Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ruhrpumpen CPP

- Page 1 Installation, Operation and Maintenance Manual...

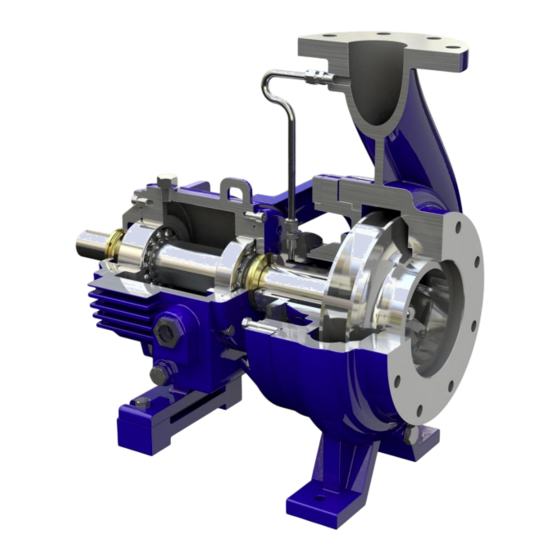

- Page 2 These units are horizontal process pumps of the overhung power frame configuration and identified by Ruhrpumpen as CPP. This pump family is divided into different lines: the CPP line meets the ANSI/ASME B73.1 – 2020 requirements, and the CPP-L line is a solution for low flow and high head applications.

- Page 3 Care must also be taken to prevent ignition of flammable fluids or other material. Information in this manual is believed to be reliable, but it is not guaranteed by Ruhrpumpen as to its completeness or accuracy. © 2022 Ruhrpumpen All Rights Reserved.

-

Page 4: Table Of Contents

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 INDEX 1. PRODUCT DESCRIPTION ........................8 1.1 INTRODUCTION ..........................8 1.2 PUMP CASE, IMPELLER, AND WEAR RINGS ..................9 1.2.1 Pump Case ..........................9 1.2.2 Impeller and Wear Rings ......................9 1.3 CASE COVER ............................ - Page 5 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 4.3.1 Equipment/Material Required ....................35 4.3.2 Grouting Precautions......................35 4.3.3 Grouting Procedure ........................ 35 4.4 AUXILIARY CONNECTIONS ......................37 4.5 ELECTRICAL CONNECTIONS ......................37 4.6 DIRECTION OF ROTATION CHECK ....................38 4.7 INSPECTION ...........................

- Page 6 8.2 INSPECTION AND CLEANING ......................82 8.3 REASSEMBLY ..........................82 8.3.1 CPP ............................83 8.3.2 CPP-L ............................. 111 8.3.2.1 CPP-L Impeller Clearance Adjustment ................121 8.3.3 Coupling Guard Assembly ....................124 8.3.4 C – Frame Assembly ......................127 8.4 SERVICING ........................... 130 8.4.1 Safety Regulations ........................

- Page 7 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 12.1 PUMP OPERATION LOG......................152 V5.080822...

-

Page 8: Product Description

1.1 INTRODUCTION Ruhrpumpen pumps of type CPP are centrifugal pumps of the horizontal, vertically (radially) split case, foot mounted heavy-duty construction with an overhung impeller, and are designed to meet the requirements of ANSI/ASME B73.1 – 2020. These pumps are designed for continuous duty... -

Page 9: Pump Case, Impeller, And Wear Rings

The CPP is a single stage, end suction pump. For these pumps, rotation is clockwise as viewed from the driver (coupling) end. - Page 10 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Figure 1.1 Cooling jacket special machining on case cover. V5.080822...

-

Page 11: Bearing Frame

6314 3314 NR * In CPP-L pump line, thrust bearings for frames 10 and 30B are 3307 and 3310 respectively. When purge or pure oil mist is specified, appropriate connections will be identified on the bearing frame. See SECTION SIX - LUBRICATION for more details. -

Page 12: Safety

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 2. SAFETY This operation manual gives basic instructions that should be observed during installation, operation and maintenance of the pump. It is therefore imperative that this manual be read by the responsible personnel/operator prior to assembly and commissioning. -

Page 13: Qualification And Training Of Operating Personnel

If the staff does not have the necessary knowledge, they must be trained and instructed. Training may be performed by a Ruhrpumpen representative on behalf of the plant operator. Moreover, the plant operator is to make sure that the contents of the operating manual are fully understood by the personnel. -

Page 14: Safety Instructions Relevant For Maintenance, Inspection And Assembly Work

On completion of work all safety and protective facilities must be re-installed and made operative again. Prior to restarting the machine, follow the instructions listed under SECTION 7.2-STARTUP. 2.7 UNAUTHORIZED ALTERATIONS AND SPARE PARTS Modifications may be made to the machine only after consultation with a Ruhrpumpen representative. V5.080822... -

