Oriental motor CVD Series Operating Manual

Drivers for 2-phase, 5-phase stepping motors

Hide thumbs

Also See for CVD Series:

- Operating manual (204 pages) ,

- User manual (56 pages) ,

- Operating manual (16 pages)

Table of Contents

Advertisement

Quick Links

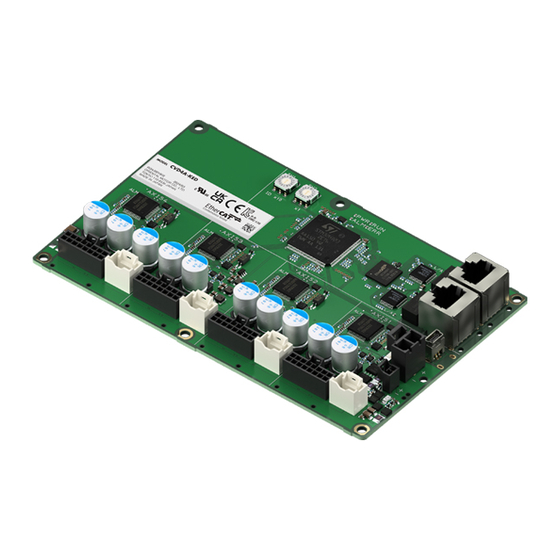

Drivers for 2-Phase, 5-Phase

Stepping Motors

CVD Series

Multi-Axis Type

EtherCAT Compatible

OPERATING MANUAL

Software Edition

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety precautions.

• Please read it thoroughly to ensure safe operation.

• Always keep the manual where it is readily available.

HM-60519

Introduction

I/O signals

EtherCAT communication

Object list

Troubleshooting

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Oriental motor CVD Series

- Page 1 OPERATING MANUAL Troubleshooting Software Edition Thank you for purchasing an Oriental Motor product. This Operating Manual describes product handling procedures and safety precautions. • Please read it thoroughly to ensure safe operation. • Always keep the manual where it is readily available.

-

Page 2: Table Of Contents

Introduction Before using the product ............................6 Related operating manuals ............................7 Safety precautions ............................... 8 Precautions for use ..............................10 I/O signals Signal type ...................................12 Direct I/O ........................................12 Remote I/O ......................................15 Signal lists ..................................17 Input signals list..................................... 17 Output signals list .................................... - Page 3 Functions ..................................69 Setting the applicable product ................................ 69 Setting of resolution .................................... 70 Touch probe ......................................71 Maintenance commands ................................... 74 Assignment of I/O functions ................................75 Saving parameters ....................................81 Operating current and stop current ............................... 81 Stopping movement ................................... 82 Coordinates management ................................

- Page 5 Introduction Table of contents Before using the product ....... 6 Related operating manuals ....7 Safety precautions ........8 Precautions for use ........ 10...

-

Page 6: Before Using The Product

The product described in this manual is designed and manufactured to be incorporated in general industrial equipment. Do not use it for any other purpose. Oriental Motor Co., Ltd. is not responsible for any compensation for damage caused through failure to observe this warning. -

Page 7: Related Operating Manuals

• OPERATING MANUAL Actuator Edition „ How to use operating manuals To use the product, read both the Hardware Edition and the Software Edition (this document) of the CVD Series Multi-Axis Type operating manuals. The Hardware Edition describes installation, connection, etc. -

Page 8: Safety Precautions

Safety precautions Safety precautions The precautions described below are intended to ensure the safe and proper use of the product and to prevent the user and other personnel from exposure to the risk of injury. Use the product only after carefully reading and fully understanding these instructions. Handling the product without observing the instructions that accompany a “WARNING”... - Page 9 Safety precautions General • Do not use the driver beyond the specifications. Doing so may result in injury or damage to equipment. • Do not touch the driver during operation or immediately after stopping. The surface is hot, and this may cause a skin burn(s).

-

Page 10: Precautions For Use

Precautions for use Precautions for use This chapter explains restrictions and requirements that the user should consider when using the product. z Note on connecting a main power supply and a control power supply whose positive terminals are grounded The USB connector (CN3) on the driver is not electrically insulated. When grounding the positive terminals of a main power supply and a control power supply, do not connect any equipment (PC, etc.) whose negative terminal is grounded. - Page 11 I/O signals This part explains input signals and output signals. Table of contents Signal type ..........12 1-1 Direct I/O ............12 1-2 Remote I/O ............15 Signal lists ..........17 2-1 Input signals list ..........17 2-2 Output signals list ........... 18 Input signals ...........

-

Page 12: Signal Type

Signal type Signal type Direct I/O Direct I/O (DIN, DOUT) is a method in which a signal is input directly by connecting the cable to the I/O connector. Signals are assigned using parameters. Refer to “2 Signal lists” on p.17 for signals that can be assigned. Applicable connector Signal name Description*... -

Page 13: Input Function

Signal type „ Direct input (DIN) • When the same input signal is assigned to multiple input terminals, the function will be executed if any of the terminals becomes active. • When the HMI input is not assigned to an input terminal, this input will always be in an ON state. If it is assigned to both direct I/O and remote I/O, the function will be executed only when both of them are turned ON. -

Page 14: Output Function

Signal type z ON signal dead-time The input signal is turned ON when the time having set is exceeded. This can be used to take a measure to eliminate the noise or to adjust the timing between the devices. Index Name Type Access... -

Page 15: Remote I/O

Signal type Remote I/O Remote I/O is I/O to be accessed via EtherCAT. „ Remote input The Driver input command (403Eh) is an input command from the MainDevice to the driver. The arrangement of bits is as follows. Bit 0 to Bit 7 are assigned to the R-IN0 to R-IN7. Bit 8 to Bit 15 are not used. Values in parentheses ( ) are initial values. - Page 16 Signal type „ Remote output The status of the R-OUT0 to R-OUT15 can be checked with the Driver status (403Fh). The arrangement of bits is as follows. Values in parentheses ( ) are initial values. Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10...

