ARAG IBX100 Installation, Use And Maintenance Manual

Electronic control unit

Hide thumbs

Also See for IBX100:

- Installation - use - maintenance (78 pages) ,

- Installation, use and maintenance manual (76 pages) ,

- Directions for installation, use and maintenance (56 pages)

Subscribe to Our Youtube Channel

Summary of Contents for ARAG IBX100

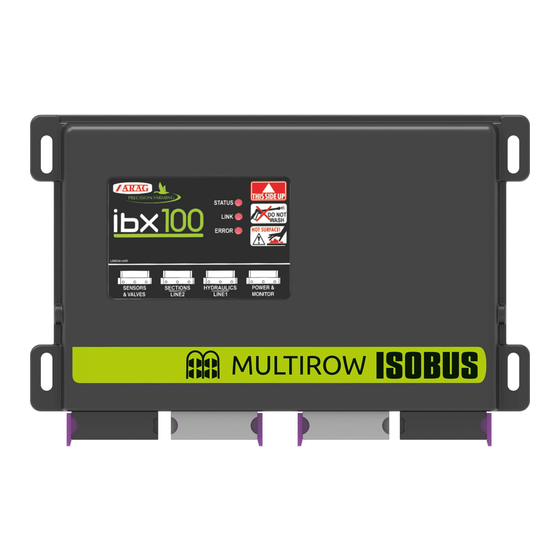

- Page 1 IBX100 ELECTRONIC CONTROL UNIT 4679005 Object Pool rel. 1.4.0 INSTALLATION, USE AND MAINTENANCE...

- Page 2 This manual is an integral part of the equipment to which it refers and must accompany the equipment in case of sale or change of ownership. Keep it for any future reference; ARAG reserves the right to modify product specifications and instructions at any moment and without notice.

-

Page 3: Table Of Contents

14.3.3 Delete OP ....................................19 14.4 Backup management ..............................20 14.4.1 Create backup ..................................20 14.4.2 Restore backup ..................................20 14.4.3 Reset to Arag factory defaults ..............................21 15 JOYSTICK: Arag DEFAULT functions ............................22 15.1 Joystick Explorer ................................22 15.2 Joystick Explorer 2 .................................23 16 Maintenance / diagnostics / repairs ............................24... -

Page 4: Manual Use Modes

VT type. RESPONSIBILITY The installer must carry out "workmanlike" installations and ensure to the end user the perfect operation of the whole system both with ARAG components only and other brands' components. ARAG always recommends using its components to install control systems. -

Page 5: Position Of Farming Machine

ISOBUS INSTALLATION DIAGRAM: IBX100 HYDRAULIC VIRTUAL ISOBUS PART NO. 4679005 TERMINAL PLUG Fig. 2 Legend of connection cables: Standard ISOBUS connector (ISOBUS PLUG) Connection cable IBX100 HYDRAULIC / Hydraulic unit Hydraulic unit Switch panel Explorer Joystick / Explorer 2 Joystick CONTINUES > > >... - Page 6 COD. 4679005 PLUG TERMINAL Fig. 3 Legend of connection cables: Standard ISOBUS connector (ISOBUS PLUG) Connection cable IBX100 HYDRAULIC / ISOBUS PLUG / IBX100 SPRAYER Connection cable for hydraulic unit Hydraulic unit Switch panel Explorer Joystick / Explorer 2 Joystick...

-

Page 7: Ibx 100 Control Unit Fixing

INSTALLATION IBX 100 control unit fixing Secure the control unit on the back of the machine, close to the control unit and the hydraulic unit. Consider all necessary connections of the device (par. ), the cable length, and make sure there is enough space for connec- tors and cables. -

Page 8: Wiring Connections

• Use of unsuitable cables not provided by ARAG automatically voids the warranty. • ARAG is not liable for any damage to the equipment, persons or animals caused by failure to observe the above instructions. General precautions for a correct harness position •... -

Page 9: Wiring Harness Connection

INSTALLATION Wiring harness connection CONNECTION POINTS Hydraulic unit VT / IBX100 Sprayer ISOBUS Fig. 7 Hydraulic valve connection The system can control up to 9 hydraulic functions through double-acting valves. Fix the connectors to the relevant valves according to the initials indicated in your assembly general diagram (par. -

Page 10: Isobus System Cable Connection

), ensure they are correctly in place and turn the ring nut clockwise until blocking them. *ARAG Auxiliary Input control system is not compulsory on all systems, and must thus be ordered separately. Some VTs allow controlling section valves directly from monitor touch-screen panel. -

