Advertisement

Quick Links

WARNING

Improper installation, adjustment, alteration, service,

or maintenance can cause property damage, injury,

or death. Read the installation, operation, and service

instructions thoroughly before installing or servicing

this equipment.

OWNER

Retain this Manual & ensure available for service.

Improper installation, adjustment, alteration, service,

or maintenance can cause injury, death, or property

damage.

Read the installation, operation, and service

instructions thoroughly before installing or servicing

this equipment.

Series SDE

Installation, Operation and Service Instructions

INFRARED HEATER

563 Barton Street, Stoney Creek, Ontario L8E 5S1, CANADA

www.superiorradiant.com

Page 1

SERIES SDE

FOR YOUR SAFETY

Do not store or use flammable vapors and liquids in the

vicinity of this or any other appliance.

If you smell gas:

1. Open windows

2. Don't touch electrical switches

3. Extinguish any open flame

4. Immediately call your gas supplier

INSTALLER

Provide Manual to Owner upon completion of

installation!

Read and thoroughly understand these Instructions

before attempting any installation

LT229 Jan. 3, 2024

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Superior Radiant SDE Series

- Page 1 Installation, Operation and Service Instructions INFRARED HEATER SERIES SDE WARNING FOR YOUR SAFETY Improper installation, adjustment, alteration, service, Do not store or use flammable vapors and liquids in the or maintenance can cause property damage, injury, vicinity of this or any other appliance. or death.

- Page 2 CAUTION: FIRE OR EXPLOSION HAZARD Maintain clearance to combustible constructions as further specified in this manual. Failure to do so could result in a serious fire hazard. Heaters should not be located in hazardous atmospheres containing flammable vapors or combustible dusts. Signs should be provided in storage areas specifying maximum safe stacking height.

- Page 3 ONTENTS CONTENTS ..................................... 3 INTRODUCTION ..................................4 ................................4 ODES AND EGULATIONS GENERAL SPECIFICATIONS ..............................5 CONFIGURATION ................................... 5 DIMENSIONAL CHARTS ................................6 CLEARANCE TO COMBUSTIBLES ............................. 7 WARNING ..................................... 7 LAYOUT RECOMMENDATIONS ............................... 8 ................................8 AYOUT ONSIDERATIONS ....................................8 EATING ..................................

- Page 4 INTRODUCTION Superior Radiant Products is a company in the infrared heating industry founded on the principles of product quality and customer commitment. Quality commitments are evidenced by superior design, a regard for design detail, and an upgrade of materials wherever justifiable.

- Page 5 GENERAL SPECIFICATIONS Gas Supply Supply Pressure Minimum Nominal Maximum Natural Gas: 17.5 mbar 20 mbar 25 mbar Propane: 28 mbar 37 mbar 50 mbar Manifold Pressure Natural Gas: 15 mbar Propane: 25 mbar Inlet Connection 1/2” female BSP Electric Supply Alternating current Voltage 230 V, 50 HZ with L, N and PE Power consumption 12 W CONFIGURATION...

- Page 6 DIMENSIONAL CHARTS Figure 1: Overall Dimensional Information Model # SDE10 SDE20 SDE30 SDE40 SDE45 Natural Gas 2.44 2.44 2.44 2.44 2.58 Injector Size (mm) Propane Gas 1.61 1.61 1.61 1.61 Burner Quantity Shipping Weight (kg) 13.2 18.2 21.8 26.8 26.8 Series SDE Page 6 LT229 Jan.

- Page 7 Table 1: Configuration Information CLEARANCE TO COMBUSTIBLES A general clearance of 500 mm (20”) in every direction is recommended for servicing. In addition to this, it is very important to observe the minimum clearances to combustibles at all times to avoid any possibility of property damage or personal injury.

- Page 8 LAYOUT RECOMMENDATIONS Layout Considerations 1. Because high intensity heaters are un-vented, verify local codes for guidance on air supply and dilution air. Also see section on Ventilation. 2. Check local codes for mounting requirements and the requirement for flexible gas connectors or rigid mounting.

- Page 9 Full Building Heat Calculate the total heat input required, ensuring the inclusion of any unheated make-up air due to exhaust fans. Use the following chart as guidance to heater placement. Model/kW SDE10 SDE20 SDE30 SDE40 SDE45 Heater Mounting 3.4 – 4.6 4.6 –...

