Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Cascade 100K THA

- Page 1 Operator’s Manual · · · cascade corporation...

-

Page 3: Table Of Contents

Table of Contents SPECIAL INSTRUCTION DEFINITIONS ..................2.4 SAFETY INFORMATION ........................2.5 TRUCK SYSTEM REQUIREMENTS ....................3.6 FITTING OF ATTACHMENT TO FORK TRUCK ................3.6 GENERAL ............................5.9 GENERAL ............................6.10 SAFETY FACTORS ........................6.10 LOAD LIMITS ..........................6.10 WORK STATION POSITIONING ....................6.10 PREPARATION BEFORE EACH SHIFT .................. - Page 4 REVOLVING CONNECTION SEALS AND CARTRIDGES............9.25 10.1 REMOVING AND INSTALLING THE CLAMP CYLINDERS............10.26 10.2 CYLINDER DISASSEMBLY......................10.26 10.3 CYLINDER INSPECTION......................10.27 10.4 CYLINDER REASSEMBLY ......................10.27 10.5 TILT CYLINDER ..........................10.27 10.6 ROTATE CYLINDER ........................10.28 12.1 SHIM SLIDE ARM .........................

- Page 5 Date of Revision Location Description of Revision...

-

Page 6: Special Instruction Definitions

2.1 SPECIAL INSTRUCTION DEFINITIONS WARNING WARNING MUST CAUTION CAUTION IMPORTANT IMPORTANT NOTE NOTE... -

Page 7: Safety Information

2.2 SAFETY INFORMATION NOTES... -

Page 8: Truck System Requirements

3.1 TRUCK SYSTEM REQUIREMENTS 3.2 FITTING OF ATTACHMENT TO FORK TRUCK CAUTION:... - Page 10 OPENING RANGE ARM LENGTH VC of G HC of G...

-

Page 11: General

5.1 GENERAL WARNING... -

Page 12: General

6.1 GENERAL 6.2 SAFETY FACTORS 6.3 LOAD LIMITS 6.4 WORK STATION POSITIONING 6.5 PREPARATION BEFORE EACH SHIFT Before conducting the following checks, ensure that the test area is free of personnel and it is safe to conduct these tests... -

Page 13: Operating Controls

Note: Do not sideshift arms until the cylinders bottom out. Conduct function test with arms approximately in the mid position. Note: Do not sideshift arms until the cylinders bottom out. Conduct function test with arms approximately in the mid position. Caution: Ensure the tyre is at ground level and horizontal for this test. -

Page 14: Operating Restrictions

6.7 OPERATING RESTRICTIONS... - Page 15 NEVER handle tyre’s filled with ballast. If load limits NEVER transport tyre in vertical position. Always transport exceeds rated capacity it may result in structural failure. in horizontal position, parallel and low to ground. NEVER drag tyre – unit is designed to lift and position tyre. NEVER operate the unit while persons not required for NEVER handle greasy tyres.

-

Page 16: Operator Training

6.8 OPERATOR TRAINING 6.9 CLAMP CONTROLS 6.10 TASK PERFORMANCE... - Page 17 WARNING WARNING WARNING WARNING WARNING WARNING WARNING...

-

Page 18: Tyre Handler Operating Restrictions

6.11 TYRE HANDLER OPERATING RESTRICTIONS Use of a single arm for lifting or carrying a load will void the tyre handler warranty. Use of one arm of the tyre handler for bead breaking will void the warranty. Never use one arm to break the beads. -

Page 19: Important Safety Information

7.1 IMPORTANT SAFETY INFORMATION WARNING 7.2 MAINTENANCE INTERVALS & CHECKS 7.2.1 WEEKLY MAINTENANCE 7.2.2 100 HOUR MAINTENANCE 7.2.3 500 HOUR MAINTENANCE... - Page 20 WARNING WARNING 7.2.4 1000 HOUR MAINTENANCE...

