Advertisement

Table of Contents

- 1 Table of Contents

- 2 General Requirements

- 3 Data for Calculation of Chimney Dimensions

- 4 Minimum Cross Sections

- 5 Thermal Insulation Materials

- 6 Installation Specifications

- 7 Fire Insert Assembly

- 8 Connection to Ceramic Flues

- 9 Example Mars 570 K - Connection to Ceramic Flues

- 10 Storage Systems

- 11 Example Uranus/Neptun Style - Assembly of Connection Box

- 12 Positioning of Type Plates

- Download this manual

Advertisement

Table of Contents

Summary of Contents for ruegg URANUS HK

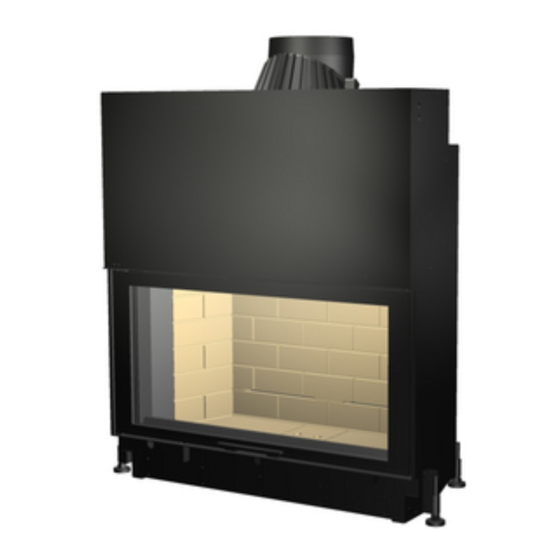

- Page 1 SMART-LINE / ECO-LINE INSTALLATION GUIDE...

-

Page 3: Table Of Contents

SMART-LINE ECO-LINE Installation Guide Content 1. General requirements Page 2. Data for calculation of chimney dimensions Page 3. Minimum cross sections Page 10-11 4. Thermal insulation materials Page 5. Installation specifications Page 13-17 6. Fire insert assembly Page 18-23 7. Connection to ceramic flues Page 24-25 8. - Page 4 SMART-LINE ECO-LINE Installation Guide Applicable regulations Rüegg fire inserts are type-tested and approved according to DIN EN13229. These assembly instructions were prepared in accordance with the Swiss “Stand- der-Technik-Papier” [State-of-the-art Paper] by the VHP [Association of Swiss Stove Fitter and Tile Businesses], version 1.1, and the applicable German regula- tions in force.

-

Page 5: General Requirements

SMART-LINE ECO-LINE Installation Guide 1. General requirements 1.1. Installation rooms Open fireplaces must not be installed: - in stair cases, with the exception of residential buildings with no more than two flats - in corridors accessible by the public - in rooms, where highly inflammable or explosive substances or mixtures are processed, stored or manufactured - in rooms or flats which are ventilated through ventilation systems or hot-air heating systems by means of fans, unless safe operation of the fireplace is... - Page 6 SMART-LINE ECO-LINE Installation Guide According to the regional building regulations, combustion air ducts in build- ings with more than two full storeys and combustion air ducts spanning fire walls are to be implemented in a way that fire and smoke cannot be trans- ferred to other storeys or fire sections.

-

Page 7: Data For Calculation Of Chimney Dimensions

SMART-LINE ECO-LINE Installation Guide 2. Data for calculation of chimney dimensions MERKUR K / HK - Temperature at flue gas outlet 182° C Open furnace - Flue gas mass flow 18.1 g/sec (EN 13229) - Minimum delivery pressure 10 Pa... - Page 8 SMART-LINE ECO-LINE Installation Guide - Temperature at flue gas outlet 309° C JUPITER 510 HK - Flue gas mass flow 7,4 g/sec flach Tunnel - Minimum delivery pressure 12 Pa Closed furnace (EN 13229) - Nominal heat output 9,0 kW - Flue gas outlet Ø...

- Page 9 SMART-LINE ECO-LINE Installation Guide VENUS K / HK - Temperature at flue gas outlet 185° C Open furnace - Flue gas mass flow 28.0 g/sec (EN 13229) - Minimum delivery pressure 10 Pa VENUS K / HK - Nominal heat output 7.0 kW Closed furnace - Temperature at flue gas outlet...

