Summary of Contents for MR COMTAP ARS

- Page 1 THE POWER BEHIND POWER. Operating instructions ® COMTAP ARS. Advanced Retard Switch 4434052/02 EN...

- Page 2 Generally the information provided and agreements made when processing the individual quotations and orders are binding. The product is delivered in accordance with MR's technical specifications, which are based on information provided by the customer. The customer has a duty of care to ensure the compatibility of the specified product with the customer's planned scope of application.

-

Page 3: Table Of Contents

Table of contents 1 Introduction ..........4 8.7 COMTAP® ARS, tracing template (726728) ..... 34 1.1 Manufacturer ..............4 8.8 COMTAP® ARS, mounting of the COMTAP® 1.2 Completeness ............... 4 ARS on the lower cage ring (user-specific, 1.3 Safekeeping ..............4 732773_1).............. -

Page 4: Introduction

Deutschland +49 941 4090-0 sales@reinhausen.com reinhausen.com MR Reinhausen customer portal: https://portal.reinhausen.com. Further information on the product and copies of this technical file are available from this address if required. 1.2 Completeness This technical file is incomplete without the supporting documents. -

Page 5: Notation Conventions

1.4 Notation conventions 1.4.1 Hazard communication system Warnings in this technical file are displayed as follows. 1.4.1.1 Warning relating to section Warnings relating to sections refer to entire chapters or sections, sub-sections or several paragraphs within this technical file. Warnings relating to sections use the following format: WARNING Type of danger! - Page 6 Aim of action Requirements (optional). Step 1 of 1. Result of step (optional). Result of action (optional). Multi-step instructions Instructions which consist of several process steps are structured as follows: Aim of action Requirements (optional). 1. Step 1. Result of step (optional). 2.

-

Page 7: Safety

2 Safety – Read this technical file through to familiarize yourself with the product. – This technical file is a part of the product. – Read and observe the safety instructions provided in this chapter. – Read and observe the warnings in this technical file in order to avoid func- tion-related dangers. - Page 8 Work area Untidy and poorly lit work areas can lead to accidents. – Keep the work area clean and tidy. – Make sure that the work area is well lit. – Observe the applicable laws for accident prevention in the relevant country. Working during operation The product may only be operated in a sound, operational condition.

-

Page 9: Personnel Qualification

2.3 Personnel qualification The person responsible for assembly, commissioning, operation, maintenance and inspection must ensure that the personnel are sufficiently qualified. Electrically skilled person The electrically skilled person has a technical qualification and therefore has the required knowledge and experience, and is also conversant with the applicable standards and regulations. - Page 10 Protective clothing Close-fitting work clothing with a low tearing strength, with tight sleeves and with no protruding parts. It mainly serves to protect the wearer against being caught by moving machine parts. Safety shoes To protect against falling heavy objects and slipping on slip- pery surfaces.

-

Page 11: Product Description

3 Product description 3.1 Scope of delivery The product is packaged with protection against moisture and is delivered as follows: – COMTAP® ARS – TAPMOTION® ED motor-drive unit – Drive shaft with coupling parts and bevel gear – Technical files Note the following information: –... -

Page 12: Name Plate

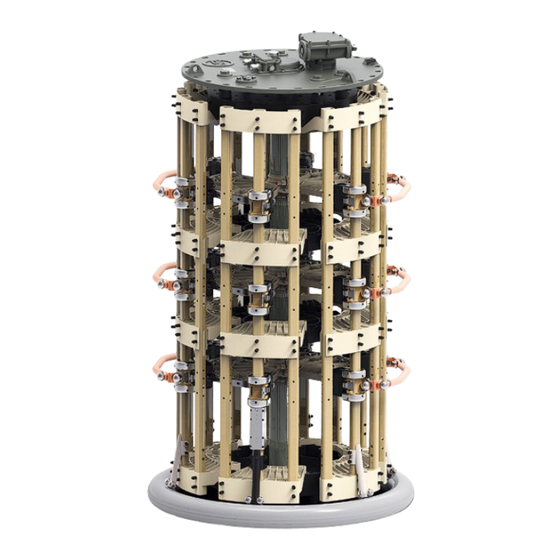

The design of the COMTAP® ARS and the designation of its main parts are shown in the installation drawings in the appendix (see page [►Section 8.1, Page 28]). Figure 1: COMTAP® ARS 1 Tap-change supervisory control with 2 COMTAP® ARS head inspection window for tap position in- dicator 3 Upper gear unit... -