Page 15: Unauthorized Modes Of Operation

ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Using spare parts and accessories authorized by Ruhrpumpen is in the interest of safety. The use of parts not authorized by the dealer exempt the manufacturer from any liability, voiding the warranty. -

Page 16: Transport & Storage

Handle all equipment carefully. Remove unit only by properly supporting the wooden shipping skid. After unloading, inspect the pump, check the shipment against the packing list, and report damages or shortages immediately to freight carrier and to the designated Ruhrpumpen representative. CAUTION Do not place lifting rig around bearing frame or under baseplate. -

Page 17: Transport

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 3.3 TRANSPORT NOTE The electric motor may be provided with a lifting eye, this lifting eye is intended only for the purpose of carrying out service activities to the electric motor only. NEVER lift a complete pump unit at the lifting eye of an electric motor. - Page 18 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CAUTION When transporting with a crane, the rope should be slung round the unit as shown in the figure below. CAUTION The rope should not be slung around the lugs attached to the motor or around the lugs attached to the pump.

- Page 19 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Figure 3.1. Correct position of the lifting ropes or chains, side view without and with C-Frame. V5.080822...

-

Page 20: Storing

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 3.4 STORING CAUTION Damage during storage due to liquid ingress, humidity, dirt or vermin. Corrosion/contamination of the pump (set). • Clean and cover pump apertures and connections as required prior to putting the pump into storage. - Page 21 When the pump is to be installed, remove all the protective coatings and desiccant or drain all oils. One month before installation, a Ruhrpumpen representative should be employed to conduct a final inspection. To properly store the motor (driver) for periods longer than one month, follow these steps: Store the motor in a clean, dry area, or cover it with a loose tarp (the tarp must be loose in order to prevent condensation).

- Page 22 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 ATTENTION Always drain the oil before moving the pump, to avoid any damages, and refill the motor on its new location. Rotate the shaft of the motor once a month. Some form of heating must be used to prevent condensation.

-

Page 23: Conservation

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 3.5 CONSERVATION All exposed, machined, working surfaces (flanges, seals, surfaces supporting the motor), shaft ends, unpainted couplings and the like have been cleaned and treated with anticorrosive agents. After being cleaned, all parts inside the pump housing have been sprayed with anticorrosive agents. - Page 24 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 WARNING Waste oil is hazardous to public health and the environment. Overhead disposal causes pollution to both the groundwater stream and the soil. • Collect, segregate, and properly dispose of waste oils. •...

-

Page 25: Inspection

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 DANGER Magnetic impact on personal health. Danger to life. • Never permit people to come in contact with Electro-Magnetic devices like motors, variable frequency drives, and magnetic drive assemblies who may have personal risks that can be impacted (e.g. - Page 26 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 NOTE All transmitting devices and radio equipment assemblies are sub-components of the pump (set) with their own installation, operating, and maintenance guidelines. All details can be found on nameplate(s) affixed to the device(s).

-

Page 27: Installation

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 4. INSTALLATION CAUTION Mishandling and improper installation of inflammable, toxic, or other substances that harmful. Danger to life and the environment. • Installation, foundation and maintenance of pumps handling inflammable liquids and other pollutive products may only be performed by authorized companies or their personnel. - Page 28 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 WARNING Unsecure installation on surfaces which are unsuitable for support the static and dynamic loads. Personal injury and damage to property. • Use concrete with compressive strength class C12/15 which meets the requirements of exposure class X0 to EN 206-1.

- Page 29 Bracket the pipe-work in close vicinity to the pump in which to isolate the pump from stress/strain. • Use expansion devices to accommodate thermal, local, and vibration movement of the piping. Correct and orderly installation/assembly is necessary for trouble-free operation of the unit. Ruhrpumpen does assume liability damage resulting...

-

Page 30: Concrete Foundation Preparation

API Recommended Practices 686. IMPORTANT The design of foundations is not the responsibility of Ruhrpumpen. It is therefore recommended that the customer consult a competent specialist skilled in the field of foundations, to insure proper design/installation of the foundation. - Page 31 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Figure 4.1. Imaginary lines. It is recommended to build foundation approximately 3 inches (76 mm) larger overall than the pump baseplate to provide ample anchorage for the foundation bolts. 3.1.

-

Page 32: Leveling Baseplate

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 4.2 LEVELING BASEPLATE NOTE The information included in this section is intended as a general guideline. For further information refer to the corresponding section in API Recommended Practices 686. Before leveling the unit onto the foundation, the following preparations must be made: Chip away all damaged concrete with a hammer and chisel, eliminating about one inch of the surface of the foundation. - Page 33 (See the figure shown below); leveling within 0.002 in/ft (0.2 mm/m) is recommended. Wedges or shim packs should feel solid when tapped lightly by a hammer. CPP and CPP-L with pedestals CPP and CPP-L with mounting blocks V5.080822...

