MR VACUTAP VR Installation And Commissioning Instructions

On-load tap-changer

Hide thumbs

Also See for VACUTAP VR:

- Operating instructions manual (84 pages) ,

- Operating instructions manual (94 pages)

Summary of Contents for MR VACUTAP VR

- Page 1 On-Load Tap-Changer VACUTAP® VR® Installation and Commissioning Instructions 4349315/00 EN...

- Page 2 © All rights reserved by Maschinenfabrik Reinhausen Dissemination and reproduction of this document and use and disclosure of its content are strictly prohibited unless expressly permitted. Infringements will result in liability for compensation. All rights reserved in the event of the granting of patents, utility models or designs.

-

Page 3: Table Of Contents

Table of contents Table of contents Introduction........................10 Validity............................... 10 Manufacturer............................. 10 Subject to change without notice....................... 10 Completeness............................ 10 Supporting documents........................11 Safekeeping............................11 Notation conventions......................... 11 1.7.1 Symbols................................11 1.7.2 Hazard communication system........................... 12 1.7.3 Information system.............................. 14 Safety.......................... - Page 4 Table of contents Drive shaft............................27 3.3.1 Function description............................27 3.3.2 Performance features............................27 3.3.3 Setup/models of drive shaft..........................27 RS protective relay..........................29 3.4.1 Function description............................30 3.4.2 Performance features............................30 3.4.3 Setup/models of protective relay......................... 31 Pressure monitoring device DW......................32 3.5.1 Function description............................

- Page 5 Table of contents 5.3.6 Change-over selector connection contacts for reversing change-over selector connection VRD/VRF....58 5.3.7 Change-over selector connection contacts for coarse tap selector connection VRD/VRF......... 58 5.3.8 Parallel bridges for VRF I 1601........................... 58 5.3.9 Fine-tap-selector and change-over-selector connection contacts VRG.............. 59 5.3.10 Parallel bridges for VRG I 1601...........................

- Page 6 Table of contents 6.3.10 Parallel bridges for VRG I 1601......................... 109 6.3.11 Connecting on-load tap-changer take-off lead....................109 Carrying out the transformer ratio test..................... 109 6.4.1 Carrying out transformer ratio test with TAPMOTION® TD test drive............... 110 6.4.2 Carrying out the transformer ratio test manually....................110 Measuring DC resistance on transformer..................

- Page 7 Table of contents 8.2.2 Installing protective relay in piping........................165 8.2.3 Installing electrics for protective relay....................... 168 Installing and connecting the pressure-operated relay..............174 8.3.1 Checking the function of the pressure-operated relay..................174 8.3.2 Installing the pressure-operated relay....................... 176 8.3.3 Making the electrical connections for the pressure-operated relay..............

- Page 8 Table of contents 11.2.2 Checking protective relay (RS 2004)......................... 218 11.3 Checking pressure monitoring device..................... 219 11.4 Filling the oil compartment of the on-load tap-changer with oil............219 11.5 Commissioning the transformer....................... 221 Fault elimination......................223 12.1 Tripping of the protective relay and re-commissioning the transformer........... 225 12.1.1 Flap valve in IN SERVICE position........................

- Page 9 Table of contents 14.14 VACUTAP® VR, adjustment positions (728557)................244 14.15 VACUTAP® VRC/VRE, adjustment plan without change-over selector (719853)......245 14.16 VACUTAP® VRD/VRF, adjustment plan without change-over selector (721089)......247 14.17 VACUTAP® VRC III/VRC II/VRE III, adjustment plan with reversing change-over selector connection (719850)............................

-

Page 10: Introduction

1 Introduction Introduction This technical file contains detailed descriptions of the safe and proper in- stallation, connection, and commissioning of the product. It also includes safety instructions and general information about the prod- uct. Information about operation can be found in the operating instructions. This technical file is intended solely for specially trained and authorized per- sonnel. -

Page 11: Supporting Documents

1 Introduction Supporting documents The following documents also apply in addition to this technical file: ▪ Unpacking instructions (included in the scope of delivery) ▪ Supplement (included in the scope of delivery) ▪ Routine test report (included in the scope of delivery) ▪... -

Page 12: Hazard Communication System

1 Introduction Symbol Meaning Visual inspection Use your hand Adapter ring Apply a coat of paint Use a file Grease Coupling bolt Use a ruler Use a saw Hose clip Wire eyelet, safety wire Use a screwdriver Table 1: Symbols 1.7.2 Hazard communication system Warnings in this technical file are displayed as follows. - Page 13 1 Introduction Type and source of danger WARNING Consequences ► Action ► Action 1.7.2.2 Embedded warning information Embedded warnings refer to a particular part within a section. These warn- ings apply to smaller units of information than the warnings relating to sec- tions.

-

Page 14: Information System

1 Introduction Pictogram Meaning Warning of danger of tipping Table 3: Pictograms used in warning notices 1.7.3 Information system Information is designed to simplify and improve understanding of particular procedures. In this technical file it is laid out as follows: Important information. -

Page 15: Safety

2 Safety Safety General safety information This technical file contains detailed descriptions of the safe and proper in- stallation, connection, and commissioning of the product. ▪ Read this technical file through carefully to familiarize yourself with the product. ▪ Particular attention should be paid to the information given in this chap- ter. -

Page 16: Inappropriate Use

2 Safety Danger of death or severe injury and damage to property and DANGER the environment! Danger of death or severe injury and damage to property and the environ- ment due to electrical voltage, falling and/or tipping parts as well as danger- ous cramped conditions resulting from moving parts! ►... -

Page 17: Operator's Duty Of Care

2 Safety Operator's duty of care To prevent accidents, disruptions and damage as well as unacceptable ad- verse effects on the environment, those responsible for transport, installa- tion, operation, maintenance and disposal of the product or parts of the prod- uct must ensure the following: ▪... -

Page 18: Protective Devices

2 Safety Always wear Protective clothing Close-fitting work clothing with a low break- ing strength, with tight sleeves and with no protruding parts. It mainly serves to protect the wearer against being caught by moving machine parts. Do not wear any rings, necklaces or other jewelry. -

Page 19: Protective Relay Rs

2.7.4 Pressure relief device MPreC® On request, in place of the rupture disk MR will supply a pre-fitted pressure relief device MPreC® that responds to a defined overpressure in the oil com- partment of the on-load tap-changer. -

Page 20: Protective Devices In The Motor-Drive Unit

2 Safety 2.7.7 Protective devices in the motor-drive unit The following protective devices are fitted in the motor-drive unit: ▪ End stop device (mechanical and electric) ▪ Device protecting against unintentional passage ▪ Motor protection device ▪ Protection against accidental contact VACUTAP®... -

Page 21: Product Description

3 Product description Product description This chapter contains an overview of the design and function of the product. Scope of delivery The product is packaged with protection against moisture and is usually de- livered as follows: ▪ Oil compartment with on-load tap-changer head and built-in diverter switch insert ▪... -

Page 22: Performance Features

3 Product description A motor-drive unit, which receives a control impulse (e.g. from a voltage reg- ulator), changes the on-load tap-changer's operating position, as a result of which the transmission ratio of the transformer is adapted to the operating requirements. Figure 1: System overview of on-load tap-changer transformer 1 Transformer tank 6 Gear unit... -

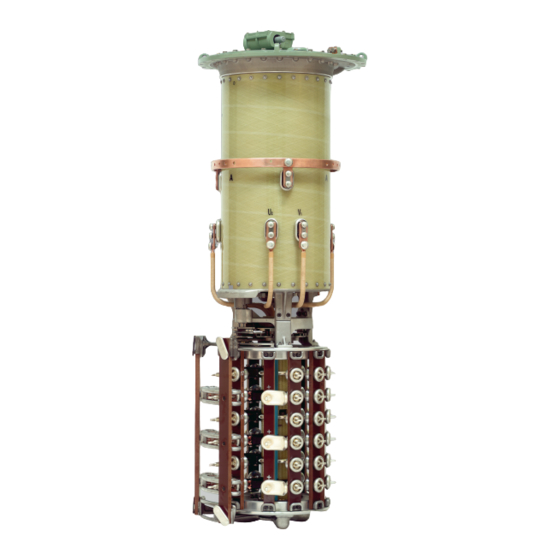

Page 23: Setup/Models

3 Product description 3.2.3 Setup/models The on-load tap-changer consists of the on-load tap-changer head, oil com- partment with built-in diverter switch insert and the tap selector mounted be- low (also available with change-over selector on request). The design and designation of the most important on-load tap-changer com- ponents are shown in the installation drawings in the appendix. - Page 24 3 Product description Figure 3: VACUTAP® VRD/VRF 1 On-load tap-changer head 3 Tap selector 2 Oil compartment 4 Change-over selector VACUTAP® VR® 4349315/00 EN Maschinenfabrik Reinhausen GmbH 2015...

