Table of Contents

Advertisement

CORPORATE OFFICE

JLG INDUSTRIES, INC.

1 JLG Drive

McConnellsburg, PA 17233-9533

USA

Telephone: (717) 485-5161

Fax: (717) 485-6417

EUROPEAN OFFICE

JLG INDUSTRIES (EUROPE)

Kilmartin Place,

Tannochside Park,

Uddingston, Scotland, G71 5PH

Telephone: 01698 811005

Fax: 01698 811055

AUSTRALIAN OFFICE

JLG INDUSTRIES (AUSTRALIA)

P.0. Box 972

11 Bolwarra Road

Port MacQuarie

N.S.W. 44

Australia

Telephone: 1 (065) 811111

Fax: 1 (065) 810122

B S E N I S O 90 01 C er tificat e N o. 6 917

Models

M45A

M45AJ

E45A

E45AJ

Issued: April 1, 1999

Updated: March 15, 2000

PRINTED IN U.S.A.

3120883

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for JLG M45AJ

- Page 1 CORPORATE OFFICE JLG INDUSTRIES, INC. 1 JLG Drive McConnellsburg, PA 17233-9533 Telephone: (717) 485-5161 Fax: (717) 485-6417 EUROPEAN OFFICE JLG INDUSTRIES (EUROPE) Kilmartin Place, Tannochside Park, Uddingston, Scotland, G71 5PH Telephone: 01698 811005 Fax: 01698 811055 AUSTRALIAN OFFICE JLG INDUSTRIES (AUSTRALIA) P.0.

- Page 3 JLG INDUSTRIES MAY HAVE ISSUED SAFETY RELATED BULLETINS FOR YOUR JLG PRODUCT. CONTACT JLG INDUSTRIES INC. OR THE LOCAL AUTHORIZED JLG DISTRIBUTOR FOR INFORMATION CONCERNING SAFETY RELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR YOUR JLG PRODUCT. ALL ITEMS REQUIRED BY THE SAFETY RELATED BULLETINS MUST BE COM- PLETED ON THE AFFECTED JLG PRODUCT Due to continuous product improvements, JLG Industries, Inc.

- Page 4 FOREWORD This page left blank intentionally. – JLG Lift – 3120883...

- Page 5 13. Personnel shall always stand on the floor of the these requirements constitute an assumption of platform, not on boxes, planks, railing or other responsibility of liability on the part of JLG Indus- devices, for a work position. tries, Inc.

- Page 6 Updated 7-13-99 3-13 Updated 7-13-99 2-11 Updated 8-4-99 Updated 8-4-99 4-5 thru 4-7 Updated 8-4-99 3-5 thru 3-8 Updated 8-18-99 Updated 9-21-99 Updated 11-3-99 2-11 Updated 11-3-99 Updated 11-3-99 Updated 12-1-99 Updated 3-15-00 Updated 3-15-00 – JLG Lift – 3120883...

-

Page 7: Table Of Contents

Work Platform ..............5-1 3120883 – JLG Lift –... - Page 8 Inspection and Repair Log ............7-1 – JLG Lift –...

-

Page 9: Section 1 - Safety Precautions

Refer to Section 6 for emergency towing procedures. son, has been completed. If there is a question on appli- cation and/or operation, JLG Industries Inc., should be SPECIAL NOTE: consulted. FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN... -

Page 10: Electrocution Hazard

SONNEL TO OPERATE MACHINE WHO HAVE DEM- LINES AND APPARATUS. ALLOW FOR BOOM SWAY, ONSTRATED THAT THEY UNDERSTAND SAFE AND ROCK OR SAG AND ELECTRICAL LINE SWAYING. PROPER OPERATION AND MAINTENANCE OF THE THE MACHINE DOES NOT PROVIDE PROTECTION UNIT. – JLG Lift – 3120883... - Page 11 BEEN SERVICED AND MAINTAINED ACCORDING TO THE MANUFACTURERS SPECIFICATIONS AND SCHEDULE. • ENSURE DAILY INSPECTION AND FUNCTION CHECK IS PERFORMED PRIOR TO PLACING MACHINE INTO OPERATION. • APPROVED HEAD GEAR MUST BE WORN BY ALL OPERATING AND GROUND PERSONNEL. 3120883 – JLG Lift –...