-

Page 17: Signal Lists

Signal lists Signal lists Assign I/O signals via EtherCAT or using the MEXE02 software. To assign signals via EtherCAT, use the “Assignment number” in the table instead of the signal name. Input signals list Refer to “3 Input signals” on p.20 for details about each signal. Assignment Signal name Functions... -

Page 18: Output Signals List

Signal lists Assignment Signal name Functions Status number These are general signals 0: OFF 1: ON EXT1 This is an external latch signal for the touch probe 1. EXT2 This is an external latch signal for the touch probe 2. Output signals list Refer to “4 Output signals”... - Page 19 Signal lists Assignment Signal name Functions Status number 0: Normal Output when the phase Z input is detected. 1: Phase Z input is present Output every time the motor output shaft rotates 0: OFF by 7.2 degrees with reference to the command 1: ON position.

-

Page 20: Input Signals

Input signals Input signals Operation control „ Excitation switching signal This signal is used to switch the motor excitation state between excitation and non-excitation. z FREE input When the FREE input is turned ON, the motor current is shut off to put the motor in a non-excitation state. The motor output shaft can be rotated manually since the motor holding force is lost. - Page 21 Input signals „ Operation stop signals These signals are used to stop the motor operation. z STOP input When the STOP input is turned ON, the motor stops the operation according to the setting of the STOP input action (4700h). The remaining travel amount is cleared. Related object Index Name...

- Page 22 Input signals When the STOP input action is set to “3: Deceleration stop” (When the motor does not stop while the STOP input is ON) 1. When the STOP input is turned ON during operation, the motor starts the stopping movement. Even after the STOP input is turned OFF, the motor continues the deceleration operation until it stops.

- Page 23 Input signals z FW-BLK input, RV-BLK input Turning the FW-BLK input ON will stop operation in the forward direction, and turning the RV-BLK input ON will stop operation in the reverse direction. While an input signal that has stopped operation is ON, the motor will not operate even if an operation start signal that operates it in the same direction as the stop signal is input.

- Page 24 Input signals 2 ms or more FW-BLK input READY output MOVE output 2 ms or less Motor operation Excitation Motor excitation Non-excitation * It varies depending on the driving condition. When the FW-BLK/RV-BLK input action is set to “1: Deceleration stop” (when the motor does not stop while the FW-BLK input is ON) 1.

-

Page 25: Position Coordinate Management

Input signals Position coordinate management „ External sensor input signals z FW-LS input, RV-LS input These are input signals from the limit sensors. The FW-LS input is a signal for a sensor in the forward direction and the RV-LS input is that in the reverse direction. •... -

Page 26: Management Of Driver

Input signals Management of driver „ Status release signals These signals are used to release the signal or status that is not automatically released. z ALM-RST input If an alarm is generated, the motor will stop. At this time, turning the ALM-RST input from OFF to ON will reset the alarm (the alarm will be reset at the ON edge of the ALM-RST input). -

Page 27: Output Signals

Output signals Output signals Management of driver „ Driver status indication signals z ALM-A output, ALM-B output If an alarm is generated, the ALM-A output is turned ON and the ALM-B output is turned OFF. At the same time, the ALM LED on the driver will blink red, and the motor will stop. -

Page 28: Management Of Operation

Output signals Management of operation „ Operation status indication signals z READY output When the driver is ready to operate, the READY output is turned ON. Input the operation start command to the driver after the READY output is turned ON. The READY output is turned ON when all of the following conditions are met. - Page 29 Output signals „ Direct data operation status indication signals z DCMD-FULL output This signal is output while data is written in the buffer area. If operation of Set of Set-points is performed in the Profile position mode, the operation command is written in the buffer area.

-

Page 30: Related Objects

Output signals z AREA0 output, AREA1 output The AREA outputs are turned ON when the motor is within the set area. They are turned ON when the motor is within the area even if the motor stops. Related objects Index Name Type Access... - Page 31 Output signals When the AREA range setting mode (4750h, 4751h) is “1: Offset/width setting from the target position” O set Motor operation Width Width AREA output z FW-SLS output, RV-SLS output If the command position exceeds the range specified in the Software limit (607Dh) when the Software overtravel (41C3h) is set to other than “−1: Disable, ”...

-

Page 32: Timing Chart

Timing chart Timing chart „ Power activation 10 s or more Control power supply 0 s or more 1 s or less Main power supply 1.5 s or less 1 s or less SYS-RDY (Output is set, and input is enabled) 2 s or less 1 s or less MPS output... - Page 33 EtherCAT communication This part explains the EtherCAT communication specifications and the corresponding objects. Table of contents Communication specifications ... 35 Functions ..........69 1-1 EtherCAT communication interface ..35 3-1 Setting the applicable product....69 1-2 CiA402 drive profile ........35 3-2 Setting of resolution ........

- Page 34 „ Setting of data and parameters Data and parameters described in this manual can be set using the MEXE02 software in addition to EtherCAT. „ Notation rules z About the update time In this manual, each update time is represented in an alphabet. Notation Description Recalculation and setup are immediately executed when the parameter is written.

