Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for idp SOLID-810

- Page 1 SOLID-810 Retransfer Card Printer User Manual...

-

Page 2: Copyright Notice

IDP Reseller. The IDP Reseller will bear the costs of shipping and insuring the printer from the repair location to the address from which the printer was shipped. -

Page 3: Table Of Contents

Table of Contents 1. BASIC INFORMATION ....................10 Printer outside features ..........................10 1.1. Printer inside feature ...........................13 1.2. Display & buttons ............................16 1.3. 2. PRINTER INSTALLATION .................... 30 Connection a power and a USB cable ....................30 2.1. Fitting the Film, Ribbon, Cleaning roller ....................31 2.2. - Page 4 Firmware update ............................83 4.4. 5. TROUBLESHOOTING ...................... 85 5.1. Error Message ..............................85 5.2. Cleaning and Replacement Printer air filter ..................90 5.3. Cleaning the printer .............................91 5.4. TPH (Thermal Print Head) replacement ....................94 5.5. Card movement .............................96 5.6. Printing quality ..............................98 5.7.

- Page 5 Figure 5 SOLID-810 inside feature ....................13 Figure 6 SOLID-810 Display and buttons ..................16 Figure 7 SOLID-810 Connection of power and communication cable ......30 Figure 8 Front cover open ....................... 31 Figure 9 Take out film cartridge ...................... 31 Figure 10 Take out Ribbon Cartridge ....................

- Page 6 Figure 23 Preparing the card 2......................37 Figure 24 Loading the card 1 ......................37 Figure 25 Loading the card 2 ......................37 Figure 26 Installation SOLID-810 card stacker ................38 Figure 27 Install printer driver 1....................... 39 Figure 28 Install printer driver 2....................... 39 Figure 29 Install printer driver 3.......................

- Page 7 Figure 60 CardPrinterConfig start ....................57 Figure 61 Cardprinterconfig Basic setup ..................58 Figure 62 Cardprinterconfig – Advanced setup ................. 61 Figure 63 Rear view of SOLID-810 ....................66 Figure 64 Running NetAdmin ......................66 Figure 65 Network printer is no found ..................67 Figure 66 Connecting to USB Port ....................

- Page 8 Figure 73 Upgrade the firmware 3 ....................71 Figure 74 Dynamic IP configuration ....................72 Figure 75 Static IP configuration...................... 72 Figure 76 Network service configuration ..................73 Figure 77 OCP configuration ......................73 Figure 78 Network service configuration ..................74 Figure 79 CardPrinterTest ........................

- Page 9 Figure 98 Printing quality trouble 2....................98 Figure 99 Printing quality trouble 3....................99 Figure 100 Printing quality trouble 4 ..................... 99 Figure 101 Printing quality trouble 5 ..................... 99 Figure 102 Printing quality trouble 6 ................... 101 Figure 103 Printing quality trouble 7 ................... 101 Figure 104 Printing quality trouble 8 ...................

-

Page 10: Basic Information

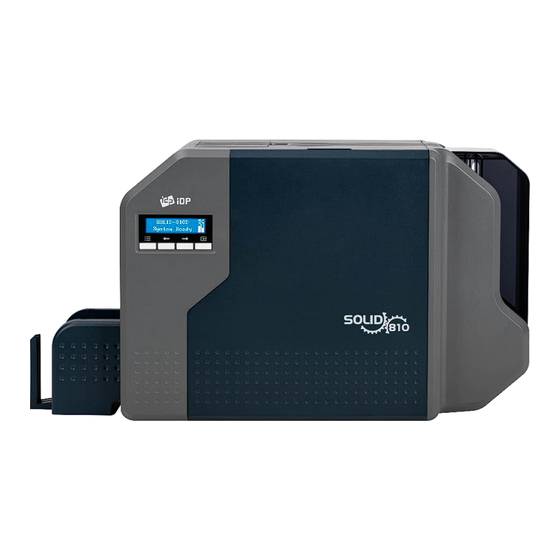

1. Basic Information 1.1. Printer outside features For the user’s convenience, SOLID-810 status can be seen through LCD. and the printer can be controlled by 4 buttons under the LCD. Using USB and Ethernet port, it is communicated with the user’s PC The following shows the outside functional features found on the printer ①... -