-

Page 21: Tyre Handler Lubrication Diagram

7.3 TYRE HANDLER LUBRICATION DIAGRAM... -

Page 22: Guidelines

IMPORTANT: 8.1 GUIDELINES... -

Page 23: Troubleshooting Chart

8.2 CHART Trouble Shooting Chart Problem Possible Cause Possible Solution Trouble Shooting Chart... -

Page 24: Clamp Circuit Test

8.3 CLAMP CIRCUIT TEST 8.4 SIDESHIFT CIRCUIT TEST NOTE: IMPORTANT: energized... -

Page 26: Revolving Connection Features

9.1 REVOLVING CONNECTION FEATURES 9.2 SIDESHIFT TEST. -

Page 27: Revolving Connection Seals And Cartridges

9.3 REVOLVING CONNECTION SEALS AND CARTRIDGES. 9.3.1 Disassemble. 9.3.2 Reassemble. -

Page 28: Removing And Installing The Clamp Cylinders

10.1 REMOVING AND INSTALLING THE CLAMP CYLINDERS. 10.2 CYLINDER DISASSEMBLY. -

Page 29: Cylinder Inspection

10.3 CYLINDER INSPECTION. 10.4 CYLINDER REASSEMBLY 10.5 TILT CYLINDER... -

Page 30: Rotate Cylinder

10.6 ROTATE CYLINDER 10.6.1 Cylinder removal. - Page 31 10.6.2 Cylinder inspection Do not adjust 10.6.3 Setting relief pressures 10.6.4 Feed hoses.

-

Page 33: Shim Slide Arm

12.1 SHIM SLIDE ARM 12.2 SHIM PAD PIVOT... -

Page 35: Index Of Drawings & Diagrams

14.1 INDEX OF DRAWINGS & DIAGRAMS... - Page 36 ITEM PART NO DESCRIPTION DESCRIPTION. cascade TIRE HANDLER - 10.000kg corporation DATE: 18/06/12 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 100K15011 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

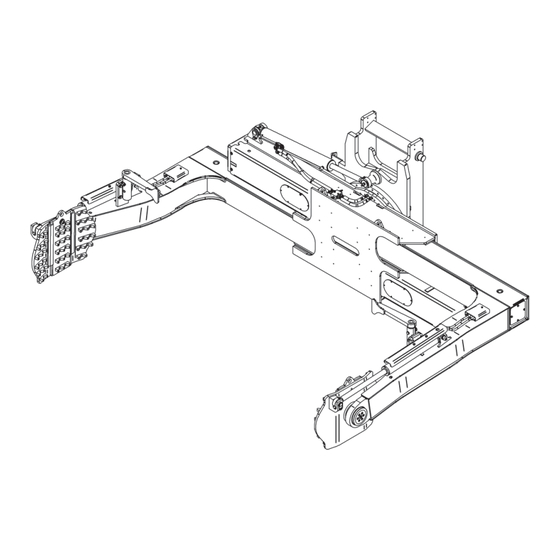

- Page 37 ITEM PART NO DESCRIPTION DESCRIPTION. cascade CARRIAGE - BASE ASSEMBLY corporation DATE: 18/06/12 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1847068 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

- Page 38 ITEM PART NO DESCRIPTION DESCRIPTION. cascade ROTATE - BASE ASSY corporation DATE: 18/06/12 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1847069 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

- Page 39 ITEM PART NO TITLE DESCRIPTION. cascade CLAMP ARM ASSEMBLY LH corporation DATE: 08/12/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1844750 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

- Page 40 ITEM PART NO TITLE DESCRIPTION. cascade CLAMP ARM ASSEMBLY RH corporation DATE: 08/12/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1844751 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

- Page 41 ITEM PART NO TITLE DESCRIPTION. cascade TYRE STOP - RH corporation DATE: 12/12/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1833152 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

- Page 42 ITEM PART NO TITLE DESCRIPTION. cascade TYRE STOP - LH corporation DATE: 12/12/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1833155 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

- Page 43 PART NO TITLE DESCRIPTION. cascade REVOLVING CONNECTION - FLOW DIVIDER corporation DATE: 18/04/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1841819 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

-

Page 44: Bracket Assy

WASHER SPRING M10 ITEM PART NO TITLE DESCRIPTION. cascade BRACKET ASSY corporation DATE: 03/05/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1844703 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL. - Page 45 SEAL KIT P/N 1844763 ITEM PART NO TITLE DESCRIPTION. cascade CLAMP CYLINDER corporation DATE: 03/05/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1829614 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