-

Page 35: Communication Specifications

Communication specifications Communication specifications EtherCAT communication interface Item Description Communications standards IEC 61158 Type12 Physical layer/Protocol 100 BASE-TX (IEEE 802.3) Transmission rate 100 Mbps • Free Run mode: 1 ms or more Communication cycle • Sync Manager 2 event synchronization mode: 1 ms or more •... -

Page 36: Ethercat State Machine (Esm)

Communication specifications EtherCAT State Machine (ESM) The EtherCAT State Machine (ESM) is controlled by the MainDevice. Init Pre-Operational Safe-Operational Operational Transmit PDO Receive PDO ESM State Status communication (TxPDO) (RxPDO) During initialization. Communication Init Not possible Not possible Not possible cannot be performed. - Page 37 Communication specifications „ PDO mapping object The PDO mapping object is different for each axis. Check the table below. Up to 8 objects can be mapped in a single PDO. Receive PDO mapping object Transmit PDO mapping object Axis Receive PDO Index Transmit PDO Index...

- Page 38 Communication specifications „ Setting of PDO mapping object PDO mapping can be changed when the ESM is Pre-Operational. Change the PDO mapping in the following steps. 1. Set the number of entries of the Sync Manager 2/Sync Manager 3 PDO assignment object to 0. 2.

-

Page 39: Service Data Objects (Sdo)

Communication specifications Service Data Objects (SDO) Service Data Objects (SDO) are used when reading or writing the parameter object or monitoring via EtherCAT. SDO is not synchronized to the EtherCAT communication cycles, but is sent and received in arbitrary timing. The setting of PDO mapping is also performed using SDO. -

Page 40: Distributed Clocks

Communication specifications Distributed Clocks The term Distributed Clocks (DC) is a method to synchronize operation by sharing the same clock between the MainDevice and the driver. The interruption signal (SYNC0) is output at a precise interval based on the DC. In the DC mode, an application is executed synchronously with SYNC0. -

Page 41: Drive Profile

Drive profile Drive profile In this manual, the index of the driver axis 1 is described for the objects in the profile area. The objects of the driver axis 2 to axis 4 are indexes offset by 800h from the object on the previous axis. Refer to the table below. - Page 42 Drive profile Setting of State Signal state Motor status parameter The driver generates an alarm and the Fault reaction active Excitation Possible to set operation stop is processing. Fault An alarm of the driver is being generated. Non-excitation Possible to set „...

- Page 43 Drive profile State Motor operation Event Action • ESM transitions to other than Operational. Transitions to “Ready to switch on. ” (Transition Switched on During stop • The main power is number 6) shut off. • The FREE input is ON. •...

-

Page 44: Operation Modes

Drive profile z Status output of Statusword State Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Start Not ready to switch on Fault −* Fault reaction active −* Switch on disabled −* Ready to switch on −* Switched on −*... -

Page 45: Related Objects

Drive profile Related objects Index Name Type Access Save Range Update 0000h to FFFFh 6040h Controlword RxPDO − (Initial value: 0000h) 6041h Statusword TxPDO − − − 0, 1, 3, 6, 8, 9 ( p.44) 6060h Modes of operation INT8 RxPDO ... - Page 46 Drive profile „ Statusword of Cyclic synchronous position mode Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Manufacturer specific Operation mode specific Internal − Remote Following Target position limit active − − −...

-

Page 47: Profile Position Mode (Pp)

Drive profile Profile position mode (PP) The Profile position mode operates in the internal profile of the driver. Path generation (profile generation) is performed with the driver. The target position, speed, acceleration and others are set with the MainDevice. Related objects Index Name Type... - Page 48 Drive profile „ Controlword of Profile position mode Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Manufacturer specific (ms) Reserved Halt Change on − Reserved Reserved Reserved − set point Bit 7 Bit 6 Bit 5 Bit 4...

- Page 49 Drive profile „ Statusword of Profile position mode Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Manufacturer specific Operation mode specific Internal Target Remote Following Set point limit active reached − − −...

-

Page 50: Positioning Operation

Drive profile „ Operation in Profile position mode z Positioning operation Positioning operation is started when the Target position (607Ah) is set and the New set point (6040h: Bit 4) is set to 1. Velocity demand value Pro le acceleration Pro le deceleration (6083h) (6084h) -

Page 51: Absolute Positioning

Drive profile Set of set-points [When the Change set immediately (6040h: Bit 5) is 0] When the New set point (6040h: Bit 4) is newly set during operation, the new operation command is saved. When the present operation is completed, the stored new operation command is started. Speed Velocity demand value Target position... - Page 52 Drive profile z Incremental positioning (Based on command position) Positioning operation with the set travel amount is performed from the present command position. In the Target position (607Ah), set the travel amount from the present command position to the target position. Example: When moving from the command position “1,000”...

-

Page 53: Cyclic Synchronous Velocity Mode (Csv)

Drive profile Cyclic synchronous velocity mode (CSV) In the Cyclic synchronous velocity mode, path generation (profile generation) is performed by the EtherCAT MainDevice. By cyclic synchronous communication, when the Target velocity (60FFh) is sent from the MainDevice to the driver, the driver performs speed control. Related objects Index Name... - Page 54 Drive profile „ Statusword of Cyclic synchronous velocity mode Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Manufacturer specific Operation mode specific Internal Reserved Remote Target velocity limit active − − Reserved −...

