Advertisement

Quick Links

Installation, Operation and Maintenance Manual

RDP

EQID# RP-62689

API 674 3

rd

ed Reciprocating Plunger Pump

Revision 1.2, 21

st

November 2015

These instructions should be read prior to installing, operating and maintaining the RDP pump.

Ruhrpumpen UK Ltd

Unit 22, Commerce Way, Lancing, West Sussex. BN15 8TA

T: +44 (0) 1273 956410. E: salesuk@ruhrpumpen.com W: www.ruhrpumpen.com

Advertisement

Summary of Contents for Ruhrpumpen RDP

- Page 1 Reciprocating Plunger Pump Revision 1.2, 21 November 2015 These instructions should be read prior to installing, operating and maintaining the RDP pump. Ruhrpumpen UK Ltd Unit 22, Commerce Way, Lancing, West Sussex. BN15 8TA T: +44 (0) 1273 956410. E: salesuk@ruhrpumpen.com W: www.ruhrpumpen.com...

- Page 2 2/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Contents GENERAL INFORMATION Use of User Manual Additional Documentation Declaration of Conformity Environment and Waste Disclaimer Duty Conditions WARRANTY SAFETY Safety Actions...

- Page 3 Disclaimer Information in this manual is believed to be reliable in spite of all the efforts of Ruhrpumpen UK to provide sound and all necessary information, the content of this manual may appear insufficient and is not guaranteed by Ruhrpumpen UK as to it completeness or accuracy.

- Page 4 4/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Do not use pumps as support for piping Only check direction of motor rotation with coupling element pins removed. Starting in reverse direction of rotation will damage the pump.

- Page 5 5/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 This symbol indicates potential risks connected with extremely high temperatures. This symbol indicates potential risks connected with extremely low temperatures. Limitations in Use The products of the manufacturer are strictly designed to perform as described in this user manual.

- Page 6 Installation and Operating Manual - RDP Type Pump Rev 1.2 Where Ruhrpumpen UK has supplied only the bare shaft pump, the Ex rating applies only to the pump. The party responsible for assembling the pump set shall select the coupling, driver and any additional equipment, with the necessary CE Certificate/ Declaration of Conformity establishing it is suitable for the area in which it is to be installed.

- Page 7 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Temperature classification “Tx” is used when the liquid temperature varies and when the pump is required to be used in differently classified potentially explosive atmospheres. In this case the user is responsible for ensuring that the pump surface temperature does not exceed that permitted in its actual installed location.

- Page 8 CORRECT MAINTENANCE IS REQUIRED TO AVOID POTENTIAL HAZARDS WHICH GIVE A RISK OF EXPLOSION See section 7 for maintenance description, contact Ruhrpumpen UK technical department for further advice if necessary (see section 4.3 for contact details). The responsibility for compliance with maintenance instructions is with the plant operator.

- Page 9 Ruhrpumpen UK’s RDP pump type is defined as a horizontal, single acting, reciprocating plunger pump. The RDP pump type can be manufactured to use either a Triplex (3) or Quintuplex (5) plunger configuration. The basic operation of the pump can be defined in 2 steps.

- Page 10 10/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 RDP Pumps Product Code Figure 4.C - Product Code...

- Page 11 4.3.3 If assistance is required please contact Ruhrpumpen UK, where our technical staff will be pleased to offer advice. Contact the UK team on: Ruhrpumpen UK Pumps UK Ltd,...

- Page 12 Shipping and Handling 5.1.1 Most RDP pump packages or bare shaft pumps are shipped on a wooden pallet type base and will be covered in a number of different ways including a solid wood box, plastic or cardboard depending on customer specification.

- Page 13 Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 5.2.5 Suction line filters should be avoided, but if filters are necessary refer to Ruhrpumpen UK technical service for advice (see section 4.3 for details). 5.2.6...

- Page 14 5.2.16 The correct lifting procedure and equipment must be used at all times to ensure safe and accurate placing of the skid. 5.2.17 Ruhrpumpen UK Pump skids can be welded or bolted in position, it is essential that the base frame remains level and is not twisted or buckled.

- Page 15 15/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Relief Valves CAUTION: Failure to install a relief valve or correctly specify relief valves installed may cause personal injury or damage to the pump or system.

- Page 16 16/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 START UP AND SHUT DOWN PROCEDURES Preparing to Start 6.1.1 Ensure that all isolation valves in the suction and discharge pipe work systems are open.

- Page 17 17/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Figure 6.A - Direction of Rotation 6.2.5 The pump can now be started with initial monitoring of flow rate and pressure. Check pump for air entrapment, if this is apparent, purge the fluid end.

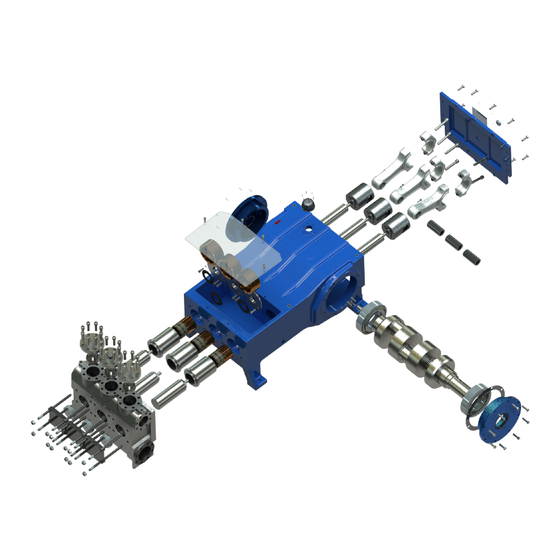

- Page 18 7.1.2 All RDP pump packages can be split into three main sections (Figure 7.A). Figure 7.A - Sections of the Pump Maintenance Schedule...

