LATER, ONLY AFTER INSTALLING ALL THE COMPONENTS. WARNING: DO NOT CONNECT THE CAN BUS SEED SENSORS TO HARNESS CABLE BRANCHES. THIS CONNECTION SHOULD ONLY BE MADE LATER DURING THE SEED SENSOR ID ASSIGNMENT PHASE.

-

Page 10: Control Unit Fixing

INSTALLATION Control unit fixing Secure the control units on the back of the machine, close to the seeding rows. Consider all necessary connections of the device , the cable length, and make sure there is enough space (par. 5.3 on page 11) for connectors and cables. -

Page 11: Wiring Harness Connection

Auxiliary sensors + electric motor BUS and seed sensors Standard ISOBUS connector (ISOBUS PLUG) Fig. 10 IBX100 PLANTER (HYDRAULIC MOTORS WITH ARAG SMART CABLE) CONNECTION POINTS Auxiliary sensors / hydraulic motors / hyd motors feedback sensors Smart cable for seed sensors Smart cable for seed sensors... -

Page 12: Wiring Connections

• Use of unsuitable cables not provided by ARAG automatically voids the warranty. • ARAG is not liable for any damage to the equipment, persons or animals caused by failure to observe the above instructions. General precautions for a correct harness position •... -

Page 13: Sensor Connection

Harness cables are marked with a symbol denoting their functions: please see the table for correct harness connection. Use ARAG sensors: use of unsuitable sensors not provided by ARAG automatically voids the warranty. ARAG is not liable for damage to the equipment, persons or animals caused by failure to observe the above instructions. ITEM... - Page 14 INSTALLATION Hydraulic valve connection The system can control up to 9 hydraulic functions through double action valves. Fix the connectors to the relevant valves according to the initials indicated in your planter general diagram. • Position seal ( ) onto connector ( ), then connect the latter pressing it fully home ( during this operation, take special care not to bend valve electric contacts.

-

Page 15: Isobus System Cable Connection

Use the cable supplied in the auxiliary input package: ARAG Auxiliary Input control system is not compulsory on all systems, and must thus be ordered separately. Some Virtual Terminals allow controlling seeding rows switching on/off directly from monitor touch-screen panel. -

Page 16: "Object Pool" Loading

OBJECT POOL LOADING “OBJECT POOL” LOADING Images and the relevant description texts contained in this manual are given as a reference as they can vary depending on the Virtual Terminal used. If the descriptions do not correspond to the text displayed in your Virtual Terminal, refer to the manual attached to the latter. -

Page 17: Control Layout

USING THE KEYS CONTROL LAYOUT Goes back to main screen Goes back to previous menu, or scrolls the pages of a menu (previous page) Scrolls the pages of a menu (next page) Saves the changes to current page Fig. 21 Quits without confirming the changes Saves the changes Fig. -

Page 18: Home

HOME HOME MENU SELECTION BUTTONS 1 Menu 2 Info and alarms 3 Preload Percentage rate control of every single row. Manage Control present only if previously activated in the menu presets > Seed rate mode Tramline activation / deactivation. Working Control present only if previously activated in the menu parameters >... -

Page 19: Implement Settings

: seed sensors with CAN BUS output with ARAGNET protocol. Seed Sensors - Arag : seed sensors with output in frequency connected to ARAG SMART cable code 46707B1x1.100. ARAG SMART cable : seed sensors with output in frequency directly connected to the electric motor. - Page 20 IMPLEMENT SETTINGS 12.1 Basic setting > > > 5 / 11 : type of seeding output control. Motor type Seed control setup Hydraulic - PWM valve Electric - DMD 0 Electric - DMD 2 Electric - ECM42x30 / I+i42 Electric - DMD 2 - 110 Control of an oil-hydraulic proportional valve for the management of...

-

Page 21: Rows Configuration

IMPLEMENT SETTINGS 12.2 Rows configuration Allows setting the data relevant to the planter configuration: Read-only item defined in the menu: 1 / 11 Basic Setting > Total number of rows Enables / disables a row for the entire spraying regardless of the status of the seeding rows set during the job. -

Page 22: Vacuum Sensor

IMPLEMENT SETTINGS 12.4 Vacuum sensor Allows setting the vacuum sensor parameters: 1 / 1 Enables / disables the vacuum sensor. Status : rated value relevant to sensor full scale. Full scale : vacuum threshold outside which the system will signal an alarm (par. -

Page 23: Seed Control Setup

IMPLEMENT SETTINGS 12.6 Seed control setup 1/4 ELECTRIC MOTOR 1/4 HYDRAULIC MOTOR Fig. 31 Fig. 32 Type of motor selected for seeding output control (Chap. 12.1 on page Type of motor selected for seeding output control (Chap. 12.1 on page ... - Page 24 15 on page 45 Electric motor problem (Under tolerance/Above tolerance). The motor rotation speed (RPM) is determined by the IBX100 control unit. It allows distributing the seeds according to the working parameters set by the user together with the speed of the vehicle.