-

Page 34: Grouting

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CPP C-Frame Figure 4.2. Baseplate leveling planes. NOTE The baseplate should be mounted without distortion. When baseplate is level, 'snug' the foundation bolt nuts, but do not tighten completely. -

Page 35: Equipment/Material Required

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 4.3.1 Equipment/Material Required • Grout Mix: Non Shrink Type • Sufficient lumber for foundation template and grout trough. • Risers or funnels for guiding grout. •... - Page 36 Once the grout has completely hardened (takes around 3 days), remove wedges (shim packs) and grout-forms. Fill the holes with grout. Tighten the foundation bolts with an appropriate torque value. In case of doubt, please contact your Ruhrpumpen representative. Apply oil paint to exposed grout to protect from air and moisture. V5.080822...

-

Page 37: Auxiliary Connections

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Use a lifting rig to position the pump and driver on their baseplate so that the mounting feet line up with their respective tapped holes. Fasten the pump and driver hold down bolts;... -

Page 38: Direction Of Rotation Check

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CAUTION Excessive time between star and delta switch-over on three-phase motors during start-up takes too long. Damage to the pump (set). • Optimize switch-over period between star and delta. •... -

Page 39: Inspection

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 4.7 INSPECTION WARNING Trapped hands & fingers around the motor and coupling elements. Risk of injuries. • Always secure coupling guards correctly, ensuring that fingers cannot enter the rotating elements, before starting the pump and during operation. -

Page 40: Piping And Alignment

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 5. PIPING AND ALIGNMENT DANGER Excessive loads acting on the pump nozzles/flanges. Danger to life from leakage of hot, toxic, corrosive or flammable fluids. • Always ensure that surrounding pipe-work is aligned to the pump without strain. - Page 41 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CAUTION Do not start the piping and alignment procedures until grouting, preliminary alignment (as seen in the previous sections of this manual) and on site welding have been performed. ATTENTION In a new installation, great care should be taken to prevent dirt, scale, welding beads, and other items from entering the pump.

-

Page 42: Piping The System

API Recommended Practices 686. IMPORTANT The design of piping and related systems is not the responsibility of Ruhrpumpen. It is, therefore recommended that the customer consult a competent specialist skilled in the field of piping to insure proper design/installation of all the piping. - Page 43 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Cone type strainers (otherwise known as “witches – hat” strainers) should be mounted as recommended by the Hydraulic Institute, with the cone pointing upstream away from the pump, into the oncoming flow.

- Page 44 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 ATTENTION Make sure that there are isolation block valves at the pump for each type of auxiliary piping. ATTENTION Consider a slope in the suction piping to avoid high points. ATTENTION In horizontal suction lines, reducers should be eccentric (with the flat side of the reducer on top).

-

Page 45: Alignment

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 ATTENTION Do not use drifts or cheater bars to force alignment of bolt holes – serious damage to the pump will result. 5.2 ALIGNMENT NOTE The information included in this section is intended as a general guideline. - Page 46 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 bottom, and reading the difference. Once the indicator sag set-up has been determined, this number can be algebraically subtracted from the alignment readings obtain at the bottom. There is no need to be concerned about the side to side readings as the sag is equal on both sides.

- Page 47 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 B. REVERSE INDICATOR ALIGNMENT GRAPHICAL ANALYSIS On a sheet of graph paper, lay out the equipment that you are trying to align. You should use a scale that is convenient to the size of the graph paper.

- Page 48 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Figure 5.2. Indicator sag. With the indicator bracket attached to the motor hub reading off the pump hub, rotate unit in 90° increments and take readings. Bottom reading is then corrected for indicator sag.

- Page 49 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Figure 5.3. Motor shaft extension relative to the pump shaft center line. Now with the indicator bracket attached to the pump hub reading off the motor hub, rotate unit again in 90°...

- Page 50 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Figure 5.4. T.I.R. second reading. We have now located the motor shaft theoretical extension in two places: A. In the plane of the pump hub. B.

- Page 51 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 C. REVERSE INDICATOR ALIGNMENT MORE THAN TWO UNITS GRAPHICAL ANALYSIS This method lends itself very well in solving alignment problems of three or more pieces of equipment in a line.

- Page 52 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Figure 5.7. Across the disc pack alignment graphical analysis example. The next step is to determine indicator sag. Set up your bracket arrangement on a pipe. Set the indicator at '0' on top.

- Page 53 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 With the indicator bracket attached to the pump hub, reading out the center member a convenient distance, (in this example 8 inches [203.2 mm] was used) rotate the unit in 90° increments and take readings.

- Page 54 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Now with the indicator bracket attached to the motor hub reading out on the center member, rotate the unit in 90° increments and take readings. Bottom reading is corrected for indicator sag: ±0.008 inch (±0.203 mm) -0.004 inch (0.102 mm) = +0.012 inch (+0.309 mm).