- Page 25 3 Product description Figure 4: VACUTAP® VRG 1 On-load tap-changer head 3 Tap selector 2 Oil compartment 4 Change-over selector 3.2.3.1 Pipe connections The on-load tap-changer head features 4 pipe connections for different pur- poses. Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®...

- Page 26 3 Product description Depending on the order, some or all of these pipe connections are fitted with pipe bends ex factory. All pipe bends can be freely swiveled once the pres- sure ring is loosened. Figure 5: Pipe connections with pipe bends 3.2.3.1.1 Pipe connection R Pipe connection R is provided for the attachment of the protective relay and...

-

Page 27: Name Plate

3 Product description 3.2.4 Name plate The name plate is on the on-load tap-changer head cover. Figure 6: Position of name plate Drive shaft 3.3.1 Function description The drive shaft is the mechanical connection between motor-drive and on- load tap-changer head / off-circuit tap-changer head. The bevel gear changes the direction from vertical to horizontal (see drawing 892916). - Page 28 3 Product description 3.3.3.1 Drive shaft without cardan shaft, without insulator (= normal model) Figure 7: Drive shaft without cardan shaft, without insulator (= normal model) Configuration V 1 min [mm] Intermediate bearing for [mm] Middle of hand crank – middle of V 1 >...

-

Page 29: Rs Protective Relay

3 Product description 3.3.3.3 Drive shaft with cardan shaft, without insulator (= special model) Figure 9: Drive shaft with cardan shaft, without insulator (= special model) Configuration V 1 min [mm] Intermediate bearing for [mm] Middle of hand crank – middle of V 1 >... -

Page 30: Function Description

3 Product description 3.4.1 Function description The protective relay is used to protect the on-load tap-changer and the transformer when a malfunction occurs in the diverter switch oil compartment or selector switch oil compartment. It is tripped when the specified speed of oil flow from the on-load tap-changer head to the oil conservator is exceeded due to a fault. -

Page 31: Setup/Models Of Protective Relay

3 Product description 3.4.3 Setup/models of protective relay Front view Figure 11: RS 2001 1 Inspection window Rear view Figure 12: RS 2001 1 Dummy plug 3 Ventilation for terminal box 2 Identification plate The protective relay RS 2001/R has an extra inspection window on the rear. Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®... -

Page 32: Pressure Monitoring Device Dw

3 Product description View from above Figure 13: RS 2001 1 Gasket 7 Cable connection 2 Grounding cable 8 Protective cover 3 Terminal box cover 9 Dummy plug 4 OPERATION (reset) test button 10 Connection terminals 5 Slotted screw 11 Cylinder head screw for protec- tive conductor connection 6 OFF (test tripping) test button The protective relay RS 2003 and RS 2004 has a 1/2"-14NPT adapter in... -

Page 33: Performance Features

The pressure-operated relay responds faster than the RS 2001 protective re- lay in relation to large pressure increases. The RS 2001 protective relay is part of the default MR protection system that comes standard. Additional use of a pressure-operated relay also requires installation of the provided RS 2001 protective relay. - Page 34 3 Product description The pressure-operated relay consists of a pressure measuring element and an adjacent snap-action switch. Figure 14: Snap-action switch and pressure measuring element 1 Snap-action switch 2 Pressure measuring element The snap-action switch has a normally open switch and normally closed switch with snap action.

- Page 35 3 Product description During operation, the snap-action switch and pressure measuring element are protected by a cover cap. Ventilation is provided on the top of the pres- sure-operated relay. Figure 15: Pressure-operated relay with cover cap and ventilation 1 Ventilation 2 Cover cap There are two variants of the pressure-operated relay ▪...

-

Page 36: Packaging, Transport And Storage

4 Packaging, transport and storage Packaging, transport and storage Packaging The products are sometimes supplied with a sealed packaging and some- times also dried depending on what is required. A sealed packaging surrounds the packaged goods on all sides with plastic foil. -

Page 37: Transportation, Receipt And Handling Of Shipments

4 Packaging, transport and storage Transportation, receipt and handling of shipments Danger of death and damage to property! WARNING Danger of death and damage to property due to tipping or falling load! ► Transport crate only when closed. ► Do not remove the mounting material used in the crate during transport. ►... -

Page 38: Storage Of Shipments

4 Packaging, transport and storage changer/de-energized tap-changer or contact Maschinenfabrik Reinhau- sen GmbH to agree on how to proceed with drying. If this is not done, the packaged goods may be damaged. ▪ Name the damaged parts. Hidden damage When damages are not determined until unpacking after receipt of the ship- ment (hidden damage), proceed as follows: ▪... -

Page 39: Unpacking Shipments And Checking For Transportation Damages

4 Packaging, transport and storage If the product is installed more than 6 months after delivery, suitable meas- ures must be taken without delay. The following measures can be used: ▪ Correctly regenerate the drying agent and restore the sealed packaging. ▪... -

Page 40: Assembly: Standard Design

5 Assembly: Standard design Assembly: Standard design Risk of crushing from moving parts! WARNING When the on-load tap-changer undertakes a tap-change operation, compo- nents move on the selector and change-over selector, some of which are freely accessible. Reaching into the selector or change-over selector during a tap-change operation may result in serious injuries. -

Page 41: Fitting Stud Bolts On Mounting Flange

5 Assembly: Standard design 5.1.2 Fitting stud bolts on mounting flange To attach the stud bolts to the mounting flange, use a tracing template. This can be provided upon request free of charge for the initial installation of the on-load tap-changer. Place tracing template on mounting flange and use the four markings to align. - Page 42 5 Assembly: Standard design CAUTION! Place the oil compartment on a level surface and secure it against tipping. An unstably positioned oil compartment may tip over, resulting in serious injuries and damage. Clean sealing surfaces on mounting flange and on-load tap-changer head, place oil-resistant gasket on mounting flange.

- Page 43 5 Assembly: Standard design Lift the oil compartment by hooking up the on-load tap-changer head and carefully lower the oil compartment into the cover opening of the transformer. Figure 19: Oil compartment Check that the on-load tap-changer head is mounted in the position specified by the design.

- Page 44 5 Assembly: Standard design Screw on-load tap-changer head to mounting flange. Figure 20: On-load tap-changer head with mounting flange Remove the blocking device from the coupling of the oil compartment base. Figure 21: VACUTAP® VRC/VRE, blocking strip VACUTAP® VR® 4349315/00 EN Maschinenfabrik Reinhausen GmbH 2015...

- Page 45 5 Assembly: Standard design Figure 22: VACUTAP® VRD/VRF, blocking plate and shackle Figure 23: VACUTAP® VRG, blocking plate and shackle Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP® VR®...

-

Page 46: Securing Tap Selector On Oil Compartment Of The On-Load Tap-Changer Vrc/Vre

5 Assembly: Standard design 5.2.2 Securing tap selector on oil compartment of the on-load tap- changer VRC/VRE WARNING! Place the selector on a level surface and secure it CAUTION! . An unstably positioned selector may tip, against tipping resulting in serious injuries and damage. Remove plastic bag with fastening materials from the selector and lay out. -

Page 47: Securing Tap Selector On Oil Compartment Of The On-Load Tap-Changer Vrd/Vrf

5 Assembly: Standard design NOTICE! Carefully lift selector below the oil compartment ensuring that the selector take-off leads are free and do not touch the oil compart- ment. If this is not done, the selector take-off leads may be damaged. Align the position of both coupling parts and attachment points on the oil compartment and the selector with one another. - Page 48 5 Assembly: Standard design Remove plastic bag with fastening materials from the selector and lay out. Figure 27: Plastic bag with fastening materials Remove the blocking strip from the selector coupling. Once the blocking strip is removed, the selector coupling must no longer be turned. Figure 28: Blocking strip Place the selector on the lifting device.

- Page 49 5 Assembly: Standard design Remove the ring nuts from the selector. Figure 29: Ring nut NOTICE! Carefully lift selector below the oil compartment ensuring that the selector take-off leads are free and do not touch the oil compart- ment. If this is not done, the selector take-off leads may be damaged. Align the position of both coupling parts and attachment points on the oil compartment and the selector with one another.

-

Page 50: Securing Tap Selector On Oil Compartment Of The On-Load Tap-Changer Vrg

5 Assembly: Standard design 5.2.4 Securing tap selector on oil compartment of the on-load tap- changer VRG WARNING! Place the selector on a level surface and secure it CAUTION! . An unstably positioned selector may tip, against tipping resulting in serious injuries and damage. Remove plastic bag with fastening materials from the selector and lay out. - Page 51 5 Assembly: Standard design Remove the ring nuts from the selector. Figure 33: Ring nut NOTICE! Carefully lift selector below the oil compartment ensuring that the selector take-off leads are free and do not touch the oil compart- ment. If this is not done, the selector take-off leads may be damaged. Align the position of both coupling parts and attachment points on the oil compartment and the selector with one another.

