Summary of Contents for Pepperl+Fuchs SIL HiC2422

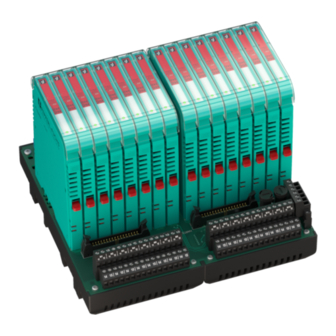

- Page 1 Functional Safety SMART Transmitter Power Supply/SMART Current Driver HiC2422 Manual ISO9001...

- Page 2 Phone: +49 621 776 - 0 E-mail: info@de.pepperl-fuchs.com North American Headquarters Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087 Phone: +1 330 425-3555 E-mail: sales@us.pepperl-fuchs.com Asia Headquarters Pepperl+Fuchs Pte. Ltd. P+F Building 18 Ayer Rajah Crescent Singapore 139942 Phone: +65 6779-9091 E-mail: sales@sg.pepperl-fuchs.com https://www.pepperl-fuchs.com...

-

Page 3: Table Of Contents

Functional Safety HiC2422 Contents Introduction ............5 Content of this Document . - Page 4 Functional Safety HiC2422 Contents...

-

Page 5: Introduction

Additionally, the following parts may belong to the documentation, if applicable: • EU-type examination certificate • EU declaration of conformity • Attestation of conformity • Certificates • Control drawings • FMEDA report • Assessment report • Additional documents For more information about Pepperl+Fuchs products with functional safety, see www.pepperl-fuchs.com/sil. -

Page 6: Safety Information

Functional Safety HiC2422 Introduction Safety Information Target Group, Personnel Responsibility for planning, assembly, commissioning, operation, maintenance, and dismounting lies with the plant operator. Only appropriately trained and qualified personnel may carry out mounting, installation, commissioning, operation, maintenance, and dismounting of the product. The personnel must have read and understood the instruction manual and the further documentation. -

Page 7: Symbols Used

Functional Safety HiC2422 Introduction Symbols Used This document contains symbols for the identification of warning messages and of informative messages. Warning Messages You will find warning messages, whenever dangers may arise from your actions. It is mandatory that you observe these warning messages for your personal safety and in order to avoid property damage. -

Page 8: Product Description

Non-safety relevant interfaces: none The HART communication is not relevant for functional safety. Note For corresponding connections see datasheet. Marking Pepperl+Fuchs Group Lilienthalstraße 200, 68307 Mannheim, Germany Internet: www.pepperl-fuchs.com HiC2422 Up to SIL 2 Standards and Directives for Functional Safety... -

Page 9: Planning

Functional Safety HiC2422 Planning Planning System Structure 3.1.1 Low Demand Mode of Operation If there are two control loops, one for the standard operation and another one for the functional safety, then usually the demand rate for the safety loop is assumed to be less than once per year. -

Page 10: Assumptions

Functional Safety HiC2422 Planning Assumptions The following assumptions have been made during the FMEDA: • Failure rate based on the Siemens standard SN 29500. • Failure rates are constant, wear is not considered. • External power supply failure rates are not included. •... -

Page 11: Safety Function And Safe State

Functional Safety HiC2422 Planning Safety Function and Safe State Safe State Device as an Analog Input The safe state is present when the output current is < 3.6 mA or > 21.5 mA. Device as an Analog Output The safe state is present when the output current is < 4 mA. Safety Function Device as an Analog Input The safety function of the device is fulfilled, as long as the output repeats the input current... -

Page 12: Characteristic Safety Values

Functional Safety HiC2422 Planning Characteristic Safety Values Device as an Analog Input in 1oo1 Structure Parameters Characteristic values Assessment type and Full assessment documentation Device type Mode of operation Low demand mode or high demand mode Safety function Control side output value of < 3.6 mA or > 21.5 mA 0 FIT ... - Page 13 Functional Safety HiC2422 Planning Device as an Analog Output in 1oo1 Structure Parameter Characteristic values Assessment type and Full assessment documentation Device type Mode of operation Low demand mode or high demand mode Safety function Field side output value of < 4.0 mA 0 FIT ...

-

Page 14: Useful Lifetime

As noted in DIN EN 61508-2:2011 note N3, appropriate measures taken by the manufacturer and plant operator can extend the useful lifetime. Our experience has shown that the useful lifetime of a Pepperl+Fuchs product can be higher if the ambient conditions support a long life time, for example if the ambient temperature is significantly below the maximum ambient temperature. -

Page 15: Mounting And Installation

Functional Safety HiC2422 Mounting and Installation Mounting and Installation Mounting and Installing the Device Observe the safety instructions in the instruction manual. Observe the information in the manual. Observe the requirements for the safety loop. Connect the device only to devices that are suitable for this safety application. Check the safety function to ensure the expected output behavior. -

Page 16: Operation

Functional Safety HiC2422 Operation Operation Danger! Danger to life from missing safety function If the safety loop is put out of service, the safety function is no longer guaranteed. • Do not deactivate the device. • Do not bypass the safety function. •... - Page 17 Functional Safety HiC2422 Operation Proof Test Procedure Put out of service the entire safety loop. Protect the application by means of other measures. Prepare a test set-up, see figures below. Test the devices. Verify the current values as given in the tables below. Set back the device to the original settings for the application after the test.

- Page 18 Functional Safety HiC2422 Operation Device as an Analog Output Step No. Set input value (mA) Set output value R () Mandatory measuring points load (safety-relevant) output value (mA) 20.00 20.00 ± 0.40 12.00 12.00 ± 0.40 4.00 4.00 ± 0.40 23.00 23.00 ±...

-

Page 19: Maintenance And Repair

Report all failures in the safety function that are due to functional limitations or a loss of device function – especially in the case of possible dangerous failures. In these cases, contact your local sales partner or the Pepperl+Fuchs technical sales support (service line). -

Page 20: List Of Abbreviations

Functional Safety HiC2422 List of Abbreviations List of Abbreviations Emergency Shutdown Failure In Time in 10 FMEDA Failure Mode, Effects, and Diagnostics Analysis Probability of safe failure Probability of dangerous detected failure Probability of dangerous undetected failure Probability of failures of components in the safety loop that have ... - Page 21 Functional Safety HiC2422 Notes...

- Page 22 Pepperl+Fuchs Quality Download our latest policy here: www.pepperl-fuchs.com/quality www.pepperl-fuchs.com © Pepperl+Fuchs · Subject to modifications DOCT-8599...

Need help?

Do you have a question about the SIL HiC2422 and is the answer not in the manual?

Questions and answers

What type of termination board should be used with barrier HiC2422

The Pepperl+Fuchs SIL HiC2422 barrier is compatible with a HiC termination board.

This answer is automatically generated