- Page 55 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 For the horizontal (side to side) results, the same procedure is used. Algebraically subtract the side to side readings. Indicator sag can be ignored as it cancels out. Plot these readings and the results can be read off the graph.

-

Page 56: Mounting Blocks Or Pedestals

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 5.3 MOUNTING BLOCKS OR PEDESTALS The driver may be fastened to the baseplate by either pedestals or a block mounting system. Figure 5.11. Above, baseplate with pedestals for driver. Below, baseplate with mounting blocks for driver. Regardless of the method to support the driver, the alignment procedure is the same. - Page 57 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 When the baseplate has pedestals for the driver, each foot is secured to the baseplate with a hexagonal head screw. Figure 5.12. Detail of pedestal system to secure the driver’s feet. The mounting blocks system consists of a mounting stud, with an intermediate nut to secure the mounting block to the baseplate, and an upper nut to fasten the driver’s foot to the mounting block.

-

Page 58: Lubrication

ATTENTION Ruhrpumpen takes every precaution during our assembly process and subsequent final assembly audits to ensure no bearing frame oil leaks exist prior to shipment. Oil can leak past the labyrinth seal in an “overfill”... -

Page 59: Quantity

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 6.1.3. Quantity Oil Quantity Frame Quarts 0.21 0.20 0.79 0.75 1.80 1.70 3.17 3.00 Always verify and replenish the oil if the level falls below the middle of the oil sight glass. V5.080822... -

Page 60: Cooling Coil Option

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 6.1.4 Cooling Coil Option If the pump has been ordered with the optional cooling coil, the pump has a cooling coil in the bearing frame, with inlet and outlet connections for the coolant. A schematic drawing of this cooling system is shown on the next figure: Figure 6.1. -

Page 61: Maintenance

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 The cooling coil option is available only when the bearings are lubricated with the standard oil lubrication (SECTION 6.1-OIL LUBRICATION) or the optional purge oil mist lubrication (6.3 PURGE OIL MIST-WET SUMP). -

Page 62: Purge Oil Mist-Wet Sump

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 • Recommended Oil: ISO VG 68 Non-Detergent Oil suitable for oil misting. (Refer to instructions with Oil Mist Generator.) • Air/Oil Ratio should be 0.40 cubic inches/hour/cfm (231.5 cc/hr/m3/min) •... -

Page 63: Oil Change

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Provide oil mist through the oil mist inlet as indicated on the General Arrangement. Oil mist can be vented out thru the vent as indicated on the General Arrangement; however, if the intent is to maintain positive pressure in the bearing housing then no venting is needed. -

Page 64: Constant Level Oiler (Optional)

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 6.4.2 Constant Level Oiler (Optional) The oil change should be carried out as follows: 1. Switch the drive motor off. 2. Drain the oil out and clean the bearing housing with a suitable cleaning liquid. Flushing the bearing housing with clean lightweight oil is possible (e.g. - Page 65 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Figure 6.2c. Oil tank cap (with socket screws). Figure 6.2d. Oil tank reservoir. 4. Untighten the socket screws of the oil tank cap. 5. Remove the oil tank cap along the oil tank reservoir. 6.

-

Page 66: Grease Lubrication

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 ATTENTION If it is suspected that the bearings have been exposed to dirt or moisture, thoroughly clean the bearings and frame with a solvent and air-dry the parts before adding lubricant. Disassembly, inspection, cleaning, and reassembly procedures are provided in SECTION EIGHT - MAINTENANCE. -

Page 67: Regular Grease Change

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 6.5.1 Regular Grease Change It is recommended that grease be changed completely every six months to one year depending on the total running hours of the pump. If the pump is a stand-by unit or if it is run only a few hours each month, the grease should be changed every six months. -

Page 68: Operation

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 7. OPERATION ATTENTION NEVER operate the pump in a system or under system conditions (flow, pressure, temperature, etc.) for which it has not been designed. NOTE The electric motor and drive assembly is a sub-component of the pump (set) with its own installation, operating, and maintenance guidelines. - Page 69 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Before starting any centrifugal pump it is necessary that the pump casing and the suction pipe are completely filled with liquid. Priming can be done in the following ways: When the liquid is over the line of the pump center it is primed by opening the suction and discharge valves.

-

Page 70: Startup

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 7.2 STARTUP DANGER Abnormal noise, vibration, temperature or leakage. Damage to the pump. • Switch off the pump (set) immediately. • Eliminate the causes before returning the pump set to service. •... - Page 71 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 WARNING Continue operation against a closed discharge valve without an additional bypass. Damage to the pump. • Make sure the discharge valve is completely open prior start-up. •...

- Page 72 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CAUTION Excessively high density fluids being handled. Motor overload. • Observe the information about fluid density in the data sheet. • Ensure the motor has sufficient power reserves. •...