-

Page 52: Connecting Tap Selector Take-Off Leads

5 Assembly: Standard design 5.2.5 Connecting tap selector take-off leads Proceed as follows to connect the tap selector take-off leads: NOTICE! Screw tap selector take-off lead to connecting piece with care. Comply with specified tightening torque and secure screw connection. Failure to do so may result in damage to the on-load tap-changer and transformer. - Page 53 5 Assembly: Standard design The screening caps are supplied separately. In this case a locking washer must be placed below each screening cap. The M10 connection screws, the nuts, and locking washers are not included in the scope of delivery. The through-holes of the connection contacts are either horizontal or verti- cal, depending on the on-load tap-changer version.

-

Page 54: Tap Selector Connection Contacts For Multiple Coarse Change-Over Selector Vrc

In this regard, please also pay attention to the dimensional drawing on which the order is based. Figure 38: Paper insulation 1 Connection from MR already p Connections to be insulated has 3 mm of paper insulation 5.3.3... - Page 55 5 Assembly: Standard design Connection contact K is designed as an extended fine tap selector connec- tion contact (also with through-hole for M10 screws). Figure 39: Change-over selector connection contacts for reversing change-over se- lector connection NOTICE Damage to the on-load tap-changer! Connection leads situated too close to the change-over selector's moving parts block the change-over selector and therefore result in on-load tap- changer damage!

-

Page 56: Change-Over Selector Connection Contacts For Coarse Tap Selector Connection Vrc/Vre

5 Assembly: Standard design 5.3.4 Change-over selector connection contacts for coarse tap selector connection VRC/VRE With coarse tap selector connection, the (+) and (-) change-over selector connection contacts are secured to the respective laminated paper bars of the coarse change-over selector. Their external appearance is identical to the fine tap selector contacts (through-hole for M10 screws, always in verti- cal position). -

Page 57: Selector Connection Contacts Vrd/Vrf

5 Assembly: Standard design Figure 42: Change-over selector connection contacts for coarse tap selector connec- tion (top view) 5.3.5 Selector connection contacts VRD/VRF The selector connection contacts have a through-hole for M12 screws. The screening caps are supplied separately. Figure 43: Selector connection contacts Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®... -

Page 58: Change-Over Selector Connection Contacts For Reversing Change-Over Selector Connection Vrd/Vrf

5 Assembly: Standard design 5.3.6 Change-over selector connection contacts for reversing change- over selector connection VRD/VRF The (+) and (-) change-over selector connection contacts are designed like fine tap selector connection contacts for reversing change-over selector con- nections. The change-over selector connection contacts (0) are produced as terminal lugs of the crimped connecting lead (=0/K) with a through-hole for M12 screws. -

Page 59: Fine-Tap-Selector And Change-Over-Selector Connection Contacts Vrg

5 Assembly: Standard design 5.3.9 Fine-tap-selector and change-over-selector connection contacts The tap selector connection contacts are indicated on the tap selector bars. The connection is made at the thread stud of the tap selector connection contact via cable shoes and locknuts. Every connection point must be covered by a screening cap. -

Page 60: Parallel Bridges For Vrg I 1601

5 Assembly: Standard design 5.3.10 Parallel bridges for VRG I 1601 Bridges for connecting the connection contacts of the fine tap selector and change-over selector in parallel in accordance with drawing 786920 [► 238] will be supplied. 5.3.11 Connecting on-load tap-changer take-off lead There are through-holes 13 mm in diameter at three points on the oil com- partment's connecting ring. -

Page 61: Carrying Out Transformer Ratio Test With Tapmotion® Td Test Drive

5 Assembly: Standard design 5.4.1 Carrying out transformer ratio test with TAPMOTION® TD test drive NOTICE Damage to the on-load tap-changer! Performing too many operations without complete oil filling will damage the on-load tap-changer! ► Do not perform more than 250 tap-change operations on the on-load tap-changer without oil before drying. - Page 62 5 Assembly: Standard design To actuate the drive shaft of the upper gear unit of the on-load tap-changer head, you can use a short tube (diameter 25 mm) with screwed-in coupling bolt (diameter 12 mm) with a hand wheel or crank. Figure 49: Upper gear unit with hand crank If using more than one on-load tap-changer column with a shared drive, you have to link all on-load tap-changer heads to one another by the horizontal...

-

Page 63: Measuring Dc Resistance On Transformer

5 Assembly: Standard design NOTICE! Carry out the transformer ratio test in all operating positions. Always check the operating position reached through the inspection win- dow in the on-load tap-changer head cover. Never overshoot the end positions, which are indicated in the connection diagram supplied with the delivery. -

Page 64: Drying On-Load Tap-Changer In Autoclave

Drying on-load tap-changer in autoclave Dry on-load tap-changer using the following instructions to ensure the dielec- tric values assured by MR on the on-load tap-changer. If you want to dry the on-load tap-changer in an autoclave, first perform the drying process and then complete transformer assembly. -

Page 65: Vapor-Phase Drying In The Autoclave

5 Assembly: Standard design 5.6.2 Vapor-phase drying in the autoclave For vapor-phase drying in the autoclave, you must open the kerosene drain plug in the oil compartment base before drying so that the kerosene conden- sate can drain from the oil compartment. NOTICE! Unscrew kerosene drain plug between oil compartment base and selector gear clockwise until it starts to get hard to turn.Never un-... -

Page 66: Drying On-Load Tap-Changer In Transformer Tank

Drying on-load tap-changer in transformer tank Dry on-load tap-changer using the following instructions to ensure the dielec- tric values assured by MR on the on-load tap-changer. If you want to dry the on-load tap-changer in the transformer tank, first com- plete transformer assembly and then undertake drying. -

Page 67: Vapor-Phase Drying In The Transformer Tank

5 Assembly: Standard design Residual pressure of no more than 10 bar. 5.7.2 Vapor-phase drying in the transformer tank For vapor-phase drying in the transformer tank, you have to open the kero- sene drain plug before drying so that the kerosene condensate can drain from the oil compartment. - Page 68 5 Assembly: Standard design 5.7.2.1.1 Moving on-load tap-changer to adjustment position ► Move on-load tap-changer to adjustment position. Figure 53: Adjustment position 5.7.2.1.2 Removing on-load tap-changer head cover Danger of death or severe injury! WARNING Danger of death or severe injury from explosive gases under the on-load tap-changer head cover! ►...

- Page 69 5 Assembly: Standard design Loosen screws with safety elements on the on-load tap-changer head cover. Figure 54: On-load tap-changer head cover NOTICE! Remove on-load tap-changer head cover. Check that the sealing surfaces on the on-load tap-changer head cover and on-load tap-changer head are in sound condition when removing and during all other work.

- Page 70 5 Assembly: Standard design 5.7.2.1.3 Removing tap position indicator (version without multiple coarse change-over selector) ► Pull the spring clip off the shaft end and remove the tap position indica- tor disc. Figure 56: Tap position indicator disk 5.7.2.1.4 Removing tap position indicator from multiple coarse change-over selector with more than 35 operating positions Ensure that the red marks on the panel, tap position indicator disk and cover disk produce a continuous red line.

- Page 71 5 Assembly: Standard design Lever cover disk off underlying disk with flat screwdriver and pull out po- sition-indication disk from between panel and bracket. Figure 58: Cover disk and position-indication disk Remove hexagon screws and associated lock tab. Figure 59: Lock tab Pull panel and bracket up and off indicator drive shaft.

- Page 72 5 Assembly: Standard design 5.7.2.1.5 Removing tap-change supervisory control (if present) Damage to the on-load tap-changer and transformer! NOTICE Removing the tap-change supervisory control without due care may dam- age it, thereby resulting in damage to the on-load tap-changer and trans- former! ►...

- Page 73 5 Assembly: Standard design Remove the tap-change supervisory control together with the mounting plate and drive shaft. Figure 63: Tap-change supervisory control with mounting plate and drive shaft Remove nut and Teflon strip from stud bolt. Figure 64: Stud bolt with Teflon strip and nut Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®...

- Page 74 5 Assembly: Standard design 5.7.2.1.6 Removing the oil suction pipe Remove cable ties from the oil suction pipe. Figure 65: Cable tie Pull oil suction pipe out of on-load tap-changer head. Figure 66: Oil suction pipe 5.7.2.1.7 Removing the oil suction pipe Remove cable ties from the oil suction pipe.

- Page 75 5 Assembly: Standard design Pull oil suction pipe out of on-load tap-changer head. Figure 68: Oil suction pipe Swivel lead of tap-change supervisory control out of on-load tap-chang- er head in direction indicated by arrow until the cable will not be dam- aged when the diverter switch insert is pulled out.

- Page 76 5 Assembly: Standard design 5.7.2.1.8 Lifting out diverter switch insert By turning the coupling tube on the upper screening ring, align it in such a manner that the triangular marks on the on-load tap-changer head and those on the coupling tube match up. Figure 70: Aligning the coupling tube Insert the lifting gear in the eyebolts of the coupling tube and position vertically above the diverter switch insert.