-

Page 10: Minimum Cross Sections

A1 design A (closed operation) (closed operation) MERKUR K/HK Ø 160 mm 120 cm 295 cm 160/160 mm 1 pipe Ø 125 mm 1 pipe Ø 125 mm + 1 pipe Ø 150 mm for... - Page 11 SMART-LINE ECO-LINE Installation Guide 3.1. Chimney As manufacturer of fire inserts we allow/recommend the following tolerances for new chimneys with triple isola- tion: - 180 mm, 200 mm chimney diameters may be reduced by 20 mm from an effective chimney length of 8 m - 250 mm chimney diameter may be reduced by 50 mm from an effective chimney length of 8 m - 160 mm, 180 mm chimney diameters for...

-

Page 12: Thermal Insulation Materials

SMART-LINE ECO-LINE Installation Guide 4. Thermal insulation materials Fire inserts in a fireplace installation always require thermal insulation to the build- ing walls/floors/ceilings. If fireplace installations are fitted to building walls/floors/ceilings which are com- bustible or require protection, the thermal insulation must meet increased require- ments (see installation specifications). -

Page 13: Installation Specifications

SMART-LINE ECO-LINE Installation Guide 5. Installation specifications Exemplary installation of fire insert in front of wall requiring protection (e.g. wood) Fire insert Concrete slab* 17 Ceiling to be protected Connector Floor to be protected 18 Thermal insulation layer Mineral construction material Glass pane 19 Roofing Convection area... - Page 14 SMART-LINE ECO-LINE Installation Guide 5.1. Connector (exhaust/flue pipe) Material: Steel sheet with min. 2 mm thickness; chrome steel sheet, material thickness ≥ 1mm (or ac- cording to manufacturer’s specifications); fireclay fit- ting for house chimneys. If the connector [2] passes through components with combustible construction materials, e.g.

- Page 15 SMART-LINE ECO-LINE Installation Guide The appliance facing [12]/cowl [16] must also be pro- tected by means of an insulation layer. Protection of the facing is not required, if the open fireplace is de- signed in a way that the free surfaces of the facing and the surfaces of the recesses for storage of fuels will not get hotter than 85°...

- Page 16 SMART-LINE ECO-LINE Installation Guide Inset Thickness of insulation on the floor Jupiter 0 cm Mars 0 cm Merkur 0 cm Neptun 4 cm Uranus mit Sockel 0 cm Uranus ohne Sockel 8 cm Venus 0 cm 5.6. Expansion joints No direct connection must exist between the fire insert [1] and the facing [12]/cowl.

- Page 17 SMART-LINE ECO-LINE Installation Guide 5.9. Convection air duct The cross sections for the air inlet opening [14] and the air outlet opening [15] should be 700 cm² each, however, at least 350 cm². At least 200 cm² of the air inlet and air outlet opening must not be sealable.

-

Page 18: Fire Insert Assembly

SMART-LINE ECO-LINE Installation Guide 6. Fire insert assembly 6.1. Function check/preparation The transport securing screw labelled in red (1) must be removed from the pane flue devices. Prior to assembly of the appliance, check the individ- ual functional elements, such as: - Pane flue - Lateral movement of door - Smooth operation of door lock... - Page 19 SMART-LINE ECO-LINE Installation Guide 6.4. Combustion air connection Sealed connection using flexible pipes Ø 125 mm to the connection piece in the base structure of the ap- pliance. The pipe is routed to the outside or in the installation room, if an adequate supply with outside/fresh air ac- cording to the specifications is ensured.

- Page 20 SMART-LINE ECO-LINE Installation Guide 6.6. Circulation/ambient air connection A free inlet flow cross section of at least 350 cm² is to be provided, with 200 cm² thereof not being sealable. 6.7. Exhaust/flue gas connection Alignment of flue gas outlet: - By rotating the exhaust gas dome (1) by 360° it can be locked in any position.

- Page 21 SMART-LINE ECO-LINE Installation Guide 6.8. Furnace Insert the fireclay elements loosely in the furnace without mortar. Order: 1. Rear panel bottom (injection stone) 2. Rear panel top 3. Side panels (secure with mounting brackets) 4. Floor front stone 5. Floor side stones Drawing is valid for flat and 6.