-

Page 73: Operating Check

SECTION ELEVEN - TROUBLESHOOTING CHART). To monitor flow, pressure, temperature, and lubrication, regular visual inspection and monitoring is advisable and/or necessary during operation. Ruhrpumpen recommends checking the pump constantly at regular intervals in order to detect problems early, in case they arise. V5.080822... - Page 74 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 The operational check routine must include at least the following points: DANGER Beware of freely rotating parts, when the pump is in operation there is a high risk of injury. •...

-

Page 75: Doweling (Optional)

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 WARNING The pump may only be operated under the minimum operating range for short periods. The minimum pump flow is given in the characteristic line. For pumps with packing seal, do not tighten excessively to the point of stopping the leakage. -

Page 76: Shutdown

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 ATTENTION If the rotor is jerky or suddenly stops, there is danger that the rotor has become blocked. The pump must be opened and all running clearances checked. Close the suction valve when the pump shaft stops rotating as the pump must be isolated before examination and made safe. -

Page 77: Short-Term Shutdown

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CAUTION Reverse rotation of the pump caused by fluid backflow is not permitted. Motor or winding damage. Mechanical seal damage. • Close the isolation valve(s) when the pump is not running. •... -

Page 78: Ambient Temperature

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Change the oil before recommencing operation, ensuring the correct grade and the correct volume has been filled in the bearing frame (see SECTION SIX - LUBRICATION for details). -

Page 79: Maintenance

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 8. MAINTENANCE To perform the maintenance of the CPP pump, no special (custom made) tools are needed. CAUTION Mishandling and improper installation of inflammable, toxic, or other substances that are harmful. -

Page 80: Disassembly

IMPORTANT For any component/accessory that has not been manufactured by Ruhrpumpen and is part of the pump’s equipment, a complete reading of said component/accessory manufacturer’s manual must be carried out for further information on proper maintenance procedures and relevant safety warnings. - Page 81 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 After removal, place the pump cover-power frame safely on suitable horizontal supports. To remove the impeller, first free and remove the cover-to-case gasket. CAUTION Do not heat the impeller. Impeller has a right-hand thread.

-

Page 82: Inspection And Cleaning

Remove radial bearing from shaft. Remove lock nut and lock washer and remove thrust bearings from shaft. For CPP-L pumps, the rotor is removed towards the coupling for all the power frames regardless of their size. -

Page 83: Cpp

Bearings should be demagnetized before mounting them, to avoid contamination. 8.3.1 CPP Please follow the steps detailed on this section to reassemble the CPP pump. To reassemble the CPP- L pump, please refer to SECTION 8.3.2-CPP-L. Place and heat the axial bearing in an induction heater. Turn on the heater. Continuously measure the temperature of the inner race, looking to reach 230 °F (110 °C). - Page 84 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Figure 8.1b Example of a bearing installation kit approved by the manufacturer. Position the shaft vertically (with the coupling side upward) in a press. ATTENTION Cover the jaws of the press with soft material to prevent damaging the shaft.

- Page 85 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 WARNING Wear sufficient hand protection to avoid personal injury. IMPORTANT Wait until the bearing has cooled down to room temperature before starting the next step. This cooling period is critical to ensure the final contraction of the bearing before the next adjustments.

- Page 86 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Position the locknut with the taper towards the side of the lock washer at full-stop. Figure 8.4. Positioning the locknut. Now take the shaft out of the press and turn it over 180°, place it back in the press to reassemble the radial bearing.

- Page 87 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 ATTENTION If there is no way of properly heating the bearing for installation, a bearing installation kit approved by the manufacturer can be used to perform a bearing installation at room temperature.

- Page 88 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Place the rotor assembly in the power frame. There are two possible options depending in the power frame size. Power frame 30-B: Install the rotor from the pump side. Figure 8.6.

- Page 89 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Tighten the bearing lock nut as tight as possible by hand using a spanner wrench. Ensure at the end of the tightening process that one of the lock washer tabs lines up with the slot in the locknut.

- Page 90 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 To insert the labyrinth seals into the covers, follow these steps: a. Lubricate the outside ring of the labyrinth seal. Lubricant supplied by isolator manufacturer or P 80 Rubber Lubricant Emulsion is recommended (grease is NOT recommended).

- Page 91 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 d. Using a sleeve and a flat surface (hard plastic) with the help of an arbor press, insert the labyrinth seal. Figure 8.12. Inserting the labyrinth seal. ATTENTION Do not use a hydraulic press, since the seal can be broken.

- Page 92 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Position the radial O-ring at the cover. Position manually the cover on the power frame, ensuring the cover is rotated in the correct position. Figure 8.14. Positioning the radial O-ring. To position the radial cover at the power frame, first put some lubricant (provided by the supplier) in the inner diameter of the radial labyrinth seal.

- Page 93 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Position the bolts manually. Now tighten these bolts diagonally (crosswise) to ensure correct reassembly. Figure 8.16. Radial cover assembly. INSPECTION POINT Check that the bearings enter evenly in the frame; the bearing should rest against the wall of the power frame.