- Page 77 5 Assembly: Standard design 5.7.2.2 Opening kerosene drain plug NOTICE! ► Unscrew kerosene drain plug with extended socket wrench counter-clockwise until it starts to get hard to turn.Never unscrew the kerosene drain plug all the way. Figure 72: Kerosene drain plug 5.7.2.3 Inserting diverter switch insert After you have inserted the diverter switch insert, you have to insert the oil...

- Page 78 5 Assembly: Standard design 5.7.2.3.1 Inserting diverter switch insert Check that all six insulating shims are present in the energy accumula- tor carrier. Figure 73: Insulating shim VACUTAP® VR® 4349315/00 EN Maschinenfabrik Reinhausen GmbH 2015...

- Page 79 5 Assembly: Standard design To fit the diverter switch insert, ensure that the tap selector coupling is in the adjustment position. Figure 74: Adjustment markings in oil compartment base VACUTAP® VRC/VRE Figure 75: Adjustment markings in oil compartment base VACUTAP® VRD/VRF Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®...

- Page 80 5 Assembly: Standard design Figure 76: Adjustment markings in oil compartment base VACUTAP® VRG Ensure that the diverter switch insert's energy accumulator is inter- locked (the energy accumulator's eccentric disk is at its highest point). Attach lifting gear to diverter switch insert and position diverter switch in- sert over oil compartment.

- Page 81 5 Assembly: Standard design Slowly lower diverter switch insert until it meets the oil compartment base. Figure 77: Markings Carefully press until energy accumulator carrier is in position. The shape of the tap selector coupling ensures that coupling is only possible in the correct position.

- Page 82 5 Assembly: Standard design Check the distance between the upper edge of the diverter switch insert coupling tube and the on-load tap-changer head flange. The distance is 10 ± 2 mm (cover mounting and bell-type tank mounting). Figure 78: Distance between the upper edge of the coupling tube and the on-load tap-changer head flange 5.7.2.3.2 Inserting oil suction pipe...

- Page 83 5 Assembly: Standard design Fasten oil suction pipe on retaining bracket with cable tie. Figure 80: Fastening the oil suction pipe 5.7.2.3.3 Inserting tap-change supervisory control (if present) Insert tap-change supervisory control with mounting plate and drive shaft. Figure 81: Mounting plate with drive shaft Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®...

- Page 84 5 Assembly: Standard design Check that drive shaft feather key is seated correctly in groove. Figure 82: Feather key and groove Secure mounting plate (3 or 4 nuts and locking elements depending on model). Figure 83: Mounting plate Connect plug connector outside its bracket. Figure 84: Plug connector VACUTAP®...

- Page 85 5 Assembly: Standard design Insert plug connector into the bracket. Figure 85: Plug connector in bracket Attach Teflon strip with nut onto stud bolts. Figure 86: Stud bolt with Teflon strip and nut 5.7.2.3.4 Inserting the tap position indicator without multiple coarse change- over selector Due to the coupling pin, the tap position indicator disc can only be installed when in the correct position.

- Page 86 5 Assembly: Standard design ► Place tap position indicator disk on indicator drive shaft, slide spring clip on to shaft end. Figure 87: Tap position indicator disk 5.7.2.3.5 Inserting tap position indicator with multiple coarse change-over selector with more than 35 operating positions Place panel with bracket on indicator drive shaft and fasten with hexa- gon screws and associated lock tab.

- Page 87 5 Assembly: Standard design Insert position-indication disk horizontally between panel and bracket and fit cover disk. Align tap position indicator disc and cover disk to pro- duce a continuous red line. Figure 89: Inserting position-indication disk Secure cover disk with countersunk head screw. The countersunk head screw must be suitable for center-punching.

- Page 88 5 Assembly: Standard design from the diverter switch oil compartment, resulting in on-load tap-chang- er damage. Also ensure that the red triangular marks on the on-load tap-changer head and the on-load tap-changer head cover match up. Figure 91: On-load tap-changer head cover with o-ring Screw on-load tap-changer head cover using screws and safety ele- ments.

- Page 89 5 Assembly: Standard design 5.7.2.4 Drying the on-load tap-changer Connect pipe connections R and Q of on-load tap-changer head to the kerosene vapor lead using one shared lead. Figure 93: Shared lead Seal off unused pipe connections with a suitable blank cover. Vapor-phase drying in the transformer tank Supply kerosene vapor at a temperature of around 90 °C.

-

Page 90: Assembly: Bell-Type Tank Design

6 Assembly: Bell-type tank design Assembly: Bell-type tank design Risk of crushing from moving parts! WARNING When the on-load tap-changer undertakes a tap-change operation, compo- nents move on the selector and change-over selector, some of which are freely accessible. Reaching into the selector or change-over selector during a tap-change operation may result in serious injuries. -

Page 91: Fitting Stud Bolts On Mounting Flange

6 Assembly: Bell-type tank design 6.1.2 Fitting stud bolts on mounting flange To attach the stud bolts to the mounting flange, use a tracing template. This can be provided upon request free of charge for the initial installation of the on-load tap-changer. - Page 92 6 Assembly: Bell-type tank design Remove plastic bag with fastening materials from the tap selector and lay out. Figure 96: Plastic bag with fastening materials Remove the blocking strip from the tap selector coupling. Once the blocking strip is removed, the tap selector coupling must no longer be turned.

- Page 93 6 Assembly: Bell-type tank design Remove the blocking device from the coupling of the oil compartment base. Figure 98: Blocking strip Lift the oil compartment by hooking up the on-load tap-changer head and carefully raise above tap selector. Align the position of both coupling parts and attachment points on the oil compartment and the tap selector with one another.

-

Page 94: Securing Tap Selector On Oil Compartment Of The On-Load Tap-Changer Vrd/Vrf

6 Assembly: Bell-type tank design 6.2.2 Securing tap selector on oil compartment of the on-load tap- changer VRD/VRF CAUTION! Place the tap selector on a level surface and secure it against tipping. An unstably positioned tap selector may tip, resulting in serious injuries and damage. - Page 95 6 Assembly: Bell-type tank design Remove the blocking strip from the tap selector coupling. Once the blocking strip is removed, the tap selector coupling must no longer be turned. Figure 102: Blocking strip CAUTION! Place the oil compartment on a level surface and secure it against tipping.

-

Page 96: Securing Tap Selector On Oil Compartment Of The On-Load Tap-Changer Vrg

6 Assembly: Bell-type tank design Carefully raise oil compartment above tap selector. Align the position of both coupling parts and attachment points on the oil compartment and the tap selector with one another. The correct position of the two coupling parts is shown in the adjustment plans in the appen- dix. - Page 97 6 Assembly: Bell-type tank design Remove plastic bag with fastening materials from the tap selector and lay out. Figure 105: Plastic bag with fastening materials Remove the ring nuts from the tap selector. Figure 106: Ring nut Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®...

- Page 98 6 Assembly: Bell-type tank design Remove the blocking strip from the tap selector coupling. Once the blocking strip is removed, the tap selector coupling must no longer be turned. Figure 107: Blocking strip CAUTION! Place the oil compartment on a level surface and secure it against tipping.

-

Page 99: Connecting Tap Selector Take-Off Leads

6 Assembly: Bell-type tank design Carefully raise oil compartment above tap selector. Align the position of both coupling parts and attachment points on the oil compartment and the tap selector with one another. The correct position of the two coupling parts is shown in the adjustment plans in the appen- dix. -

Page 100: Inserting On-Load Tap-Changer Into Supporting Structure

6 Assembly: Bell-type tank design 6.2.5 Inserting on-load tap-changer into supporting structure NOTICE! Using spacers, insert on-load tap-changer vertically into sup- porting structure (maximum 1° deviation from the vertical) so that the on-load tap-changer reaches its final installation height and only has to be raised a maximum of 5 to 20 mm after fitting the bell-type tank. -

Page 101: Connecting Tap Winding And On-Load Tap-Changer Take-Off Lead

6 Assembly: Bell-type tank design Temporarily fasten on-load tap-changer to supporting structure. The supporting flange has through holes for this purpose. Figure 112: Fastening the on-load tap-changer Connecting tap winding and on-load tap-changer take-off lead NOTICE Damage to the on-load tap-changer! Connecting leads which place mechanical strain on the on-load tap-changer will damage the on-load tap-changer! ►... -

Page 102: Tap Selector Connection Contacts For Multiple Coarse Change-Over Selector Vrc

6 Assembly: Bell-type tank design The through-holes of the connection contacts are either horizontal or verti- cal, depending on the on-load tap-changer version. Figure 113: Selector connection contacts Figure 114: Screening caps 6.3.2 Tap selector connection contacts for multiple coarse change- over selector VRC In the case of multiple coarse change-over selectors, special attention must be paid when routing the cables for connecting the tap selector connection... -

Page 103: Change-Over Selector Connection Contacts For Reversing Change-Over Selector Connection Vrc/Vre

6 Assembly: Bell-type tank design In this regard, please also pay attention to the dimensional drawing on which the order is based. Figure 115: Paper insulation 1 Connection from MR already p Connections to be insulated has 3 mm of paper insulation 6.3.3... - Page 104 6 Assembly: Bell-type tank design NOTICE Damage to the on-load tap-changer! Connection leads situated too close to the change-over selector's moving parts block the change-over selector and therefore result in on-load tap- changer damage! ► Connection leads in the area of the change-over selector have to be routed such that they are at a sufficient distance from the change-over selector's moving parts.