-

Page 55: Profile Velocity Mode (Pv)

Drive profile Profile velocity mode (PV) The Profile velocity mode operates in the internal profile of the driver. Path generation (profile generation) is performed with the driver. The speed, acceleration, and others are set with the MainDevice. Related objects Index Name Type Access... - Page 56 Drive profile „ Statusword of Profile velocity mode Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Manufacturer specific Operation mode specific Internal Target Remote limit active reached − − − Speed − Bit 7 Bit 6 Bit 5...

-

Page 57: Homing Mode (Hm)

Drive profile Homing mode (HM) The Homing mode is used to set the home. Path generation (profile generation) is performed with the driver. If return-to-home operation is performed, the position preset (P-PRESET) is executed when the operation is completed, and the home will be the value set in the Home offset (607Ch). z Related objects Refer to “Selection of return-to-home (Homing) method”... - Page 58 Drive profile „ Statusword of Homing Mode Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Manufacturer specific Operation mode specific Internal Target Remote Homing Homing limit active reached Reserved − − error attained Bit 7 Bit 6...

- Page 59 Drive profile „ Selection of return-to-home (Homing) method The return-to-home method is selected with the Homing method (6098h). The driver supports the following methods to return to the home. Homing method Description Return-to-home with the limit sensor (FW-LS/RV-LS), to start running in the negative direction. Return-to-home with the limit sensor (FW-LS/RV-LS), to start running in the positive direction.

- Page 60 Drive profile z Return-to-home operation of Oriental Motor’s specifications When the Homing method (6098h) is set to −1, the return-to-home mode of Oriental Motor’s specifications is applied. Related objects (Oriental Motor’s specifications) Index Name Type Access Save Range Update −2,147,483,648 to...

- Page 61 (HOMES) Positive limit switch (FW-LS) In the case of return-to-home operation of Oriental Motor’s specifications, the same operation is performed if the following data is set. • (HOME) Return-to-home mode (4160h): 1 [3-sensor] • (HOME) Return-to-home starting direction (4161h): 1 [Positive side] •...

- Page 62 Drive profile In the case of return-to-home operation of Oriental Motor’s specifications, the same operation is performed if the following data is set. • (HOME) Return-to-home mode (4160h): 1 [3-sensor] • (HOME) Return-to-home starting direction (4161h): 0 [Negative side] • (HOME) Return-to-home SLIT detection (4166h): 0 [Disable] •...

- Page 63 Drive profile „ Operation in return-to-home mode of Oriental Motor’s specifications z Return-to-home operation sequence of 3-sensor mode The motor operates at the Speed during search for switch (6099h-01h). When the limit sensor is detected during operation, the motor rotates in the reverse direction and pulls out of the limit sensor. The motor stops when the ON edge of the HOME sensor is detected, and the position at which the motor stopped is set as the home.

- Page 64 Drive profile When the SLIT input, TIM signal, and/or ZSG signal are used simultaneously Even after return-to-home operation is completed, operation is continued until an external signal is detected. If an external signal is detected while the HOME sensor is ON, return-to-home operation is completed. •...

- Page 65 Drive profile z Return-to-home operation sequence of 2-sensor mode The motor operates at the the (HOME) Return-to-home starting speed (4163h). When the limit sensor is detected, the motor rotates in the reverse direction and pulls out of the limit sensor. After pulling out of the limit sensor, the motor rotates according to the value set in the (HOME) Backward steps in 2 sensor return-to-home (4169h) and stops.

- Page 66 Drive profile When the SLIT input, TIM signal, and/or ZSG signal are used simultaneously Even after return-to-home operation is completed, operation is continued until an external signal is detected. If an external signal is detected, return-to-home operation is completed. • VR: Speed during search for switch (6099h-01h) •...

- Page 67 Drive profile z One-way rotation mode The motor operates at the Speed during search for switch (6099h-01h). When the HOME sensor is detected, the motor decelerates to a stop and pulls out of the HOME sensor at the Speed during search for zero (6099h-02h). After pulling out of the limit sensor, the motor rotates according to the value set in the (HOME) Operating amount in uni-directional return-to-home (416Ah) and stops.

- Page 68 Drive profile When the SLIT input, TIM signal, and/or ZSG signal are used simultaneously Even after return-to-home operation is completed, operation is continued until an external signal is detected. If an external signal is detected, return-to-home operation is completed. • VR: Speed during search for switch (6099h-01h) •...

-

Page 69: Functions

Functions Functions Setting the applicable product Set the applicable motor setting (413Ah) according to the product combined. If the parameter is set, the output current of the driver is automatically set. Be sure to set the parameter according to the product combined. If the output current of the driver is set to a value higher than the rated current of the product combined by mistake in setting, fire or a skin burn(s) may result. -

Page 70: Setting Of Resolution

Functions Product to be Applicable motor Output current of driver Type Series combined*1 setting (413Ah) to be set (A/phase) PK513 0.35 PK52P PK52H 0.75 PK54 PK56*2 PKP52MN03 0.35 PKP52N03 5-Phase stepping motors PKP52MN07 0.75 PKP52N07 PKP52N12 PKP54MN PKP54N18„ PKP54N18„2 PKP56FMN PKP56FN24„2 DRLM20 0.35... -

Page 71: Touch Probe

Functions Touch probe The touch probe is a function that sets the external latch input signal (EXT1 input, EXT2 input) or the output signal (TIM output) as a trigger and latches the internal command position when the trigger is input. Select the signal that is set as a trigger with the Trigger selection (Bit 2 / Bit 10) of the Touch probe function (60B8h). - Page 72 Functions „ Details of touch probe function The action of the touch probe is set with the Touch probe function (60B8h). Set the action of the touch probe 1 in the lower 8 bits and that of the touch probe 2 in the upper 8 bits. Set the trigger condition using the Touch probe 1 trigger action/Touch probe 2 trigger action (Bit 1 / Bit 9) and the Touch probe 1 trigger selection/Touch probe 2 trigger selection (Bit 2 / Bit 10).