Page 13: Protective Devices

3.2.4 Protective devices Tap-change supervisory control The COMTAP® ARS is equipped with a tap-change supervisory control, which is fitted in a housing on the head of the COMTAP® ARS (see page [►Section 8.4, Page 31]). Depending on the application, the tap-change supervisory control may have dif- ferent safety functions in conjunction with the motor-drive unit and the associ- ated on-load tap-changer units. -

Page 14: Drive Shaft

3.3 Drive shaft 3.3.1 Function description The drive shaft is the mechanical connection between the drive and the on-load tap-changer/de-energized tap-changer. The bevel gear changes the direction from vertical to horizontal. Accordingly, the vertical drive shaft has to be mounted between drive and bevel gear, and the horizontal drive shaft between bevel gear and on-load tap- changer or de-energized tap-changer. - Page 15 3.3.2.1 Drive shaft without cardan joint and without insulator Figure 4: Drive shaft without cardan joint and without insulator (= standard version) Configuration V 1 min Intermediate bearing Middle of hand crank – middle of bevel 536 mm When the maximum value of gear (maximum permissible axial offset 2472 mm is exceeded, it is 2°)

- Page 16 3.3.2.2 Drive shaft without cardan joint and with insulator Figure 5: Drive shaft without cardan joint and with insulator (= special model) Configuration V 1 min Intermediate bearing Middle of hand crank – middle of bevel 706 mm When the maximum value of gear (maximum permissible axial offset 2472 mm is exceeded, it is 2°)

- Page 17 3.3.2.3 Drive shaft with cardan joints, without insulator Figure 6: Drive shaft with cardan joints, without insulator (= special model) Configuration V 1 min [mm] Intermediate bearing for [mm] Middle of hand crank – middle of bevel V 1 > 2564 gear (maximum permissible axial offset 20°) 4434052/02 EN Product description ...

- Page 18 3.3.2.4 Drive shaft with cardan joints, with insulator Figure 7: Drive shaft with cardan joints, with insulator (= special model) Configuration V 1 min [mm] Intermediate bearing for [mm] Middle of hand crank – middle of bevel V 1 > 2772 gear (maximum permissible axial offset 20°) Product description 4434052/02 EN...

-

Page 19: Commissioning

4 Commissioning WARNING Danger of explosion! Explosive gases in the transformer, pipe system, oil conservator and at the de- hydrating breather opening can deflagrate or explode and result in severe in- jury or death. Ensure that there are no ignition sources such as naked flame, hot surfaces or sparks (e.g. -

Page 20: Commissioning Transformer

Switch off transformer on high and low-voltage side. Failure to do so may result in severe injuries and property damage. 2. Lock transformer to prevent unintentional restart. 3. Perform function checks as described in relevant MR operating instructions for motor-drive unit. NOTICE! An incorrectly coupled motor-drive unit will lead to damage to the... -

Page 21: Operation

5 Operation The following sections describe how to operate the COMTAP® ARS and monitor the COMTAP® ARS and motor-drive unit. 5.1 Temperature range When using a vegetable oil as insulating fluid, the permissible temperature range for operation of the DEETAP® DU/COMTAP® ARS is limited. Please observe the relevant information in the specific order documents and on the indicator plate on the drive. -

Page 22: Operating The Motor-Drive Unit With The Hand Crank

5.3 Operating the motor-drive unit with the hand crank WARNING Danger of explosion! Unauthorized operation of the motor-drive unit with the hand crank may re- sult in death or serious injury. Never operate the motor-drive unit electrically or with the hand crank be- fore the transformer has been disconnected if you think there may be a fault in the transformer or on-load tap-changer / de-energized tap-changer. -

Page 23: Monitoring During Operation

5.4 Monitoring during operation Monitoring of the COMTAP® ARS and motor-drive unit is limited to occasional visual inspections on the COMTAP® ARS head and motor-drive unit. For effi- ciency reasons these visual checks can be combined with the usual checks on the transformer. -

Page 24: Maintenance

6 Maintenance 6.1 Safety precautions WARNING Danger of death and severe injury! An energized transformer and energized COMTAP® ARS components could cause death or serious injuries during maintenance work! Adherence to the following safety precautions is mandatory. 1. Switch off transformer on high and low-voltage side. 2. -

Page 25: Fault Elimination

In the event of faults on the COMTAP® ARS and motor-drive unit, which cannot be easily corrected on site, or if a protective device has been tripped, please in- form your authorized MR representative, the transformer manufacturer or con- tact us directly at:... - Page 26 Ensure proper mounting of the drive shaft in accordance with sition its operating instructions. Check that hose clips and protective covers are seated correctly. Contact MR in the event of noise from the motor-drive unit. Warning or tripping of Buchholz relay on transformer Notify manufacturer of transformer.

