Table of Contents

Advertisement

CORPORATE OFFICE

JLG INDUSTRIES, INC.

1 JLG Drive

McConnellsburg, PA 17233-9533

USA

Telephone: (717) 485-5161

Fax: (717) 485-6417

EUROPEAN OFFICE

JLG INDUSTRIES (EUROPE)

Kilmartin Place,

Tannochside Park,

Uddingston, Scotland, G71 5PH

Telephone: 01698 811005

Fax: 01698 811055

AUSTRALIAN OFFICE

JLG INDUSTRIES (AUSTRALIA)

P.0. Box 972

11 Bolwarra Road

Port MacQuarie

N.S.W. 44

Australia

Telephone: 1 (065) 811111

Fax: 1 (065) 810122

B S E N I S O 90 01 C er tificat e N o. 6 917

Models

M45A

M45AJ

E45A

E45AJ

Issued: April 1, 1999

Updated: March 15, 2000

PRINTED IN U.S.A.

3120883

Advertisement

Table of Contents

Summarization of Contents

FOREWORD

Safety Alert Symbol Definitions

Defines safety alert symbols and their meanings for potential hazards.

OSHA Regulations Overview

Summarizes key OSHA safety regulations for aerial lift operation.

SECTION 1 - SAFETY PRECAUTIONS

1.1 GENERAL

Outlines safe practices, manual importance, and operator responsibility for machine usage.

1.2 DRIVING/TOWING

Provides guidance on driving safely and notes the machine's towing provisions.

1.3 ELECTROCUTION HAZARD

Details minimum safe approach distances to electrical conductors and hazards.

1.4 PRE-OPERATIONAL

Emphasizes manual reading, understanding, and use by authorized, qualified personnel.

Operator Responsibilities

Highlights operator's duty for training, work area safety, and machine maintenance.

Operational Restrictions

Lists restrictions on operation, including wind limits, modifications, and temperature ranges.

Safe Operation Practices

Details safe practices like reading manuals, using ground controls, and maintaining three-point contact.

Driving Safety

Provides safety guidelines for driving, including speed, grades, obstructions, and personnel proximity.

Operation Safety

Covers safe operation, checking travel paths, grades, surfaces, and platform entry/exit.

Platform Safety

Emphasizes fall protection device use and safe procedures for entering/leaving the platform.

Transfer Safety

Details safety measures for transfers between structures and the platform, including lanyard use.

General Operation Precautions

Lists precautions for platform items, footing, cleanliness, and avoiding boom walking.

Load Limits and Malfunctions

Addresses load limits, handling malfunctions, footswitch, stuck machines, and prohibited boom uses.

1.7 TOWING AND HAULING

Details procedures for towing and hauling, including turntable locking.

SECTION 2 - PREPARATION AND INSPECTION

2.1 GENERAL

Stresses the importance of read/understood information and the owner/operator's responsibility for safety.

2.2 PREPARATION FOR USE

Covers initial inspection of new machines and periodic checks for operational readiness.

2.3 DELIVERY AND FREQUENT INSPECTION

Outlines requirements for periodic safety and maintenance inspections by an authorized dealer.

Chassis Inspection Points

Details specific inspection points for the machine's chassis, including tires, axles, and steering.

Turntable Inspection Points

Lists inspection points for the turntable, including cylinders, drive motor, and bearing.

Boom Inspection Points

Details inspection points for the boom, including pins, hydraulic lines, and cylinders.

Platform Inspection Points

Lists inspection points for the platform, including console, controls, and wiring.

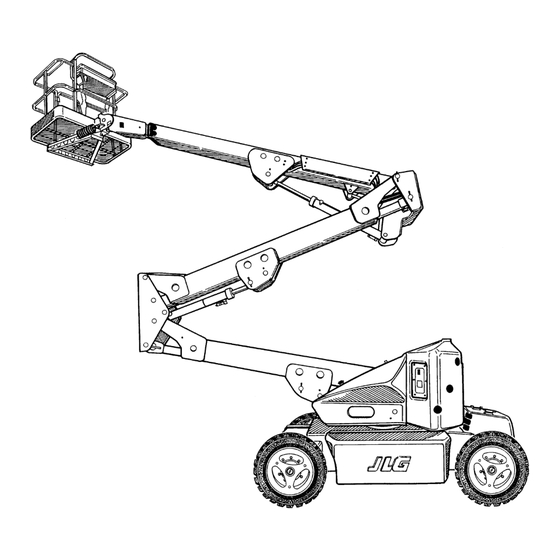

Basic Nomenclature

Illustrates and labels the major components of the JLG Lift machine.

2.4 DAILY WALK-AROUND INSPECTION

Details the operator's daily inspection routine, including cleanliness, placards, and manuals.

2.5 DAILY FUNCTIONAL CHECK

Outlines the process for performing a daily functional check of all machine systems.

Functional Checks - Boom and Controls

Describes specific functional checks for boom movements, controls, and the footswitch.

2.6 TORQUE REQUIREMENTS

Explains the purpose of the torque chart for bolt tightening and maintenance.

Lubrication Chart

Illustrates lubrication points on the machine with corresponding numbers.

Table 2-1. Lubrication Chart

Provides a detailed chart of components, lube points, capacity, intervals, and lubricant types.

Figure 2-4. Torque Chart

Displays standard torque values for various bolt sizes and grades for proper fastener tightening.

