Table of Contents

Advertisement

Quick Links

Great Plains

OPERATOR MANUAL

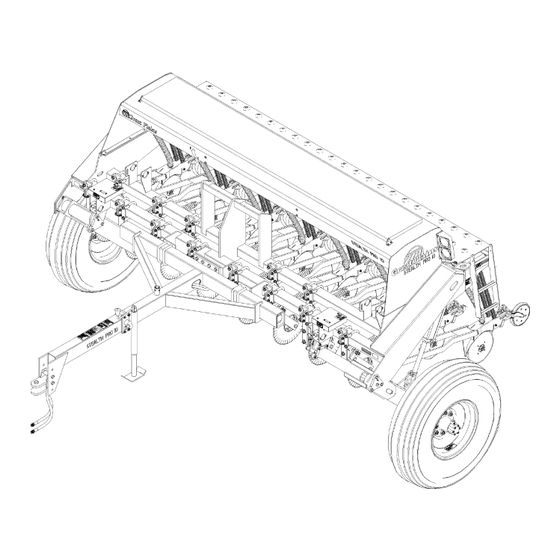

MODEL CDH020-10

Original Instructions

Read the operator manual entirely. When you see

!

this symbol, the subsequent instructions and

warnings are serious - follow without exception.

Your life and the lives of others depend on it!

Illustrations may show optional equipment not

supplied with standard unit.

151-368M

Advertisement

Table of Contents

Summary of Contents for GREAT PLAINS STEALTH PRO CDH020-10

- Page 1 Great Plains OPERATOR MANUAL MODEL CDH020-10 151-368M Original Instructions Read the operator manual entirely. When you see this symbol, the subsequent instructions and warnings are serious - follow without exception. Your life and the lives of others depend on it! Illustrations may show optional equipment not supplied with standard unit.

- Page 2 Machine Identification Record your machine details in the log below. If you replace this manual, be sure to transfer this information to the new manual. If you or the dealer have added options not originally ordered with the machine, or removed options that were originally ordered, the weights and measurements are no longer accurate for your machine.

- Page 3 Printed 08/21/2024 | English Great Plains reserves the right to revise and improve its products at any time. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future. The content of this publication may be...

- Page 4 Trademarks of Great Plains Manufacturing, Inc. include: AccuShot, DrillCommand, Max-Chisel, Row-Pro, Singulator Plus, Short Disk, Swath Command, Terra-Tine, Ultra-Chisel, and X-Press. Registered trademarks of Great Plains Manufacturing, Inc. include: Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand, Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo-Max, Turbo-Trill, Ultra-Till, Whirlfilter, and Yield-Pro.

-

Page 5: Table Of Contents

Stealth Pro Table of Contents Introduction ......1 Pre-start Checklist ..... . . 11 Description of Unit . - Page 6 Fertilizer Tray Bearings ....33 Gauge Wheel Arms ....34 Small Seeds Shaft Bearings (Option).

-

Page 7: Introduction

The QR Code to the left will take The QR Code to the left will take you you to this machine’s parts manual. to Great Plains’ catalog of product Use your smart phone or tablet to manuals. Use your smart phone or scan and start viewing. -

Page 8: Owner Assistance

Great Plains Service Department If you need customer service or repair parts, contact 1525 E. North St. a Great Plains dealer. They have trained personnel, P.O. Box 5060 repair parts and equipment specially designed for Salina, KS 67402-5060 products. -

Page 9: Safety Information

Non-Great Plains components on this machine may machine and advises on how to avoid it. contain additional safety information not found in this The notice symbol indicates a potential for manual. -

Page 10: Machine Use

Safety Information Machine Use Chemicals and Waste Operate Responsibly Agricultural chemicals can be dangerous. Improper Maintain attention on operation at all times to avoid use can seriously injure persons, animals, plants, injury to yourself or others. soil and property. Do not operate machine while distracted by a smart ... -

