Table of Contents

Advertisement

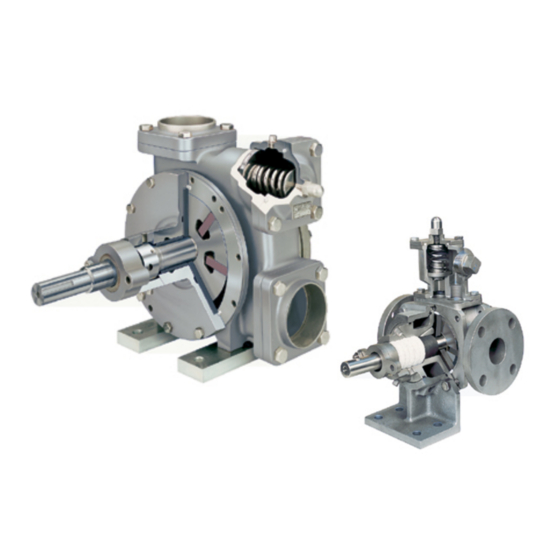

BLACKMER POWER PUMPS

INSTALLATION OPERATION AND MAINTENANCE INSTRUCTIONS

MODELS: SNP1.25, SNP1.5, SNP2, SNP2.5, SNP3A

SNPJ1.25 *, SNPJ1.5 *, SNPJ2 *, SNPJ2.5 *

TABLE OF CONTENTS

Technical Data ...................................................... 2

Initial Pump Start Up Information........................... 2

Pre-Installation Cleaning ....................................... 3

Location and Piping............................................... 3

Pump Mounting ..................................................... 4

Coupling Alignment ............................................... 4

Pump Rotation....................................................... 4

To Change Pump Rotation.................................... 4

Check Valves ........................................................ 4

Jacketed Heads..................................................... 4

Pre-Start Up Check List......................................... 5

Start Up Procedures.............................................. 5

Running the Pump in Reverse Rotation ................ 6

Flushing the Pump ................................................ 6

Pump Relief Valve................................................. 7

Relief Valve Setting and Adjustment ..................... 7

Strainers................................................................... 8

Lubrication................................................................ 8

Vane Replacement................................................... 8

Pump Disassembly .................................................. 9

Parts Replacement................................................... 9

Pump Assembly ..................................................... 11

TROUBLE SHOOTING ................................................. 13

* Effective Jan 2006, jackets are considered an option and

no longer change the model number.

NOTE: Numbers in parentheses following individual parts

indicate reference numbers on Blackmer Parts List No.

104-A01, 104-A02, 104-A03 and 104-A04.

Blackmer pump manuals and parts lists may be obtained

from Blackmer's website (www.blackmer.com) or by

contacting Blackmer Customer Service.

When you see this symbol on the product, or in the manual,

look for one of the following signal words and be alert to the

potential for personal injury, death or major property damage

Warns of hazards that WILL cause serious personal injury,

Warns of hazards that CAN cause serious personal injury,

Page

Warns of hazards that CAN cause personal injury

Indicates special instructions which are very

Blackmer Pumps MUST only be installed in systems, which

have been designed by qualified engineering personnel.

The system MUST conform to all applicable local and

national regulations and safety standards.

This manual is intended to assist in the installation and

operation of the Blackmer SNP / SNPJ Series pumps, and

MUST be kept with the pump.

Pump service shall be performed by qualified technicians

ONLY. Service shall conform to all applicable local and

national regulations and safety standards.

Thoroughly review this manual, all instructions and hazard

warnings, BEFORE performing any work on the pump.

Maintain ALL system and pump operation and hazard

warning decals.

960255

INSTRUCTIONS NO. 104-A00

Section

Effective

Replaces

SAFETY DATA

This is a SAFETY ALERT SYMBOL.

death or major property damage.

death or major property damage.

or property damage.

NOTICE:

important and must be followed.

NOTICE:

104

May 2010

Oct 2007

Advertisement

Table of Contents

Summarization of Contents

SAFETY DATA

DANGER

Warns of hazards causing serious personal injury, death, or major property damage.

WARNING

Warns of hazards that can cause serious personal injury, death, or major property damage.