- Page 73 Functions „ Details of touch probe status The status of the touch probe is output by the Touch probe status (60B9h). The status of the touch probe 1 is output in the lower 8 bits and that of the touch probe 2 is output in the upper 8 bits. Name Value Description...

-

Page 74: Maintenance Commands

Functions Maintenance commands Maintenance commands are used to execute resetting alarms, batch processing of non-volatile memory or the like. All commands are for WRITE. The maintenance commands include a process in which the memory is operated. Be careful not to execute them unnecessarily in succession. -

Page 75: Assignment Of I/O Functions

Functions Even if monitor is executed while Configuration is being executed, the correct monitor value may not return. „ How to execute the maintenance commands There are two types of execution methods. Use them selectively in accordance with the intended use. z Write 1 to data (Recommended) When data is changed from 0 to 1 after 1 is written to it, the command is executed. - Page 76 Functions „ Direct I/O The status of direct I/O can be checked with the Direct I/O (406Ah). The arrangement of bits is as follows. Bit 31 Bit 30 Bit 29 Bit 28 Bit 27 Bit 26 Bit 25 Bit 24 −...

- Page 77 Functions Index Name Type Access Save Range Update 0 to 127 R-IN7 input 4907h (Initial value: 0 function [No function]) * Set an axis number (1 to 4) in Sub-index due to the driver objects of the manufacturer-specific area. „...

- Page 78 Functions Index Name Type Access Save Range Update 0 to 255 R-OUT14 output 491Eh (Initial value: function 128 [CONST-OFF]) 0 to 255 R-OUT15 output 491Fh (Initial value: function 128 [CONST-OFF]) * Set an axis number (1 to 4) in Sub-index due to the driver objects of the manufacturer-specific area. „...

- Page 79 Functions Assignment Signal name Functions Status number These are general signals. 0: OFF 1: ON EXT1 This is an external latch signal for the touch probe 1. EXT2 This is an external latch signal for the touch probe 2. • When the same input signal is assigned to multiple input terminals, the function will be executed if any of the terminals becomes active.

- Page 80 Functions Assignment Signal name Functions Status number 0: Coordinates setting is not completed ABSPEN Output when coordinates have been set. 1: Coordinates setting is completed After the position preset (P-PRESET) was executed, this 0: Normal state PRST-DIS signal is output when the position preset (P-PRESET) is 1: Preset is not completed required again before the motor is operated.

-

Page 81: Saving Parameters

Functions Saving parameters Parameters are stored in RAM or non-volatile memory in the driver. The parameters stored in RAM are erased when the control power supply is shut off, but the parameters stored in non-volatile memory remain stored even when the control power supply is shut off. -

Page 82: Stopping Movement

Functions Stopping movement „ Operation stop input Inputting the operation stop signal during motor operation causes the motor to stop. Related objects Index Name Type Access Save Range Update 0: Immediate stop 4700h STOP input action INT8 3: Deceleration stop ... - Page 83 Functions „ Software overtravel Software overtravel is a function that limits the travel range by setting the upper and lower limits of the travel range with the parameters. If the Software overtravel (41C3h) is set to “0: Immediate stop” or “1: Deceleration stop, ” the motor can be stopped according to the setting of the parameter when the software limit is reached.

-

Page 84: Coordinates Management

Coordinates management The driver manages the position information. The home is set if one of the following is executed, and the ABSPEN output is turned ON. • Return-to-home operation • Position preset: The command position will be the value set in the Preset position (41C6h). The absolute positioning operation cannot be executed without setting coordinates. - Page 85 Object list This part describes the lists of objects supported by the driver. Table of contents Composition of object dictionary ..86 Objects of CoE communication area.. 88 2-1 Descriptions of each object ......88 2-2 Object list ............98 Objects of profile area ......102 3-1 Descriptions of each object ......102 3-2 Object list ............113...

-

Page 86: Composition Of Object Dictionary

Composition of object dictionary Composition of object dictionary Objects are configured as follows. Index (Hex) Object Overview 2000h to 3FFFh No function 4000h to 4FFFh Manufacturer-Specific Area Sets an axis number (1 to 4) to the Sub-Index of the driver objects. 5000h to 5FFFh No function 6000h to 67FFh... - Page 87 Composition of object dictionary Item Description Indicates the timing for updating the change when a value in the object is changed. • A: Update immediately • B: Update after operation stop Update • C: Update after executing Configuration • D: Update after turning on the control power supply again...

-

Page 88: Objects Of Coe Communication Area

Objects of CoE communication area Objects of CoE communication area These objects are used to make settings related to EtherCAT communication or to indicate the status. Descriptions of each object z Device Type (1000h) This indicates the device profile. Index Name Type Access... - Page 89 Objects of CoE communication area z Identity Object (1018h) This indicates the product information of the driver. The serial number is always 0. Index Name Type Access Save Initial value Range Update Number of entries − − − Vendor ID −...

- Page 90 Objects of CoE communication area z Driver axis 2 Receive PDO mapping 1 (1610h) This is used to set the receive PDO mapping 1 of the driver axis 2. Index Name Type Access Save Initial value Range Update Number of −...

- Page 91 Objects of CoE communication area z Driver axis 3 Receive PDO mapping 2 (1621h) This is used to set the receive PDO mapping 2 of the driver axis 3 Index Name Type Access Save Initial value Range Update Number of −...