-

Page 12: Driving

WH E N D RI V IN G IN ARE A S WH E RE V I SI O N I S OBSTRUCTED. • KEEP NON-OPERATING PERSONNEL AT LEAST 2 M (6 FEET) AWAY FROM MACHINE DURING DRIVING OPERATIONS. • WATCH FOR OBSTRUCTIONS AROUND MACHINE AND OVERHEAD WHEN DRIVING. – JLG Lift – 3120883... -

Page 13: Operation

• DO NOT TRAVEL ON SOFT OR UNEVEN SURFACES, THROUGH GATE OPENING. AS TIPPING WILL OCCUR. • JLG RECOMMENDS ALL PERSONS IN THE PLAT- • DO NOT DRIVE MACHINE NEAR PITS, LOADING FORM TO WEAR LANYARDS WITH AN APPROVED DOCKS OR OTHER DROP-OFFS. - Page 14 TO WARN THEM NOT TO WORK, WALK OR STAND • KEEP ALL NON-OPERATING PERSONNEL AT LEAST UNDER A RAISED BOOM OR PLATFORM. POSITION 2 METERS AWAY FROM THE MACHINE AT ALL BARRICADES ON FLOOR IF NECESSARY. TIMES. – JLG Lift – 3120883...

- Page 15 THEN MOVE SWITCH TO THE DESIRED POSITION. OPERATE LEVERS WITH SLOW, EVEN PRESSURE. • DO NOT CARRY MATERIALS ON PLATFORM RAILING UNLESS APPROVED BY JLG INDUSTRIES INC. • NEVER PUSH OR PULL THE MACHINE OR OTHER OBJECTS BY TELESCOPING THE BOOM.

-

Page 16: Towing And Hauling

BEING USED REACHES END OF TRAVEL. THIS APPLIES TO MACHINES IN OPERATION OR IN STOWED MODE. • DO NOT OPERATE ANY MACHINE ON WHICH DAN- GER, WARNING, CAUTION OR INSTRUCTION PLAC- ARDS OR DECALS ARE MISSING OR ILLEGIBLE. – JLG Lift – 3120883... -

Page 17: Section 2 - Preparation And Inspection

Daily Walk Around Inspec- filter for condition of element. Replace as required. tion. NOTE: JLG recommends replacing the hydraulic filter ele- It should be assured that the items appearing in the Deliv- ment after the first 50 hours of operation and then... - Page 18 5. Check Lower Upright cross pins and hydraulic lines for damage, wear, lubrication, leakage and security. 6. Check Lower Upright for damage, wear, lubrication and security. 7. Check hydraulic lines mounted on upright for dam- age, leakage and security. – JLG Lift – 3120883...

-

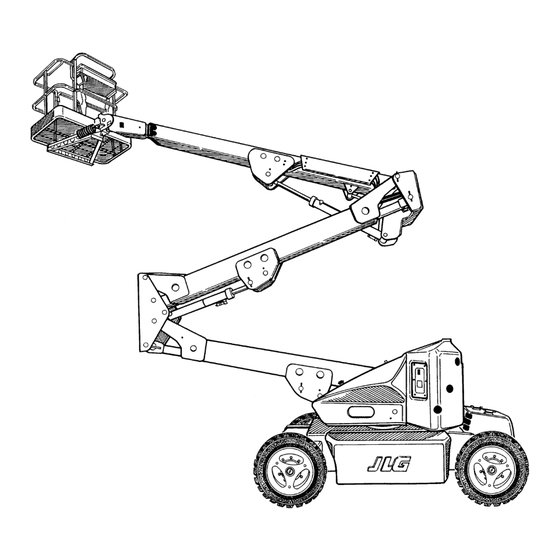

Page 19: Basic Nomenclature

5. Check Platform Rotator mechanism for proper oper- READABLE. USE OF MACHINE WITHOUT CORRECT PLACARDS ation, damage, and security. IS A SAFETY VIOLATION. NOTE: Check all DANGER, WARNING, CAUTION, and INSTRUCTION placards for legibility and security on the entire machine. 3120883 – JLG Lift –... -

Page 20: Daily Walk-Around Inspection

TO STOP MACHINE. 1. Check boom limit switches. Raise and lower the Lower Boom. Check for smooth operation. Check Boom Upright tilting. (See Section 4). NOTE: Perform checks from ground controls first, then from platform controls. – JLG Lift – 3120883... -

Page 21: Torque Requirements

FOOTSWITCH MUST BE ADJUSTED SO THAT FUNCTIONS WILL OPERATE WHEN PEDAL IS APPROXIMATELY AT ITS CENTER OF TRAVEL. IF SWITCH OPERATES WITHIN LAST 1/4" (6 MM) OF TRAVEL, TOP OR BOTTOM, IT SHOULD BE ADJUSTED. Updated 5-21-99 3120883 – JLG Lift –... -

Page 22: Daily Walk-Around Inspection

SECTION 2 - PREPARATION AND INSPECTION Figure 2-2. Daily Walk-Around Inspection (Sheet 1 of 3) – JLG Lift – 3120883... - Page 23 8. Limit Switches - Switches operable; no visible dam- age. 9. Drive Axle and Motor - No loose or missing hard- ware; No visible damage; no evidence of leakage. (Sheet 2 of 3) Figure 2-2., Daily Walk-Around Inspection 3120883 – JLG Lift –...

