Table of Contents

Advertisement

Quick Links

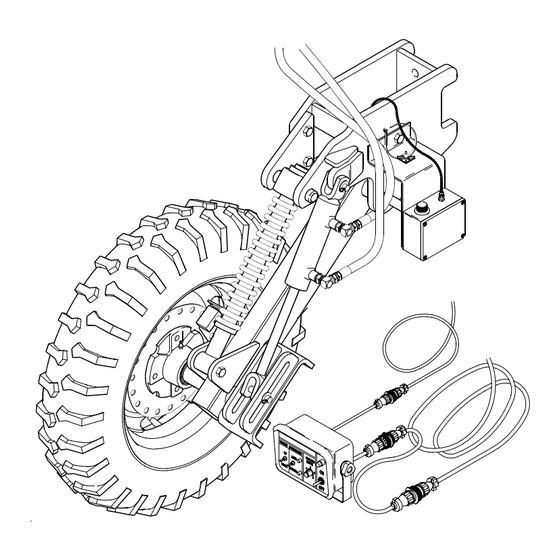

Operator's/Parts Manual

CPH and CP1000

Coulter Command System

Manufacturing, Inc.

P.O. Box 5060

Salina, Kansas 67402-5060

●

!

Read the operator's manual entirely. When you see this symbol, the subsequent in-

structions and warnings are serious - follow without exception. Your life and the lives of

others depend on it!

12611

Cover illustration may show optional equipment not supplied with standard unit.

© Copyright 1999 Printed

2/30/2002

148-258M-B

Advertisement

Table of Contents

Need help?

Do you have a question about the CPH and is the answer not in the manual?

Questions and answers