Table of Contents

Advertisement

Quick Links

OPERATOR'S MANUAL

INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE

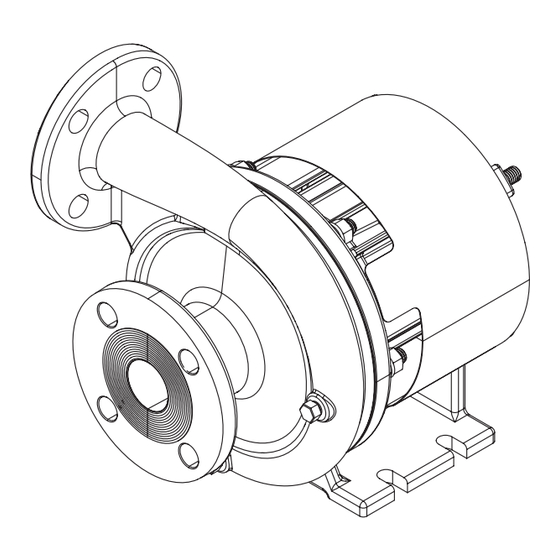

HTO® 80

(1-1/2" x 1-1/4")

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

80 Series

180 Series

INGERSOLL RAND COMPANY INC

34800 BENNETT DR, FRASER, MI 48026

1-800-563-8006

support@mppumps.com

www.gardnerdenver.com/en-us/mppumps

RELEASED 04/Apr/2022 17:04:49 GMT

HTO® 120

(2" x 1-1/2")

OPERATING OR SERVICING THIS EQUIPMENT.

Figure 1

© 2022

HOT OIL PUMP

HTO® 180

(3" x 1-1/2")

120 Series

300 Series

RELEASED:

4-1-22

(REV: A)

HTO® 300

(3" x 2-1/2")

Advertisement

Table of Contents

Summary of Contents for Ingersoll-Rand MP PUMPS 180 Series

- Page 1 RELEASED 04/Apr/2022 17:04:49 GMT OPERATOR’S MANUAL HOT OIL PUMP RELEASED: 4-1-22 INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE (REV: A) HTO® 80 HTO® 120 HTO® 180 HTO® 300 (1-1/2” x 1-1/4”) (2” x 1-1/2”) (3” x 1-1/2”) (3” x 2-1/2”) READ THIS MANUAL CAREFULLY BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT.

-

Page 2: General Description

RELEASED 04/Apr/2022 17:04:49 GMT GENERAL DESCRIPTION HTO 80, 120, 180 and 300 Series: The pumps are air cooled and close coupled to standard High Temperature Oil – Centrifugal Pump Series NEMA C face motors. MP Pumps’ HTO line of centrifugal pumps are made for pumping hot oil up to 650°... -

Page 3: Operating And Safety Precautions

RELEASED 04/Apr/2022 17:04:49 GMT OPERATING AND SAFETY PRECAUTIONS READ, UNDERSTAND, AND FOLLOW THIS INFORMATION TO AVOID INJURY AND PROPERTY DAMAGE. Maximum temperatures are based on CAUTION EXCESSIVE AIR PRESSURE HAZARDOUS MATERIALS mechanical stress of seals and elastomers only. Cer- STATIC SPARK HAZARDOUS PRESSURE tain chemicals will significantly reduce maximum safe operating temperature. -

Page 4: Installation

RELEASED 04/Apr/2022 17:04:49 GMT STORAGE PRECAUTIONS After all fasteners are tight including the drive clamp assem- bly, rotate the driver slowly by hand to make certain that Do not store filled with fluid at or below freezing temp of there is no rubbing. process fluid. - Page 5 RELEASED 04/Apr/2022 17:04:49 GMT PRESSURE - TEMPERATURE LIMITS HTO Pressure Temperature Limits HTO80, HTO120 with NPT Process Fluid Temperature (qF) Figure 2 SEAL COOLING PERFORMANCE HTO Seal Cooling Performance Process Fluid Temperature (qF) Figure 3 HTO Series (en) Page 5 of 24...