- Page 19 19/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Fluid Head Figure 7.B - Fluid Head 7.3.1 The inlet and discharge valves can be serviced with the fluid head still attached to the pump although care must be used as the plungers will be exposed on some configurations.

- Page 20 20/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Figure 7.C - Top Plug Assembly 7.3.3 The Top plugs can be removed by un-screwing the relevant fasteners as shown in Figure 7.C.

- Page 21 21/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Figure 7.E - Valve Assembly 7.3.5 The valve assembly consists of parts shown in Figure 7.E. The spring cage has a thread that is used to attach it to the valve seat.

- Page 22 22/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Figure 7.F - Valve Removal 7.3.7 As the valve seats have a tapered press fit they require a special extractor tool to remove them.

- Page 23 23/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Figure 7.G - Valve Seat Extractor Figure 7.H - Valve Seat Removal...

- Page 24 7.3.9 Inspect all parts for any damage or wear. If upon inspection there is significant damage then the part must be replaced with a spare part. Please contact Ruhrpumpen UK for supply of addition spare parts if required. 7.3.10 During re-assembly great care must be taken to ensure that all seating areas are spotlessly clean;...

- Page 25 25/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Power End Figure 7.I - Power End 7.5.1 The Main power end parts can be seen in Figure 7.I . 7.5.2 Maintenance of the power end will be limited to oil changes and checking for leaks on the distance piece seal housing.

- Page 26 26/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 7.5.5 Inspect the magnetic drain plug once removed. If the plug has attracted a large quantity of metal particles then this is an indication that there is a problem somewhere in the power end and it is likely that a part is damaged.

- Page 27 27/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 7.5.9 If the distance piece is scored it must be replaced. Loosen and remove from pump as shown in Figure 7.M. Figure 7.M – Distance Piece Removal 7.5.10 Repair or replace items where necessary making sure all parts are clean and grit free before...

- Page 28 28/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Power End Overhaul 7.6.1 In the unlikely event that a complete overhaul is required these procedures must be followed. CAUTION: IF A COMPLETE OVERHAUL IS REQUIRED THE PUMP MUST FIRST BE REMOVED FROM ANY SKID AND DRIVE TRAIN.

- Page 29 29/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 7.6.7 Remove bolts from the connecting rods as shown in Figure 7.O. Figure 7.O - Big End Removal 7.6.8 Push all three connecting rods fully forward.

- Page 30 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 7.6.12 If required the Connecting Rod / Cross-Head / Distance piece assemblies may be withdrawn. 7.6.13 To separate the connecting rod from the cross head the wrist pin must be removed. The wrist pin is secured by a bolt as shown in Figure 7.Q.

- Page 31 Elf Tecnic Super 15W/40 Or any other 15W/40 lubricant meeting the requirements of Specification API CE/SF Applications with running temperatures between 100 and 120 °C: BP Vanellus M20/50. Applications with running temperatures greater than 120°C - Contact Ruhrpumpen UK Engineering Department.

- Page 32 Installation and Operating Manual - RDP Type Pump Rev 1.2 Stuffing Box 7.7.1 Ruhrpumpen UK use several different configurations of Stuffing box but the two main types are braided type packing (Figure 7.R) and chevron type packing (Figure 7.S). Figure 7.R - Stuffing Box with Braided Packing Figure 7.S - Stuffing Box with Chevron Packing...

- Page 33 33/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 7.7.2 The gland nut should be checked periodically and tightened if required. The packing's should not require regular attention and over tightening will cause damage.

- Page 34 34/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Figure 7.U - Removal of Packing 7.7.10 Remove any remaining packing. 7.7.11 Inspect the plungers, if damaged or scored the plungers must be replaced.

- Page 35 35/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Fault Finding SYMPTOM: Incorrect pressure or flow from pump POSSIBLE CAUSE REMEDY No liquid in reservoir or tank. Ensure lines are connected and valves are open.

- Page 36 36/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Low oil level in power end. Fill to proper level. Excessive main bearing clearance. Adjust end-play. Worn wrist pin. Replace worn components.

- Page 37 37/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 Pump located too close to heat source. Remove heat source or install crank case cooler. Worn or damaged power end bearings. Replace damaged bearings.

- Page 38 Be sure oil is reaching all bearings. Liquid in Power End. Drain Power End. Check stuffing box and filler breather for damage or wear. These notes are a guide only. Contact Ruhrpumpen UK for confirmation or advice (see section 4.3 for details).

- Page 39 1.5 meters of a tank holding 6-10 times the capacity of the pump suction. All sharp bends and pipe reductions should be avoided as much as possible. Contact Ruhrpumpen UK Pumps for advice (see section 4.3 for details).

- Page 40 Installation and Operating Manual - RDP Type Pump Rev 1.2 APPENDIX B - LIMITED WARRANTY Ruhrpumpen UK will repair or replace any component of its own manufacture which, in the opinion of Ruhrpumpen UK, is defective in workmanship or material under normal or proper use provided the same is returned at the customer's risk and expense to ‘Ruhrpumpen UK Pumps' facilities within 12 months or 1000...

- Page 41 41/42 API 674 3 ed Reciprocating Plunger Pump Installation and Operating Manual - RDP Type Pump Rev 1.2 10 APPENDIX C - ORDER FORM FOR SPARE PARTS FAX / E-MAIL : ADDRESS : Your order will only be dealt if this order form has been correctly completed and signed...

- Page 42 Please note, the following can invalidate warranty: - Use of non-genuine Ruhrpumpen UK parts for maintenance and repairs - Servicing or repairs conducted by non Ruhrpumpen UK personnel during warranty period The information contained in these documents is subject to change without notice.

Need help?

Do you have a question about the RDP and is the answer not in the manual?

Questions and answers