Page 11: Figure 2 Solid-810 Rear Features

And can fit a laminate device on the left side of the printer depending on the application. SOLID-810 (Figure. 3) is the standard card printer. It can be printed single-sided or dual-sided. And it can be written/read MS, IC, RF card data with option installation. -

Page 12: Figure 4 Solid-810 & Laminator

SOLID-810 & Laminator (Figure. 4) is installed Laminator on the SOLID-810. SOLID-810 & Laminator can be laminated on the printed card. Figure 4 SOLID-810 & Laminator... -

Page 13: Printer Inside Feature

Printer inside feature 1.2. In SOLID-810 printer, the ribbon and film are installed by each cartridge which can be used semi-permanently. The following shows the inside functional features found on your SOLID-810 printer. ④ ① ② ⑥ ⑤ ③ Figure 5 SOLID-810 inside feature ①... - Page 14 ② Ribbon cartridge Cartridge to which the printer ribbon is mounted. it can be separated from the printer by holding and pulling a handle. This semi-permanent ribbon cartridge is a component of printer. Printer does not operate if it will be broken or damaged.

- Page 15 ⑥ Cleaning roller cartridge Cartridge to which the cleaning roller is mounted. it can be separated from the printer by holding and pulling a handle. It removes dust on the surface of card to improve print quality before the card is printed.

-

Page 16: Display & Buttons

1.3. Display & buttons SOLID-810’s control panel consists of LCD and 4 buttons. LCD shows the status of the printer, and view each status and changes the setting with buttons. Figure 6 SOLID-810 Display and buttons The status of SOLID-810 is ‘Initializing’ when booting up. - Page 17 The left side shows the residual volume of the re-transfer film, and the right side shows the residual volume of the ribbon. And the icon displays the remaining consumables in percentage. Mark ‘X’, if the film or ribbon is not fitted. ※...

- Page 18 - Laminator LED status by color When Install and use Laminator on the SOLID-810(Figure), You can check status of laminator with indicator(LED)’s color. ※ Laminator LED Location LED Status Description Blue (on) Normal standby ■ Green (on) Executing Printer’s command.

- Page 19 The below table shows LCD messages based on their status and functions when the button is pressed. Messages KEY0 KEY1 KEY2 KEY3 State Description Menu/Cance Left/Down Right/Up Select/OK Initializing Initialization Initialization when booting, or Case Open [x.xx.xx][xx][xx] and Close Display Printer Firmware Version, Vendor, Region Code.

- Page 20 will power on again (DCL Mode) SMART-81xx MENU Information Information Standby System is ready to print, Menu - Menu + mode you can check the ribbon System Ready information by pressing left button, and power is off by pressing the right button.

- Page 21 rising. The normal temperature is 15’C~35’C. Spool Error Delete spool System Spool error Error occurs while receive and cancel reset spool print data. KEY0 is <Cancel Reset> delete and cancel, KEY3 is System Reset xxxxxxxxxxxxxxx+ Retry Cancel and Error occurs Error occurs while Initialization while printing...

- Page 22 card to right KEY4 : Flipper Flip Hopper Cov Open Cover open Hopper Cover open Hopper Cover must be Close Cover close to release, and it is not displayed when the Hopper cover Open Ignore mode. and not applicable during printing open.

- Page 23 Ext Fwdr Bwd --- Cancel Film Film Cover open Case Open Menu - Forward Backward FilmMove motion Menu Move[xxxxx] mm Move Move KEY0 : Cancel, KEY1 : Film Forward Move, KEY2 : Film Backward Move DIsply Film distance is indicated by value of mm. Ext Top Bot Flp Cancel Flipper Top...

- Page 24 >> X Print Pos Cancel Print Print Config Setting Print Config X Print Position Setting. Config Menu + Menu - >> Y Print Pos Cancel Print Print Config Setting Print Config Y Print Position Setting. Config Menu + Menu - >>...

- Page 25 >>Temperature Cancel Information Information Check Heater(display if Bending Menu - Menu + Information Heater is installed), Thermal Head temp display. You can check it Information Menu. T : Print Head, H : Retransfer Head , B : Bending Heater >>HeadInfo Cancel Information Information...