-

Page 6: Operation And Maintenance

RELEASED 04/Apr/2022 17:04:49 GMT WORKING OF END SUCTION CENTRIFUGAL PUMP OVER HEAD WATER TANK DISCHARGE HEAD DISCHARGE PIPE SUCTION PIPE DISCHARGE VALVE UNION FLANGE SUCTION VALVE SUCTION HEAD (NPSHr) MINIMIZE LENGTH & AVOID UNION FLANGE SHARP BENDS NEAR INLET DRAIN PULG Figure 4 OPERATING INSTRUCTIONS When servicing the pump, care should be taken that the... -

Page 7: Seal Replacement Instructions

RELEASED 04/Apr/2022 17:04:49 GMT SEAL REPLACEMENT INSTRUCTIONS DISASSEMBLE THE PUMP: inspect the lapped sealing face of carbon washer (Part 3) for wear which would necessitate replacement. Drain the system of liquid, break suction and discharge pipe Inspect lapped sealing face of floating seat (Part 4) in adapter unions, and, if necessary, remove all piping from the suction housing counterbore for scuffing or cracks. -

Page 8: Maintenance

RELEASED 04/Apr/2022 17:04:49 GMT MAINTENANCE The HTO pump is of simple construction with only one mov- Before removing the seal from the impeller, inspect the ing part. The impeller on the HTO is threaded to a stainless carbon washer. If nicked or worn - replace it with a new one. steel drive sleeve. - Page 9 RELEASED 04/Apr/2022 17:04:49 GMT PARTS LIST / HTO 80 Figure 7 PARTS LIST / HTO 80 Item Description Qty Part No. Item Description Qty Part No. (size) (size) Isolator MP29158 ST. Marys Grade 251 Pipe Plug MP21585 Zinc Plated Steel (1/8"...

- Page 10 RELEASED 04/Apr/2022 17:04:49 GMT PARTS LIST / HTO 120 Figure 8 PARTS LIST / HTO 120 Item Description Qty Part No. Item Description Qty Part No. (size) (size) Isolator MP29158 ST. Marys Grade 251 Pipe Plug MP21585 Zinc Plated Steel (1/8"...

- Page 11 RELEASED 04/Apr/2022 17:04:49 GMT PARTS LIST / HTO 180 Figure 9 PARTS LIST / HTO 180 Item Description Qty Part No. Item Description Qty Part No. (size) (size) Isolator MP30842 ST. Marys Grade 251 Pipe Plug MP41475 Steel (1/8" NPT) O-Ring MP30841 Viton...

- Page 12 RELEASED 04/Apr/2022 17:04:49 GMT PARTS LIST / HTO 300 Figure 10 PARTS LIST / HTO 300 Item Description Qty Part No. Item Description Qty Part No. (size) (size) Pipe Plug MP41479 Cast Iron Capscrew MP41279 Steel (1/2” -13” x 2”) (1/2"...

-

Page 13: Service Kits

RELEASED 04/Apr/2022 17:04:49 GMT SERVICE KITS PUMP MODEL PUMP DESCRIPTION SEAL KIT MP37106 HTO80PMP D:3-3 56C 5.9 HD VENT MP30762 MP37084 HTO80PMP D:PED 56C FA 4.25 HD MP30762 MP51172 HTO80PMP D:1-3 56C 208/460 XP 4.25 VD MP30762 MP29559 HTO80PMP D:3-3 56C XP 5.9 HD MP30762 MP30082 HTO80PMP D:1.5-3 56C 208/460 4.8 HD... - Page 14 RELEASED 04/Apr/2022 17:04:49 GMT SERVICE KITS PUMP MODEL PUMP DESCRIPTION SEAL KIT MP34474 HTO80PMP D:3-1 56C 208/230 60HZ 5.75 HD MP30762 MP50045 HTO80PMP D:3-3 56C 575V 5.75 HD MP30762 MP34655 HTO80PMP D:1.5-3 56C 208/460 5.25 HD MP30762 MP50554 HTO80PMP D:1/2-3 56C 1750 XP 5.9 HD MP30762 MP34799 HTO80PMP D:3-3 56C 5.75 HD...

- Page 15 RELEASED 04/Apr/2022 17:04:49 GMT SERVICE KITS PUMP MODEL PUMP DESCRIPTION SEAL KIT MP33755 HTO80PMP D:3-3 56C 4.75 FF VD MP30762 MP30227 HTO80PPK D:CCMTR 5/8 FA 56C 4.25 HD MP30762 MP50956 HTO80PMP D:3-3 56C 5.25 FF VD BALDOR MP30762 MP32064 HTO80PMP D:3-3 56C 5.9 FF HD MP30762 MP37889 HTO80PMP D:1.5-3 56C 380V 4.75 F-FLG VD...