-

Page 25: Granular 1 Control Setup / Granular 2 Control Setup

IMPLEMENT SETTINGS 12.7 Granular 1 control setup / Granular 2 control setup ELECTRIC MOTOR HYDRAULIC MOTOR Fig. 35 Fig. 36 Type of motor selected for granular product 1 / 2 output control (Chap. 12.1 on page 19) Type of motor selected for granular product 1 / 2 output control ... - Page 26 Electric motor problem (Under tolerance/Above tolerance). The motor rotation speed (RPM) is determined by the IBX100 control unit. It allows distributing the granular product according to the working parameters set by the user together with the speed of the vehicle.

-

Page 27: Rev Counter

Tractor-ECU that detects the data sent by the radar installed on the tractor. NOTE: Tractor-ECU can be a standard ECU in the ISOBUS tractor, installed by the after-sales service (ARAG IBX20 TECU) or emulated by the VT in the cabin. -

Page 28: Pressure Sensor

IMPLEMENT SETTINGS 12.10 Pressure sensor 1 / 1 Enables / disables the pressure sensor. Status : full scale value present on sensor label. The value must be provided by the sensor manufacturer. Full scale : threshold outside which the system triggers an alarm (Chap. -

Page 29: System Configurations

If it does not have it (total number of sequential switches 2) choose NO. Item available for sequential type control panel ONLY. Joystick Tractor joystick Select the option if it is Arag. All the other joysticks from third parties need the option. Joystick Tractor joystick Hydraulic only HYDR INP : Select the number of hydraulic sections connected to the system. - Page 30 ARAG default functions. Enable Arag preferred assignments Item NOT available for Tractor joystick option. : The VT assigns to each function of the IBX100 a control of the Auxiliary input Enable auxiliary inputs ...

-

Page 31: Device Calibration

: enter the number of seconds after which the alarm will be displayed, which is Curvature wheel sensor problem Sensor alarm delay shown when one of the two sensors sends no data to IBX100. : current left wheel speed. Left wheel speed : current right wheel speed. -

Page 32: Row Reduction Configuration

IMPLEMENT SETTINGS 12.15 Row reduction configuration It allows setting the data relevant to the configuration of the planter when you want to use a reduced number of rows compared to those available in the planter. 2 / 11 This menu is displayed only if the following function has been enabled: Basic Setting >... -

Page 33: Manage Presets

MANAGE PRESETS MANAGE PRESETS This menu allows: - Set 8 different treatment configurations: Preset - Activating one configuration among the preset ones. - Consult job data of the treatment selected: Preset - Perform the calibration procedure of granular products. Fig. 45 Seed target rate Granular 1/2 number... -

Page 34: Seed Rows Target Rate And Units Setting

MANAGE PRESETS 13.1 Seed rows target rate and units setting Select the seed rate mode you want to use : enter the seed target rate value in the next • Single rate item to apply that value to all rows. : it is possible to set seed target rate for •... -

Page 35: Seed Setting And Distributor Check

MANAGE PRESETS 13.2 Seed setting and distributor check Type in the job program name. Enter the value relevant to the space between the rows. Enter the number of holes present in the seeding spinner. Enable this function if you want to use the planter in row reduction configuration: the device displays only the rows you want to use in the working page. -

Page 36: Start Distributor Check

MANAGE PRESETS 13.3 Start distributor check This function allows operating only one motor to perform checks on proper distributor operation (e.g. doubles selector adjustment). - Insert the seeds in the tank. WARNING: DURING THE CHECK PAY ATTENTION TO THE MOVING PARTS. Use buttons 3, 4, 6 and 7 to select on which rows to operate the motor and thus perform the check. -

Page 37: Preset Totals - Preset Averages For Seed

MANAGE PRESETS 13.4 Preset totals - Preset averages for seed Allows displaying and deleting the seed data of the selected. Preset Fig. 53 - Select the Preset - Use the keys to scroll the pages: Preset totals - Preset averages - Use key to delete job data;... -