-

Page 27: Drawings

8 Drawings 4434052/02 EN Drawings ... -

Page 28: Comtap® Ars, Installation Drawing (732771)

8.1 COMTAP® ARS, installation drawing (732771) Drawings 4434052/02 EN... -

Page 29: Comtap® Ars, Installation Drawing Bell-Type Tank Design (733023)

8.2 COMTAP® ARS, installation drawing bell-type tank design (733023) 4434052/02 EN Drawings ... -

Page 30: Comtap® Ars, Position Of Supporting Structure (Supporter, 735714)

8.3 COMTAP® ARS, position of supporting structure (supporter, 735714) Drawings 4434052/02 EN... -

Page 31: Comtap® Ars, Tap-Change Supervisory Control (726977)

8.4 COMTAP® ARS, tap-change supervisory control (726977) 4434052/02 EN Drawings ... -

Page 32: Comtap® Ars, Mounting Flange (725857)

8.5 COMTAP® ARS, mounting flange (725857) Drawings 4434052/02 EN... -

Page 33: Comtap® Ars, Mounting Flange Made By The Customer (742013)

8.6 COMTAP® ARS, mounting flange made by the customer (742013) 4434052/02 EN Drawings ... -

Page 34: Comtap® Ars, Tracing Template (726728)

8.7 COMTAP® ARS, tracing template (726728) Drawings 4434052/02 EN... -

Page 35: Comtap® Ars, Mounting Of The Comtap® Ars On The Lower Cage Ring (User-Specific, 732773_1)

8.8 COMTAP® ARS, mounting of the COMTAP® ARS on the lower cage ring (user-specific, 732773_1) 4434052/02 EN Drawings ... -

Page 36: Comtap® Ars, Mounting Of The Comtap® Ars On The Lower Cage Ring (User-Specific, 732773_2)

8.9 COMTAP® ARS, mounting of the COMTAP® ARS on the lower cage ring (user-specific, 732773_2) Drawings 4434052/02 EN... -

Page 37: Comtap® Ars, Head With Upper Gear Unit (725737)

8.10 COMTAP® ARS, head with upper gear unit (725737) 4434052/02 EN Drawings ... -

Page 38: Comtap® Ars, Connection Contact (734095)

8.11 COMTAP® ARS, connection contact (734095) Drawings 4434052/02 EN... -

Page 39: Comtap® Ars, Connecting Leads (10015335)

8.12 COMTAP® ARS, connecting leads (10015335) 4434052/02 EN Drawings ... -

Page 40: Comtap® Ars, Horizontal Drive Shaft (Limit Dimensions, 778664_2)

8.13 COMTAP® ARS, horizontal drive shaft (limit dimensions, 778664_2) Drawings 4434052/02 EN... -

Page 41: Comtap® Ars, Swivel Range Of Upper Gear Unit (732769_2)

8.14 COMTAP® ARS, swivel range of upper gear unit (732769_2) 4434052/02 EN Drawings ... -

Page 42: Comtap® Ars, Supplementary Drawings (734087)

8.15 COMTAP® ARS, supplementary drawings (734087) Drawings 4434052/02 EN... -

Page 43: Bevel Gear Cd 6400, Dimensional Drawing (892916)

8.16 Bevel gear CD 6400, dimensional drawing (892916) 4434052/02 EN Drawings ... -

Page 44: Lifting Traverse (72673703)

8.17 Lifting traverse (72673703) Drawings 4434052/02 EN... - Page 46 Maschinenfabrik Reinhausen GmbH Falkensteinstrasse 8 93059 Regensburg Germany +49 941 4090-0 info@reinhausen.com reinhausen.com Please note: The data in our publications may differ from the data of the devices delivered. We reserve the right to make changes without notice. ® 4434052/02 EN - COMTAP ARS Operating instructions - 11/23 THE POWER BEHIND POWER.

Need help?

Do you have a question about the COMTAP ARS and is the answer not in the manual?

Questions and answers