- Page 26 SMART-81x Printing Retransferring Retransferring SMART-81x Laminating Laminating. Laminating Board Test Mode Test mode Test mode for test function of Smart81’s Wait Sensor/Motor. RibbonNotFound Retry Ribbon Retry Retry Retry Ribbon Ribbon recognize error, recognize Ribbon Ribbon Ribbon recognize ribbon is not installed or Check Ribbon recognize recognize...

- Page 27 transfer when Laminator is not installed, Combination of devices (such as 300dpi transfer when 600dpi / 600dpi transfer when 300dpi) and the spool data option do not match, press key to delete the current spool. Check Please.. Ribbon & Ribbon & Ribbon &...

- Page 28 System Ready Menu - Menu + warning Count 5000 or higher, (Ready) and Card Printer Config Utility program - Cleaning Warning is “Permanent” Message continues to be displayed until the cleaning is performed. Except message display, it is same as system ready state Cleaning Mode Cleaning...

- Page 29 The below table shows LCD messages based on Laminator status and functions when the button is pressed. (Laminator is installed) Messages KEY0 KEY1 KEY2 KEY3 State Description Menu/Cancel Left/Down Right/Up Select/OK L Film Zero+ Laminator Laminator Film all use error ‘+’...

-

Page 30: Printer Installation

2.1. Connection a power and a USB cable Connect the power and USB cable as the below picture and install the communication cable protection cover. Please refer to the ‘Network configuration’ if you use the LAN connection. Figure 7 SOLID-810 Connection of power and communication cable... -

Page 31: Fitting The Film, Ribbon, Cleaning Roller

2.2. Fitting the Film, Ribbon, Cleaning roller Before printing, prepare the related items such as a card, a ribbon and a cleaning roller. In this section, we invite you to know the proper method of installing the retransfer film, ribbon and the cleaning roller into the printer. (Caution! Please turn off the printer) (1) Open the front side of the printer cover. -

Page 32: Figure 10 Take Out Ribbon Cartridge

(3) Hold the Ribbon cartridge handle and pull it out as figure 10. Figure 10 Take out Ribbon Cartridge (4) Hold the disposable cleaning roller cartridge handle and take it out as figure 11. Figure 11 Take out Cleaning roller Cartridge (5) Insert the film into the film cartridge as figure.12. -

Page 33: Figure 13 Loading The Ribbon

(6) Insert the ribbon into the film cartridge as figure 13. After inserting, tighten the ribbon. (Caution! If the ribbon is not tightened, a rolling up error might be happened) Figure 13 Loading the ribbon (7) Insert the disposable cleaning roller into the cartridge as figure 14. -

Page 34: Figure 15 Installing The Cleaning Roller Cartridge

(8) Install cleaning roller cartridge into the printer. Figure 15 Installing the cleaning roller cartridge (9) Install film cartridge into printer. At this point, Do not fully mount the cartridge to the printer as figure 16. Figure 16 Installing film cartridge (10) Install Ribbon cartridge into printer. -

Page 35: Figure 18 Installing Film Cartridge

(11) Press below the handle to fully mount and adhere the Film cartridge to printer. Figure 18 Installing Film cartridge (12) Close the front cover. Figure 19 Close cover... -

Page 36: Loading The Cards

2.3. Loading the cards This section shows how to load plastic card. Open the Input hopper cover in the direction of the arrow. Figure 20 Take out hopper cover If necessary, release card gate screw to adjust height of gate to match thickness of the card. -

Page 37: Figure 22 Preparing The Card 1

To separate cards from each other, push a stack of cards back and forth to an angle about 45 degrees vertically. Figure 22 Preparing the card 1 Figure 23 Preparing the card 2 Stand the stack of cards vertically after separating. Figure 24 Loading the card 1 Load the cards on the hopper properly and install... -

Page 38: Stacker Installation

2.4. Stacker Installation Install the card stacker. Figure 26 Installation SOLID-810 card stacker... -

Page 39: Driver Installation (Windows 7/8/10/11)

2.5. Driver installation (Windows 7/8/10/11) Scan the QR Code or Go to idp-solid.com/download move to Printer Driver folder. Download the “SOLID-810 Printer Driver”. Extract the driver and all tis components from the ZIP file and save it on your PC. -