Page 38: Granular 1 And 2 Setting

MANAGE PRESETS 13.5 Granular 1 and 2 setting Granular 1 / Granular 2 Characteristics to set for granular product 1 and 2: Enable this function to indicate a more accurate target rate value using decimal values. Enter granular product rate value. Fig. -

Page 39: Start Calibration Granular 1 / Granular 2

MANAGE PRESETS 13.6 Start calibration granular 1 / granular 2 - Insert the granular product in the tank. - Select the type of control to check calibration parameters (par. 12.7 on page 25) WARNING: DURING CALIBRATION PAY ATTENTION TO THE MOVING PARTS. To perform the constant calculation it is necessary to deliver and weigh the product. - Page 40 MANAGE PRESETS THE VALUE TO BE ENTERED MUST CORRESPOND TO THE DETECTED WEIGHT OF PRODUCT DISTRIBUTED FROM A SINGLE ROW. Confirm. Fig. 59 Save calibration. Fig. 60...

-

Page 41: Preset Totals - Preset Averages Of Granular 1 And 2

MANAGE PRESETS 13.7 Preset totals - Preset averages of granular 1 and 2 Allows displaying and deleting the granular product data of the selected. Preset Fig. 61 - Select the Preset - Use the keys to scroll the pages: Preset totals - Preset averages - Use key to delete job data;... -

Page 42: Working Parameters

WORKING PARAMETERS WORKING PARAMETERS Allows setting the working parameters required by the user. Fig. 62 Enables / disables the automatic control of the seeding output. Enables / disables the automatic control of Granular product 1 output. ... -

Page 43: Tramline Configuration

2-3-4 Enter the allowed overlapping percentage (percentage value of space between rows). If the automatic tramline calculation, carried out by IBX100, defines that a seed row will be overlapped by the sprayer wheel, if this overlapping is lower than the percentage entered here, the row will remain open. - Page 44 Enter the number of sprays you want to use to program Tramline (the number of programmed sprays will be then cyclically and automatically repeated by IBX100). Accesses the configuration page of Tramline program. Fig. 67 Displays the number of the current spray you are programming.

-

Page 45: Info & Alarms Setup

( Fig. 57 on page 39 Enables / disables the alarm when a sensor loses communication with the IBX100 control unit. Enables / disables the alarm when the sensor has been restarted by the system. - Page 46 24-25 Enables / disables the alarm when the value is outside the set threshold (par. 12.8 on page 27) ECU alarm: Enables / disables a generic error alarm relevant to the IBX100 control unit. Fig. 75...

-

Page 47: Job Data

JOB DATA JOB DATA Allows consulting treatment total data. Fig. 76 Scroll the pages: Seed - Granular 1 - Granular 2 Resets job data. BUTTON PRESENT ONLY IF THE FUNCTION IS NOT ACTIVE. (TC-BAS) Fig. 77... -

Page 48: Capacity

CAPACITY CAPACITY Allows checking system performance based on machine configurations. Fig. 78 - Use the keys 1 to scroll the pages 1/2 and 2/2. - Use the keys 2 to scroll the pages: Seed controller - Granular 1 controller - Granular 2 controller - Press 3 and 4 to increase or decrease the simulated speed. -

Page 49: System

SYSTEM SYSTEM Allows checking the IBX100 system parameters. Fig. 80 1 Press Restart ECU button to restart ECU and confirm the control unit restart. Fig. 81 18.1 Device status Fig. 83 Fig. 84 1 Sensor references on page 8 - Sensor 1: HS... -

Page 50: Isobus

: IBX100 will use the data contained in the relevant messages, regardless of the source they come from. TECU : IBX100 will only use the message coming from the Tractor ECU present in the system. : IBX100 will only use the message coming from the Virtual Terminal present in the system. Fig. 85 It displays information about the File Server function if it is also available in the connected Virtual Terminal. -

Page 51: System Settings

The IBX100 will restart. The button is only visible if a backup file was previously created and saved to the internal memory of IBX100 using the button Save active config [ECU] (see par. 18.4.1 All settings in the application menu at the time of reset WILL BE PERMANENTLY LOST. -

Page 52: Export Saved Configuration [Ecu] (This Button Is Present Only If The Vt Supports The File Server Feature)

18.4.3 (this button is present only if the VT supports the File server feature) Export saved configuration [ECU] Allows exporting the backup file present in the internal memory of IBX100, previously saved via the button. Save active config [ECU] Press... -

Page 53: Restore Config From Last Import

List of files contained within the current folder. In order to be loaded, the backup file must have the extension .bak and must be inside the folder MCMC0258. This folder refers to ARAG because 0258 is the code that identifies ARAG as the ISOBUS component manufacturer. -