-

Page 46: Tilt Cylinder

INCLUDES ITEMS MARKED * ITEM PART NO TITLE DESCRIPTION. cascade TILT CYLINDER corporation DATE: 21/04/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1835475 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL. - Page 47 INCLUDES ITEMS MARKED * ITEM PART NO TITLE DESCRIPTION. cascade TILT CYLINDER corporation DATE: 05/08/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1845806 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

- Page 48 INCLUDES ITEMS MARKED * ITEM PART NO TITLE DESCRIPTION. cascade ROTATE CYLINDER corporation DATE: 28/04/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1840332 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

- Page 49 RELIEF VALVE ITEM PART NO TITLE DESCRIPTION. cascade VALVE, RELIEF, CROSS-PORT corporation DATE: 18/04/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 105627 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

-

Page 50: Hose Layout

WASHER SPRING M10 ITEM PART NO TITLE DESCRIPTION. cascade HOSE LAYOUT corporation DATE: 03/05/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1840351 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL. - Page 51 UNION ADAPTOR 8 JIC ITEM PART NO TITLE DESCRIPTION. cascade FEED TUBES corporation DATE: 18/04/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1836679 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

- Page 52 PART NO TITLE DESCRIPTION. cascade BEARING ASSEMBLY - 3 HOLE corporation DATE: 18/04/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1834455 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

- Page 53 PART NO TITLE DESCRIPTION. cascade BEARING ASSEMBLY - 2 HOLE corporation DATE: 18/04/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1834456 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

- Page 54 PART NO TITLE DESCRIPTION. cascade BEARING ASSEMBLY - 3 HOLE CHF corporation DATE: 18/04/11 THIS DRAWING IS THE PROPERTY OF CASCADE AND CONTAINS CONFIDENTIAL INFORMATION PART NO. / DWG NO. 1834457 SHEET : DO NOT REPRODUCE OR USE WITHOUT WRITTEN APPROVAL.

-

Page 55: Index Of Hydraulic Circuit & Layout Diagrams

15.1 INDEX OF HYDRAULIC CIRCUIT & LAYOUT DIAGRAMS... -

Page 57: Index Of Electric Circuit & Layout Diagrams

16.1 INDEX OF ELECTRIC CIRCUIT & LAYOUT DIAGRAMS... -

Page 60: Arm Inspection

18.1 ARM INSPECTION RATING OF SEVERITY: 1- Advised Supervisor 2- Advised Supervisor - Plan for Repairs 3-Advised Supervisor - Repair Immediately DATE LOCATION OF CRACK LENGTH OF RATE OF COMMENTS ACTIONS TAKEN CRACK SEVERITY SUPERVISOR NAME: …………………………………………………. SUPERVISOR SIGNATURE: ………………………………………… DATE: ………………………….. -

Page 61: Base & Rear Carriage Inspection

18.2 BASE & REAR CARRIAGE INSPECTION. RATING OF SEVERITY: 1- Advised Supervisor 2- Advised Supervisor - Plan for Repairs 3-Advised Supervisor - Repair Immediately DATE LOCATION OF CRACK LENGTH OF RATE OF COMMENTS ACTIONS TAKEN CRACK SEVERITY SUPERVISOR NAME: …………………………………………………. SUPERVISOR SIGNATURE: …………………………………………... -

Page 62: Lift Truck Product Warranty Policy

Restrict your repairs to adjustments and/or replacements of Cascade Australia parts (repairs, i.e. Honing, grinding, drilling, welding etc. are not covered by warranty) unless previously authorised to perform a specific modification or alteration by a Cascade Australia Service Representative. Warrants its products to conform to published specifications as found in its quotations, specification sheets, brochures and price lists. - Page 63 FOR INFORMATION: EXCLUSIONS: THERE ARE NO WARRANTIES EITHER EXPRESS OR IMPLIED INCLUDING ANY WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, WHICH EXTEND BEYOND THOSE STATED IN THIS WARRANTY AND THE PRODUCT DESCRIPTION ON THE FACE OF CASCADE AUSTRALIA’S ORDER ACKNOWLEDGMENT.

- Page 64 Appendix 1 TYRE HANDLER INDUCTION LOG Induction Date: Mine: Operator Name: Company: Inducted By: Signature of Inductee:...

Need help?

Do you have a question about the 100K THA and is the answer not in the manual?

Questions and answers