- Page 92 Objects of CoE communication area z Driver axis 1 Transmit PDO mapping 1 (1A00h) This is used to set the transmit PDO mapping 1 of the driver axis 1. Index Name Type Access Save Initial value Range Update Number of −...

- Page 93 Objects of CoE communication area z Driver axis 2 Transmit PDO mapping 2 (1A11h) This is used to set the transmit PDO mapping 2 of the driver axis 2. Index Name Type Access Save Initial value Range Update Number of −...

- Page 94 Objects of CoE communication area z Driver axis 4 Transmit PDO mapping 1 (1A30h) This is used to set the transmit PDO mapping 1 of the driver axis 4. Index Name Type Access Save Initial value Range Update Number of −...

- Page 95 Objects of CoE communication area z Sync Manager communication (1C00h) This is used to set the communication type of Sync Manager (SM). Index Name Type Access Save Initial value Range Update Number of − − − entries Communication 1: Mailbox output type sync −...

- Page 96 Objects of CoE communication area z Sync Manager 2 Synchronization (1C32h) This is used to set the Synchronization Type of the Sync Manager 2 (SM2) and indicates the status. Initial Index Name Type Access Save Range Update value Number of entries −...

- Page 97 Objects of CoE communication area z Sync Manager 3 Synchronization (1C33h) This is used to set the Synchronization Type of the Sync Manager 3 (SM3) and indicates the status. Initial Index Name Type Access Save Range Update value Number of entries −...

-

Page 98: Object List

Objects of CoE communication area Object list Index Name Type Access Save Initial value Range Update 1000h Device Type − FFFF0192h − − 1001h Error Register − − − Manufacturer Device 1008h STRING − CVD4A-KED − − Name Manufacturer Indicates the 1009h STRING −... - Page 99 Objects of CoE communication area Index Name Type Access Save Initial value Range Update Axis 3 Receive PDO Mapping 2 (Axis 3 - RxPDO2) Number of entries − 0 to 8 Mapping entry 1 − 7040 0010h Mapping entry 2 −...

- Page 100 Objects of CoE communication area Index Name Type Access Save Initial value Range Update Axis 3 Transmit PDO Mapping 1 (Axis 3 - TxPDO1) Number of entries − 0 to 8 Mapping entry 1 − 7041 0010h 1A20h Mapping entry 2 −...

- Page 101 Objects of CoE communication area Index Name Type Access Save Initial value Range Update Sync Manager 3 PDO assignment Number of entries − 0 to 4 Index of assigned − 1A00h PDO 1 Index of assigned 1C13h − 1A10h PDO 2 0000h to FFFFh Index of assigned −...

-

Page 102: Objects Of Profile Area

Objects of profile area Objects of profile area Objects in the profile area are defined by the CiA402 drive profile. These are used to set the driver operation and to indicate the status. Descriptions of each object z Error code (603Fh) This indicates the error code being generated in the driver. -

Page 103: Quick Stop Option Code (605Ah)

Objects of profile area z Statusword (6041h) This is used to indicate the status of the drive state machine and the operation status of the driver. Index Name Type Access Save Range Update 6041h Statusword TxPDO − − − Details of bits Name Description Ready to switch on... -

Page 104: Halt Option Code (605Dh)

Objects of profile area z Shutdown option code (605Bh) This is used to set the action when transitioning from “Operation enabled” to “Ready to switch on. ” Index Name Type Access Save Range Update 0, 1 605Bh Shutdown option code INT16 ... - Page 105 Objects of profile area Details of range Setting value Description Operation function disable Profile position mode (PP) Profile velocity mode (PV) Homing mode (HM) Cyclic synchronous position mode (CSP) Cyclic synchronous velocity mode (CSV) z Modes of operation display (6061h) This indicates the operation mode that is enabled actually.

- Page 106 Objects of profile area z Target position (607Ah) This is used to set the target position in the Cyclic synchronous position mode and the Profile position mode. Index Name Type Access Save Range Update −2,147,483,648 to Target position 607Ah INT32 RxPDO −...

- Page 107 35, 37* Home preset −1 Return-to-home operation of Oriental Motor’s specifications * 35 and 37 perform the same action. z Homing speed (6099h) This is used to set the operating speed and feedback speed for return-to-home operation. The feedback speed is the operating speed when position adjustment is performed with the home finally.

- Page 108 Objects of profile area z Homing acceleration (609Ah) This is used to set the acceleration/deceleration for return-to-home operation. Index Name Type Access Save Range Update Homing acceleration 1 to 1,000,000,000 609Ah [step/s (Initial value: 300,000) z Touch probe function (60B8h) This is used to set the action of the touch probe.

- Page 109 Objects of profile area z Touch probe status (60B9h) This indicates the status of the touch probe. Refer to p.71 for details. Index Name Type Access Save Range Update 60B9h Touch probe status TxPDO − − − Details of bits Name Value Description...

- Page 110 Objects of profile area z Supported homing methods (60E3h) This indicates the Homing (return-to-home) method supported by the driver. Index Name Type Access Save Range Update Number of entries − − 1st supported homing method − − 2nd supported homing method −...

- Page 111 Objects of profile area Details of bits Name Description RV-BLK*1 Status of RV-BLK input (0: OFF, 1: ON)*2 FW-BLK*1 Status of FW-BLK input (0: OFF, 1: ON)*2 HOMES*1 Status of HOMES input (0: OFF, 1: ON)*2 3 to 15 − Reserved EXT1*1 Status of EXT1 input (0: OFF, 1: ON)*2...