Page 11: Machine Maintenance

Stealth Pro Machine Maintenance Machine Transport Follow Tire Recommendations This machine does not meet all local, regional, or Consult the tire manufacturer’s recommendations for national regulations for transport on a public road. maintenance and replacement of your machine’s Know and comply with your local laws and regulations tires. -

Page 12: Safety Decals

Read and follow decal directions. Keep all safety decals clean and legible. Replace all damaged, faded, or missing decals. Order new decals from your Great Plains dealer. Refer to this section for proper decal placement. When ordering new parts or components, also request corresponding safety decals. -

Page 13: Reflectors: Amber

Stealth Pro Reflectors: Amber Caution: Operation of Machine 21748B 68374D 818-587C 838-265C CAUTION Read Owner’s Manual before using machine. Stand clear when folding and unfolding markers. Stand clear when raising and lowering machine. Keep all safety shields and devices in place. On side frames at walkboard ends, on front face of Keep hands, feet, and clothing away from moving chains and sprockets. -

Page 14: Caution: Tires Not A Step

Safety Decals Caution: Tires Not A Step Caution: Moving Chain (Option) 32610 y f r A v o i d I n j u r n s p o r t T i r e T r a U n s e c u r e d n o r... -

Page 15: Warning: High Pressure Fluid

Stealth Pro Warning: High Pressure Fluid Warning: Jack Angle 858-895C 21748B WARNING 818-437C To prevent serious injury or death: Do not adjust jack angle without being hitched and connected to a tractor. HIGH PRESSURE FLUID HAZARD P.N. 858-895c To prevent serious injury or death: On face of jack mount;... -

Page 16: Danger: Possible Chemical Hazard

Safety Decals Danger: Possible Chemical Hazard 32761 838-467C Under lid of Small Seeds box; 1 total See “Field Operation” on page 20. 08/21/2024... -

Page 17: Preparation And Setup

Stealth Pro Preparation and Setup Hitching Tractor to Drill This section will help you prepare your tractor and drill for use. Before going to the field, you must hitch You may be severely injured or killed by a tractor to the drill, hook up hydraulics and check being crushed between the tractor and that hydraulics have been bled. -

Page 18: Hitch Height

Preparation and Setup Hitch Height Hitching to Tractor For proper field operation, drill tongue should run 1. Back tractor to drill. Using the screw jack, adjust level in field position. drill tongue to get drawbar under upper hitch plate . a. -

Page 19: Route Hose Bundle

Great Plains hydraulic hose connectors have color 3. Once hydraulic hoses are routed through the coded handle grips to help you hookup hoses to your tongue, attach color-coded grips to the correct tractor outlets. -

Page 20: Bleeding Hydraulics

Preparation and Setup Bleeding Hydraulics 6. Pin cylinders to drill frame and gauge wheel arm with transport cylinder locks in place. If any air still is trapped in either cylinder, the cylinder will have a spongy, erratic movement and drill will not raise evenly. -

Page 21: Calibration

For more assistance and calculated material 1, 2, 3 or 4. Drive type is determined by the handle rates, download the Great Plains app. on the gearbox cover at left front of the drill. Move the Accurately obtaining the desired seed population... -

Page 22: Seed Rate Handle

Preparation and Setup Main Seed & Small Seeds Rate Calibration Note: Handle position is used for clean-out, not planting. If set to this position with seed loaded, Tools required: crank, scale, and three light-weight it may be difficult to reset it to a normal operating containers. - Page 23 Stealth Pro 9. Turn crank at a steady rate until one tenth acre is metered. Drill Model Rotations Per Acre (ha) CDH020-10 Crank: 411 (1016) rotations 10. Weigh metered seed. Subtract initial weight of container(s). NetWeight GrossWeight ContainerWeight – 11. Divide the net seed weight by three. Multiply by number of openers on your drill, and then by ten, to determine the total of pounds per acre seeded.