-

Page 105: Change-Over Selector Connection Contacts For Coarse Tap Selector Connection Vrc/Vre

6 Assembly: Bell-type tank design 6.3.4 Change-over selector connection contacts for coarse tap selector connection VRC/VRE With coarse tap selector connection, the (+) and (-) change-over selector connection contacts are secured to the respective laminated paper bars of the coarse change-over selector. Their external appearance is identical to the fine tap selector contacts (through-hole for M10 screws, always in verti- cal position). -

Page 106: Selector Connection Contacts Vrd/Vrf

6 Assembly: Bell-type tank design Figure 119: Change-over selector connection contacts for coarse tap selector con- nection (top view) 6.3.5 Selector connection contacts VRD/VRF The selector connection contacts have a through-hole for M12 screws. The screening caps are supplied separately. Figure 120: Selector connection contacts VACUTAP®... -

Page 107: Change-Over Selector Connection Contacts For Reversing Change-Over Selector Connection Vrd/Vrf

6 Assembly: Bell-type tank design 6.3.6 Change-over selector connection contacts for reversing change- over selector connection VRD/VRF The (+) and (-) change-over selector connection contacts are designed like fine tap selector connection contacts for reversing change-over selector con- nections. The change-over selector connection contacts (0) are produced as terminal lugs of the crimped connecting lead (=0/K) with a through-hole for M12 screws. -

Page 108: Fine-Tap-Selector And Change-Over-Selector Connection Contacts Vrg

6 Assembly: Bell-type tank design 6.3.9 Fine-tap-selector and change-over-selector connection contacts The tap selector connection contacts are indicated on the tap selector bars. The connection is made at the thread stud of the tap selector connection contact via cable shoes and locknuts. Every connection point must be covered by a screening cap. -

Page 109: Parallel Bridges For Vrg I 1601

6 Assembly: Bell-type tank design 6.3.10 Parallel bridges for VRG I 1601 Bridges for connecting the connection contacts of the fine tap selector and change-over selector in parallel in accordance with drawing 786920 [► 238] will be supplied. 6.3.11 Connecting on-load tap-changer take-off lead There are through-holes 13 mm in diameter at three points on the oil com- partment's connecting ring. -

Page 110: Carrying Out Transformer Ratio Test With Tapmotion® Td Test Drive

6 Assembly: Bell-type tank design 6.4.1 Carrying out transformer ratio test with TAPMOTION® TD test drive NOTICE Damage to the on-load tap-changer! Performing too many operations without complete oil filling will damage the on-load tap-changer! ► Do not perform more than 250 tap-change operations on the on-load tap-changer without oil before drying. - Page 111 6 Assembly: Bell-type tank design To actuate the drive shaft of the upper gear unit of the on-load tap-changer head, you can use a short tube (diameter 25 mm) with screwed-in coupling bolt (diameter 12 mm) with a hand wheel or crank. Figure 126: Upper gear unit with hand crank If using more than one on-load tap-changer column with a shared drive, you have to link all on-load tap-changer heads to one another by the horizontal...

-

Page 112: Measuring Dc Resistance On Transformer

6 Assembly: Bell-type tank design NOTICE! Carry out the transformer ratio test in all operating positions. Always check the operating position reached through the inspection win- dow in the on-load tap-changer head cover. Never overshoot the end positions, which are indicated in the connection diagram supplied with the delivery. -

Page 113: Drying On-Load Tap-Changer In Autoclave

Drying on-load tap-changer in autoclave Dry on-load tap-changer using the following instructions to ensure the dielec- tric values assured by MR on the on-load tap-changer. If you want to dry the on-load tap-changer in an autoclave, first perform the drying process and then complete transformer assembly. -

Page 114: Vapor-Phase Drying In The Autoclave

6 Assembly: Bell-type tank design 6.6.2 Vapor-phase drying in the autoclave For vapor-phase drying in the autoclave, you must open the kerosene drain plug in the oil compartment base before drying so that the kerosene conden- sate can drain from the oil compartment. NOTICE! Unscrew kerosene drain plug between oil compartment base and selector gear clockwise until it starts to get hard to turn.Never un-... -

Page 115: Removing On-Load Tap-Changer Head

6 Assembly: Bell-type tank design Removing on-load tap-changer head 6.7.1 Removing on-load tap-changer head cover Danger of death or severe injury! WARNING Danger of death or severe injury from explosive gases under the on-load tap-changer head cover! ► Ensure that there are no naked flames, hot surfaces or sparks (for ex- ample caused by static charging) in the immediate surroundings and that none occur. - Page 116 6 Assembly: Bell-type tank design Loosen screws with safety elements on the on-load tap-changer head cover. Figure 130: On-load tap-changer head cover NOTICE! Remove on-load tap-changer head cover. Check that the sealing surfaces on the on-load tap-changer head cover and on-load tap-changer head are in sound condition when removing and during all other work.

-

Page 117: Removing Tap Position Indicator (Version Without Multiple Coarse Change-Over Selector)

6 Assembly: Bell-type tank design 6.7.2 Removing tap position indicator (version without multiple coarse change-over selector) ► Pull the spring clip off the shaft end and remove the tap position indica- tor disc. Figure 132: Tap position indicator disk 6.7.3 Removing tap position indicator from multiple coarse change- over selector with more than 35 operating positions Ensure that the red marks on the panel, tap position indicator disk and... - Page 118 6 Assembly: Bell-type tank design Lever cover disk off underlying disk with flat screwdriver and pull out po- sition-indication disk from between panel and bracket. Figure 134: Cover disk and position-indication disk Remove hexagon screws and associated lock tab. Figure 135: Lock tab Pull panel and bracket up and off indicator drive shaft.

-

Page 119: Removing Tap-Change Supervisory Control (If Present)

6 Assembly: Bell-type tank design 6.7.4 Removing tap-change supervisory control (if present) Damage to the on-load tap-changer and transformer! NOTICE Removing the tap-change supervisory control without due care may dam- age it, thereby resulting in damage to the on-load tap-changer and trans- former! ►... - Page 120 6 Assembly: Bell-type tank design Remove the tap-change supervisory control together with the mounting plate and drive shaft. Figure 139: Tap-change supervisory control with mounting plate and drive shaft Remove nut and Teflon strip from stud bolt. Figure 140: Stud bolt with Teflon strip and nut VACUTAP®...

-

Page 121: Removing The Oil Suction Pipe

6 Assembly: Bell-type tank design 6.7.5 Removing the oil suction pipe Remove cable ties from the oil suction pipe. Figure 141: Cable tie Pull oil suction pipe out of on-load tap-changer head. Figure 142: Oil suction pipe 6.7.6 Removing the oil suction pipe Remove cable ties from the oil suction pipe. - Page 122 6 Assembly: Bell-type tank design Pull oil suction pipe out of on-load tap-changer head. Figure 144: Oil suction pipe Swivel lead of tap-change supervisory control out of on-load tap-chang- er head in direction indicated by arrow until the cable will not be dam- aged when the diverter switch insert is pulled out.

-

Page 123: Lifting On-Load Tap-Changer Head Off Supporting Flange

6 Assembly: Bell-type tank design 6.7.7 Lifting on-load tap-changer head off supporting flange Remove nuts and safety elements between on-load tap-changer head and supporting flange. Figure 146: On-load tap-changer head with nuts Lift off the on-load tap-changer head from the supporting flange. Figure 147: On-load tap-changer head Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN... -

Page 124: Attaching Bell-Type Tank And Connecting On-Load Tap-Changer Head With On-Load Tap-Changer

6 Assembly: Bell-type tank design Attaching bell-type tank and connecting on-load tap- changer head with on-load tap-changer The following chapters explain how to attach the bell-type tank and connect the on-load tap-changer head with the on-load tap-changer. 6.8.1 Mounting the bell-type tank Clean sealing surface of supporting flange, place o-ring on supporting flange. - Page 125 6 Assembly: Bell-type tank design Lift the bell-type tank over the active part of the transformer. Figure 149: Bell-type tank Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP® VR®...

