Table of Contents

Advertisement

Quick Links

INSTALLATION AND

OPERATORS MANUAL

COPY YOUR MODEL AND SERIAL NUMBER HERE

No other WINCO generator has the same serial number as

yours. If you should ever need to contact us on this unit, it

will help us to respond to your needs faster.

MODEL _____________________________________________

SERIAL NUMBER _____________________________________

PURCHASE DATE ____________________________________

DEALER NAME ______________________________________

DEALER PHONE # ____________________________________

1

www.wincogen.com

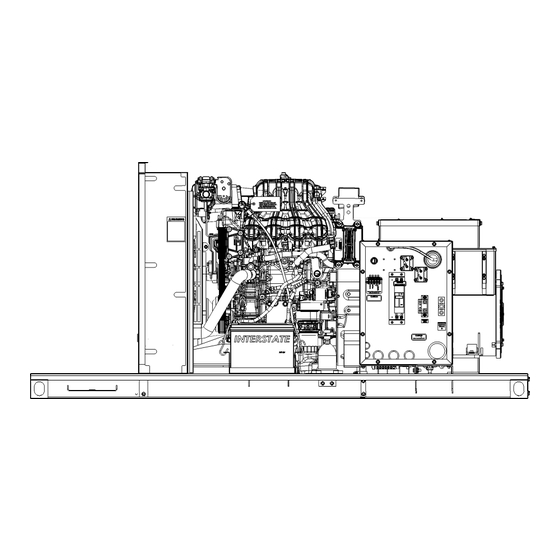

PSS21F4/3

PSS30F4/3

GENERATOR

OPM-182/A

Advertisement

Table of Contents

Summary of Contents for Winco PSS21F4/3

- Page 1 OPERATORS MANUAL COPY YOUR MODEL AND SERIAL NUMBER HERE No other WINCO generator has the same serial number as yours. If you should ever need to contact us on this unit, it will help us to respond to your needs faster.

-

Page 2: Table Of Contents

TABLE OF CONTENTS SAVE THESE INSTRUCTIONS MAINTENANCE SCHEDULE SAFETY INFORMATION TROUBLE SHOOTING TABLES SAFETY DEFINITIONS WIRING SIZE TABLE SPECIFICATIONS DSE7310 WIRING DIAGRAM INTRODUCTION THREE PHASE AC WIRE TESTING POLICY HIGH WYE PRODUCT DESCRIPTION THREE PHASE AC WIRE PREPARING THE UNIT LOW WYE WIRING DIAGRAMS START-UP CHECK LIST... -

Page 3: Save These Instructions

Should you experience a problem please follow the “Troubleshooting Tables” near the end of this manual. The warranty listed in the manual describes what you can expect from WINCO should you need service assistance in the future. OPM-182/A... -

Page 4: Safety Information

SAFETY INFORMATION IMPORTANT SAFETY INSTRUCTIONS DANGER: FIRE HAZARD This engine generator set has been designed and Gasoline and other fuels present a hazard of possible manufactured to allow safe, reliable performance. Poor explosion and/or fire. maintenance, improper or careless use can result in A. -

Page 5: Specifications

SPECIFICATIONS PSS21 STANDBY PSS21F4-03 PSS21F4-04 PSS21F4-17 PSS21F4-18 PSS21F4-21 Watts 21,000 22,000 22,000 24,000 24,000 Volts 120/240 120/208 120/240 277/480 346/600 Phase Single Three Three Three Three Amps Hertz Watts 21,000 22,000 22,000 24,000 24,000 Volts 120/240 120/208 120/240 277/480 346/600 Phase Single Three... - Page 6 PSS30 STANDBY PSS30F4-03 PSS30F4-04 PSS30F4-17 PSS30F4-18 PSS30F4-21 Watts 27,000 28,000 28,000 28,000 28,000 Volts 120/240 120/208 120/240 277/480 346/600 Phase Single Three Three Three Three Amps Hertz Watts 26,000 27,000 27,000 27,000 27,000 Volts 120/240 120/208 120/240 277/480 346/600 Phase Single Three Three...