Page 40: Figure 30 Install Printer Driver 4

STEP 1: Please turn off printer if it is connected to PC. Please click “Next”, when you click “Next”, older driver will be removed automatically. This process will take several minutes to remove older driver. You can select the languages by selecting the combo box as shown on the left picture. -

Page 41: Figure 32 Install Printer Driver 6

(In case of USB connection, click “Next” and move to step (9). If you are planning on setting up the SOLID-810 as a network device, Please proceed to Step 3: Network (8). Figure 33 Install printer driver 7 STEP 3: Network Please select the printer that you want to install in the list and click “OK”. -

Page 42: Figure 35 Install Printer Driver 9

Right click “SOLID-810 Card Printer” and select “Print Properties”.) Figure 36 Install printer driver 10 Please select General” tab and (11) click “Print Test page” in “IDP SOLID-810 Card Printer Properties” window. Figure 37 Install printer driver 11... -

Page 43: Figure 38 Install Printer Driver 12

(12) Please check test card if it is printed properly and click “Close” if a card is printed properly. (If card is not printed or error comes out, please refer to “Trouble Shooting”.) Figure 38 Install printer driver 12... -

Page 44: Option Installation (Ic, Rf)

2.6. Option installation (IC, RF) Step 1: Detach each module form main body’s top cover (1) Turn off Printer, Open top cover, Separate Ribbon film cartridge and stacker under the module. (2) Release the two screws shown and remove them from main body as shown the below picture. -

Page 45: Figure 41 Install Module (Ic, Rf) 3

(3) Install the ribbon film cartridge and the error card stacker and close the cover. Figure 41 Install module (IC, RF) 3... -

Page 46: Option Installation (Laminator)

2.7. Option Installation (Laminator) Step 1: Fitting Binding Clamp on the printer bottom (1) Turn off Printer, Open top cover, take off card stacker, and fit and fix Binding Clamp on printer bottom as shown picture. Figure 42 Install Laminator Module 1 Step 2: Fitting module (Laminator) (1) Fit the module to be installed (Laminator) to the Binding Clamp mounted on the printer as shown picture and connect the power cord of the laminator. -

Page 47: Figure 44 Lcd Display (With Laminator)

(3) If the module is installed successfully and printer is completely booted, ‘L’ I will be added to the LCD as shown picture to confirm that the laminator installation is complete. Figure 44 LCD display (with Laminator) -

Page 48: Driver Configuration

3. Driver Configuration To check printer properties, you need to open printer driver. Please open “Devices and Printers” and right-click “IDP SOLID-810 Card Printer”. Click “Printer Properties”. 3.1. Printer Properties Printing Preferences Please click “Preferences…” shown on the left picture. -

Page 49: Figure 47 Input / Output Setting

Input / Output Supply Tray Supply: You can select “Auto” if SOLID-810 has 1 input hopper. Please select the hopper if it has a multi hopper. Tray: SOLID-810 supports CR-80 card only. Figure 47 Input / Output Setting Printing Do Print: you can select printing or not. -

Page 50: Figure 49 Laminating Setting

Ribbon Save: Select split function or not when use Mono ribbon. Anti-Aliasing: Set Anti-Aliasing level of printer image. Color Sense: Set print image’s color sense. Laminating Setting This tap will be shown only when SOLID- 810 printer is connected to Laminator. Do Laminating: You can select laminating or not. -

Page 51: Figure 51 Encoding Advanced Setting

Encoding Advanced Option Card Stripe Side: the location of magnetic stripe [Bottom / Top] Before Flip: Do flipping before encoding [No / Yes] After Flip: Do flipping after encoding [No / Yes] Figure 51 Encoding advanced Setting Track Advanced Options: Format: Encoding format (IATA, ABA, MINS, JISII, Bits Mode) Track 1: (default) IATA... -

Page 52: Advanced Options

3.2. Advanced Options To change the detailed configuration, In the ‘Layout’ tab shown, Please click “Advanced…” shown on the bottom of the ‘Layout’ tab of the ‘Preferences’. [ Graphic ] ⚫ Print Quality : You can select the print quality (DPI). [ Document option ] ⚫... - Page 53 > Black Text: to extract resin black for text only. > Black Dots: to extract resin black for all of black. > Black Dots Only: to extract resin black for all of black and not to print on color panels. >...