-

Page 24: Seeding Adjustments

Preparation and Setup Seeding Adjustments 08/21/2024... -

Page 25: Grass Seed Rates

Stealth Pro Grass Seed Rates... -

Page 26: Operation

Operation Operation Pre-start Checklist This section covers general operating procedures. Experience, machine familiarity and the following 1. Carefully read See “Safety Information” starting information will lead to efficient operation and good on page 3. working habits. Always operate farm machinery with 2. -

Page 27: Cylinder Locks

Stealth Pro Transporting Towing the drill at high speeds or with a Unload Drill Box vehicle that is not heavy enough could lead The drill can be transported with a full box of grain, to loss of vehicle control. Loss of vehicle but the added weight will increase stopping distance control could... -

Page 28: Acre Meter Operation

Operation Acre Meter Operation Operating Instructions The electronic acre meter operates in two modes: A battery-operated electronic acre meter is supplied sleep and entry. In sleep mode, the display is blank, with the drill. The display module for the system is and the counter is accumulating acres. -

Page 29: Acre Meter Screens

Stealth Pro Acre Meter Screens Password Field Acre Count Displays the password screen. Entering your system password enables access configuration Displays the number of acres covered since the field parameters. acre counter was last reset. if there is an additional acre counting sensor on the machine, an A2 screen The default password screen shows a salted - **** - will immediately follow the A1 and T1 screens. - Page 30 Operation Swath Width Use the arrow buttons to change the units of measurement to either USA - Imperial - or METRIC. Pressing Select saves the unit selection, converts the swath width value, and navigates to the SENSOR screen. Sensor Count Displays the machine’s swath width.

-

Page 31: Parking And Unhitching

Stealth Pro Parking and Unhitching If the foot is not parallel to the ground, loosen the three nuts (3) in the middle of the jack adjustment Perform the following steps when parking the drill. plate (4). Rotate the jack so the foot is parallel to See “Storage”... -

Page 32: Adjustments

Adjustments Adjustments Coulter Adjustments Coulter Depth Control The master-slave lift cylinders on your drill control A no-till coulter is mounted directly ahead of each the depth of the coulters. A depth valve regulates the opener on the drill. The coulters cut through heavy retracted length of these cylinders. -

Page 33: Coulter Down Pressure

Stealth Pro Coulter Down Pressure Individual Coulter Adjustment Individual coulters can be lowered if coulters follow in Weights tractor tire tracks and do not give satisfactory depth. If more weight is required for your soil conditions, To do so: add weights to weight brackets located on box frame. -

Page 34: Opener Seeding Depth

Adjustments To adjust the pressure, remove “W” clip at bottom of Set opener seeding depth by adjusting press-wheel spring. Place “W” clip in a higher hole in spring rod height. To adjust, first raise drill slightly, then lift and for more pressure or in a lower hole for less slide T-handles on top of openers. -

Page 35: Disc Blade Adjustments

Stealth Pro Disc Blade Adjustments Adjusting Disc Contact Opener disc angle and stagger is not adjustable, but Sharp Object Hazard: disc-to-disc spacing is, and may need attention as Row unit disc blades may be sharp. Use discs experience normal wear. Spacers must be caution when making adjustments in this reset when blades are replaced. -

Page 36: Gauge Wheel Idler Adjustment

Adjustments Gauge Wheel Idler Adjustment Drive Clutch The main drive clutch on your drill is a mechanical- Located inside the left hand gauge wheel arm are release, jaw-style design. You may need to adjust two idler sprockets which should be readjusted after clutch proper engagement... -

Page 37: Drive Train Operation

Stealth Pro Drive Train Operation NOTE: Do not over tighten chains. Over tightening chains Check all chain idlers at beginning of each season will cause excess wear on idlers and drive for proper adjustment. Check that each idler is taking components. -

Page 38: Maintenance

4. Inflate tires as specified on “Tire Information” on page 41. 5. Clean out build up of seed treatment in feed cups. 6. Replace any worn, damaged or illegible safety decals. Order new decals from your Great Plains dealer. See “Safety Information” starting on page 3. 08/21/2024... -

