Advertisement

Quick Links

Great Plains

OPERATOR MANUAL

MODELS CDH000-6 & CDH020-6

Table of Contents

S e

F

e d

E

To prevent

Read

Lower

and understa

injury

or death:

key before

impleme

nd Operato

nt, stop

Do not

Keep

allow

servicing

tractor

, adjusting

engine,

r' s Manual

before

Safely

others

riders.

away

, repairing

brake

set park

using.

support

and secure

during

operatio

n.

or unplugg

and remove

ing.

ignition

impleme

nt before

repairs

are made.

818-719

C

MOV

To Preve

ING

Keep

nt Seriou

PAR

TS HAZ

clothi

hands

s Injury

, feet,

ARD

when

Do

ng away

not

from

hair,

or Death

and

opera

stand

or climb

movin

clot

g pa

:

ting.

on m

To prevent

REMOV

E DRAWB

Remove

hookup

tractor

equipm

damage

ent

AR

drive

Failure

to do

implem

ent.

drawba

r before

:

wheel.

so will

result

in da

att

S e

F

e d

E

To prevent

injury

and understa

Read

or death:

key before

impleme

Lower

nd Operato

Do not

allow

servicing

nt, stop

tractor

r' s Manual

others

Safely

Keep

riders.

away

, adjusting

, repairing

engine,

before

set park

using.

support

and secure

during

operatio

or unplugg

brake

and remove

impleme

n.

ing.

ignition

nt before

repairs

are made.

818-719

C

MOV

ING

To Preve

nt Seriou

PAR

TS HAZ

Keep

clothi

hands

s Injury

ARD

Do

not

ng away

, feet,

from

hair,

or Death

when

opera

stand

or climb

movin

and

:

clot

ting.

on m

g pa

1 1/2

1 1/2

1 1/2

1 1/2

Original Instructions

Read the operator manual entirely. When you see

!

this symbol, the subsequent instructions and

warnings are serious - follow without exception.

Your life and the lives of others depend on it!

Illustrations may show optional equipment not

supplied with standard unit.

ARD

ID HAZ

RE FLU

ing

or

H PRE

or death

SSU

:

e repair

searc

hing

838-094C

HIG

s injury

on system

befor

when

hand

s.

nt seriou

ure

nnect

ing.

prote

ction

instea

d of

To preve

Reliev

e press

or disco

and

or cardb

eye

oard

repair

.

adjus

prope

ting

r hand

wood

ts in

good

Wear

leaks.

all comp

Use

onen

Keep

for

151-312M

Advertisement

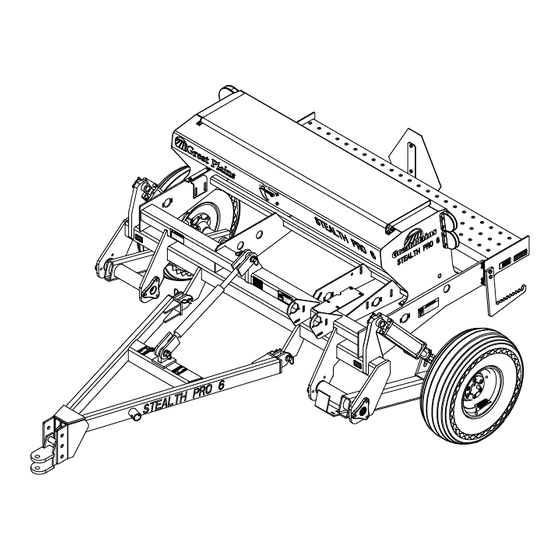

Summary of Contents for GREAT PLAINS STEALTH PRO CDH000-6

- Page 1 Table of Contents Great Plains OPERATOR MANUAL MODELS CDH000-6 & CDH020-6 To prevent Read Lower injury and understa or death: key before impleme nd Operato nt, stop Keep Do not allow servicing , adjusting tractor r' s Manual engine, before...

- Page 2 Machine Identification Record your machine details in the log below. If you replace this manual, be sure to transfer this information to the new manual. If you or the dealer have added options not originally ordered with the machine, or removed options that were originally ordered, the weights and measurements are no longer accurate for your machine.

- Page 3 Printed 07/09/2024 | English Great Plains reserves the right to revise and improve its products at any time. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future. The content of this publication may be...

- Page 4 Trademarks of Great Plains Manufacturing, Inc. include: AccuShot, DrillCommand, Max-Chisel, Row-Pro, Singulator Plus, Short Disk, Swath Command, Terra-Tine, Ultra-Chisel, and X-Press. Registered trademarks of Great Plains Manufacturing, Inc. include: Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand, Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo-Max, Turbo-Trill, Ultra-Till, Whirlfilter, and Yield-Pro.