-

Page 126: Mounting On-Load Tap-Changer Head On Bell-Type Tank

6 Assembly: Bell-type tank design 6.8.2 Mounting on-load tap-changer head on bell-type tank Clean sealing surfaces on mounting flange and on-load tap-changer head, place oil-resistant gasket on mounting flange. Figure 150: Mounting flange with gasket 1 Gasket 2 Mounting flange VACUTAP®... -

Page 127: Connecting On-Load Tap-Changer Head And On-Load Tap-Changer

6 Assembly: Bell-type tank design Position on-load tap-changer head on mounting flange such that the markings on the supporting flange and on-load tap-changer head match up. Note fitted bolt on supporting flange. Figure 151: Markings and fitted bolt 6.8.3 Connecting on-load tap-changer head and on-load tap-changer NOTICE! Carefully insert lifting device into the on-load tap-changer head with claws turned in. - Page 128 6 Assembly: Bell-type tank design flange are used to lift the on-load tap-changer, the screws may be dam- aged, which makes it impossible to properly screw the on-load tap- changer and the on-load tap-changer head together! Figure 152: Lifting device NOTICE! Swing claws of lifting device outwards, use lifting device to lift on-load tap-changer.

- Page 129 6 Assembly: Bell-type tank design When screwing the on-load tap-changer head onto the supporting flange, leave the bolts for the mounting plate of the tap-change supervisory control as well as the bolts for the mounting bracket of the oil suction pipe (if pres- ent) free.

-

Page 130: Inserting Oil Suction Pipe

6 Assembly: Bell-type tank design Screw on-load tap-changer head to the mounting flange. Figure 156: Screwing on-load tap-changer head to the mounting flange 6.8.4 Inserting oil suction pipe NOTICE Damage to the on-load tap-changer! Damage to the on-load tap-changer and oil suction pipe due to incorrect or- der of installation. -

Page 131: Inserting Tap-Change Supervisory Control (If Present)

6 Assembly: Bell-type tank design Fasten oil suction pipe on retaining bracket with cable tie. Figure 158: Fastening the oil suction pipe 6.8.5 Inserting tap-change supervisory control (if present) Insert tap-change supervisory control with mounting plate and drive shaft. Figure 159: Mounting plate with drive shaft Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®... - Page 132 6 Assembly: Bell-type tank design Check that drive shaft feather key is seated correctly in groove. Figure 160: Feather key and groove Secure mounting plate (3 or 4 nuts and locking elements depending on model). Figure 161: Mounting plate Connect plug connector outside its bracket. Figure 162: Plug connector VACUTAP®...

-

Page 133: Inserting The Tap Position Indicator Without Multiple Coarse Change-Over Selector

6 Assembly: Bell-type tank design Insert plug connector into the bracket. Figure 163: Plug connector in bracket Attach Teflon strip with nut onto stud bolts. Figure 164: Stud bolt with Teflon strip and nut 6.8.6 Inserting the tap position indicator without multiple coarse change-over selector Due to the coupling pin, the tap position indicator disc can only be installed when in the correct position. -

Page 134: Inserting Tap Position Indicator With Multiple Coarse Change-Over Selector With More Than 35 Operating Positions

6 Assembly: Bell-type tank design ► Place tap position indicator disk on indicator drive shaft, slide spring clip on to shaft end. Figure 165: Tap position indicator disk 6.8.7 Inserting tap position indicator with multiple coarse change-over selector with more than 35 operating positions Place panel with bracket on indicator drive shaft and fasten with hexa- gon screws and associated lock tab. -

Page 135: Securing On-Load Tap-Changer Head Cover

6 Assembly: Bell-type tank design Insert position-indication disk horizontally between panel and bracket and fit cover disk. Align tap position indicator disc and cover disk to pro- duce a continuous red line. Figure 167: Inserting position-indication disk Secure cover disk with countersunk head screw. The countersunk head screw must be suitable for center-punching. -

Page 136: Drying On-Load Tap-Changer In Transformer Tank

Drying on-load tap-changer in transformer tank Dry on-load tap-changer using the following instructions to ensure the dielec- tric values assured by MR on the on-load tap-changer. If you want to dry the on-load tap-changer in the transformer tank, first com- plete transformer assembly and then undertake drying. -

Page 137: Vacuum-Drying In The Transformer Tank

6 Assembly: Bell-type tank design 6.9.1 Vacuum-drying in the transformer tank Before you start vacuum-drying in the transformer tank, you must place a connecting lead between the corresponding pipe connections and seal off the pipe connections not being used with blank covers. The on-load tap-changer head cover remains closed during the entire drying process. - Page 138 6 Assembly: Bell-type tank design The kerosene drain plug is located in the oil compartment base and is not generally accessible from the outside. For this reason, you first have to re- move the diverter switch insert, open the kerosene drain plug, and then in- stall the diverter switch insert again.

- Page 139 6 Assembly: Bell-type tank design 6.9.2.1.2 Removing on-load tap-changer head cover Danger of death or severe injury! WARNING Danger of death or severe injury from explosive gases under the on-load tap-changer head cover! ► Ensure that there are no naked flames, hot surfaces or sparks (for ex- ample caused by static charging) in the immediate surroundings and that none occur.

- Page 140 6 Assembly: Bell-type tank design other work. Ensure that o-ring is in sound condition too. Damaged seal- ing surfaces lead to oil escaping and therefore to on-load tap-changer and transformer damage. Figure 174: On-load tap-changer head cover NOTICE! Do not expose the open oil compartment to ambient humidity for more than 10 hours.

- Page 141 6 Assembly: Bell-type tank design Remove countersunk head screw. Figure 176: Countersunk head screw Lever cover disk off underlying disk with flat screwdriver and pull out po- sition-indication disk from between panel and bracket. Figure 177: Cover disk and position-indication disk Remove hexagon screws and associated lock tab.

- Page 142 6 Assembly: Bell-type tank design Pull panel and bracket up and off indicator drive shaft. Figure 179: Panel 6.9.2.1.5 Removing tap-change supervisory control (if present) NOTICE Damage to the on-load tap-changer and transformer! Removing the tap-change supervisory control without due care may dam- age it, thereby resulting in damage to the on-load tap-changer and trans- former! ►...

- Page 143 6 Assembly: Bell-type tank design Remove nuts and locking elements (3 or 4 depending on model) on the mounting plate. Figure 181: Mounting plate Remove the tap-change supervisory control together with the mounting plate and drive shaft. Figure 182: Tap-change supervisory control with mounting plate and drive shaft Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®...

- Page 144 6 Assembly: Bell-type tank design Remove nut and Teflon strip from stud bolt. Figure 183: Stud bolt with Teflon strip and nut 6.9.2.1.6 Removing the oil suction pipe Remove cable ties from the oil suction pipe. Figure 184: Cable tie Pull oil suction pipe out of on-load tap-changer head.

- Page 145 6 Assembly: Bell-type tank design 6.9.2.1.7 Removing the oil suction pipe Remove cable ties from the oil suction pipe. Figure 186: Cable tie Pull oil suction pipe out of on-load tap-changer head. Figure 187: Oil suction pipe Swivel lead of tap-change supervisory control out of on-load tap-chang- er head in direction indicated by arrow until the cable will not be dam- aged when the diverter switch insert is pulled out.

- Page 146 6 Assembly: Bell-type tank design 6.9.2.1.8 Lifting out diverter switch insert By turning the coupling tube on the upper screening ring, align it in such a manner that the triangular marks on the on-load tap-changer head and those on the coupling tube match up. Figure 189: Aligning the coupling tube Insert the lifting gear in the eyebolts of the coupling tube and position vertically above the diverter switch insert.

- Page 147 6 Assembly: Bell-type tank design 6.9.2.2 Opening kerosene drain plug NOTICE! ► Unscrew kerosene drain plug with extended socket wrench counter-clockwise until it starts to get hard to turn.Never unscrew the kerosene drain plug all the way. Figure 191: Kerosene drain plug 6.9.2.3 Inserting diverter switch insert After you have inserted the diverter switch insert, you have to insert the oil...

- Page 148 6 Assembly: Bell-type tank design 6.9.2.3.1 Inserting diverter switch insert Check that all six insulating shims are present in the energy accumula- tor carrier. Figure 192: Insulating shim VACUTAP® VR® 4349315/00 EN Maschinenfabrik Reinhausen GmbH 2015...

- Page 149 6 Assembly: Bell-type tank design To fit the diverter switch insert, ensure that the tap selector coupling is in the adjustment position. Figure 193: Adjustment markings in oil compartment base VACUTAP® VRC/VRE Figure 194: Adjustment markings in oil compartment base VACUTAP® VRD/VRF Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®...

- Page 150 6 Assembly: Bell-type tank design Figure 195: Adjustment markings in oil compartment base VACUTAP® VRG Ensure that the diverter switch insert's energy accumulator is inter- locked (the energy accumulator's eccentric disk is at its highest point). Attach lifting gear to diverter switch insert and position diverter switch in- sert over oil compartment.

- Page 151 6 Assembly: Bell-type tank design Slowly lower diverter switch insert until it meets the oil compartment base. Figure 196: Markings Carefully press until energy accumulator carrier is in position. The shape of the tap selector coupling ensures that coupling is only possible in the correct position.

- Page 152 6 Assembly: Bell-type tank design Check the distance between the upper edge of the diverter switch insert coupling tube and the on-load tap-changer head flange. The distance is 10 ± 2 mm (cover mounting and bell-type tank mounting). Figure 197: Distance between the upper edge of the coupling tube and the on-load tap-changer head flange 6.9.2.3.2 Inserting oil suction pipe...