- Page 16 RELEASED 04/Apr/2022 17:04:49 GMT SERVICE KITS PUMP MODEL PUMP DESCRIPTION SEAL KIT MP35049 HTO120PMP D:3-3 145TC 5.0 FF HD MP30763 MP35100 HTO120PMP D:3-3 145TC XP 4.5 FF VD MP30763 MP35284 HTO120PMP D:5-3 184C 50/60HZ 5.96 FF HD MP30763 MP38530 HTO120PMP D:3-3 145TC XP 5.0 FF VD MP30763 MP39097 HTO120PMP D:5-3 184C 5.75 FF HD...

- Page 17 RELEASED 04/Apr/2022 17:04:49 GMT SERVICE KITS PUMP MODEL PUMP DESCRIPTION SEAL KIT MP34808 HTO180PMP D:7.5-3 184TC ODP 5.125 550 VD MP34857 MP34457 HTO180PMP D:7.5-3 184TC 5.8 VD MP34857 MP35568 HTO180PMP D:3-3 182TC 1750 XP 6.5 VD MP34857 MP38324 HTO180PMP D:7.5-3 184TC 5.18 HD MP34857 MP35838 HTO180PMP D:7.5-3 184TC 6.5 HD...

- Page 18 RELEASED 04/Apr/2022 17:04:49 GMT SERVICE KITS PUMP MODEL PUMP DESCRIPTION SEAL KIT MP36669 HTO300PMP D:15-3 215TC ODP 6.62 HD MP35224 MP35230 HTO300PMP D:15-3 215TC 7.0 HD MP35224 MP35223 HTO300PPK D:CCMTR 1.375 215TC 7.0 HD MP35224 MP37246 HTO180PMP D:7.5-3 215TC 50HZ MD 6.5 HD MP35224 MP38270 HTO300PPK D:CCMTR 1.375 215TC 5.5 HD...

-

Page 19: Dimensional Data

RELEASED 04/Apr/2022 17:04:49 GMT DIMENSIONAL DATA 1-1/4" CLASS 150 OUTLET FLANGE 15.88 .625 THRU HOLES EQ. SPACED AS SHOWN ON A 3.500 B.C. 1-1/2" CLASS 150 INLET FLANGE 212.77 15.88 8.38 248.97 108.46 .625 THRU HOLES 9.80 67.56 4.27 EQ. SPACED AS SHOWN 2.66 ON A 3.875 B.C. - Page 20 RELEASED 04/Apr/2022 17:04:49 GMT DIMENSIONAL DATA 1-1/2" CLASS 150 OUTLET FLANGE (4) .63 DIA HOLES THRU 65.66 EQ. SPACED AS SHOWN 2.59 ON A 3.875 DIA B.C. 135.64 3" CLASS 150 INLET FLANGE 5.34 45° 258.21 (4) .66 DIA HOLES THRU 10.17 EQ.

-

Page 21: Troubleshooting

RELEASED 04/Apr/2022 17:04:49 GMT TROUBLESHOOTING PROBLEM PROBABLE CAUSE REMEDY 1. Reprime pump, check that pump and 1. Pump not primed. there are no obstructions in the suc- tion line. 2. Discharge valve closed 2. Check discharge valve. 3. Suction line clogged. 3. - Page 22 RELEASED 04/Apr/2022 17:04:49 GMT PROBLEM PROBABLE CAUSE REMEDY 1. Improper pump/driver alignment. 1. Align shafts. 2. Partly clogged impeller causing 2. Back-flush pump to clean impeller. imbalance. 3. Broken or bent impeller or shaft. 3. Replace as required. 4. Tighten bolts of pump and motor or 4.

- Page 23 RELEASED 04/Apr/2022 17:04:49 GMT HTO Series (en) Page 23 of 24...

- Page 24 RELEASED 04/Apr/2022 17:04:49 GMT PN MPHTO-IOM Page 24 of 24 HTO Series (en)

Need help?

Do you have a question about the MP PUMPS 180 Series and is the answer not in the manual?

Questions and answers