- Page 5 NOTICE: Petroleum Products ... 10 Disc Blade Adjustments ....36 Great Plains | 151-312M | 07/09/2024...

- Page 6 Weight Bracket Installation....50 Warranty ......51 Great Plains | 151-312M | 07/09/2024...

- Page 7 Table of Contents Introduction Introduction Using This Manual Great Plains welcomes you to its growing family of new product owners. Your drill has been designed This manual familiarizes you with safety, assembly, with care and built by skilled workers using quality...

- Page 8 Great Plains Service Department If you need customer service or repair parts, contact 1525 E. North St. a Great Plains dealer. They have trained personnel, P.O. Box 5060 repair parts and equipment specially designed for Salina, KS 67402-5060 products.

- Page 9 Non-Great Plains components on this machine may machine and advises on how to avoid it. contain additional safety information not found in this The notice symbol indicates a potential for manual.

- Page 10 Avoid contacting overhead obstructions such as low bridges, overpasses, and power lines. Do not operate near ditches, holes, steep slopes, embankments, or other surfaces which may collapse under the machine’s weight or tip the machine over. Great Plains | 151-312M | 07/09/2024...

- Page 11 Detach the tractor. Secure the implement using Stay clear of and never step over any rotating parts. blocks. Great Plains | 151-312M | 07/09/2024...

- Page 12 Keep all safety decals clean and legible. Reflectors: Red Replace all damaged or missing decals. Order new 838-266C decals from your Great Plains dealer. Refer to this section for proper decal placement. When ordering new parts or components, also request corresponding safety decals.

- Page 13 Reflectors: Amber (With Weights Option) 838-266C Danger: Possible Chemical Hazard (Option) 838-467C On decal mounts attached to top front tool bar; 2 total (with Small Seeds Option only) Under lid; 1 total 18621A 32696 Great Plains | 151-312M | 07/09/2024...

- Page 14 Use wood or cardboard instead of hands. Keep all components in good repair. 838-094C (CDH020-6 only) On side frames, near cylinder; 2 On front face, upper front frame tube, below total gearbox; 1 total 80352 80351 Great Plains | 151-312M | 07/09/2024...

- Page 15 Tires may be in light contact with ground, or off the ground, when the drill is lowered. 80351 Warning: Clevis Adjustment 838-406C WARNING (CDH000-6 only) On tongue cross-tube near turnbuckle; 2 total 80351 See “Height and Leveling the Drill” on page 13 Great Plains | 151-312M | 07/09/2024...

- Page 16 CDH020-6: On front face, upper front frame tube, 80351 right end; NOTICE: Petroleum Products 80352 858-679C 80351 (CDH000-6 and CDH020-6 only) On the left-hand ends of each seed box; 1 per seed box See “Safety Information” starting on page 3 80351 Great Plains | 151-312M | 07/09/2024...

- Page 17 See “Safety Decals” starting on Depth (Press Wheel Height)” page 6. page 33. Set your tractor 3-point draft 6. Inflate tires and tighten wheel bolts as at “Tire control to Float position for planting. Information” on page 46. Great Plains | 151-312M | 07/09/2024...

- Page 18 4. Securely attach drill safety chain to an anchor on tractor capable of pulling drill. 57.2 cm 49.6 cm 46.4 cm 38.8 cm 18544 Clevis Hitch Height Adjustment Great Plains | 151-312M | 07/09/2024...

- Page 19 Machine Adjustments extended-cylinder symbol feeds cylinder base ends. The drive may need to be adjusted due to Hose under retracted-cylinder symbol feeds cylinder ground conditions. rod ends. 3. Level drill with top 3-point link. Great Plains | 151-312M | 07/09/2024...

- Page 20 Pull forward to put openers in ground. Set the remote to Neutral. Shut off the 3/ 8 in. 10 mm tractor. 1/ 4 in. 6 mm f. Factory setting. 32774G n. Depth is with new coulter blades. Great Plains | 151-312M | 07/09/2024...

- Page 21 1. Use hitch turnbuckle to level drill. 18513 Pull-Type Turnbuckles 2. Lower unit to take weight off of drill. Do not adjust with unit in raised position. 3. Loosen jam nuts on hitch turnbuckle. Great Plains | 151-312M | 07/09/2024...

- Page 22 For more assistance and calculated material Setting Drive Type rates, download the Great Plains app. The charts on the decal list drive types as Accurately obtaining the desired seed population 1, 2, 3 or 4. Drive type is determined by the handle requires four steps: on the gearbox cover at left front of the drill.