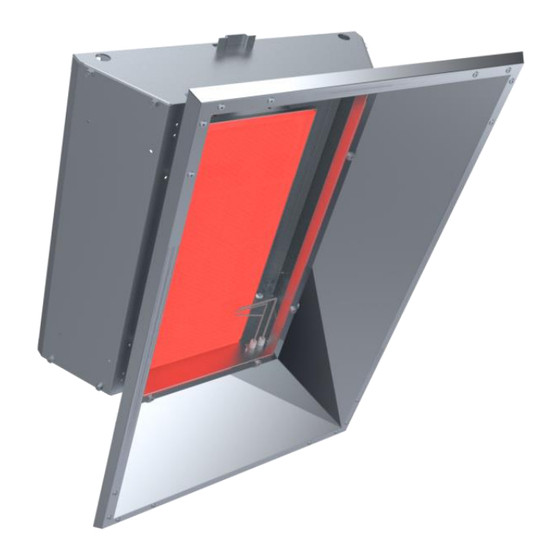

- Page 10 INSTALLATION Heater Mounting • Figure 3 illustrates typical rigid and chain mounting configurations for the Series SDE heaters; verify which is permissible by local codes. • Heaters must be hung at an angle between 10° and 35°. Typically, at the walls they are at 35° facing into the building.

- Page 11 • Before connecting burners to the gas supply system, verify that high pressure testing of the system has been completed. Failure to do so may expose the burner components to damaging high pressure, requiring replacement of key components. • Ensure that there is a plugged tap upstream of the heater or a fitting on the valve itself to verify incoming pipeline pressure.

- Page 12 VENTILATION / CONDENSATION General Requirements The heater should be installed in accordance with the relevant provisions of National Standards and Codes of Practice in the destination country. Heaters can be operated according to the appliance Type A, Gas appliance without flue gas system. The combustion air is taken from the installation space.

- Page 13 Ventilation by Natural Air Change Gas-fired radiant heaters may be operated without any special exhaust system if the exhaust gases are discharged to the outside atmosphere by a sufficient natural air change in the installation room. No provision for thermal or mechanical ventilation is required in the following particular cases: Buildings with natural air change greater than 1.5 volumes per hour Buildings with a density of operating heat input not greater than 5W/m³...

- Page 14 COMMISSIONING / OPERATION / MAINTENENCE Commissioning 1. Ensure that the service cock to the heater is OFF. 2. Purge air from gas supply. 3. Connect pressure gauge on the test point screw (located on the gas valve). 4. Open the service cock and check supply line from cock to combination valve for leak-tightness. 5.

- Page 15 Conversion heater to another gas 1. Disconnect electrical supply to the heater. 2. Turn off gas supply to the heater. 3. Check for correct injector size. 4. Remove old injector from heater. 5. Install and tighten new injectors supplied. Use suitable pipe sealant for injectors. 6.

- Page 16 Adjusting the manifold pressure S.I.T gas valve Check inlet and outlet pressure using the pressure test points provided. After testing, carefully seal test points with the provided screw. 1. Remove the protective plug A. 2. Screw in the screw B to increase the pressure and screw it out to decrease it. 3.

- Page 17 SERVICING - TROUBLESHOOTING Symptom Possible Cause Corrective Action Defective thermostat Repair or replace Heater will not turn off Stuck solenoid valve Repair or replace Verify all connections are sealed Gas Odor Loose pipe connection by using an appropriate leak test Burning of gas/air mixture Cracks between or across ceramic grids Replace burner head assembly...

- Page 18 REPLACEMENT PARTS (P/N RP-SG071) (P/N RP-CE295) (P/N RP-CE006) (P/N RP-SG009) FOR G31 HEATERS FIRST HEAD ONLY (P/N RP-SE001) ORDER P/N RP-SG061 Series SDE Page 18 LT229 Jan. 3, 2024...

- Page 19 TECHNICAL DETAILS Heat Input (kW) Injector Weight Dimensions (mm) Model Gross mm (#) Natural Gas SDE10 10.5 2.44 (#41) 13.2 SDE20 20.0 18.0 2.44 (#41) 18.2 SDE30 31.0 28.0 2.44 (#41) 21.8 SDE40 41.0 37.0 2.44 (#41) 26.8 SDE45 45.0 40.5 2.58 (#38) 26.8...

- Page 20 TECHNICAL DETAILS – ErP Directive Information required for eco-design (ErP) Directive 2009/125 Model SDE10 SDE20 SDE30 SDE40 SDE45 Natural Gas 18.0 28.0 37.0 40.5 Heat Input (Net) 10.5 20.0 31.0 41.0 45.0 Heat Input (Gross) η Useful Efficiency (GCV) 85.6 85.6 85.6 85.6...

Need help?

Do you have a question about the SDE Series and is the answer not in the manual?

Questions and answers