CAUTION

Warns of hazards that can cause personal injury or property damage.

NOTICE

Indicates special instructions that are very important and must be followed.

PUMP DATA

TECHNICAL DATA

Provides specifications for different Blackmer SNP/SNPJ pump models.

INITIAL PUMP START UP INFORMATION

Fields to record pump identification and initial operating data.

INSTALLATION

LOCATION AND PIPING

Suggestions for optimal pump placement and system piping design.

PRE-INSTALLATION CLEANING

Instructions for cleaning new pumps and intake systems to prevent damage.

PUMP MOUNTING

Guidance on securing the pump to a foundation for stability and performance.

COUPLING ALIGNMENT

Procedures for ensuring proper alignment between pump and driver shafts.

PUMP ROTATION

How to determine and confirm correct pump rotation direction.

CHECK VALVES

Recommendations regarding the use of check valves with these pumps.

OPTIONAL JACKETED HEADS

Information on circulating hot oil or steam through jacketed heads.

OPERATION

PRE-START UP CHECK LIST

Essential checks before starting the pump to ensure safe operation.

START UP PROCEDURES

Step-by-step instructions for safely starting the pump.

RUNNING THE PUMP IN REVERSE ROTATION

Guidelines for operating the pump in reverse rotation for maintenance.

FLUSHING THE PUMP

Procedures for flushing the pump with cleaning fluid.

PUMP RELIEF VALVE

Explanation of the pump's relief valve function and types.

RELIEF VALVE SETTING AND ADJUSTMENT

Steps for setting and adjusting the relief valve pressure.

MAINTENANCE

SCHEDULED MAINTENANCE

Routine maintenance tasks for pump longevity.

STRAINERS

Importance of keeping strainers clean to prevent pump starvation.

LUBRICATION

Lubrication requirements for the pump and gear reducer.

VANE REPLACEMENT

Step-by-step instructions for replacing pump vanes.

PUMP DISASSEMBLY

Detailed instructions for disassembling the pump.

PUMPS EQUIPPED WITH BLACKMER TRIPLE-LIP SEAL OR A COMMERCIAL MECHANICAL SEAL

Specific disassembly steps for pumps with these seals.

PARTS REPLACEMENT

Guidance on replacing O-rings, seals, bearings, and discs.

SLEEVE BEARINGS (Bushings)

Procedures for installing new sleeve bearings (bushings).

CYLINDER BORE

Inspection and cleaning of the cylinder bore for smoothness.

PUMP ASSEMBLY

Instructions for reassembling the pump after maintenance.

ROTOR AND SHAFT

Steps for installing the rotor and shaft with vanes.

PACKING AND PACKING FOLLOWER

Procedures for installing new packing rings and follower.

PACKING ADJUSTMENT

How to properly adjust pump packing to prevent overheating.

BLACKMER TRIPLE-LIP SEAL

Reference to separate literature for triple-lip seal installation.

COMMERCIAL MECHANICAL SEAL

Reference to separate literature for mechanical seal installation.

SHAFT SUPPORT BEARING

Installation procedure for the shaft support bearing on SNP3A models.

RELIEF VALVE ASSEMBLY

Steps for installing the relief valve assembly.

TROUBLESHOOTING

LEAKAGE

Common causes and corrective actions for pump leakage.

SHAFT BINDING

Identifies causes and solutions for shaft binding issues.

OVERHEATING

Addresses causes and solutions for pump overheating.

LOW DELIVERY RATE

Diagnoses and corrects issues leading to reduced pump output.

EXCESSIVE NOISE AND VIBRATION

Troubleshooting guide for noise and vibration problems.

POOR OR NO PRIMING

Identifies causes and solutions for priming failures.

DAMAGED VANES

Common causes for vane damage and their solutions.

BROKEN SHAFT

Probable causes and corrective actions for a broken pump shaft.

SEAL LEAKAGE

Troubleshooting steps for mechanical seal leakage.

MOTOR OVERLOAD

Identifies causes of motor overload and their remedies.

Need help?

Do you have a question about the SNP3A and is the answer not in the manual?

Questions and answers