- Page 94 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Lubricate the internal diameter of the labyrinth seal. Lubricant supplied by isolator manufacturer or P 80 Rubber Lubricant Emulsion is recommended (grease is NOT recommended). Figure 8.18.

- Page 95 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Use the proper wrench to install plugs, sight glass, breather and any other necessary plug. Figure 8.20. Identifying the plugs in the bearing frame. ATTENTION Apply pipe tape sealant only if it is a pass-through thread (except for the vent).

- Page 96 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 ATTENTION Apply pipe tape sealant only if it is a pass-through thread. INSPECTION POINT Verify that the plugs are not in contact with the mechanical seal head. Figure 8.22.

- Page 97 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Insert the wear ring completely in the shoulder of the case using a press. Figure 8.24. Positioning the wear ring. Insert the wear ring completely in the shoulder of the case cover using a press. Figure 8.25.

- Page 98 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 This step applies only for pumps with Mechanical Seal. If the pumps has Packing Seal, please skip this reassembly step and go to step 23. To position the mechanical seal in the power frame, first check the drawing of the mechanical seal, to be sure of assembling the seal at its correct position.

- Page 99 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Insert the mechanical seal head in the shaft until tight. Figure 8.28. Positioning the mechanical seal head. Grease the seal’s rotary face and install it in the shaft to the limit with the mechanical seal head.

- Page 100 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Install the spring in the shaft. Figure 8.30. Positioning the spring in the shaft. Install the two set screws in the spacer. Figure 8.31. Positioning the set screws. Install the spacer in the shaft.

- Page 101 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Tighten the set screws to set the spacer in that position. Figure 8.33. Fixing the spacer in the shaft. To install the four studs in the case cover, follow these steps: Place the four studs in the case cover by hand.

- Page 102 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Tighten both nuts as shown. Figure 8.36. Tightening the paired nuts. Use the spanner to tighten the stud. Figure 8.37. Tightening the studs. V5.080822...

- Page 103 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Loosen the two nuts as shown. Figure 8.38. Removing the nuts. Repeat these steps to tighten each of the remaining studs. Install the case cover in the power frame. Figure 8.39.

- Page 104 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Position the screws to hold the case cover with the power frame. Figure 8.40. Positioning the screws to hold the case cover. Position the O-ring in the impeller. Apply antiseize protection on the shaft thread and position the impeller.

- Page 105 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 This step applies only for pumps with Mechanical Seal. If the pump has Packing Seal, please skip this reassembly step and go to step 29. Install the studs and nuts in the mechanical seal head.

- Page 106 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Lift the assembly of the power frame and position it over the case shoulder. Figure 8.43. Positioning the power frame assembly on the case. Position the bolts by hand. Tighten these bolts diagonally (crosswise) to ensure the correct assembly.

- Page 107 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 This step applies only for pumps with Packing Seal. Insert the packing rings one by one into the stuffing box in such a way that every ring’s coupling points fit 180° from each other: Insert two strips of packing in the packing chamber rolled around the sleeve.

- Page 108 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Place two strips of packing in the packing chamber. Make sure the packing is touching the lantern ring. Figure 8.46. Inserting the next two strips of packing. ATTENTION The joining faces of each strip must not be aligned, to ensure a proper assembly and function.

- Page 109 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Assemble the two parts of the packing gland around the previously placed studs. Figure 8.48. Assembling and inserting the packing gland. While holding the two parts of the packing gland, join them with their screws, and nuts.

- Page 110 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Place and tighten the corresponding washers and nuts in their position to hold the packing gland against the packing. Figure 8.50. Fastening the packing gland. V5.080822...

-

Page 111: Cpp-L

Figure 8.51. Connecting the tubing for the packing sealing. 8.3.2 CPP-L The CPP-L pump shares reassembly steps 1 through 5, and 23 through 31, with the CPP pump. Please follow the aforementioned steps from the CPP pump reassembly procedure found in SECTION 8.3.1- CPP when reassembling the CPP-L pump. - Page 112 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Now take the shaft out of the press and turn it over 180°, place it back in the press to reassemble the radial bearing. Insert the bearing retainer in the shaft before installing the radial bearing.

- Page 113 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Figure 8.52b Example of a bearing installation kit approved by the manufacturer. As soon as the bearing reaches the 230 °F (110 °C) temperature, it is manually positioned in the shaft (with the serial number visible from the outside).

- Page 114 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 ATTENTION Protect the bearings with oil and cling wrap plastic if you are not going to continue the assembling process immediately. When resuming the assembling process, remove this protection.

- Page 115 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Using a sleeve and a flat surface (hard plastic) with the help of an arbor press, insert the labyrinth seal. Figure 8.56. Inserting the labyrinth seal (image for illustration purposes, it is not the bearing carrier). ATTENTION Do not use a hydraulic press, since the seal can be broken.