- Page 153 6 Assembly: Bell-type tank design Fasten oil suction pipe on retaining bracket with cable tie. Figure 199: Fastening the oil suction pipe 6.9.2.3.3 Inserting tap-change supervisory control (if present) Insert tap-change supervisory control with mounting plate and drive shaft. Figure 200: Mounting plate with drive shaft Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®...

- Page 154 6 Assembly: Bell-type tank design Check that drive shaft feather key is seated correctly in groove. Figure 201: Feather key and groove Secure mounting plate (3 or 4 nuts and locking elements depending on model). Figure 202: Mounting plate Connect plug connector outside its bracket. Figure 203: Plug connector VACUTAP®...

- Page 155 6 Assembly: Bell-type tank design Insert plug connector into the bracket. Figure 204: Plug connector in bracket Attach Teflon strip with nut onto stud bolts. Figure 205: Stud bolt with Teflon strip and nut 6.9.2.3.4 Inserting the tap position indicator without multiple coarse change- over selector Due to the coupling pin, the tap position indicator disc can only be installed when in the correct position.

- Page 156 6 Assembly: Bell-type tank design ► Place tap position indicator disk on indicator drive shaft, slide spring clip on to shaft end. Figure 206: Tap position indicator disk 6.9.2.3.5 Inserting tap position indicator with multiple coarse change-over selector with more than 35 operating positions Place panel with bracket on indicator drive shaft and fasten with hexa- gon screws and associated lock tab.

- Page 157 6 Assembly: Bell-type tank design Insert position-indication disk horizontally between panel and bracket and fit cover disk. Align tap position indicator disc and cover disk to pro- duce a continuous red line. Figure 208: Inserting position-indication disk Secure cover disk with countersunk head screw. The countersunk head screw must be suitable for center-punching.

- Page 158 6 Assembly: Bell-type tank design from the diverter switch oil compartment, resulting in on-load tap-chang- er damage. Also ensure that the red triangular marks on the on-load tap-changer head and the on-load tap-changer head cover match up. Figure 210: On-load tap-changer head cover with o-ring Screw on-load tap-changer head cover using screws and safety ele- ments.

- Page 159 6 Assembly: Bell-type tank design 6.9.2.4 Drying the on-load tap-changer Connect pipe connections R and Q of on-load tap-changer head to the kerosene vapor lead using one shared lead. Figure 212: Shared lead Seal off unused pipe connections with a suitable blank cover. Vapor-phase drying in the transformer tank Supply kerosene vapor at a temperature of around 90 °C.

-

Page 160: Filling The Oil Compartment Of The On-Load Tap-Changer With Oil

7 Filling the oil compartment of the on-load tap-changer with oil Filling the oil compartment of the on-load tap- changer with oil After drying, completely fill the oil compartment (diverter switch insert fitted) with oil again as soon as possible so that an impermissible amount of humid- ity is not absorbed from the surroundings. - Page 161 7 Filling the oil compartment of the on-load tap-changer with oil Fill on-load tap-changer with oil using one of the remaining pipe connec- tions of the on-load tap-changer head. Figure 214: Pipe connection S and R Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®...

-

Page 162: Fitting Protective Devices And Drive Components

8 Fitting protective devices and drive components Fitting protective devices and drive components Connecting tap-change supervisory control (if present) ► Connect monitoring contacts integrated in on-load tap-changer head (terminal box on pipe connection Q, ) to corresponding motor-drive unit terminals using connecting lead (see connection diagram of relevant motor-drive unit). -

Page 163: Checking Function Of Protective Relay

8 Fitting protective devices and drive components 8.2.1 Checking function of protective relay Check the function of the protective relay before installing in piping between on-load tap-changer head and oil conservator. Open terminal box. Figure 215: Protective relay with open terminal box NOTICE Damage to protective relay! Damage to protective relay resulting from improper operation! - Page 164 8 Fitting protective devices and drive components Figure 216: OFF position Press IN SERVICE test button. ð Flap valve is vertical. Figure 217: In service position VACUTAP® VR® 4349315/00 EN Maschinenfabrik Reinhausen GmbH 2015...

-

Page 165: Installing Protective Relay In Piping

8 Fitting protective devices and drive components Close terminal box. Figure 218: Terminal box cover The associated contact positions for checking electrical continuity are evi- dent from the dimensional drawing provided. 8.2.2 Installing protective relay in piping The following requirements must be satisfied in order to install the protective relay in the piping: ▪... - Page 166 8 Fitting protective devices and drive components ▪ The reference arrow on the terminal box cover must point towards the on-load tap-changer's oil conservator. ▪ Install protective relay such that it can be easily accessed for subse- quent maintenance work. Figure 219: Piping with inclination of at least 2 % Figure 220: Protective relay with test button at the top VACUTAP®...

- Page 167 8 Fitting protective devices and drive components Figure 221: Reference arrow pointing towards the on-load tap-changer's oil conser- vator Install the protective relay horizontally in the pipe between on-load tap- changer head and oil conservator as near as possible to the on-load tap-changer head taking the above points into consideration.

-

Page 168: Installing Electrics For Protective Relay

2001/R) or adapter (RS 2003 und RS 2004) in the tapped hole which seems to be in the most favorable position. Figure 223: Cable bushing Seal open tapped hole with MR dummy plug. Figure 224: Dummy plug VACUTAP® VR® 4349315/00 EN... - Page 169 8 Fitting protective devices and drive components Open terminal box. Figure 225: Terminal box Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP® VR®...

- Page 170 8 Fitting protective devices and drive components Loosen screw, remove terminal box cover and take off protective cover. Figure 226: Terminal box cover and protective cover VACUTAP® VR® 4349315/00 EN Maschinenfabrik Reinhausen GmbH 2015...

- Page 171 8 Fitting protective devices and drive components Guide cable through cable bushing and into protective relay. Ensure that the cable connection is well secured and sealed. Figure 227: Cable bushing Danger of death or severe injury! WARNING Danger of death and severe injury due to unprofessional electrical connec- tion of protective relay.

- Page 172 8 Fitting protective devices and drive components Connect protective conductor to cylinder head screw. Figure 229: Protective conductor Insert protective cover. Figure 230: Protective cover VACUTAP® VR® 4349315/00 EN Maschinenfabrik Reinhausen GmbH 2015...

- Page 173 8 Fitting protective devices and drive components Secure terminal box cover. Figure 231: Terminal box cover Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP® VR®...

-

Page 174: Installing And Connecting The Pressure-Operated Relay

8 Fitting protective devices and drive components 10. Close terminal box. Figure 232: Terminal box cover Installing and connecting the pressure-operated relay 8.3.1 Checking the function of the pressure-operated relay Check the function of the pressure-operated relay before you install it on a pipe bend or the on-load tap-changer head. - Page 175 8 Fitting protective devices and drive components Figure 233: OFF position 1 Snap-action switch 2 Sensor in OFF position Activate the snap-action switch again. ð Sensor is in the OPERATION position below the snap-action switch. Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®...

-

Page 176: Installing The Pressure-Operated Relay

8 Fitting protective devices and drive components Figure 234: OPERATION position 1 Snap-action switch 2 Sensor in the OPERATION position Secure the cover cap. Always check the position of the sensor! 8.3.2 Installing the pressure-operated relay The pressure-operated relay can be installed in 2 variants. ▪... -

Page 177: Making The Electrical Connections For The Pressure-Operated Relay

8 Fitting protective devices and drive components 8.3.3 Making the electrical connections for the pressure-operated relay Risk of fatal injury due to electric shock! DANGER Failure to disconnect the switch housing or junction box from the power grid before opening can result in electric shock! ►... -

Page 178: Fitting Motor-Drive Unit On Transformer

8 Fitting protective devices and drive components Fitting motor-drive unit on transformer Fit 4 stud bolts (not supplied by MR) to transformer tank. Figure 235: Stud bolt NOTICE! Fit the drive vertically to the transformer tank so that its output shaft is correctly aligned with the vertical shaft of the bevel gear. - Page 179 Figure 237: Securing drive Vibration dampers must be used on transformers where the motor-drive unit is subject to vibration (MR special design). Connect the grounding screw of the motor-drive unit to the transformer tank. Figure 238: Grounding screw...

-

Page 180: Fitting Bevel Gear

8 Fitting protective devices and drive components Connect main grounding conductor to grounding conductor terminal on terminal bar X1 (minimum connection cross-section 2.5 mm Figure 239: Main grounding conductor Fitting bevel gear The stamped serial number of the bevel gear must match the serial number of the on-load tap-changer. - Page 181 8 Fitting protective devices and drive components NOTICE Damage to the on-load tap-changer! Damage to the on-load tap-changer by actuating the on-load tap-changer without oil! ► Before actuating the on-load tap-changer for the first time, the tap se- lector must be completely immersed in transformer oil and the oil com- partment completely filled with oil.