- Page 112 Objects of profile area z Supported drive modes (6502h) This indicates the operation mode supported by the product. Index Name Type Access Save Range Update 6502h Supported drive modes − 0000 01A5h − Details of bits Name Value Description PP (Profile position mode) 1: Supported VL (Velocity mode) 0: Not supported...

-

Page 113: Object List

Objects of profile area Object list In this manual, the index of the driver axis 1 is described for the objects in the profile area. The objects of the driver axis 2 to axis 4 are indexes offset by 800h from the object on the previous axis. Index Name Type... - Page 114 Objects of profile area Index Name Type Access Save Initial value Range Update 60B8h Touch probe function RxPDO − 0000h 0000h to FFFFh 60B9h Touch probe status TxPDO − − − − Touch probe position 1 60BAh INT32 TxPDO − −...

-

Page 115: Objects Of Manufacturer-Specific Area

Objects of manufacturer-specific area These are Oriental Motor’s specific objects. The driver objects are the objects for driver axes 1 to axis 4. In this manual, the Sub-index is described as “*”. Set the axis number (1 to 4) in the Sub-Index of each object to access. - Page 116 Objects of manufacturer-specific area z Command speed (4064h) This is the present command speed. (r/min) Index Name Type Access Save Range Update 4064h Command Speed INT32 TxPDO − − − z Feedback position (4066h) This is the present feedback position. (step) Index Name Type...

- Page 117 Objects of manufacturer-specific area z Main power supply time (40A1h) This is the time elapsed since the main power supply was turned on in minutes. (min) Index Name Type Access Save Range Update 40A1h Main power supply time INT32 TxPDO −...

- Page 118 Objects of manufacturer-specific area Details of range Setting value Description Not executed. A command is executed when the data changes from 0 to 1. A command is executed. It will automatically return to 1 after executing. z Configuration (40C6h) This is used to execute recalculation and setup of the parameter. Index Name Type...

- Page 119 Objects of manufacturer-specific area z All data batch initialization (40CAh) This is used to reset all parameters stored in non-volatile memory to their initial values. Index Name Type Access Save Range Update All data batch 0, 1, 2 40CAh − −...

- Page 120 Objects of manufacturer-specific area z Operating current (4120h) This is used to set the motor operating current based on the rated current being 100 %. (1=0.1 %) In the Profile position mode, it will be updated when operation is started. Index Name Type...

- Page 121 Objects of manufacturer-specific area z Starting speed (4142h) This is used to set the starting speed for the Profile position mode (PP) and the Profile velocity mode (PV). Index Name Type Access Save Range Update 0 to 4,000,000 Hz 4142h Starting speed INT32 ...

- Page 122 Objects of manufacturer-specific area z (HOME) Return-to-home mode (4160h) This is used to set the return-to-home method. Index Name Type Access Save Range Update 0: 2-sensor (HOME) Return-to- 1: 3-sensor 4160h home mode 2: One-way rotation (Initial value: 1) z (HOME) Return-to-home starting direction (4161h) This is used to set the starting direction for detecting the home.

- Page 123 Objects of manufacturer-specific area z (HOME) Operating amount in uni-directional return-to-home (416Ah) This is used to set the operating amount after return-to-home operation in the one-way rotation mode. Index Name Type Access Save Range Update (HOME) Operating amount in uni- 0 to 8,388,607 steps 416Ah INT32...

- Page 124 Objects of manufacturer-specific area z Software overtravel (41C3h) This is used to set the action when the software overtravel is detected. Index Name Type Access Save Range Update −1: Disable 0: Immediate stop 1: Deceleration stop Software 41C3h INT8 2: Immediate stop with alarm ...

- Page 125 Objects of manufacturer-specific area z Information history 1 (4510h) This is the most recent item in the information history. When information is being generated, its code is also indicated on the information history 1 simultaneously. Index Name Type Access Save Range Update 4510h...

- Page 126 Objects of manufacturer-specific area z Information time history 2 to 15 (4521h to 452Eh) These are the history items of the time when the information was generated. Index Name Type Access Save Range Update 4521h Information time history 2 INT32 −...

- Page 127 Objects of manufacturer-specific area z FW-BLK/RV-BLK input action (4702h) This is used to set how to stop the motor when the FW-BLK input or the RV-BLK input is turned ON. Index Name Type Access Save Range Update 0: Immediate stop FW-BLK/RV-BLK 4702h INT8...

- Page 128 Objects of manufacturer-specific area z AREA range setting mode (4750h, 4751h) This is used to set the range setting method for the AREA output. Index Name Type Access Save Range Update 0: Range setting with AREA0 range 4750h absolute value setting mode 1: Offset/width setting from AREA1 range...

- Page 129 Objects of manufacturer-specific area z DIN inverting mode (4850h to 4853h) These are used to change the ON-OFF setting of DIN. Index Name Type Access Save Range Update 4850h DIN0 inverting mode 0: Non invert 4851h DIN1 inverting mode ...

- Page 130 Objects of manufacturer-specific area z R-OUT output function (4910h to 491Fh) These are used to select an output signal to be assigned to R-OUT. (Output signal list p.18) Index Name Type Access Save Initial value Update 4910h R-OUT0 output function ...

-

Page 131: Object List

Object list These are Oriental Motor’s specific objects. The driver objects are the objects for driver axes 1 to axis 4. In this manual, the Sub-index is described as “*”. Set the axis number (1 to 4) in the Sub-Index of each object to access. - Page 132 Objects of manufacturer-specific area Index Name Type Access Save Initial value Range Update Permission of absolute 0: Disable 4148h positioning without setting 1: Enable absolute coordinates 4151h (JOG) Operating speed [Hz] INT32 10,000 1 to 4,000,000 (JOG) Acceleration/ 4152h INT32 300,000...