-

Page 54: Other Settings

Ports Port tab shows which port is connected with SOLID-810. SOLID-810 has connection with USB Virtual printer port as left picture because SOLID-810 uses USB connected to PC. (Caution! This port is selected automatically. It is recommended to maintain default.) -

Page 55: Figure 55 Advanced Setting

Color Management In “Color management” tab, you can select color management profile fit to the printer. SOLID-810 uses color profile to express optimal color. The driver selects color profile automatically to fit each ribbon. (It is recommended to maintain default.) -

Page 56: Figure 57 Security

Security You can set the permission to use a printer. Depend on the permission, the certain group or user can print, manage the printer/documents or not. Figure 57 security Service You can recognize the modules to connect, printer serial, printer ID, driver version, firmware version, type of ribbon &... -

Page 57: Utilities

If you input the correct password, the recorded setup value will be shown and you can change values. The password is saved to SOLID-810 printer. So if you use another PC with same printer, previous password is required to run this program. -

Page 58: Figure 61 Cardprinterconfig Basic Setup

① To show connected printers. Device: You can select a printer using pull-down menu. “IDP SOLID-810 Card Printer” is a name of printer. “SMART” is printer ID, “USB002” is connected port. If you connect the Network printer, please check the “Allow Network Printer”... - Page 59 ⑦ To set density. SOLID-810 enables to set different density for each color, resin black and overlay. Please set each density for high quality and optimize the quality by adjusting each value. Insert the color ribbon(YMCK) and click “⑧ Print” to print the card to optimize each setting.

- Page 60 Color (YMC) Density: To set color density. Please maximize YMC density as you can, which enables to express range of color and vivid images. But If it is too strong, green or red marks are appeared. orIf it is too weak, the print quality will be dull.

-

Page 61: Figure 62 Cardprinterconfig - Advanced Setup

① To set the printer’s information Change Printer ID: When using SDK, you can set a unique ID for SOLID-810 printer regardless of whether it is connected by USB or what IP address is. It is useful to connect and use several printers. Default ID is “SMART”. - Page 62 Set Mag. Encrypt Key: One of security function. When you use SDK, you can encrypt magnetic stripe encoding data transmitted by USB. You can define and save the encryption key to SOLID-810 using “Set Mag. Encrypt Key”. ② Adjust printer’s detailed setting value. (Function tabs) Print: Tab showing the printer setting value.

- Page 63 Retransfer: tab showing the retransfer setting value. Retransfer: Front Card card position when start retransfer (Front) Position Retransfer: Back Card card position when start retransfer (back) Position Retransfer: Operation Retransfer temperature Temperature Retransfer: Standby Retransfer heater Standby temperature Temperature Retransfer: Heating Heating trigger temperature when printing panel Trigger Temperature Retransfer: Former...

- Page 64 Extra: Tab showing other setting values Card In Speed Card in speed Card Out Speed Card out speed Card Move Speed Card move speed(inside printer) DCL Mode DCL mode SBS Only Only SBS commend mode Dump Mode Dump mode Card Out Card out direction Error Card Out Error card out direction...

- Page 65 Count: Tab showing about printer operate history. “Total issue Count” is number of card print since the factory shipped, “User Issue Count” is number of card print after head has been replaced. “User Issue Count” is initialized by checking “Reset User Issue Count” when replacing the printer head.

-

Page 66: Network Configuration

(Network cable is not supplied. Please ask network administrator for more questions.) Figure 63 Rear view of SOLID-810 SOLID printers support the ability to print in a variety of ways over the network. Network settings require network expertise, so when you change settings, you should get help from a network specialist engineer. -

Page 67: Figure 65 Network Printer Is No Found

Select network printer When no printer is connected to network, there is no printer shown on the box. Please click “Refresh”. If no printer shown, please check as below. ⚫ Please check the printer is turned on. ⚫ Please check network cable is connected to network hub and works properly. -