-

Page 7: Introduction

Rated output of generator is based on engineering or distributor. Go to the WINCO website (wincogen.com) tests of typical units, and is subject to, and limited by the for a list of engine dealers or contact the WINCO Service temperature, altitude, fuel, and other conditions specified Department. -

Page 8: Preparing The Unit

This must be completed and of the unit to the opposite side frame rail. returned to WINCO Inc. within 180 days of the factory invoice date. If this form is not returned, the Warranty may be voided. -

Page 9: Installation

INSTALLATION Follow local codes for clearance from combustible surfaces. This unit should be installed in a well ventilated area, ensuring the exhaust air cannot be recirculated back into The unit’s main frame must be bolted securely to a solid the engine. base. -

Page 10: Exhaust Installation

If in doubt, always consult Discharge your local fire marshal, gas supplier or building inspector. The WINCO installation manual OPM-112 contains WARNING: FIRE HAZARD additional information on indoor, open skid installations All fuel runs should be installed by a licensed fuel supplier. -

Page 11: Natural Gas (Ng)

a larger line be installed to provide a fuel reservoir. This is Feet* Size of pipe also true for the single low pressure regulator, it should Up to 25 ft ¾” pipe also be a minimum of 10 feet from the unit. If this is not done, the demand regulator on the unit and the pressure 25 - 100 ft 1”... -

Page 12: Fuel Pressure Tables

7-11 in 7-11 in 4-6 oz 4-6 oz weather. We have partnered with a national lubrication oil manufacturer to give you access to Winco private branded Full load Line PSI 7-11 in 7-11 in premium oil available at comparable prices to conventional... -

Page 13: Electrical Connections

(see the actual breaker for technical references. additional information and restrictions) NEUTRAL CONFIGURATION Volts Wire Capability This Winco generator ships with either a bonded or floating Torque neutral depending upon the configuration. The distribution 120/240 #12 AWG-2/0 AWG 50 in lbs panel will be labeled indicating the configuration. -

Page 14: Dc Wiring

DSE 7310 controller. to be adjusted using the free DSE configuration software to enable the commutation. Contact Winco service for a list of Depending on the distance, 14 to 16 gauge stranded wire register values. -

Page 15: Mounting The Ats

two (2) wires from the engine generator set to the transfer normal A.T.S. Control and safety systems will eliminate all switch. You will be using terminals 4 and 5, wire Start # 23 paths for feedback. will connect to terminal # 5 and wire Battery Negative # 1 will connect to terminal # 4. -

Page 16: Installing The Battery

INSTALLING THE BATTERY WARNING CAUTION The electrolyte is a diluted sulfuric acid that is harmful to In the following battery installation procedure, check to be the skin and eyes. It is electrically conductive and corrosive, sure the engine control is in the “stop” position. This should The following precautions must always be taken. -

Page 17: Battery Charger & Block Heater

plates. Never allow the battery to remain in a discharge condition. CAUTION: EQUIPMENT DAMAGE NEVER JUMP START these units. Doing so will destroy the engine control module, rendering the unit non- operational. Remove and fully recharge the battery before attempting to start. BATTERY CHARGER &... -

Page 18: Starting Procedure

We have partnered with a national lubrication oil serious personal injury or equipment damage. manufacturer to give you access to Winco private branded premium oil available at comparable prices to conventional DO NOT jump start these engine-generator sets. Starting oils. -

Page 19: Control Layout

CONTROL LAYOUT fault condition is removed. The icon will appear steady in the display. SHUTDOWN Shutdowns are critical alarm conditions that stop the engine and draw the operator’s attention to an undesirable condition. Shutdown alarms are latching. The fault must be removed and the STOP/RESET button pressed to reset the module. -