- Page 23 RateSample SamplePerRow ------------------------------ - the seed rate chart on the decal, then back to the RowCount desired value. ExpectedSample SamplePerRow SampledRows 3. Tighten wing nut. Great Plains | 151-312M | 07/09/2024...

- Page 24 TargetRate NewScale PreviousScale ---------------------------------- MeasuredRate 13. Once finished, store calibration crank, re-engage hub if locked-out, reinstall any removed chains or sprockets, and reconnect seed hoses. Great Plains | 151-312M | 07/09/2024...

- Page 25 Stealth Pro Table of Contents Preparation and Setup Seeding Adjustments Great Plains | 151-312M | 07/09/2024...

- Page 26 Stealth Pro Table of Contents Preparation and Setup Grass Seed Rates Great Plains | 151-312M | 07/09/2024...

- Page 27 Avoid transport with material loaded in boxes. page 3. 2. Lubricate drill “Lubrication Maintenance” starting on page 38. 3. Check all tires for proper inflation. See “Tire Information” on page 46. 4. Check all bolts, pins and fasteners. Great Plains | 151-312M | 07/09/2024...

- Page 28 Ensure that the tractor weighs at least (67%) of the drill (including the weight of any Options and materials). Avoid transport with material loaded in boxes. 36177 Lift Cylinder Lock Storage Great Plains | 151-312M | 07/09/2024...

- Page 29 Reduce speed on rough roads. 18480 Lock-Out Hub Engaged At lock-out on left hub, pull pin away from wheel and rest in outer shallow detents . This disengages Great Plains | 151-312M | 07/09/2024...

- Page 30 7. Raise drill. Using calibration crank or 3-point gauge wheel, operate the meter drive system. Check that feed cups, seed tubes and drives are working properly and free from foreign material by looking for seed flow under each opener. Great Plains | 151-312M | 07/09/2024...

- Page 31 Down Arrow - Decrements current value. If the current screen only displays a reading, then arrow buttons can be used to reset current reading or for navigation. Great Plains | 151-312M | 07/09/2024...

- Page 32 Use the arrow buttons to increase or decrease the Battery Life scaling factor. Pressing Select will save the configuration and navigate to the P2 or SW screen. Displays the percentage of remaining battery life. Pressing Select navigates to screen PW. Great Plains | 151-312M | 07/09/2024...

- Page 33 YES, pressing Select allows for a new Units of Measurement password to be entered. If displaying the status and status is NO, pressing Select navigates to the A1 screen. Displays the units of measurement used by the acre meter. Great Plains | 151-312M | 07/09/2024...

- Page 34 90 degrees. Do not allow hose ends or cable ends to rest on the ground. 8. Remove hitch bolt and safety chain from tractor drawbar. 24481 Parking Jack Storage 18473 Parking Jack Lowered Great Plains | 151-312M | 07/09/2024...

- Page 35 Consistent seed depths in challenging conditions Disc Blade Adjustments Compensate for disc wear Disc Scraper Adjustment Consistent seeding depth Opener Depth (Press Wheel Height) Primary control of seed depth Drive Idler Adjustment (CDH020-6) Consistent seed flow Great Plains | 151-312M | 07/09/2024...

- Page 36 780 pounds (354 kg) additional weight. Coulter Depth Possible Transport Hazard: Great Plains recommends operating at a tool bar height of 24 in. (62.9 cm). Small adjustments may Re-check that the tractor or towing vehicle...

- Page 37 Grade 5 torque specification. 1. Measure current spring length. 2. Loosen or remove jam nut . 3. Rotate adjust nut to set spring length. 4. Tighten set jam nut. Great Plains | 151-312M | 07/09/2024...

- Page 38 (not shown) between the opener discs. The hose and seed Each opener spring can be adjusted for down tube require no adjustments. pressure. This is useful when planting in tractor tire tracks. Great Plains | 151-312M | 07/09/2024...

- Page 39 For deeper seeding, slide T handles backward than placed deeper. away from implement. If moving the T handle backward doesn’t cause the opener to achieve desired depth, adjust the opener frame down-force (page 32). Great Plains | 151-312M | 07/09/2024...

- Page 40 5. Inspect hydraulic hoses for cuts, cracks and aging. Check fittings for evidence of leaks. 6. Replace any worn, damaged or illegible safety decals. Order new decals from your Great Plains dealer. See “Safety Decals” starting on page 6. Great Plains | 151-312M | 07/09/2024...

- Page 41 To adjust, loosen bolts on clutch tab . Slide tab flutes from the open seed boxes. up or down to change point at which cam plates meet. When satisfied with adjustment, tighten bolts on clutch tab. Great Plains | 151-312M | 07/09/2024...