- Page 116 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Slide the bearing carrier over the outer race of the thrust (axial) bearing to the limit where it stops. First put some lubricant (provided by the supplier) in the inner diameter of the thrust labyrinth seal.

- Page 117 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Position the two O-rings of the bearing carrier in their grooves. Be careful when placing the O-rings in their matching grooves, since they are of different sizes. Figure 8.60.

- Page 118 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Install the set screws loosely. Figure 8.62. Installing the set screws. Position the radial O-ring at the cover. Position manually the cover on the power frame, ensuring the cover is rotated in the correct position.

- Page 119 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Position the bolts manually. Now tighten these bolts diagonally (crosswise) to ensure correct reassembly. Figure 8.65. Radial cover assembly. INSPECTION POINT Check that the bearings enter evenly in the frame; the bearing should rest against the wall of the power frame.

- Page 120 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 ATTENTION Apply pipe tape sealant only if it is a pass-through thread (except for the vent). INSPECTION POINT Check visually that all the threads in the power frame have a plug installed (no thread should remain free after this step).

-

Page 121: Cpp-L Impeller Clearance Adjustment

Figure 8.69. Positioning the adapter ring. 8.3.2.1 CPP-L Impeller Clearance Adjustment This section applies for the CPP-L pump with bearing carrier. The adjustment of the impeller should be performed with the pump casing. Depending on the operating conditions is how the impeller clearance should be adjusted, and if those conditions change, the adjustment should be redone according to the new operating conditions. - Page 122 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Temperature in °F (°C) Clearance in inches (mm) < 200 (93) 0.018 ± 0.003 (0.46 ± 0.08) 200 to 250 (93 to 121) 0.021 (0.53) 251 to 300 (122 to 149) 0.024 (0.61) 301 to 350 (150 to 176)

- Page 123 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 clockwise until the impeller lightly rubs the casing. Now turn the bearing carrier counterclockwise to get the correct clearance between the impeller and the casing (as shown on the table). Turning the carrier through each mark represents a 20°...

-

Page 124: Coupling Guard Assembly

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 8.3.3 Coupling Guard Assembly Please follow these steps to assemble the coupling guard. Before installing the coupling guard in the pump, the coupling must be properly mounted and aligned. - Page 125 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Position both components in the lower side of the coupling. Insert the bolt of the lower cover in one of the frame supports as shown. Tighten the ½ inch (12.7 mm) nut by hand to support the two components.

- Page 126 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Position the pump side upper cover and insert the two bolts in the upper frame supports. Install the nuts to secure the coupling guard assembly and tighten by hand. Figure 8.76.

-

Page 127: C - Frame Assembly

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Tighten all the bolts and nuts with a spanner to rigid the assembly. Figure 8.78. Coupling guard assembly. 8.3.4 C – Frame Assembly For the C-Frame option, follow the next steps for its installation: Once the pump is installed over the baseplate, position the half coupling over the shaft of the pump and the other half coupling over the shaft of the motor. - Page 128 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Position the C-Frame over the register of the frame on the coupling side. Figure 8.80. Positioning the C-Frame. Place the three screws of the C-Frame and tighten them diagonally (crosswise). Figure 8.81.

- Page 129 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Place the hex screws of the C-Frame to fix it to the baseplate. Tighten the hex screws. Figure 8.82. Securing the C-Frame to the baseplate. With the help of a crane or hoist, install the C-Face motor (driver) over the register of the C-Frame.

-

Page 130: Servicing

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Install the spacer coupling between the shafts. Tighten the screws of each half coupling to secure them to the spacer coupling. Make sure that the rotor is able to turn with no major resistance. Figure 8.84. -

Page 131: Safety Regulations

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 NOTE The electric motor and drive assembly is a sub-component of the pump (set) with its own installation, operating, and maintenance guidelines. All details can be found on nameplate affixed to the drive(s). -

Page 132: Inspection

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 WARNING Unintentional starting of the pump set. Risk of injury by moving components and shock currents. • Ensure that the pump set cannot be started unintentionally. •... - Page 133 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CAUTION Excessively high temperature of fluid handled. Damage to the pump. • Prolonged operation against a closed isolation valve(s) is not permitted because it can heat the fluid being handled. •...

- Page 134 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 DANGER Electrical connection work by unqualified personnel. Risk of fatal injury due to electric shock. • Always have the electrical connections installed by a trained and qualified electrician.