Page 54: Reset To Arag Factory Defaults

SYSTEM 18.4.6 Reset to Arag factory defaults Allows resetting the factory settings in the IBX100 menu. Press Reset to Arag factory defaults to reset the IBX100 configuration to factory settings. All settings in the application menu at the time of reset WILL BE PERMANENTLY LOST. -

Page 55: Seed Sensor Status

SYSTEM 18.6 Seed sensor status This menu has two main functions: INSTALLATION Allows displaying the progress during seed sensor pairing procedure (Chap. 20 on page 57) DIAGNOSTICS Allows checking the connection of each single seed sensor (Chap. 20 on page 57) par. -

Page 56: User Preferences

• : allows configuring both the machine features and Technician the treatment: an access PIN can be set. • : for ARAG staff, only. ARAG Tech Fig. 99 Set the full scale for speed displayed in HOME job screen. Select the job data displayed on the RIGHT side of HOME job screen. -

Page 57: Connection Of Seed Sensors

CONNECTION OF SEED SENSORS CONNECTION OF SEED SENSORS PROCEDURE VALID ONLY IF “seed sensors - ARAG” HAS BEEN SELECTED IN THE BASIC SETTING PLEASE CAREFULLY FOLLOW THE INSTRUCTIONS PROVIDED IN THIS CHAPTER. ANY MISTAKES DURING SEED SENSOR PAIRING/REPLACEMENT MAY LEAD TO SYSTEM OPERATION FAILURE. -

Page 58: Reset Seed Sensor Can Ids

CONNECTION OF SEED SENSORS Baptism procedure of each single seed sensor with completed with positive outcome. Fig. 103 20.1 Reset seed sensor CAN IDs Allows resetting the identification numbers of all saved sensors, before repeating the pairing procedure (Chap. 20 on page 57) TO PREVENT SYSTEM MALFUNCTIONS, THIS OPERATION MUST BE CARRIED OUT ONLY IF STRICTLY NECESSARY Press key to delete identification numbers. -

Page 59: Motor Connection: Seeding And Granular Product Lines

MOTOR CONNECTION: SEEDING AND GRANULAR PRODUCT LINES MOTOR CONNECTION: SEEDING AND GRANULAR PRODUCT LINES PLEASE CAREFULLY FOLLOW THE INSTRUCTIONS PROVIDED IN THIS CHAPTER. ANY MISTAKES DURING MOTOR PAIRING/REPLACEMENT MAY LEAD TO SYSTEM OPERATION FAILURE. In the example indicated below machinery setup features 6 seeding rows and 2 motors for each granular product. •... -

Page 60: Detailed Motor Status

MOTOR CONNECTION: SEEDING AND GRANULAR PRODUCT LINES Seeding rows Seeding rows Granular 1 Granular 1 Granular 2 Granular 2 Baptism procedure of each single seeding and granular product motor completed with positive outcome. In the example indicated machinery setup features 6 seeding rows and 2 motors for each granular product. -

Page 61: Restart Electric Motors

MOTOR CONNECTION: SEEDING AND GRANULAR PRODUCT LINES 21.2 Restart electric motors Access the menu: Menu > System > Restart electric motors Fig. 109 Press to restart all motors: - seeding lines - for granular products. Press key to confirm. Fig. 110... -

Page 62: Upgrade Motor Firmware

MOTOR CONNECTION: SEEDING AND GRANULAR PRODUCT LINES 21.3 Upgrade motor firmware The internal memory of IBX100 contains the motor firmware validated with the version in use of IBX100 ISOBUS PLANTER application. Select " " to access the screen to check the current Upgrade motor firmware firmware version present in motors currently connected to IBX100. -

Page 63: Connection Of Seed Sensors

CONNECTION OF ARAG SMART CABLE FOR SEED SENSORS AND ROW SHUT-OFF DEVICES CONNECTION OF SEED SENSORS PLEASE CAREFULLY FOLLOW THE INSTRUCTIONS PROVIDED IN THIS CHAPTER. ANY MISTAKES DURING SEED SENSOR PAIRING/REPLACEMENT MAY LEAD TO SYSTEM OPERATION FAILURE. • Disconnect connector number 1 Fig. -

Page 64: Use

DISPLAY ITEMS Automatic row management ON/ OFF (TC-SC) Check of job counters ON / OFF (TC-BAS) Variable application ON/OFF (TC-GEO) ISOBUS lift switch (only present if 3-point hitch position [via ISOBUS] Auxiliary Input ON/OFF Lift switch (only present if " "... -