Page 68: Figure 67 Netadmin Log-In

NetAdmin log-in ⚫ Please select a proper printer and click “connect”. Please enter password and click “OK”. “admin”. Default password is Figure 67 NetAdmin Log-in (6) USB port state Click “Use Port State” to show device s ⚫ connected to USB hub of network module. -

Page 69: Figure 69 Rebooting Network Module

Reboot network module ⚫ Please click “yes” when pop-up window comes out for reboot. ⚫ It takes 1 minute to reboot. ⚫ Please click “Refresh” after reboot. When proper printer shown, please connect printer by clicking “connect”. Figure 69 Rebooting network module “Reset to default”... -

Page 70: Figure 71 Upgrade The Firmware 1

Upgrade network module firmware ⚫ You can choose a firmware file. ⚫ Select and save firmware file that need to upgrade. Figure 71 Upgrade the firmware 1 ⚫ Warning box will be shown during firmware upgrade for network module. ⚫ It is recommended not to do other work during firmware upgrade for system reliability. -

Page 71: Figure 73 Upgrade The Firmware 3

⚫ When firmware upgrade is completed, pop-up comes out for reboot. Please click “yes”. ⚫ It takes 1 minute to reboot. ⚫ Please click “refresh” after reboot. When proper printer shown, please connect printer by clicking “Connect”. Figure 73 Upgrade the firmware 3... -

Page 72: Figure 74 Dynamic Ip Configuration

IP. ⚫ Please click “Set Configuration” and save. And please reboot printer. ⚫ We recommend using static IP because it is more stable for using SOLID-810 network printer. Figure 74 Dynamic IP configuration (11) Wireless network configuration ⚫... -

Page 73: Figure 76 Network Service Configuration

(12) Change network service configuration ⚫ “Use USB Spool” is service for print with USB. ⚫ “Use Network Spool” is service for print with network. ⚫ “Use Network SDK” is service for print with SDK. You can control printer and printer card well, and printer supports SSL(Secure Sockets Layer) an User Authentication for security. -

Page 74: Figure 78 Network Service Configuration

(14) User configuration ⚫ “Admin” is administrator and you can’t delete this account. Please don’t forget password for “admin”. ⚫ “Get User”: shows available users. ⚫ “Add User”: makes new user. ⚫ “Del User”: deletes selected user. ⚫ “Change Password”: changes password. Figure 78 Network service configuration... -

Page 75: Card Printer Test

⑦ Figure 79 CardPrinterTest ① Select Printer: select printer to test. In the picture, “IDP SOLID-810 Card Printer” is the Printer name, SMART1 is the Printer ID, and USB002 is the connected port. ② Control: To execute each step to test. - Page 76 “DoPrint”. It is the main difference between NORMAL mode and SBS mode. When you click “Start”, SOLID-810 is operated in SBS mode, and existing spooled data will be eliminated. To exit SBS mode, click “End”.

- Page 77 ⚫ Rotate Rotator is to flip over a card in the printer installed flipper. “Auto” is to move a card from printer to flipper and flip over a card and move a card to the printing position automatically. “Batch” is to repeat “Auto” as many times as the number of set. “To Bottom”...

- Page 78 (4) Batch Batch is to repeat encoding/decoding test continuously. In the Repeat, you input the number of repeats and click “Batch Start”, then the test is run as many times as the number of sets. When you check “Include Card In/Out”, each time the printer brings a card from the input hopper and performs an encoding test and ejects the card.

-

Page 79: Figure 80 Magnetic Stripe Encoding

Figure 80 Magnetic stripe encoding IC(PC/SC) : Contact Smartcard Encoding In SOLID-810 printer, a contact smartcard encoder can be installed and SOLID-810 printer supports the contact smartcard encoder in the printer inside. “IC(PC/SC)” is to test a contact smartcard encoding. -

Page 80: Figure 81 Contact Smartcard Encoding

Figure 81 Contact smartcard encoding RF(PC/SC) : Contactless Smartcard Encoding In SOLID-810 printer, a contactless smartcard encoder can be installed and SOLID- 810 printer has the internal and external contactless smartcard encoder. RF(PC/SC) is to read and write the contactless smartcard. Using internal encoder, the printer brings a card into the printer from input hopper and encodes a smartcard. -

Page 81: Figure 82 Contactless Smartcard Encoding

“Reset” is to finish the function electrically. After “Contact”, you can run “Read”, “Write” and “Clear”. “Get UID” is for getting Chip Serial Number(CSN). “Read” and “Write” are to read and write the defined data (Name, Address and Phone). These could not be applied to all cards. “Clear”... - Page 82 Printer and Laminator status “Get Temperature” is to get and display the temperature of Thermal Print Head. When the “Realtime Check” is ticked, it displays the current temperature of Thermal Print Head in real time. “Get Status” is to get and display the printer status. Please refer to the ‘SOLID SDK manual’...