-

Page 24: Battery Maintenance And Charging

When adding water to the battery, fill only to level indicated or 3/8" above separators. 2. Remove all vent caps and inspect electrolyte level of each cell. Electrolyte level should be to the ring approximately one inch from top of battery. Fill bat- – JLG Lift – 3120883... - Page 25 5. Depleted batteries will take approximately 17 hours to charge. TO AVOID INJURY FROM AN EXPLOSION, DO NOT SMOKE OR ALLOW SPARKS OR A FLAME NEAR BATTERY DURING SERVIC- ING. ALWAYS WEAR EYE AND HAND PROTECTION WHEN SER- VICING BATTERIES. Updated 11-3-99 3120883 – JLG Lift –...

- Page 26 SECTION 2 - PREPARATION AND INSPECTION Figure 2-3. Lubrication Chart Updated 6-1-99 2-10 – JLG Lift – 3120883...

-

Page 27: Lubrication Chart

BLOWING OUTER SEAL IN HOUSING. ** Under certain conditions, it may be necessary to replace the hydraulic filter on a more frequent basis. A common symptom of a dirty filter is sluggishness experienced in hydraulic functions. Updated 11-3-99 3120883 – JLG Lift – 2-11... - Page 28 SECTION 2 - PREPARATION AND INSPECTION 2-12 – JLG Lift – 3120883...

-

Page 29: Section 3 - User Responsibilities And Machine Control

Operator Training. the machine or the job site and to request further informa- Operator training must include instruction in the following tion from his/her supervisor or an authorized JLG Distribu- areas: tor before proceeding. 1. Use and limitations of the platform controls, ground NOTE: Manufacturer or Distributor will provide qualified per- controls, emergency controls and safety systems. -

Page 30: Operating Characteristics And Limitations

3. All machine systems are functioning properly. 1. Power/Emergency Stop Switch. 4. Proper tire pressure. A two-position red mushroom shaped switch fur- 5. Machine is as originally equipped from JLG. nishes power to PLATFORM/GROUND SELECT switch when pulled out (on). When pushed in (off), Stability power is shut off to the PLATFORM/GROUND SELECT switch. -

Page 31: Position Of Least Forward Stability

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL Figure 3-1. Position of Least Forward Stability 3120883 – JLG Lift –... -

Page 32: Position Of Least Backward Stability

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL Figure 3-2. Position of Least Backward Stability – JLG Lift – 3120883... - Page 33 SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL Figure 3-3. Ground Control Station Updated 8-18-99 3120883 – JLG Lift –...

- Page 34 FOOTSWITCH MUST BE ADJUSTED SO THAT FUNCTIONS WILL OPERATE WHEN PEDAL IS APPROXIMATELY AT ITS CENTER OF TRAVEL. IF SWITCH OPERATES WITHIN LAST 1/4" OF TRAVEL, TOP OR BOTTOM, IT SHOULD BE ADJUSTED. Updated 8-18-99 – JLG Lift – 3120883...

-

Page 35: Platform Console

TO AVOID SERIOUS INJURY, DO NOT OPERATE MACHINE IF ANY bulb check. CONTROL LEVERS OR TOGGLE SWITCHES CONTROLLING PLATFORM MOVEMENT DO NOT RETURN TO THE OFF OR NEU- TRAL POSITION WHEN RELEASED. Updated 8-18-99 3120883 – JLG Lift –... - Page 36 Re-depress the footswitch to power the arrangement, causing available power to be distrib- controls and extinguish the light. uted evenly between the two drive wheels. The con- trol system may also engage the posi-track function automatically. Updated 8-18-99 – JLG Lift – 3120883...

- Page 37 * These functions may move very slowly (or not at all) if the first function selected (Lower Lift or Swing) is being operated at full speed, due to sharing of oil. ** Lower Lift and Upper Lift will not function simultaneously. Upper lift alway prevails. Updated 5-12-99 3120883 – JLG Lift –...

- Page 38 SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL Updated 6-1-99 3-10 – JLG Lift – 3120883...

- Page 39 3. CHECK SAFETY PROTECTION ITEMS. + 70kg 4. CHECK ALL OPERATIONS FOR MALFUNCTION. 5. CHECK BRAKES. 6. ENSURE THAT JLG OPERATION AND SAFETY MANUAL IS WITH THE MACHINE. 7. DO NOT OPERATE A MALFUNCTIONING MACHINE. 8. CHECK THE ENGINE AND DRIVE SPEED CUT-OUT SWITCHES.

- Page 40 3. CHECK SAFETY PROTECTION ITEMS. 4. CHECK ALL OPERATIONS FOR MALFUNCTION. 5. CHECK BRAKES. 6. ENSURE THAT JLG OPERATION AND SAFETY MANUAL IS WITH THE MACHINE. 7. DO NOT OPERATE A MALFUNCTIONING MACHINE. 8. CHECK THE ENGINE AND DRIVE SPEED CUT-OUT SWITCHES.