Page 11: 11 "Object Pool" Loading

"OBJECT POOL" LOADING - HYDRAULIC CONTROLS “OBJECT POOL” LOADING Images and the relevant description texts contained in this manual are given as a reference as they can vary depending on the Virtual Terminal used. If the descriptions do not correspond to the text displayed in your Virtual Terminal, refer to the manual attached to the latter. -

Page 12: Control Layout

USING THE KEYS CONTROL LAYOUT Takes to menu screen Goes to the following page Goes back to the previous page ENTERING A NUMERICAL VALUE Icons are given as a reference as they can vary depending on the Virtual Terminal used: Before system setup, check: •... -

Page 13: Menu

MENU MENU Allows accessing the following pages: Hydraulic controls User level System status Settings Menu From the main page, press button to access the Fig. 13 Fig. 14... -

Page 14: Settings

AUX configuration: SWITCH BOX The system detects the presence of a switch box. Press button to assign the ARAG preset functions to the switch box. To display the assigned functions, use the OP (Object Pool) of the switch box. Function assignment can be customized through your VT. -

Page 15: Aux Configuration: Joystick

Allows you to select the hydraulic functions to be disabled when the boom status detected by IBX100 Sprayer is LOCKED. "Fig. 20" These settings are applied only in case of installation of IBX100 Hydraulics with IBX100 Sprayer, in case the latter has connected a sensor that detects the LOCKED/NON LOCKED status of the boom. -

Page 16: User Level

Allows tool limited configuration: an access PIN number can be set. Technician Level Allows the configuration of all tool features: an access PIN number can be set. Arag-Tech Level Reserved to ARAG personnel: It requires an access PIN number. Fig. 21 14.2.1 Entering the PIN number ONLY Manager and Technician users can set an access PIN number. -

Page 17: Removing The Pin Number

USER LEVEL 14.2.2 Removing the PIN number If set ONLY for Manager and Technician users, the PIN number can be removed. Select the access level for which you want to remove the PIN number. Example: select "Technician" to remove the "Technician" level PIN number. Press to display the PIN number entry / removal screen. -

Page 18: System Status

- Variable geometry boom leveling control management (VGC) - Boom leveling management (BLC) - Draw bar / steering axle management (TTC) Request ARAG the activation code to enable additional functions, which can be purchased separately. 1 Enter the supplied code and confirm. -

Page 19: Restart Ecu

SYSTEM STATUS 14.3.2 Restart ECU Press button to Restart ECU Fig. 31 14.3.3 Delete OP Allows deleting the OP on VT. Fig. 32... -

Page 20: Backup Management

14.4.1 Create backup Allows performing a backup of system settings. 1 Press key to create a backup file on IBX100 containing all the saved configurations and system data. IBX100 cannot contain more than one backup file. If a backup file is already present, the device displays button Load backup. -

Page 21: Reset To Arag Factory Defaults

SYSTEM STATUS 14.4.3 Reset to Arag factory defaults 1 Restores factory default settings of the system. The device will be restarted. All the data and configurations NOT saved in the backup file WILL BE LOST. The backup file saved on the system will not be deleted. -

Page 22: Joystick: Arag Default Functions

JOYSTICK: ARAG DEFAULT FUNCTIONS 15.1 Joystick Explorer Press keys to scroll pages. PAGE 0 A = opens the hydraulic valve - C = closes the hydraulic valve Var. Geom. L (A) Height (A) Boom tilt (A) Var. Geom. R (A) Var. -

Page 23: Joystick Explorer 2

15.2 Joystick Explorer 2 PAGE 1 A = opens the hydraulic valve - C = closes the hydraulic valve Not mapped Not mapped Not mapped Not mapped Not mapped Arm no. 2 L (A) Var. Geom. R (A) Arm no. 1 R (A) Arm no. -

Page 24: Maintenance / Diagnostics / Repairs

REMEDY Valves not connected • Connect the connection cable to the valves. Hydraulic valve controls take no effect IBX100 has not been released • Enter the release code. One valve does not open No power supply to valve • Check valve electric connection and operation. -

Page 25: Technical Data

Dispose of the system in compliance with the established legislation in the country of use. GUARANTEE TERMS 1. ARAG s.r.l. guarantees this apparatus for a period of 360 days (1 year) from the date of sale to the client user (date of the goods delivery note). - Page 26 Only use genuine ARAG accessories or spare parts to make sure manufacturer guaranteed safety conditions are maintained in time. Always refer to the internet address www.aragnet.com 42048 RUBIERA (RE) - Italy Via Palladio, 5/A Tel. +39 0522 622011 http://www.aragnet.com info@aragnet.com...

Need help?

Do you have a question about the IBX100 and is the answer not in the manual?

Questions and answers