-

Page 83: Firmware Update

4.4. Firmware update When you run the CardPrinterFirmware, you can see the pop-up window. CardPrinterFirmware Menu Device: Select the local printer that you want to upgrade. Card Printer / Laminator: Select the device you want upgrade. Device Version: Displays the current firmware version of selected printer. -

Page 84: Figure 85 Update Firmware

Firmware update ⚫ Click “Update” button to upgrade automatically, then the printer is upgraded after rebooting. ⚫ In case there are some problems in the automatic upgrade, you click “Manual Update” and can see the pop-up widow as below picture. It shows procedure of manual upgrade. -

Page 85: Troubleshooting

5. Troubleshooting 5.1. Error Message SOLID-810 printer shows the error message in the LCD display when it occurs. Click the Menu button to retry, and ‘select’ button to cancel an operation. The following shows the error message on your SOLID Printer. For checking a status of printer, please use a CardPrinterTest or CardPrinterDiagnostics in the Utilities folder. - Page 86 Error occurs while printing -. Check a card is jammed Printing Err -. Check usage of a genuine ribbon and cards -. Check the rollers, encoders and cards, and clean them if they are polluted The printer can’t search the ribbon panel in printing or booting up -.

- Page 87 The IC Head Up/Down Motor or Sensor don’t work correctly in printing, encoding or booting up Check the state of the Cable between a module and a main board IC UpDown Err -. Check the operating state of the IC Motor -.

- Page 88 Thermal Print Head is not installed or not recognized TPH None -. Check the print head installation -. Contact the place of purchase Retransfer heater is not installed or not recognized Heater None -. Check the Retransfer installation -. Contact the place of purchase Band heater is not installed or not recognized Bheater None -.

- Page 89 The following shows the error message on your Laminator. For checking a status of Laminator, please use a CardPrinterTest or CardPrinterDiagnostics in the Utilities folder. Message Discription L CardIn Err Card in error L CardFeed Err Card feeding error L CardOut Err Card out error L HT UpDown Err Head up/down error...

-

Page 90: Cleaning And Replacement Printer Air Filter

5.2. Cleaning and Replacement Printer air filter If printer air filter is much dust, need to cleaning and replacement it for prevent dust. 1. As shown in the below picture, you can remove the protect cover by pressing the locking part in the direction of the arrow and pulling it up. -

Page 91: Cleaning The Printer

5.3. Cleaning the printer To maintain the best condition of SOLID printer, you must clean the printer periodically. If you use the exclusive cleaning card as the picture, you can clean the printer easily. For purchase the exclusive cleaning card, ask to SOLID printer provider. Figure 86 Exclusive cleaning card If the exclusive cleaning card is ready, click the “Clean Printer”... -

Page 92: Figure 88 Printer Cleaning Step 1

Step 1: Connect the SOLID printer to PC and turn it on, and prepare the exclusive cleaning card. Click “Start cleaning” to move on to step 2. Figure 88 Printer cleaning step 1 Step 2: Check the printer entering cleaning mode with LCD window. Open the Cover, and remove card cartridge, ribbon cartridge, and cleaning roller. -

Page 93: Figure 90 Printer Cleaning Step 3

Step 3: Insert the cleaning card moderately(5-10cm) as shown in the figure 101 and press LCD key to display temperature of the printer heater. When temperature of printer heater drops below 50degrees, cleaning card will insert to printer and moving back and forth to clean. -

Page 94: Tph (Thermal Print Head) Replacement

Step 5: Remove exclusive cleaning card and install cleaning roller, ribbon cartridge, film cartridge. And close the cover. Click “finish” to exit. Figure 92 Printer cleaning step 5 5.4. TPH (Thermal Print Head) replacement TPH (Thermal Print Head)’s life is over or damaged, replace it in the follow. 1. -