-

Page 135: Dismantling

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 8.4.3 Dismantling DANGER Electrical shock hazard. Risk of personal injury. • The power supply to the motor must be interrupted and the driver secured prior to disassembling the pump. -

Page 136: Reassembly

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 WARNING Inadequate preparation of work on the pump (set). Risk of injury. • Properly shut down the pump set, as stated in SECTION 7.6 - SHUTDOWN. •... -

Page 137: Returning Pump To Factory

ATTENTION All pumps returned to factory may be disassembled or maintained by RUHRPUMPEN service personnel only if the pumped liquid is clearly defined by the pump user. According to the "Decree for dangerous Goods", a safety data sheet DIN 52900 completely filled in must accompany the shipping documents. -

Page 138: Disposal

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 8.4.6 Disposal ATTENTION Make sure the used oil is discharged safely and no liquid or oil gets into the environment. NOTE All transmitting devices and radio equipment assemblies are sub-components of the pump (set) with their own installation, operating, and maintenance guidelines. -

Page 139: Spare Parts

Case wear ring (optional), impeller wear ring (optional) Adapter ring Shaft with coupling key Bearing Axial (thrust) cover (CPP) or Axial (thrust) bearing carrier (CPP-L) & Radial bearing cover Bearing frame complete with shaft, bearings, etc. Gasket for pump case 150%... - Page 140 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 Material storage of spare parts • Store the spare parts in their original packaging. • Store in a dry place, preferably at a constant temperature. •...

-

Page 141: Parts Information

HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 10. PARTS INFORMATION CPP Bearing Frame: B-10 Mechanical Seal Option Case Axial Labyrinth Seal Case Cover 423-1 Radial Labyrinth Seal Shaft Mechanical Seal Impeller Mechanical Seal Head... - Page 142 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CPP Bearing Frame: B-10 Packing Option Case Axial Labyrinth Seal Case Cover 423-1 Radial Labyrinth Seal Shaft Packing Impeller Packing Gland Ball Bearing Adapter Ring...

- Page 143 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CPP Bearing Frame: B-30A / B-30B Mechanical Seal Option Case Axial Labyrinth Seal Case Cover 423-1 Radial Labyrinth Seal Shaft Mechanical Seal Impeller Mechanical Seal Head...

- Page 144 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CPP Bearing Frame: B-30A / B-30B Packing Option Case Axial Labyrinth Seal Case Cover 423-1 Radial Labyrinth Seal Shaft Packing Impeller Packing Gland Ball Bearing...

- Page 145 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CPP Bearing Frame: B-50 Mechanical Seal Option Case Axial Labyrinth Seal Case Cover 423-1 Radial Labyrinth Seal Shaft Mechanical Seal Impeller Mechanical Seal Head Ball Bearing...

- Page 146 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CPP Bearing Frame: B-50 Packing Option Case Axial Labyrinth Seal Case Cover 423-1 Radial Labyrinth Seal Shaft Packing Impeller Packing Gland Ball Bearing Adapter Ring...

- Page 147 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CPP-L Bearing Frame: B-10 Case Axial Labyrinth Seal Case Cover 423-1 Radial Labyrinth Seal Shaft Mechanical Seal Impeller Mechanical Seal Head Ball Bearing Adapter Ring...

- Page 148 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CPP-L Bearing Frame: B-30B Case Axial Labyrinth Seal Case Cover 423-1 Radial Labyrinth Seal Shaft Mechanical Seal Impeller Mechanical Seal Head Ball Bearing Adapter Ring...

-

Page 149: Troubleshooting Chart

Inner pump parts are a. Change worn parts. worn. b. Consult a Ruhrpumpen dealer. b. Density or viscosity of c. Apply correct voltage to the motor. pumped fluid is not same d. Check the cables, connections, and fuses. - Page 150 Install vent valve or lay piping elsewhere. plugged j. Change worn parts. CAPACITY OR i. Formation of air pockets k. Consult a Ruhrpumpen dealer. DISCHARGE in the piping l. Apply correct voltage to the motor. PRESSURE LOW j. Inner pump parts are m.

-

Page 151: Extended Warranty

Fifteen days prior to the initial operation, a Ruhrpumpen Service Engineer must be hired by the customer to thoroughly inspect the pump to confirm that the pump is in a “as shipped” condition. - Page 152 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 • The customer must send the equipment to an authorized Ruhrpumpen service center for maintenance every 48 months to replace all worn parts and so that a general inspection on the pump can be performed.

- Page 153 HORIZONTAL END SUCTION, HEAVY DUTY, SINGLE STAGE ANSI CHEMICAL PROCESS PUMP ANSI/ASME B73.1 - 2020 CONDITION RECORDED ITEM YES NO VALUES equipped drain is able to empty the drip pan. If no mechanical seals are equipped, make sure that all environmental controls are correctly connected and fully functional.

- Page 154 +70 years creating the pumping technology that moves our world Ruhrpumpen is an innovative and efficient pump technology company that offers highly-engineered and standard pumping solutions for the oil & gas, power generation, industrial, water and chemical markets. We offer a broad range of centrifugal and reciprocating pumps that meet and exceed the requirements of the most demanding quality specifications and industry standards such as API, ANSI, UL, FM, ISO and Hydraulic Institute.

Need help?

Do you have a question about the CPP and is the answer not in the manual?

Questions and answers