-

Page 41: Control Panel Symbols (Sheet 1 Of 2)

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL Figure 3-6. Control Panel Symbols (Sheet 1 of 2) Updated 7-13-99 3120883 – JLG Lift – 3-13... -

Page 42: Control Panel Symbols (Sheet 2 Of 2)

SECTION 3 - USER RESPONSIBILITIES AND MACHINE CONTROL Figure 3-7. Control Panel Symbols (Sheet 2 of 2) 3-14 – JLG Lift – 3120883... -

Page 43: Section 4 - Machine Operation

Within about 2 seconds of pulling the switch out, the The JLG Lift is not intended to be used to lift material other machine will perform a diagnostic check of the various than supplies which personnel in the platform require to electrical circuits, and if everything is OK, the platform do their job. -

Page 44: Traveling (Driving)

Depress footswitch, position thumb switch on Drive/Steer controller to RIGHT for steering right, or to LEFT for steer- ing left. 4.6 PLATFORM Loading From Ground Level 1. Position chassis on a smooth, firm and level surface. – JLG Lift – 3120883... -

Page 45: Boom

PLATFORM ROTATE control switch is positioned to STOP WHEN A CONTROL SWITCH OR LEVER IS RELEASED, the RIGHT and held until desired position is REMOVE FOOT FROM FOOTSWITCH OR USE EMERGENCY STOP reached. SWITCH TO STOP THE MACHINE. Updated 5-21-99 3120883 – JLG Lift –... -

Page 46: Generator

2. The switch on the platform control console is in the Off or Disable position. In this mode the machine will operate as a conventional battery operated unit. The batteries can be used until they are fully discharged. – JLG Lift – 3120883... -

Page 47: Machine Lifting And Tie Down

NOTE: If the Lower Boom assembly does not fully lower: Lifting 1. Remove all personnel from the platform. 1. Call JLG Industries or weigh the individual unit to obtain GVW. 2. Pull the red knob located besided the main control valve. - Page 48 SECTION 4 - MACHINE OPERATION Updated 8-4-99 – JLG Lift – 3120883...

- Page 49 SECTION 4 - MACHINE OPERATION Updated 9-21-99 3120883 – JLG Lift –...

-

Page 50: Chassis & Platform Tie Down

SECTION 4 - MACHINE OPERATION Figure 4-4. Chassis & Platform Tie Down Updated 3-15-00 – JLG Lift – 3120883... -

Page 51: Section 5 - Optional Equipment

5.5 WHEEL COVERS 5.10 WORK PLATFORM Provide protection for wheels and wheel bearings from These machines are available with a 0.76 x1.52M size plat- dirt, grease, mud, rocks, etc. form. Updated 11-3-99 3120883 – JLG Lift –... - Page 52 SECTION 5 - OPTIONAL EQUIPMENT This page left blank intentionally. – JLG Lift – 3120883...

-

Page 53: Section 6 - Emergency Procedures

Install wrench on nut and ratchet in the direction tion and shut down the machine. desired. Updated 12-1-99 3120883 – JLG Lift –... -

Page 54: Emergency Operation

It is imperative that JLG Industries, Inc. be notified imme- 1. Operate the machine from ground controls only with diately of any incident involving a JLG product. Even if no the assistance of other personnel and equipment injury or property damage is evident, the factory should (cranes, overhead hoists, etc.) as may be required... -

Page 55: Section 7. Inspection And Repair Log

SECTION 7 - INSPECTION AND REPAIR LOG SECTION 7. INSPECTION AND REPAIR LOG Table 7-1.Inspection and Repair Log Date Comments 3120883 – JLG Lift –... - Page 56 SECTION 7 - INSPECTION AND REPAIR LOG Table 7-1.Inspection and Repair Log Date Comments – JLG Lift – 3120883...

- Page 57 If you now own, but ARE NOT the original purchaser of the product covered by this manual, we would like to know who you are. For the purpose of receiving safety-related bulletins, it is very important to keep JLG Industries, Inc. updated with the current ownership of all JLG products. JLG maintains owner information for each JLG product and uses this information in cases where owner notification is necessary.

- Page 60 England Fax: (49) 421 693 5035 Fax: (61) 2 65 810122 Phone: (44) 870 200 7700 Fax: (44) 870 200 7711 JLG Latino Americana Ltda. JLG Europe B.V. JLG Industries (Norge AS) JLG Polska Rua Eng. Carlos Stevenson, Jupiterstraat 234 Sofeimyrveien 12 UI.

Need help?

Do you have a question about the M45AJ and is the answer not in the manual?

Questions and answers