Page 95: Figure 94 Printer Head Setup

Step 4: Click “Set Config” to set the new Print Head’s configuration. ③ ② ① ④ Figure 94 Printer head setup 3. Replacing the new Print Head Step 1: Remove the old printer head from the top cover. (1) Turn off the print and open the top cover. (2) Remove the ribbon cartridge first, and release the screw, hold the head with one hand, and remove it. -

Page 96: Card Movement

Step 2: Installing the new printer head. (1) Connect new printer head to the Print Head Wire. (2) hang the Head and tighten the screws. Figure 96 Printer head assemble 4. Setup the print position and the color density After installing the new Print Head, you must reset the print position and the color density using CardPrinterConfig utility. -

Page 97: Figure 97 Printing Quality Trouble 1

Card Transfer Error occurs when the ribbon is coiled around the transfer roller or the printing roller. Open the top cover and remove the card and the coiled ribbon from SOLID-810 printer using front buttons. If this problem occurred frequently, check the below things. -

Page 98: Printing Quality

An Error occurs while the card is being transferred. Check the error message at LCD display and open the top cover and remove the card by front buttons. If this problem occurs frequently, check the followings. ⚫ Non-standard cards or bad cards. Change the cards. - Page 99 ⚫ The ribbon cartridge is installed improperly. Check the ribbon cartridge installation state and whether the ribbon has wrinkles. ⚫ The printer head is contaminated with the dust and dirt. Clean the printer head with cleaning kit. ⚫ The printer head is damaged. Figure 99 Printing quality trouble 3 Please contact the local supplier to replace the printer head.

- Page 100 Change Retransfer start condition setting to use CardPrinterConfig. Retransfer start position setting doesn’t match the card. ⚫ Change Retransfer start position setting to use CardPrinterConfig.

- Page 101 Retransfer film is stuck and does not fall off properly (side of the card) ⚫ Non standard card change the card. ⚫ The card surface is uneven or contaminated with the dust and dirt. After checking the card, change it to another card.

-

Page 102: Not Aligned Color Print

Raise the retransfer temperature to use CardPrinterConfig. (8) Not aligned color print. ⚫ Non-standard cards or bad cards. Change the cards. You can use only ISO CR-80 card (54mm x 86mm). ⚫ The transfer roller or printing roller is contaminated with the dust and dirt. Figure 105 Printing quality trouble 9 Clean the rollers with the cleaning kit. -

Page 103: Magnetic Stripe Encoding

5.7. Magnetic stripe encoding Magnetic encoding error. Please press front-left button to retry. ⚫ The magnetic head is contaminated with the dust and dirt: Clean the magnetic head with the cleaning kit. ⚫ The magnetic encoding data is not transmitted or the wrong data is transmitted: Check the setting of the program and the driver and the magnetic encoding data you transmitted. - Page 104 Printer doesn’t operate even if the printing data has been transmitted. Check the following. ⚫ Printer power off: Check the power. Turn on the printer power. Check the printer adaptor whether it is connected with a socket and the printer. ⚫...

-

Page 105: Specification

6. Specification Model SOLID-810S SOLID-810D Printing Print Type Dye-Sublimation & Retransfer Print Area Edge to Edge Resolution 300dpi Dual Side Printing Option Card Card Feeding Automatic Card Size ISO CR80 Card Thickness 0.8mm ~ 1.6mm Card Type PVC, PC, sPET, Composite PVC Printing Speed Monochrome 20sec./card (180 cards/hour) - Page 106 <제품 사양 및 인증> 항목 내용 13.56 ㎒ 주파수범위 변조방식 전파형식 채널 2 CH 출력 10 M의 거리에서 47.544 ㎷/M이하 기자재 명칭(모델명): RFID용 무선기기(13.56MHz 주파수 대역) (SOLID-810) 인증번호: R-R-IAS-SOLID-810 인증 받은 자의 상호: 아이디피(주) 제조년월일: 제조자/제조국가: 아이디피(주) / 한국...

Need help?

Do you have a question about the SOLID-810 and is the answer not in the manual?

Questions and answers