- Page 133 Objects of manufacturer-specific area Index Name Type Access Save Initial value Range Update 4510h Information history 1 4511h Information history 2 4512h Information history 3 4513h Information history 4 4514h Information history 5 INT32 − − − − 4515h Information history 6 4516h Information history 7 4517h...

- Page 134 Objects of manufacturer-specific area Index Name Type Access Save Initial value Range Update INFO action (Driver 47A2h temperature information (INFO-DRVTMP)) INFO action (Overvoltage 47A4h information (INFO-OVOLT)) INFO action (Undervoltage 47A5h information (INFO-UVOLT)) INFO action (Start operation 47A9h error information (INFO- START)) INFO action (PRESET request 47ABh...

- Page 135 Objects of manufacturer-specific area Index Name Type Access Save Initial value Range Update 4910h R-OUT0 output function 4911h R-OUT1 output function 4912h R-OUT2 output function 4913h R-OUT3 output function 4914h R-OUT4 output function 4915h R-OUT5 output function 4916h R-OUT6 output function 4917h R-OUT7 output function Output signal list...

- Page 137 Troubleshooting This part explains the alarm and information functions. Table of contents Alarms ............138 1-1 Alarm reset ............138 1-2 Alarm history ..........138 1-3 Generation condition of alarms ....138 1-4 Alarm lists ............139 1-5 Timing chart ...........143 Information ...........144 2-1 Status when information is generated ............144 2-2 Information history ........145 2-3 Information list ..........145...

-

Page 138: Alarms

Alarms Alarms This driver is equipped with the alarm function to protect against temperature rise, poor connection, operation error, and the like. If an alarm is generated, the ALM-A output is turned ON and the ALM-B output is turned OFF to stop the motor. At the same time, the ALM LED blinks red. -

Page 139: Alarm Lists

1 network CPU. Oriental Motor sales office. Turn on the control power supply Turn on the Driver internal An error was detected in again. If the alarm still cannot be... - Page 140 The main power supply was Any of reset correcting the wiring of the shut off during operation. operations main power supply, contact your nearest Oriental Motor sales office. The main power supply was Check the input voltage of the Any of reset Undervoltage momentarily shut off or the main power supply.

- Page 141 Alarms Number Alarm of LED Alarm type Cause Remedial action How to reset code blinks • Reconsider the setting of the Permission of absolute positioning without setting Absolute positioning operation Return-to-home Any of reset absolute coordinates (4148h). was started in a state where the incomplete operations coordinates were not set.

- Page 142 Alarms Number Alarm of LED Alarm type Cause Remedial action How to reset code blinks • Reconsider the setting of the operation data. When the FW-LS/RV-LS input • Operate the motor in the action (4701h) is set to opposite direction to escape “Immediate stop with alarm”...

-

Page 143: Timing Chart

Alarms Timing chart 1. If an error occurs, the ALM-B output, the MOVE output, and the DCMD-RDY output are turned OFF. At the same time, the motor stops to go into a non-excitation state. 2. Remove the cause of the alarm before turning the ALM-RST input ON. The alarm is reset, and the ALM-B output is turned ON. -

Page 144: Information

Information Information The driver is equipped with a function to generate information output before an alarm is generated. This function can be utilized for periodic maintenance of equipment by setting a suitable value in the parameter of each information. Status when information is generated „... -

Page 145: Information History

Information Initial Name Description Setting range value INFO action (Electronic gear setting error information (INFO-EGR-E)) INFO action (Forward operation prohibition information (INFO- FW-OT)) INFO action (Reverse operation prohibition information (INFO- RV-OT)) Sets the status of the bit output 0: Only the bit output is ON INFO action (Start operation and the INFO output when 1: Bit output and INFO output... - Page 146 Information Information bit Information item Cause Condition to clear output signal • Operation in the direction having stopped by the FW-BLK input or the RV-BLK input was started. • Operation in the direction having stopped by Start operation error INFO-START Operation was started normally.

-

Page 147: Monitor Of Information

Information Monitor of information Details of information can be checked with the Information (407Bh) of the driver object. The information code having read is indicated in 8-digit hexadecimal number. It can also be read in 32 bits. If multiple information items are generated, the logical sum (OR) of the information codes is indicated. Information code 32 bits indication Information item... - Page 148 Information „ Related objects Index Name Type Access Save Range Update Driver temperature 40 to 85 41A0h information INT16 RxPDO (Initial value: 85) (INFO-DRVTMP) [°C] Overvoltage information 180 to 430 41ABh INT16 RxPDO (INFO-OVOLT) [V] (Initial value: 430) Undervoltage information 180 to 430 41ACh...

-

Page 149: Troubleshooting And Remedial Actions

In motor operation, the motor or the driver may not operate properly due to an improper setting or incorrect connection. When the motor cannot be operated properly, refer to the contents provided in this chapter and take an appropriate remedial action. If the problem persists, contact your nearest Oriental Motor sales office. Phenomenon Possible cause Remedial action Connection error of the motor •... - Page 152 If a new copy is required to replace an original manual that has been damaged or lost, please contact your nearest Oriental Motor sales office. • Oriental Motor shall not be liable whatsoever for any problems relating to industrial property rights arising from use of any information, circuit, equipment or device provided or referenced in this manual.

Need help?

Do you have a question about the CVD Series and is the answer not in the manual?

Questions and answers