- Page 22 SMART-LINE ECO-LINE Installation Guide 6.9. Supply air/hot air connection A free inlet flow cross section of at least 350 cm² is to be provided, with 200 cm² thereof not being sealable. 6.10. Facing Insert a surrounding fibre glass expansion strap on all sides, between the appliance and the facing and be- tween the support frame and the facing.

- Page 23 SMART-LINE ECO-LINE Installation Guide 6.14. External fan box for HK with convection casing only (option) For improved hot air distribution, e.g. for several rooms or for a small hypocaust with bench, connec- tion of the “external fan box” (3) is also an option. The detailed assembly instructions are included with every set.

-

Page 24: Connection To Ceramic Flues

SMART-LINE ECO-LINE Installation Guide 7. Connection to ceramic flues The above specifications regarding the installation specifications (pages 12-16) and assembly instruc- Direct flue tions (pages 17-21) still apply (see distances, thermal insulation, flue gas pipe connection). This series of appliances has been especially de- signed for installation with ceramic flues. - Page 25 SMART-LINE ECO-LINE Installation Guide The fuel pipe connection to the ceramic flue is to be made flue-gas-tight using pluggable steel pipes. The connection of the pipes to the ceramic flue is to be made preferably by means of a prefabricated fireclay connection stone.

-

Page 26: Example Mars 570 K - Connection To Ceramic Flues

SMART-LINE ECO-LINE Installation Guide 8. Mars 570 K with ceramic flue (example with KMS system) -

Page 27: Storage Systems

SMART-LINE ECO-LINE Installation Guide 9. Storage systems 9.1. General Modern houses with high heat requirements indicate the installation of furnaces with low heating power. The fire inserts of such installations are enclosed by a storage casing and faced with a ceramic cover (radiation plates, tiles, etc.). The gap between the fire insert and the facing and the internal storage casing is heat- ed during operation. - Page 28 SMART-LINE ECO-LINE Installation Guide Combustible environment Floor: The mounts of the fire insert must be placed directly on the load-bearing support. The installation floor under the fire insert must be covered by means of a concrete slab of 12 cm thick- ness.

- Page 29 SMART-LINE ECO-LINE Installation Guide Non-combustible environment Floor: The mounts of the fire insert must be placed directly on the load-bearing support. 8 cm A thermal insulation layer of 6 cm thickness must be provided between the fire insert and the installation floor.

- Page 30 SMART-LINE ECO-LINE Installation Guide 9.4. Storage casing The casing is made using storage tiles. It must be built around the fire insert in a possibly compact manner. The material used must have the following characteristics: high density (≈ 2.8 kg/dm³) good conductivity high temperature resistance The distance between the fire insert and the storage casing should be ap-...

- Page 31 SMART-LINE ECO-LINE Installation Guide The relation of the minimum required facing surface and the nominal heat output is as follows: facing surface If for construction-related reasons the optimum facing surface cannot be met, a sealable hot air screen is to be fitted in the area of the facing cowls.

-

Page 32: Example Uranus/Neptun Style - Assembly Of Connection Box

SMART-LINE ECO-LINE Installation Guide 10. Uranus & Neptun HK style – assembly of connection box for outside/fresh air 1. Knock out the perforated part (A) on the required side using a hammer and fold the two lugs (B) to the outside. The FL shutter (C) can now be secured in any direction on top of the connection box (D) by means of the tapping screws included in the set. -

Page 33: Positioning Of Type Plates

SMART-LINE ECO-LINE Installation Guide 11. Positioning of type plates Positioning of type plates K appliances below ash pan/insert stone HK appliances below insert stone round HK appliances Upper right corner above the door at the flat head plate (side of lock) Example of a type plate (without values):... - Page 34 SMART-LINE ECO-LINE Installation Guide Notes...

- Page 35 SMART-LINE ECO-LINE Installation Guide...

- Page 36 89.90.00454 ma_smart-line_en_rev2_07.2013...

Need help?

Do you have a question about the URANUS HK and is the answer not in the manual?

Questions and answers