Page 65: Info And Alarms

INFO AND ALARMS - PRELOAD INFO AND ALARMS Info and alarms Allows displaying alarm notifications. Fig. 114 For the procedure to be followed when an alarm occurs, please refer to par. 32.3 on page 74 Enabled alarm. Alarm corrected. Fig. 115 PRELOAD Preload Allows pre-loading the seeds and the granular product 1 and 2 to start the... -

Page 66: Operating Modes

PRELOAD 24.1 Operating modes To preload each distributor for seed and granular products (if any), press and hold “ ” (Fig. 116). Preload The system will automatically stop the motors once the machine is ready to start seeding. The end of the stage will be indicated to the user with green graphic elements. -

Page 67: Row Seed Rate

ROW SEED RATE ROW SEED RATE Row seed rate BUTTON PRESENT ONLY IF IN THE BEING USED THE Preset SEED RATE MODE SELECTED IS Rate per row It accesses the seed target rate settings of each individual row for the Preset being used. -

Page 68: Tramline Control Panel

TRAMLINE CONTROL PANEL TRAMLINE CONTROL PANEL BUTTON PRESENT ONLY IF THE TRAMLINE CONTROL PANEL IS ENABLED IN THE Working parameters -Displays the calculation result of the Tramline function in automatic mode or the diagram set in manual mode. -Allows changing the current number of spray. Tramline control panel Fig. -

Page 69: Hydraulic Functions

HYDRAULIC FUNCTIONS HYDRAULIC FUNCTIONS BUTTON PRESENT ONLY IF THE HYDRAULIC FUNCTIONS ARE AVAILABLE IN THE Basic Setting Allows accessing the hydraulic functions control page. Hydraulic functions Fig. 125 By pressing each button the relevant output is activated (see table 6.4 on page 14 Fig. -

Page 70: Selective Activation / Deactivation

SELECTIVE ACTIVATION / DEACTIVATION OF EACH ROW SELECTIVE ACTIVATION / DEACTIVATION For the selective activation / deactivation of one or more seeding lines refer to Fig. point 5 Fig. 127 Fig. 128 Row number Displays sensor status Displays previous row number Displays following row number ... -

Page 71: Total Activation / Deactivation Control

Controls with Auxiliary Input efer to the user's manual supplied with the device. ARAG Auxiliary Input control system is not compulsory on all systems, and must thus be Auxiliary Input ON ordered separately. Some systems allow controlling section valves directly from monitor touch-... - Page 72 JOYSTICK: ARAG DEFAULT FUNCTIONS (DOUBLE MODE) JOYSTICK: ARAG DEFAULT FUNCTIONS ( DOUBLE MODE ) The functions described below are illustrative. Press keys O = opens the hydraulic valve The following contents may NOT be updated and may differ to scroll C = closes the hydraulic valve from the product in your possession.

-

Page 73: Maintenance / Diagnostics / Repairs

MAINTENANCE / DIAGNOSTICS / REPAIRS MAINTENANCE / DIAGNOSTICS / REPAIRS 32.1 Cleaning rules - Clean only with a soft wet cloth. - DO NOT use aggressive detergents or products. - DO NOT aim water jets directly at control unit. Fig. 133 32.2 LED status key COLOR... -

Page 74: Error Messages

ICON STATUS Check the connection of the implement ISOBUS cable to the tractor ISOBUS socket The IBX100 control unit is OFF Check the connection of the tractor ISOBUS cable and make sure that the ISOBUS socket is correctly powered The Virtual Terminal... -

Page 75: Motor Alarm Details

Motor jammed The motor jammed due to a mechanical problem the distributor The motor does not communicate correctly with the Check the electrical connection of the motor with the IBX100 control Communication error control unit unit The motor RPM value is outside the tolerance limits... -

Page 76: Technical Data

Dispose of the system in compliance with the established legislation in the country of use. GUARANTEE TERMS 1. ARAG s.r.l. guarantees this apparatus for a period of 360 days (1 year) from the date of sale to the client user (date of the goods delivery note). - Page 77 NOTES...

- Page 78 Only use genuine ARAG accessories or spare parts to make sure manufacturer guaranteed safety conditions are maintained in time. Always refer to the Internet address www.aragnet.com. 42048 RUBIERA (Reggio Emilia) - ITALY Via Palladio, 5/A Tel. +39 0522 622011 Fax +39 0522 628944 http://www.aragnet.com...

Need help?

Do you have a question about the IBX100 and is the answer not in the manual?

Questions and answers