Battery Maintenance and Charging

Details procedures for battery maintenance, including cleaning and electrolyte checks.

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL

3.1 GENERAL

Emphasizes the user's responsibility for machine application, operation, and safety.

3.2 PERSONNEL TRAINING

Stresses the necessity of operating and maintaining the machine by authorized, qualified, and trained personnel.

3.3 OPERATING CHARACTERISTICS AND LIMITATIONS

Covers machine characteristics, limitations, placards, capacities, and stability factors.

3.4 CONTROLS AND INDICATORS

Introduces control panels, symbols, and ground control station functions.

Position of Least Forward Stability

Illustrates the machine's configuration for least forward stability, highlighting tip-over risk.

Position of Least Backward Stability

Illustrates the machine's configuration for least backward stability, highlighting tip-over risk.

Ground Control Station Diagram

Displays the layout and labels of the ground control station components.

Ground Control Station Functions

Explains the operation and functions of the ground control station switches and controls.

Platform Console Layout

Displays the layout and labels of the platform control console components.

Platform Control Functions

Explains the operation and functions of platform controls, including joystick and footswitch.

Simultaneous Functions Table

Details which machine functions can be operated simultaneously and their interactions.

Decal Location Guide

Illustrates the locations of various safety decals (Danger, Caution, Warning, Important) on the machine.

Safety Decals and Daily Checklist

Presents safety warnings and a daily inspection checklist with operational limits.

Generator Operation Warnings

Provides critical warnings and instructions for safe operation of the onboard generator.

Control Panel Symbols - Part 1

Shows and explains the symbols used for various functions on the control panels.

Control Panel Symbols - Part 2

Continues the explanation of control panel symbols for machine functions.

SECTION 4 - MACHINE OPERATION

4.1 DESCRIPTION

Describes the JLG Lift as a self-propelled hydraulic lift with a work platform and boom.

4.2 GENERAL

Highlights the importance of understanding operating procedures for traveling, steering, and parking.

4.3 MOTOR OPERATION

Explains the function of the Power/Emergency Stop switch and its role in machine operation.

Platform/Ground Select & Motor Activation

Explains how motors are activated, emphasizing the footswitch requirement and safety warnings.

Traveling (Driving) Procedures

Provides notes and warnings related to driving the machine, including speed and conditions.

Steering

Explains how to steer the machine using the thumb switch on the controller.

Platform Loading and Adjustment

Covers platform loading from ground level and platform level adjustment procedures.

Platform Rotation

Details the procedure for rotating the platform to the left or right.

Boom Operation

Provides warnings related to boom operation, including tilt and slope hazards.

Generator Operation

Describes the machine's generator and its automatic and battery-only operating modes.

Machine Function Speeds

Describes the Function Speed Control and its effect on boom and swing speeds.

Shut Down and Park

Outlines the correct procedures for shutting down and parking the machine.

Machine Lifting and Tie Down

Provides instructions for lifting and tie-down procedures for the machine.

Boom Synchronizing Procedure

Details the procedure to synchronize the boom assembly if it does not fully lower.

Upright Positioning Guidelines

Illustrates correct and incorrect upright positioning to prevent tip-over hazards.

Lifting Chart

Provides lifting instructions and a chart with dimensions and weights for different models.

Chassis and Platform Tie Down

Illustrates how to properly secure the chassis and platform for transport.

SECTION 5 - OPTIONAL EQUIPMENT

Motion Alarm

Describes the audible warning provided by the motion alarm.

Foam Filled Tires

Explains the benefit of foam-filled tires for use in challenging jobsite conditions.

Rotating Beacon

Details the function of the amber rotating beacon as a visual warning.

Tilt Alarm

Describes the audible warning that sounds when the machine is out of level.

Wheel Covers

Explains the protective function of wheel covers against dirt and debris.

Battery Packs

Notes the availability of spare battery packs for continuous operation.

Platform Lights

Mentions the availability of platform lights for improved operator visibility.

Control Console Cover

Describes the clear acrylic cover protecting the platform control console.

Cylinder Bellows

Explains the purpose of cylinder bellows in protecting cylinder rods.

Work Platform

States the available size for the work platform.

SECTION 6 - EMERGENCY PROCEDURES

6.1 GENERAL

Stresses reviewing emergency procedures for all personnel interacting with the machine.

6.2 EMERGENCY TOWING PROCEDURES

Provides procedures for moving the machine in emergency situations, like malfunctions.

6.3 EMERGENCY CONTROLS AND THEIR LOCATIONS

Details the location and function of the Emergency Stop switch.

Ground Control Station

Identifies the location of the Ground Control Station and its overriding capabilities.

Manual Descent System

Explains how to use the manual descent system to lower booms in case of power failure.

Manual Swing Override

Details how to manually swing the boom/turntable assembly in an emergency.

6.4 EMERGENCY OPERATION

Outlines the use of ground controls during emergencies and training requirements.

Operator Unable to Control Machine

Provides instructions for handling situations where the platform operator is incapacitated.

Platform or Boom Caught Overhead

Details procedures if the platform or boom becomes jammed overhead.

6.5 INCIDENT NOTIFICATION

Stresses the importance of immediate notification to JLG Industries regarding any incidents.

SECTION 7 - INSPECTION AND REPAIR LOG

Table 7-1. Inspection and Repair Log

Provides a template for recording inspection and repair details.

Need help?

Do you have a question about the E45A and is the answer not in the manual?

Questions and answers