Page 20: Auto Mode

WARNING: EQUIPMENT DAMAGE Failure to insure proper rotation will cause three phase motors to spin backwards, possibly causing damage to the equipment. NOTICE If for any reason during the check out procedure the voltage and frequency are not correct, depress the STOP/ RESET button and correct the trouble before proceeding. -

Page 21: Operating Conditions

OPERATING CONDITIONS NORMAL OPERATION This generator-engine set needs load and should not idle for long periods of time. If the generator application is for emergency standby the generator should be exercised at least monthly ideally under load. Load banking the generator at least annually will help keep the engine in good condition. -

Page 22: Maintenance

2. Place a drip pan or suitable container for catching the 6. Add engine oil to engine oil filler port as needed until oil . WINCO has supplied a valve on the skid frame to the level is between the maximum and minimum lines hook a customer supplied 5/8”... -

Page 23: Changing Coolant

3. Remove the coolant drain plug from the engine block. 4. After draining the engine coolant, flush the radiator and engine block with water to remove any rust, scale and contaminants. Then reinstall and tighten the drain plug. 1. Engine should be cooled down to at least 110˚F 5. -

Page 24: Adjusting The Governor

4. Replace the element with a new one if the element is 4. Check coolant protection. Store indoors in dry area. damaged, excessively dirty or oily. INFINITE PERIOD 5. Clean inside of the air cleaner cover. 1. Perform the next Preventive Maintenance procedure. 6. -

Page 25: Maintenance Schedule

MAINTENANCE SCHEDULE COOLING SYSTEM FREQUENCY Check and refill engine coolant Daily Check and clean radiator fans Every 250 hours Check and adjust cooling fan V-Belt Every 250 hours Change Coolant Every 1000 hrs/1yr ELECTRICAL EQUIPMENT FREQUENCY Check indicators Daily Check battery and recharge Every 250 hours ENGINE OIL FREQUENCY... -

Page 26: Trouble Shooting Tables

TROUBLE SHOOTING TABLES Problem Possible Causes Unit will not crank when Digital genset not in AUTO power fails Transfer control switch not in AUTOMATIC position Incorrect wiring between ATS and genset Defective control relay in ATS Fuse(s) blown in the DSE 7310 Defective DSE 7310 Loose or dirty battery terminals Defective starter... -

Page 27: Wiring Size Table

WIRING SIZE TABLE The table below is based on Table 310.16 in the National Electric Code 2020 edition. Allowable ampacitier of insulated conductrs rated 0 through 2000V, 75°C through 90°C. Not more than three current-carrying conductors in Raceway, Cable, or Earth (direct buried). Adjust for 40°C (104°F) ambient temperature. -

Page 28: Dse7310 Wiring Diagram

DSE7310 WIRING DIAGRAM OPM-182/A... -

Page 29: Three Phase Ac Wiring- Delta

WIRING DIAGRAMS THREE PHASE AC WIRE THREE PHASE AC WIRING- DELTA HIGH WYE THREE PHASE AC WIRE SINGLE PHASE 311 WINDING LOW WYE OPM-182/A... -

Page 30: Limited Warranty

Air cooled units purchased for stock have 1 year to be sold. The warranty to the original retail customer commences on the date of sale of the product to them. All liquid cooled units have 180 days from the Winco invoice to submit a start up date. If no startup form is submitted, then warranty period starts on the Winco invoice date unit was sold. -

Page 31: What Is Not Covered By Warranty

Note 2: 3rd Year warranty coverage is parts only/no labor. Note 3: Round trip mileage is limited to 200 miles per trip and a total of 2 trips per repair unless authorized in writing by the WINCO Service Dept. - Page 32 225 S. CORDOVA AVE • LE CENTER, MN 56057 Sales: 507-357-6821• sales@wincogen.com Service: 507-357-6831 • service@wincogen.com www.wincogen.com OPM-182/A...

Need help?

Do you have a question about the PSS21F4/3 and is the answer not in the manual?

Questions and answers