-

Page 182: Fitting Vertical Drive Shaft

8.6.1 Fitting vertical drive shaft Couple drive shaft with motor-drive unit and on-load tap-changer as descri- bed in MR operating instructions for TAPMOTION® ED. The motor-drive unit may be started by accident if the motor WARNING protective switch is not tripped! Risk of injury from starting the motor-drive unit by accident! ►... - Page 183 8 Fitting protective devices and drive components Determine dimension A between the shaft end of the drive and the shaft end of the bevel gear. Shorten square tube to length of A–9 mm. Figure 241: Shortening square tube Deburr cut surface of square tube. Figure 242: Deburring cut surfaces Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN...

- Page 184 8 Fitting protective devices and drive components Slide loosely screwed together coupling part onto square tube until stop is reached. Figure 243: Sliding coupling part onto square tube Insert coupling bolt into lower shaft end. Grease coupling parts and cou- pling bolts.

- Page 185 8 Fitting protective devices and drive components Secure vertical drive shaft to drive. Figure 245: Mounting vertical drive shaft on drive Pivot square tube with coupling part. Figure 246: Pivoting square tube When installing inner tube of telescopic protective tube, if necessary shorten on side without slits.

- Page 186 8 Fitting protective devices and drive components Figure 247: Deburring inner tube Dimension A (= distance be- Inner tube Outer tube tween the shaft end of the drive and the shaft end of the bevel gear) 170 mm...190 mm Shorten to 200 mm = 200 mm 191 mm...1130 mm Dimension...

- Page 187 8 Fitting protective devices and drive components Slide outer tube over inner tube (with slot at bottom). Slide telescopic protective tubes onto square tube. Then slide hose clips over telescopic protective tubes. Figure 248: Sliding on telescopic protective tube 10. Place adapter ring over bearing collar of bevel gear and slide upwards. Push in coupling bolt.

- Page 188 3 mm between the coupling bolt and upper coupling piece. To prepare for alignment, tighten screws to approx. 6 Nm. After aligning on- load tap-changer to drive (see MR operating instructions for TAPMOTION® ED), tighten screws to 9 Nm. Figure 250: Mounting coupling brackets VACUTAP®...

-

Page 189: Fitting Horizontal Drive Shaft

8 Fitting protective devices and drive components 12. Attach protective tube (inner tube) with a hose clip to the bearing collar of the drive . Then slider upper protective tube (outer tube) over adapter on bevel gear . Secure upper protective tube with hose clip both at top end and at transition to bottom protective tube Figure 251: Mounting protective tube 8.6.2... - Page 190 8 Fitting protective devices and drive components To fit the horizontal drive shaft, proceed as follows. Calculate dimension A between shaft end of upper gear unit and shaft end of bevel gear and shorten square tube to length A – 9 mm. Figure 252: Shortening square tube Calculate inside width B between housings of upper gear unit and bevel gear.

- Page 191 8 Fitting protective devices and drive components Slide loosely screwed together coupling part onto square tube until stop is reached. Figure 254: Sliding coupling part onto square tube Grease coupling bolt. Fit coupling bolt onto bevel gear and slide square tube with coupling part over it.

- Page 192 8 Fitting protective devices and drive components Mount horizontal drive shaft on bevel gear. Figure 256: Mounting horizontal drive shaft on bevel gear Grease coupling bolts and coupling brackets for upper gear unit. Mount coupling brackets on upper gear unit. Figure 257: Mounting horizontal drive shaft on upper gear unit VACUTAP®...

- Page 193 8 Fitting protective devices and drive components Now attach shortened guard plate to housing lugs on the on-load tap- changer head and bevel gear. Secure each end of guard plate with a hose clip. Figure 258: Fitting guard plate If using a bearing bracket or angle gear, attach caps to the guard plate. Figure 259: Bearing bracket caps Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN...

-

Page 194: Fitting Drive Shaft With Cardan Joints

8 Fitting protective devices and drive components Figure 260: Angle gear caps 8.6.3 Fitting drive shaft with cardan joints NOTICE Damage to drive shaft! Damage to expansion bellows from bending cardan joint! ► Ensure a matching position of the opposing cardan joint straps! VACUTAP®... - Page 195 8 Fitting protective devices and drive components Installation of the drive shaft with cardan joints is mainly designed as a verti- cal drive shaft between motor-drive unit and bevel gear. Technically, a hori- zontal design is also possible. Note, however, that when using the horizontal design the guard plate supplied has to be adapted accordingly.

- Page 196 8 Fitting protective devices and drive components To fit the drive shaft with cardan joints, proceed as follows: Grease the coupling bolts, coupling brackets and ball heads, e.g. ISO- FLEX TOPAS L 32. Figure 262: Grease the coupling bolts, coupling brackets and ball heads. VACUTAP®...

- Page 197 8 Fitting protective devices and drive components Insert adapter in neck of pivotable protective tubes . Place both parts of pivotable protective tube inside one another and turn towards one another to set the corresponding angle. Figure 263: Inserting adapter in pivotable protective tubes When supplied, the cardan joints are fitted with coupling bolts .

- Page 198 8 Fitting protective devices and drive components Connect shorter cardan joint supplied to ball-shaped head of motor- drive unit with cardan joint bolt. Figure 265: Fitting cardan joint to ball-shaped head of motor-drive unit Fit second, longer cardan joint to bevel gear. If a cardan joint is attached to the upper gear unit, then use a cardan joint with an inner hub diameter of 25 mm.

- Page 199 8 Fitting protective devices and drive components Provisionally connect loose shaft ends of the joints to an angle bar and align. Figure 268: Connecting shaft ends with angle bar Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP® VR®...

- Page 200 8 Fitting protective devices and drive components Determine dimension A between the shaft ends. Cut square tube to LR = A + 106 mm (LR = length of square tube). Deburr cut surface of square tube. Figure 269: Shortening square tube VACUTAP®...

- Page 201 8 Fitting protective devices and drive components Before mounting, shorten both telescopic tubes to dimension A/ 2 + 120 mm (A = dimension between both cardan joint ends) and de- burr. Figure 270: Shortening telescopic tubes 10. Fit one adapter to bearing collar of motor-drive unit and fit other adapter to bearing collar of bevel gear.

- Page 202 8 Fitting protective devices and drive components 11. Slide previously shortened and deburred square tube over upper cardan joint end until stop is reached. Figure 272: Sliding square tube over upper cardan joint end 12. Thread upper flexible protective tube with long outlet up onto square tube from below.

- Page 203 8 Fitting protective devices and drive components 13. Thread on outer and inner tubes such that the slotted sides of the outer and inner tube are both facing down. Figure 274: Sliding on telescopic tubes 14. Slide everything up and secure with a screw clamp. Figure 275: Securing everything with a screw clamp Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN...

- Page 204 8 Fitting protective devices and drive components 15. Slide bottom flexible protective tube (also with long outlet up) on to the square tube and secure with screw clamp. Figure 276: Sliding bottom flexible protective tube onto square tube VACUTAP® VR® 4349315/00 EN Maschinenfabrik Reinhausen GmbH 2015...

- Page 205 To prepare for alignment, tighten screws to approx. 6 Nm. After aligning on- load tap-changer to drive (see MR operating instructions for TAPMOTION® ED), tighten screws to 9 Nm. Maschinenfabrik Reinhausen GmbH 2015 4349315/00 EN VACUTAP®...

- Page 206 8 Fitting protective devices and drive components Figure 278: Tightening lower coupling brackets 18. Fit upper coupling brackets with 3 mm axial clearance. Figure 279: Fitting upper coupling brackets 19. Working from top to bottom, mount the individual parts of the shaft pro- tection.

-

Page 207: Fitting Drive Shaft With Insulator

8 Fitting protective devices and drive components The plastic adapters must be at the respective end of the pivotable protec- tive tube. Only slide telescopic pipe into upper and lower pivotable protec- tive tubes by the width of the adapter before tightening the hose clips. Figure 280: Securing telescopic pipes and flexible protective tubes with hose clips 8.6.4 Fitting drive shaft with insulator... -

Page 208: Centering On-Load Tap-Changer And Motor-Drive Unit

Centering on-load tap-changer and motor-drive unit Center on-load tap-changer and motor-drive unit as described in relevant MR operating instructions "TAPMOTION® ED". Installing electrics for motor-drive unit Install electrics for motor-drive unit as described in relevant MR operating in- structions "TAPMOTION® ED". VACUTAP® VR® 4349315/00 EN... -

Page 209: Commissioning Of On-Load Tap-Changer By Transformer Manufacturer

9 Commissioning of on-load tap-changer by transformer manufacturer Commissioning of on-load tap-changer by transformer manufacturer Bleeding on-load tap-changer head and suction pipe Before first commissioning, the on-load tap-changer head and the suction pipe on pipe connection S must be bled. 9.1.1 Bleeding on-load tap-changer head Open all forward and return valves in the pipe system. -