Page 39: Lubrication And Scheduled Maintenance

Stealth Pro Lubrication Scheduled Maintenance Intervals (operating hours) Multi-purpose Multi-purpose Multi-pupose Inspection at which service oil lubricant spray lubricant grease lubricant is required Clutches Drive Chains 12227 14755 8 Hrs. Required Two zerks on each Smear grease on clutch engagement teeth. See “Drive Train Operation”... -

Page 40: Gauge Wheel Arms

Maintenance Gauge Wheel Arms Felt Barrier Seals 16381 21709 15 Hrs. Type of Lubrication: Grease 30 Hrs. Quantity = Until grease emerges Small Seeds Shaft Bearings (Option) 1 seal at each shaft end, 2 total Type of Lubrication: Oil Quantity: Soak seal If Small Seeds is also installed, access these seals from below or through the end wall gaps. -

Page 41: Small Seeds Feed Cup Drive Sprocket

Stealth Pro Small Seeds Feed Cup Drive Sprocket Ground Drive Wheel Bearings 12226 28299 50 Hrs. Seasonal Type of Lubrication: Oil Quantity = Coat sprocket bore thoroughly 2 races per wheel; 4 total Coulter Hub Bearings Type of Lubrication: Grease Quantity = Repack 13879 Seasonal... -

Page 42: Gearbox

Maintenance Gearbox 14757 sparingly. Excess sealant squeeze off the intended surface and lock bearings or gears. The gearbox is lubricated and sealed at the factory. Under normal conditions, it does not require maintenance or lubrication. If the gearbox has been opened for repair, repack all gears and around shaft bearings using at least 7 oz. -

Page 43: Options

For seed rates, see seed rate decal on bottom side Without 118-899A of seed box lid. For lubrication points, “Lubrication small seeds, and Scheduled Maintenance” on page 33. With small seeds 118-900A To order the small seeds attachment, contact your Great Plains dealer. -

Page 44: Seed-Lok® Firming Wheels

The Seed-Lok® option provides more even emergence since seeds are planted and firmed at the same depth. To order the Seed-Lok® firming wheels, contact your Great Plains dealer. Seed-Lok® Packages Part Number Seed-Lok® Assembly 122-193K... -

Page 45: Troubleshooting

Stealth Pro Troubleshooting Problem Cause Solution Excessive field speed. Reduce field speed. Uneven seed spacing or uneven stand Feed cups plugging. Clean out feed cups. Seed tubes plugging. Clean out seed tubes. See “Opener disks not turning freely” in Opener disks not turning freely. this Troubleshooting section. - Page 46 Troubleshooting Problem Cause Solution Too wet or cloddy. Wait until drier weather or rework ground. Press wheels not compacting soil as desired Incorrect hitch height. Readjust hitch height, page 12. Press wheel depth does not match coulter Readjust press wheel depth, page 28. depth.

- Page 47 Stealth Pro...

-

Page 48: Appendix

Appendix Appendix Torque Values Chart Bolt Head Identification Bolt Head Identification Bolt Bolt 10.9 Size Size Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9 ft-lb ft-lb ft-lb ft-lb ft-lb in-tpi ft-lb mm x pitch M 5 X 0.8 M 6 X 1 M 8 X 1.25 M 8 X 1... -

Page 49: Specifications And Capacities

Stealth Pro Specifications and Capacities Row Spacing, Inches Rows Per Drill Approx. Weight, Pounds 4,300 lb (1950 lb) Working Width 10 feet (3.0 m) Transport Width 12 feet 7 inches (3.8 m) Transport Height 6 feet 7 inches (2.0) Transport Length 13 feet 10 inches (4.2 m) Tongue Weight, Transport... - Page 50 Great Plains reserves the right to make changes in materials or design of the product at any time without notice. The warranty shall not be interpreted to render Great Plains liable for damages of any kind, direct or consequential or contingent to property.

- Page 51 Stealth Pro...

- Page 52 08/21/2024...

- Page 54 Great Plains, Mfg. 1525 E. North St. P.O. 5060 Salina, KS 67402...

Need help?

Do you have a question about the STEALTH PRO CDH020-10 and is the answer not in the manual?

Questions and answers