- Page 42 If the contact region varies with blade rotation, one or both blades is likely bent and in need of replacement. If removing all spacers cannot bring the blades into contact, they are worn out and need replacing. Great Plains | 151-312M | 07/09/2024...

- Page 43 Chain Slack 1. Measure the span for allowable slack: Locate the longest span of each chain (usually the span which does not run through the idlers) 27264 Measuring Chain Slack Great Plains | 151-312M | 07/09/2024...

- Page 44 25093 If the gearbox has been opened for repair, repack all gears and around shaft bearings using at least 7 oz. (200 mL) of gear lube, Great Plains Part No. 788067. Keep moisture and dirt out of gearbox. Inspect 1 grease bank zerk per coulter; 9 total...

- Page 45 Move the seed rate adjustment handle back and Quantity: Until grease emerges forth to get oil into the square bore. Perform this with seed box empty, or handle may be difficult to set to 100. Great Plains | 151-312M | 07/09/2024...

- Page 46 (SGS) front jackshaft SGS front right jackshaft to rear jackshaft SGS front jackshaft to rear jackshaft SGS rear jackshaft to meter shaft drive SGS rear jackshaft to meter shaft drive Great Plains | 151-312M | 07/09/2024...

- Page 47 Type of Lubrication: Bearing grease Wheel Bearings (CDH000-6) Quantity: Re-pack Right Wheel Bearings (CDH020-6) 32672 32578 Seasonal Seasonal 2 races total Type of Lubrication: Bearing grease 2 races total Quantity: Re-pack Type of Lubrication: Bearing grease Quantity: Re-pack Great Plains | 151-312M | 07/09/2024...

- Page 48 Option Field Kit Drill Option Field Kit CDH000-6 (91) 133-243A CDH000-6 (66) 151-223A CDH020-6 (91) 133-472A CDH020-6 (66) 151-058A See the Transporting topic starting on page 21 and “Frame Weight Adjustment” on page 30. Great Plains | 151-312M | 07/09/2024...

- Page 49 Stealth Pro Table of Contents Options Weight Option Drill Option Field Kit CDH000-6 (70) 151-243A CDH020-6 (70) 151-243A Great Plains | 151-312M | 07/09/2024...

- Page 50 Main box seed cup door setting Set all doors the same, per seed size. Seed plug(s) installed Remove seed plug(s). Meter or tube blocked Clear blockage. Great Plains | 151-312M | 07/09/2024...

- Page 51 Move adjustable divider to create more volume in Adjustable divider not set evenly emptying evenly areas that run out first. Be sure retainer clip is facing opposite way of Chain fouling Debris in retainer clip chain travel (page 37). Great Plains | 151-312M | 07/09/2024...

- Page 52 For assistance or information, contact your nearest Authorized Farm Tire Retailer. Manufacturer Website Firestone www.firestoneag.com 7.00-15 LT 60 psi Goodyear www.goodyearag.com 2040 lb (925 kg) load rating 414 kPa Titan www.titan-intl.com www.bkt-tires.com Gleason www.gleasonwheel.com Great Plains | 151-312M | 07/09/2024...

- Page 53 7. Check that all working parts are moving freely, bolts are tight, and cotter pins are spread. 8. Check for proper tension and alignment on all drive chains. 9. Check that all safety labels and reflectors are correctly located legible. Replace Great Plains | 151-312M | 07/09/2024...

- Page 54 4. Stop lifting about 12 inches from the trailer bed. 5. Slowly pull the trailer straight out from under the drill. 6. Making sure to keep the drill level, front-to-back and side-to-side, slowly lower the drill to 12 inches from the ground. Great Plains | 151-312M | 07/09/2024...

- Page 55 , up against the ribs. Slide the outlet end of the hose fully onto the seed tube inlet at the forward row unit opening . Move the clamp to just below the raised lip of the seed tube inlet. Great Plains | 151-312M | 07/09/2024...

- Page 56 151-271D WEIGHT BRACKET ADJ. 13. Repeat the above steps for the opposite side of the drill. sets: See “Frame Weight Adjustment” on page 30 for 802-055C 5/8-11X2 weight selection. 804-021C WASHER FLAT 5/8 SAE PLT Great Plains | 151-312M | 07/09/2024...

- Page 57 Great Plains reserves the right to make changes in materials or design of the product at any time without notice. This warranty is not valid unless the unit is registered with Great Plains within 10 days from the date of the original purchase.

- Page 58 Table of Contents...

- Page 59 Table of Contents...

- Page 60 Great Plains, Mfg. 1525 E. North St. P.O. 5060 Salina, KS 67402...

Need help?

Do you have a question about the STEALTH PRO CDH000-6 and is the answer not in the manual?

Questions and answers